Home

>

Reprappers

>

Topic

i3 Video Build Log

Posted by ikilledkenny

|

i3 Video Build Log October 12, 2012 10:48AM |

Registered: 12 years ago Posts: 99 |

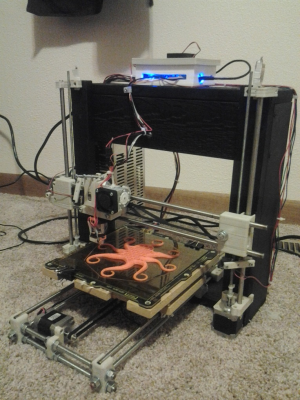

After building two Prusa i2 with a friend I decided to start from the ground up and design/build my own version of the new i3. My main goal was to have a full 200x200x200 build volume (with option to go larger on the build volume), utilize the previous Prusa i2 smooth rod lengths, and use as many standard i3 STL's as possible.

So far this has been a fun experiment for myself, I have made some mistakes, but learned a lot. Below are links to my video log. I will keep updating this thread as I create more logs. Feel free to ask questions, make suggestions, or critique.

Stage 1 - [www.youtube.com]

Stage 2 - [www.youtube.com]

P.S. This is NOT a build tutorial. I am going to try and cover as much as I can in each video, but I'll miss things. If you are interested in building your own i3 I suggest following the build docs at [github.com]

So far this has been a fun experiment for myself, I have made some mistakes, but learned a lot. Below are links to my video log. I will keep updating this thread as I create more logs. Feel free to ask questions, make suggestions, or critique.

Stage 1 - [www.youtube.com]

Stage 2 - [www.youtube.com]

P.S. This is NOT a build tutorial. I am going to try and cover as much as I can in each video, but I'll miss things. If you are interested in building your own i3 I suggest following the build docs at [github.com]

|

Re: i3 Video Build Log October 16, 2012 03:38PM |

Registered: 12 years ago Posts: 99 |

Alright Stage 3 now uploaded. This build I work on attaching the hot bed to the Y-carriage as well as connecting both the y-carriage to the frame built in stage 1. It's a long build log, but hope you enjoy

Stage 3 - [www.youtube.com]

Stage 3 - [www.youtube.com]

|

Re: i3 Video Build Log October 16, 2012 05:40PM |

Registered: 13 years ago Posts: 248 |

Hi there,

Nice going! Keep the videos coming. I really like that headed bed you plan to use. Haven't seen them on sales in Europe yet. Are they in common use on printers in the US? (Here's the reference for those who haven't watched the video: [www.panucatt.com] )

)

I like the casual video diary style, but I couldn't work on the carpet as you do! Just wait until you loose some small screw or washer down there on the carpet! Hope you leave that bit in the video!

Regards,

NumberSix

[numbersixreprap.blogspot.com]

Nice going! Keep the videos coming. I really like that headed bed you plan to use. Haven't seen them on sales in Europe yet. Are they in common use on printers in the US? (Here's the reference for those who haven't watched the video: [www.panucatt.com]

)

)I like the casual video diary style, but I couldn't work on the carpet as you do! Just wait until you loose some small screw or washer down there on the carpet! Hope you leave that bit in the video!

Regards,

NumberSix

[numbersixreprap.blogspot.com]

|

Re: i3 Video Build Log October 17, 2012 09:04AM |

Registered: 12 years ago Posts: 99 |

NumberSix,

Thanks for the comment!. Panucatt just came out with their hot bed the same time their Azteeg X3 controller controller came out. I think they have only been shipping both the controller and hot bed for maybe two months now. Previous builds I have used an MK2 and RAMPS 1.4 set up, so I am excited to see how this set-up works. So far I am very happy with the quality from Panucatt.

Trust me I have lost a few screws, washers, and nuts so far in that sea of carpet My detached garage does not have heat at the moment so I was left with working in my office. I think I will have to sweep the floor with a magnet a few times before I vacuum next.

My detached garage does not have heat at the moment so I was left with working in my office. I think I will have to sweep the floor with a magnet a few times before I vacuum next.

Thanks for the comment!. Panucatt just came out with their hot bed the same time their Azteeg X3 controller controller came out. I think they have only been shipping both the controller and hot bed for maybe two months now. Previous builds I have used an MK2 and RAMPS 1.4 set up, so I am excited to see how this set-up works. So far I am very happy with the quality from Panucatt.

Trust me I have lost a few screws, washers, and nuts so far in that sea of carpet

My detached garage does not have heat at the moment so I was left with working in my office. I think I will have to sweep the floor with a magnet a few times before I vacuum next.

My detached garage does not have heat at the moment so I was left with working in my office. I think I will have to sweep the floor with a magnet a few times before I vacuum next.

|

Re: i3 Video Build Log October 19, 2012 03:17PM |

Registered: 12 years ago Posts: 99 |

Stage 4 is done. In this video I put the cold and hot end together as well as attached the whole extruder assembly to the X-carriage.

[www.youtube.com]

[www.youtube.com]

|

Re: i3 Video Build Log October 23, 2012 11:06PM |

Registered: 12 years ago Posts: 99 |

Well printer is done!!! I am working on calibration and getting the kinks out. Session 5 is done and I will be posting shortly.

|

Re: i3 Video Build Log October 24, 2012 03:38PM |

Registered: 12 years ago Posts: 99 |

Stage 5 is finished. From here on out the videos might me a bit shorter and more of an overview (I don't think anyone wants to watch me string wire for 10 mins).

[www.youtube.com]

[www.youtube.com]

|

Re: i3 Video Build Log October 25, 2012 12:41AM |

Registered: 11 years ago Posts: 250 |

Thanks for the videos!

I'd like to see the calibration process (programming)

and showing how you tweak and tune things.

Show how different settings effect things!

Again, thanks!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

I'd like to see the calibration process (programming)

and showing how you tweak and tune things.

Show how different settings effect things!

Again, thanks!

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: i3 Video Build Log October 28, 2012 05:48PM |

Registered: 12 years ago Posts: 3 |

I've been going over the Prusa i3 files as preparation for building one myself, and I've discovered 2 problems with the Z motor holder.

1) The blind hole for the smooth rod seems to be on the wrong side of the motor holder. Or is this hole supposed to be a through hole?

2) One of the 2 holes for screwing the motor holder to the frame doesn't go all the way through, so you end up with a cavity inside the part which can't be used for screwing down the bracket.

I encountered these problems in the z-axis.scad file of the master branch. Did you use different files or did you just fix the parts by drilling through the holes? Anyway, thanks for the videos, really helpful!

1) The blind hole for the smooth rod seems to be on the wrong side of the motor holder. Or is this hole supposed to be a through hole?

2) One of the 2 holes for screwing the motor holder to the frame doesn't go all the way through, so you end up with a cavity inside the part which can't be used for screwing down the bracket.

I encountered these problems in the z-axis.scad file of the master branch. Did you use different files or did you just fix the parts by drilling through the holes? Anyway, thanks for the videos, really helpful!

|

Re: i3 Video Build Log October 29, 2012 12:10PM |

Registered: 12 years ago Posts: 99 |

Soono,

1) The hole should be a through hole. The STL did not seem to have this issue for me and all parts printed out fine.

2) In each of the STL's only one hole ended up needing to be drilled out, I am not sure why the models are this way but after I printed it I took a knife and just cut open the hole again.

1) The hole should be a through hole. The STL did not seem to have this issue for me and all parts printed out fine.

2) In each of the STL's only one hole ended up needing to be drilled out, I am not sure why the models are this way but after I printed it I took a knife and just cut open the hole again.

|

Re: i3 Video Build Log November 02, 2012 06:33AM |

Registered: 13 years ago Posts: 62 |

|

Re: i3 Video Build Log November 05, 2012 10:43PM |

Registered: 12 years ago Posts: 99 |

|

Re: i3 Video Build Log November 06, 2012 02:00AM |

Registered: 13 years ago Posts: 62 |

|

Re: i3 Video Build Log November 06, 2012 10:14AM |

Registered: 12 years ago Posts: 99 |

I am using a modified version of WildBill's cold end (http://www.thingiverse.com/thing:24992)

I have attached the STL's that I created, but I HIGHLY suggest that you do not use them. I have been working on this design for about 6+ months now, and over time there has been multiple changes to the source STL's for the i3.

Currently there is an improved X-carriage design that makes tightening the belt simpler (https://github.com/josefprusa/Prusa3/tree/carriage-update), but the mounting holes for the extruder has changed with the update. In the future I plan on updating my design, but until then I am staying with what I have printed.

If this is your first build I would suggest using either the Wades/Greg's cold end or the Raldrish geared direct drive set up outlined in the i3 documentation.

The source files for the i3 can be found here (https://github.com/josefprusa/Prusa3) If you are looking to use the Box method use the "master" branch, if you are using the single flat plate method use the Jo-Final" branch

I have attached the STL's that I created, but I HIGHLY suggest that you do not use them. I have been working on this design for about 6+ months now, and over time there has been multiple changes to the source STL's for the i3.

Currently there is an improved X-carriage design that makes tightening the belt simpler (https://github.com/josefprusa/Prusa3/tree/carriage-update), but the mounting holes for the extruder has changed with the update. In the future I plan on updating my design, but until then I am staying with what I have printed.

If this is your first build I would suggest using either the Wades/Greg's cold end or the Raldrish geared direct drive set up outlined in the i3 documentation.

The source files for the i3 can be found here (https://github.com/josefprusa/Prusa3) If you are looking to use the Box method use the "master" branch, if you are using the single flat plate method use the Jo-Final" branch

|

Re: i3 Video Build Log November 14, 2012 09:27AM |

Registered: 12 years ago Posts: 99 |

Hey

Sorry for the long time between build logs. Here is a nice and short video just as an update on my printer. Right now I am in battle with some banding. It It seems that the Z may not move its full height and then causes smashed layers. Anyone with thoughts let me know.

[www.youtube.com]

Sorry for the long time between build logs. Here is a nice and short video just as an update on my printer. Right now I am in battle with some banding. It It seems that the Z may not move its full height and then causes smashed layers. Anyone with thoughts let me know.

[www.youtube.com]

|

Re: i3 Video Build Log November 18, 2012 10:57PM |

Registered: 12 years ago Posts: 99 |

|

Re: i3 Video Build Log November 19, 2012 02:59AM |

|

Re: i3 Video Build Log November 19, 2012 01:07PM |

Registered: 12 years ago Posts: 99 |

[i.imgur.com]

Here is my test samples. All same g-code. Far left you can see that the lines would repeat about twice. In the middle I swapped out the 100k thermester with a 10K thermester. Far right I PID tuned both my hot end and heated bed, as well as allowed more "slop" in the hot bed to the Y bed.

Issue - my heated bed was constrained so much that it had no place to go but up when it would expand and contract. Also I was using "bang bang" method (AKA it would pump current into the bed, then stop). This caused my heated bed to rise and fall during a print. This happened in a cycle based on time, so if the cycle happens every 12 layers at 100%, it would happen every 6 layers at 200% (twice the print time).

The solution was to allow the bed to expand in other directions reducing the upward moment. Also the current Marlin firmware allows you to PID tune the heated bed. PID tuning is a "softer" way of applying current to the heated bed to keep it at temp, thus reducing the temp change your bed will see.

I just completed 2 tests samples here with good results. I hope to continue to test to ensure this is the answer. More as it comes.

Here is my test samples. All same g-code. Far left you can see that the lines would repeat about twice. In the middle I swapped out the 100k thermester with a 10K thermester. Far right I PID tuned both my hot end and heated bed, as well as allowed more "slop" in the hot bed to the Y bed.

Issue - my heated bed was constrained so much that it had no place to go but up when it would expand and contract. Also I was using "bang bang" method (AKA it would pump current into the bed, then stop). This caused my heated bed to rise and fall during a print. This happened in a cycle based on time, so if the cycle happens every 12 layers at 100%, it would happen every 6 layers at 200% (twice the print time).

The solution was to allow the bed to expand in other directions reducing the upward moment. Also the current Marlin firmware allows you to PID tune the heated bed. PID tuning is a "softer" way of applying current to the heated bed to keep it at temp, thus reducing the temp change your bed will see.

I just completed 2 tests samples here with good results. I hope to continue to test to ensure this is the answer. More as it comes.

|

Re: i3 Video Build Log November 20, 2012 07:15AM |

Registered: 12 years ago Posts: 809 |

Thanks for the tip about PID in the new Marlin firmware! I was hoping that would be implemented at some point. Autotuned my heated bed and now it's rock-steady.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: i3 Video Build Log November 22, 2012 08:40PM |

Registered: 11 years ago Posts: 633 |

|

Re: i3 Video Build Log November 23, 2012 05:50PM |

Registered: 12 years ago Posts: 809 |

nic0laz Wrote:

-------------------------------------------------------

> isnt autotune (m303 ) just for the hotend?

Latest version of Marlin supports it.

// Bed Temperature Control

// Select PID or bang-bang with PIDTEMPBED. If bang-bang, BED_LIMIT_SWITCHING will enable hysteresis

//

// uncomment this to enable PID on the bed. It uses the same ferquency PWM as the extruder.

// If your PID_dT above is the default, and correct for your hardware/configuration, that means 7.689Hz,

// which is fine for driving a square wave into a resistive load and does not significantly impact you FET heating.

// This also works fine on a Fotek SSR-10DA Solid State Relay into a 250W heater.

// If your configuration is significantly different than this and you don't understand the issues involved, you proabaly

// shouldn't use bed PID until someone else verifies your hardware works.

// If this is enabled, find your own PID constants below.

//#define PIDTEMPBED

//

//#define BED_LIMIT_SWITCHING

// This sets the max power delived to the bed, and replaces the HEATER_BED_DUTY_CYCLE_DIVIDER option.

// all forms of bed control obey this (PID, bang-bang, bang-bang with hysteresis)

// setting this to anything other than 255 enables a form of PWM to the bed just like HEATER_BED_DUTY_CYCLE_DIVIDER did,

// so you shouldn't use it unless you are OK with PWM on your bed. (see the comment on enabling PIDTEMPBED)

#define MAX_BED_POWER 255 // limits duty cycle to bed; 255=full current

#ifdef PIDTEMPBED

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from FOPDT model - kp=.39 Tp=405 Tdead=66, Tc set to 79.2, argressive factor of .15 (vs .1, 1, 10)

#define DEFAULT_bedKp 10.00

#define DEFAULT_bedKi .023

#define DEFAULT_bedKd 305.4

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from pidautotune

// #define DEFAULT_bedKp 97.1

// #define DEFAULT_bedKi 1.41

// #define DEFAULT_bedKd 1675.16

// FIND YOUR OWN: "M303 E-1 C8 S90" to run autotune on the bed at 90 degreesC for 8 cycles.

#endif // PIDTEMPBED

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

-------------------------------------------------------

> isnt autotune (m303 ) just for the hotend?

Latest version of Marlin supports it.

// Bed Temperature Control

// Select PID or bang-bang with PIDTEMPBED. If bang-bang, BED_LIMIT_SWITCHING will enable hysteresis

//

// uncomment this to enable PID on the bed. It uses the same ferquency PWM as the extruder.

// If your PID_dT above is the default, and correct for your hardware/configuration, that means 7.689Hz,

// which is fine for driving a square wave into a resistive load and does not significantly impact you FET heating.

// This also works fine on a Fotek SSR-10DA Solid State Relay into a 250W heater.

// If your configuration is significantly different than this and you don't understand the issues involved, you proabaly

// shouldn't use bed PID until someone else verifies your hardware works.

// If this is enabled, find your own PID constants below.

//#define PIDTEMPBED

//

//#define BED_LIMIT_SWITCHING

// This sets the max power delived to the bed, and replaces the HEATER_BED_DUTY_CYCLE_DIVIDER option.

// all forms of bed control obey this (PID, bang-bang, bang-bang with hysteresis)

// setting this to anything other than 255 enables a form of PWM to the bed just like HEATER_BED_DUTY_CYCLE_DIVIDER did,

// so you shouldn't use it unless you are OK with PWM on your bed. (see the comment on enabling PIDTEMPBED)

#define MAX_BED_POWER 255 // limits duty cycle to bed; 255=full current

#ifdef PIDTEMPBED

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from FOPDT model - kp=.39 Tp=405 Tdead=66, Tc set to 79.2, argressive factor of .15 (vs .1, 1, 10)

#define DEFAULT_bedKp 10.00

#define DEFAULT_bedKi .023

#define DEFAULT_bedKd 305.4

//120v 250W silicone heater into 4mm borosilicate (MendelMax 1.5+)

//from pidautotune

// #define DEFAULT_bedKp 97.1

// #define DEFAULT_bedKi 1.41

// #define DEFAULT_bedKd 1675.16

// FIND YOUR OWN: "M303 E-1 C8 S90" to run autotune on the bed at 90 degreesC for 8 cycles.

#endif // PIDTEMPBED

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: i3 Video Build Log December 01, 2012 09:39AM |

Registered: 12 years ago Posts: 99 |

|

Re: i3 Video Build Log December 04, 2012 03:08PM |

Registered: 12 years ago Posts: 972 |

I have finished building my i3. I have a short blog entry about it with some pictures. Not the same as a detailed step-by-step video but maybe it can help: [fightpc.blogspot.com.es]

|

Re: i3 Video Build Log December 05, 2012 08:50AM |

Registered: 12 years ago Posts: 99 |

|

Re: i3 Video Build Log December 06, 2012 05:16AM |

Registered: 12 years ago Posts: 972 |

Hi ikilledkenny:

For the moment the acrylic is going better than I expected: taping worked ok and the build feels solid and I can carry the frame with all mounted hanging from the top without fear of it breaking. But please note I have used GS acrylic (not XT) which I hope is going to be a much better choice as it is more forgiving than extruded acrylic (XT). Over tightening can cause trouble for sure, if not cracks it can damage the threads, but if that happens you can put a bolt on the other side.

I wanted to get an Aluminium frame but I was unable to get one, maybe this will change soon.

For the moment the acrylic is going better than I expected: taping worked ok and the build feels solid and I can carry the frame with all mounted hanging from the top without fear of it breaking. But please note I have used GS acrylic (not XT) which I hope is going to be a much better choice as it is more forgiving than extruded acrylic (XT). Over tightening can cause trouble for sure, if not cracks it can damage the threads, but if that happens you can put a bolt on the other side.

I wanted to get an Aluminium frame but I was unable to get one, maybe this will change soon.

|

Re: i3 Video Build Log December 20, 2012 02:50PM |

Registered: 12 years ago Posts: 99 |

|

Re: i3 Video Build Log December 20, 2012 11:36PM |

Registered: 11 years ago Posts: 250 |

You can use Cam Studio for your screen capture...

Then throw it through Handbrake to adjust quality/size.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

Then throw it through Handbrake to adjust quality/size.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: i3 Video Build Log December 31, 2012 12:27PM |

Registered: 12 years ago Posts: 99 |

Happy Holiday's to everyone! Per request I have done up a calibration video. This video will go over the basic settings in the firmware, what they do, and what needs to be tested before you print your first object. Thanks everyone for the comments, and keep the suggestions/ questions coming.

stage 8 - [www.youtube.com]

stage 8 - [www.youtube.com]

|

Re: i3 Video Build Log February 17, 2013 10:32PM |

Registered: 12 years ago Posts: 99 |

I am back after a very LONG break.

In this log I go over some more advance firmware settings. I will be the first to say I am not an expert on firmware so my explanations may be off. Please feel free to correct me.

Here is the link to the 200 series G-codes mentioned in the video - [reprap.org]

Stage 9 - [youtu.be]

In this log I go over some more advance firmware settings. I will be the first to say I am not an expert on firmware so my explanations may be off. Please feel free to correct me.

Here is the link to the 200 series G-codes mentioned in the video - [reprap.org]

Stage 9 - [youtu.be]

|

Re: i3 Video Build Log March 15, 2013 10:36PM |

Registered: 12 years ago Posts: 99 |

Doing something a bit different this time. This is a tutorial on how to convert an picture to an STL.

[www.youtube.com]

[www.youtube.com]

Sorry, only registered users may post in this forum.