Home

>

Reprappers

>

Topic

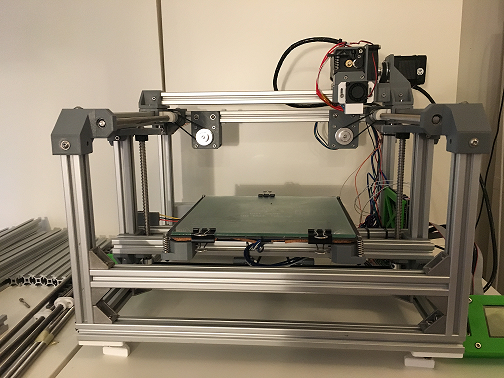

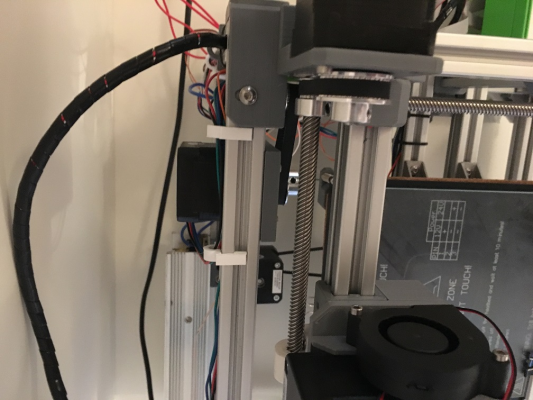

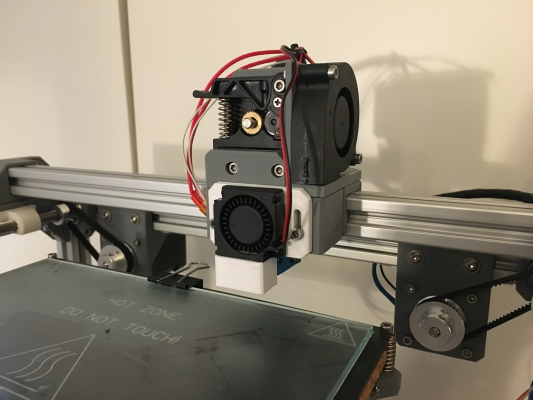

New build. A Leadscrew driven , T-slot sliding 3D printer.

Posted by Bjoern

|

New build. A Leadscrew driven , T-slot sliding 3D printer. September 02, 2018 05:56AM |

Registered: 6 years ago Posts: 11 |

Hi All.

First , Thanks a lot to all of you guys, for sharing a ton of information on this site, it is an great inspiration.

This will be my first post, so please bare with me.

I've been working on a lead screw design for some years, and have tried to make a couple of mockups but always hated the noise it generated.

both the vibration and the "screaming" steppers, so the project has been "shelved" a couple of times.

But, here i am again, a leadscrew driven , T-slot sliding 3D printer.

So, i started (probably the wrong way around) with Lead screw , T-slot sliding , and to some extend noise in mind, and wanted to see where this could bring me.

and i must say that i'm actually quite pleased with the result. The prints quality is not perfect, but are better than the ones on my "prusa style" with less noise.

So, is the noise and vibration gone with this design ? No, not completely, but it is very much acceptable. compared to my "prusa style" it is so much better. at lower speeds, the fan is the loudest part.

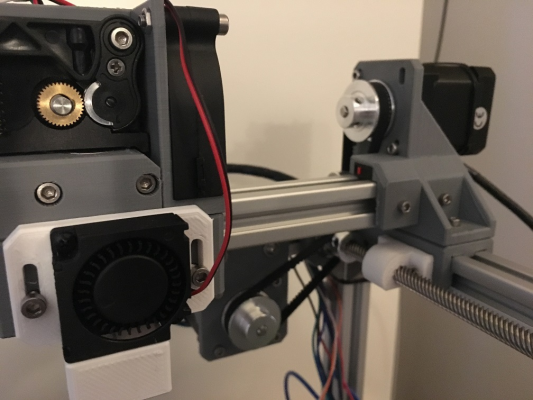

All is printed in PETG, except for the X and Y nuts, which is printed in IGUS Iglidur I150.

The first test where done with PETG nuts, but they tend to stick to much and where causing vibration and missed steps. in order to make them work in PETG i had to increase the gap to the point they where no longer useful.

The Z-Axis is still using PETG nuts, as the Z-axis can function with some backlash.

The Z axis nut still have some "sticking" but so far it has not been a problem.

The slides where actually not that difficult to get to an acceptable "sticking" point. these where printed a bit "tight" and adjusted with a needle file.

The design is by no means perfect, and there are some points i still would like to adress :

Change to an single motor on Y Axis - this was not possible due to the sticking of the slides. currently i'm working on a slide using Iglidur I150 and hopefully these will slide better.

Add an tool cleaner.

Add a prime channel.

Filament runout sensor.

Maybe a bed probe, but so far the first layer has been quite consistent.

Better wiring

Enclosed electronics.

Again, this is by no means perfect, and i'm sure there are much better solutions.

Still, i very much like the idea of the T-Slot sliding and the movements from the lead screws, so i'll stick to this and see how far this will go

Let me know if you need more details, and,

Please feel free to share your thoughts and feedback, i would very much appreciate this

BR

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 02, 2018 08:47AM |

Registered: 7 years ago Posts: 507 |

have you considered using non printed nuts? the tolerances would be better and it would probably decrease noise and friction. I like the collet style anti backlash nuts like this one. [www.aliexpress.com]

Otherwise cool build, I've been thinking about doing something like this for a while but the cost of extrusions has been putting me off, especially for "experimenting".

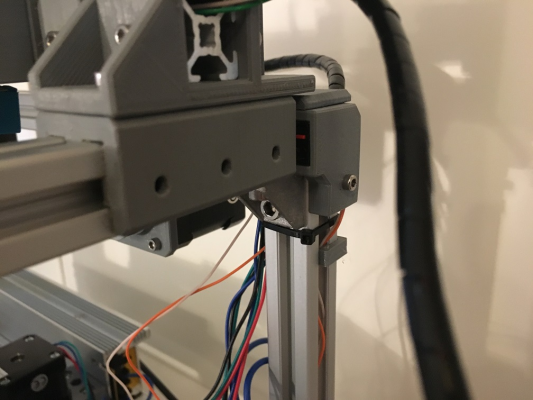

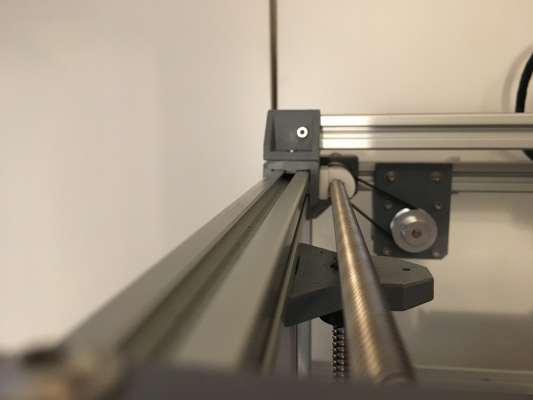

As for sticking of the slides, maybe they are a bit over constrained? Have you tried maybe only having the slide contact one or two of the slots rather than 3 (or is it 4?) that it currently does. That'll minimize the chance for misalignment and binding. Also, I could be wrong here, but I think less surface contact would be better for lower friction. Your slides right now look like they have a large contact surface.

Edited 1 time(s). Last edit at 09/02/2018 08:48AM by Trakyan.

Otherwise cool build, I've been thinking about doing something like this for a while but the cost of extrusions has been putting me off, especially for "experimenting".

As for sticking of the slides, maybe they are a bit over constrained? Have you tried maybe only having the slide contact one or two of the slots rather than 3 (or is it 4?) that it currently does. That'll minimize the chance for misalignment and binding. Also, I could be wrong here, but I think less surface contact would be better for lower friction. Your slides right now look like they have a large contact surface.

Edited 1 time(s). Last edit at 09/02/2018 08:48AM by Trakyan.

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 02, 2018 10:47AM |

Registered: 6 years ago Posts: 11 |

Thanks for your comments

Yes, i did consider anti backlash nut, but i have not been able to find any for 16mm lead, plus i wanted to try out the Iglidur I150 filament.

The printed nuts have very little or no play (at least from what i can feel, but have no measurements to back that up) but maybe i could print an anti backlash nut

I print them a bit tight, and use a piece of lead screw that i've cut a couple of grooves in, to make the threads fit firmly.

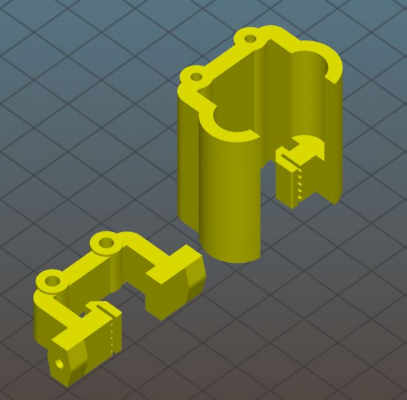

I think you might be right about the constraints, i'm currently drawing on a slide with iglidur, maybe i could just have the iglidur in the first and last 10mm or so from the ends?

the current slide is 60mm long with contact all the way, on 3 sides, so i think i might be able to fit in 10mm as a "pad", in lack of better words

And as you suggest, maybe remove the top pad which goes in to the T-Slot.

I think i'll try to draw up something tonight

Yes, i did consider anti backlash nut, but i have not been able to find any for 16mm lead, plus i wanted to try out the Iglidur I150 filament.

The printed nuts have very little or no play (at least from what i can feel, but have no measurements to back that up) but maybe i could print an anti backlash nut

I print them a bit tight, and use a piece of lead screw that i've cut a couple of grooves in, to make the threads fit firmly.

I think you might be right about the constraints, i'm currently drawing on a slide with iglidur, maybe i could just have the iglidur in the first and last 10mm or so from the ends?

the current slide is 60mm long with contact all the way, on 3 sides, so i think i might be able to fit in 10mm as a "pad", in lack of better words

And as you suggest, maybe remove the top pad which goes in to the T-Slot.

I think i'll try to draw up something tonight

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 03, 2018 12:33AM |

Registered: 8 years ago Posts: 5,232 |

I made a T-slot slider using Delrin-rods as inserts. It is way cheaper than Igus-filament and very precise. You can also use PTFE-rods, but they are pricey and less durable. ( they slide a bit better, tho )

This is an older pic for a different extrusion

I started a thread in the 'Delta' section about my "compact carrier".

Ignore the belt-clamps.

The latest version has adjustable tension, which makes it easier to print.

Edited 1 time(s). Last edit at 09/03/2018 12:38AM by o_lampe.

This is an older pic for a different extrusion

I started a thread in the 'Delta' section about my "compact carrier".

Ignore the belt-clamps.

The latest version has adjustable tension, which makes it easier to print.

Edited 1 time(s). Last edit at 09/03/2018 12:38AM by o_lampe.

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 03, 2018 12:53PM |

Registered: 5 years ago Posts: 71 |

Great unique printer! I have a friend who is very keen on an all lead-screw printer; i'll point him here. Are the X-Y lead screws 4-turn?

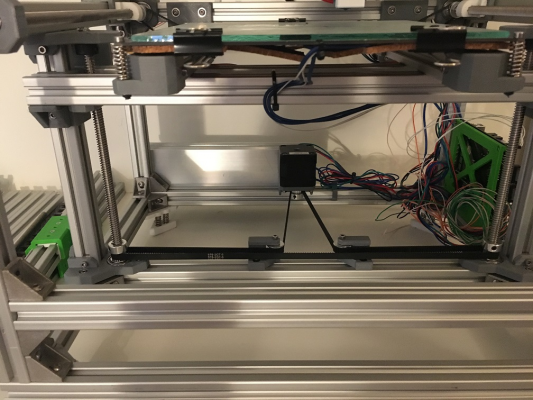

My DIY printer has a very similar Z-axis arrangement including bed mounting (with two extrusions along the center plane and two lead screws).

Looking forward to more updates.

Edited 1 time(s). Last edit at 09/03/2018 12:54PM by gmedlicott.

My DIY printer has a very similar Z-axis arrangement including bed mounting (with two extrusions along the center plane and two lead screws).

Looking forward to more updates.

Edited 1 time(s). Last edit at 09/03/2018 12:54PM by gmedlicott.

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 03, 2018 01:20PM |

Registered: 6 years ago Posts: 11 |

gmedlicott : Thanks

I really like the design, and it's actually very rigid even though there is no top profile on the front.

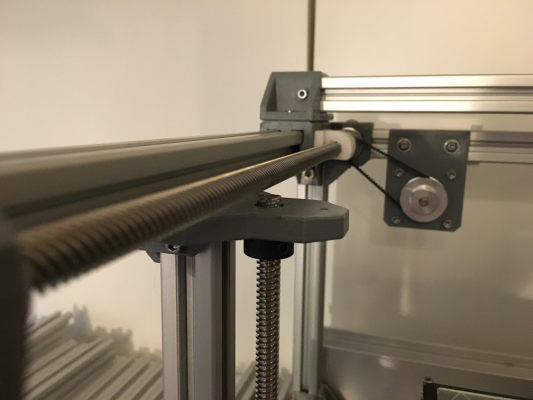

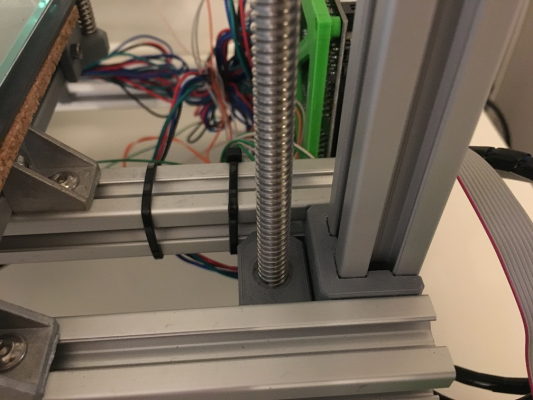

The Lead screw are 8mm diameter, 2mm pitch, 8 start , which gives a lead of 16mm.

They can be found on Aliexpress.

I use an 40 teeth pulley on the stepper and a 20 teeth on the lead screw. this gives a lead of 32mm/rev.

with 1/16 microstepping it's 100 steps/mm.

About the Z axis, i was actually in doubt if this design would be rigid enough, but it seems to be fine.

i was thinking about making it 3 point, but that would complicate the design quite a lot , and for now i'm satisfied with the result.

For the Z axis i use 8mm lead screw, 2mm pitch , 2 start , aka 4mm lead. with 20 teeth pulleys all around and 1/16 micro it's 800 steps/mm.

Let me know if you need more info

I really like the design, and it's actually very rigid even though there is no top profile on the front.

The Lead screw are 8mm diameter, 2mm pitch, 8 start , which gives a lead of 16mm.

They can be found on Aliexpress.

I use an 40 teeth pulley on the stepper and a 20 teeth on the lead screw. this gives a lead of 32mm/rev.

with 1/16 microstepping it's 100 steps/mm.

About the Z axis, i was actually in doubt if this design would be rigid enough, but it seems to be fine.

i was thinking about making it 3 point, but that would complicate the design quite a lot , and for now i'm satisfied with the result.

For the Z axis i use 8mm lead screw, 2mm pitch , 2 start , aka 4mm lead. with 20 teeth pulleys all around and 1/16 micro it's 800 steps/mm.

Let me know if you need more info

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 03, 2018 01:26PM |

Registered: 6 years ago Posts: 11 |

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 03, 2018 01:29PM |

Registered: 6 years ago Posts: 11 |

Quote

Bjoern

That is a very nice solutionSorry to post again, just trying to get the hang of this forum.though i think i'll stick to just using the T-Slot , and Iglidur. I have already purchased iglidur I150 as i wanted to try it out and would like to gain some experience with this material.

And the 2in1 delta looks very interesting

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 03, 2018 03:21PM |

Registered: 5 years ago Posts: 71 |

Quote

Bjoern

The Lead screw are 8mm diameter, 2mm pitch, 8 start , which gives a lead of 16mm.

8 start, nice, they do look really aggressive, and geared up, sounds like the X-Y could move quite quickly in theory. What travel speed are you printing at? And what problems do you notice, ringing from mass/backlash or other?

Quote

Bjoern

About the Z axis, i was actually in doubt if this design would be rigid enough, but it seems to be fine.

i was thinking about making it 3 point, but that would complicate the design quite a lot , and for now i'm satisfied with the result.

Likewise. Mine turned out very stiff, and bed stiffness if more relative for 3d printers depositing liquid filament, just feel the stiffness of the end of the build plate on an Ultimaker or similar! I almost wonder if they purposefully build in some Z-flex so prints don't get torn off the bed when printing over a raised cooled section.

|

Re: New build. A Leadscrew driven , T-slot sliding 3D printer. September 03, 2018 03:57PM |

Registered: 6 years ago Posts: 11 |

Quote

gmedlicott

For now i'm using 120mm/sec for max speed of XY, but that's mainly due to the whining sound that i don't like.8 start, nice, they do look really aggressive, and geared up, sounds like the X-Y could move quite quickly in theory. What travel speed are you printing at? And what problems do you notice, ringing from mass/backlash or other?Quote

Bjoern

The Lead screw are 8mm diameter, 2mm pitch, 8 start , which gives a lead of 16mm.

could probably go higher but for me it's plenty fast. 800mm/s for acc

I use 50mm/s for printing(PLA/PETG) for now and it seems that the biggest problem right now is some inconsistent layers.

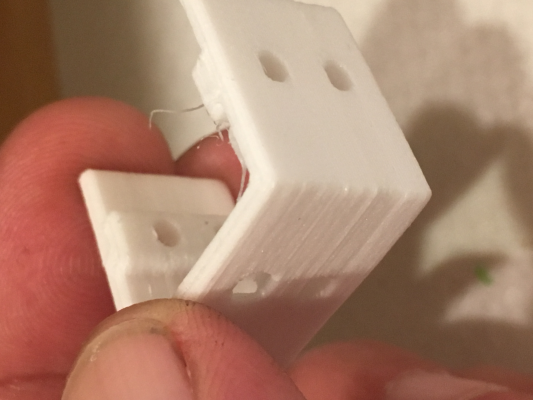

This is freshly printed in Iglidur I150 on this printer, at 25mm/sec

The result is similar in PETG at 50mm/sec. i'll see if i can print the new slide in PETG tomorrow and post a pic.

i think it's more of a design choice along with cost, and i think i read something about oscillating with this type of Z-axis which can be a problem, but i have never used this type myself,Likewise. Mine turned out very stiff, and bed stiffness if more relative for 3d printers depositing liquid filament, just feel the stiffness of the end of the build plate on an Ultimaker or similar! I almost wonder if they purposefully build in some Z-flex so prints don't get torn off the bed when printing over a raised cooled section.Quote

Bjoern

About the Z axis, i was actually in doubt if this design would be rigid enough, but it seems to be fine. i was thinking about making it 3 point, but that would complicate the design quite a lot , and for now i'm satisfied with the result.

so i really don't know.

I was thinking of a fixed bed printer when i started this one, but skipped the idea for simplicity. but definitely something i would like to try out.

Edited 3 time(s). Last edit at 09/03/2018 04:21PM by Bjoern.

Sorry, only registered users may post in this forum.