|

Printing in air? January 02, 2013 10:21AM |

Registered: 11 years ago Posts: 26 |

Is it possible to print in air without support structure? I don't mean just a straight bridge. What I mean is: is it possible to print bends and corners in air?

I'm thinking of printing a fan duct to focus high flow air on the nozzle tip to solidify the plastic instantly, but if this whole thing is not possible then I will scratch the idea.

Maybe the high flow air would have to be so powerful to solidify that it would just blow the extrusion away. I dunno.

I think it's possible to print a couple mm's in air, but anything more it too much huh?

So who knows for sure?

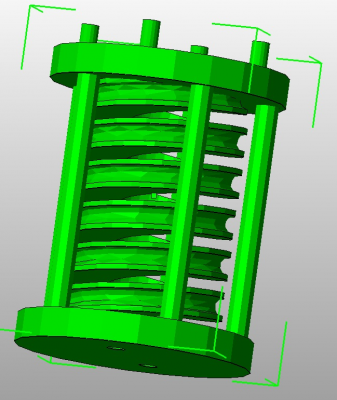

What I'm trying to print is a coil type of thing. Picture here...

The plastic just droops down when it tries to print the next layer of the coil. Support structure would probably be too troublesome to remove.

I'm thinking of printing a fan duct to focus high flow air on the nozzle tip to solidify the plastic instantly, but if this whole thing is not possible then I will scratch the idea.

Maybe the high flow air would have to be so powerful to solidify that it would just blow the extrusion away. I dunno.

I think it's possible to print a couple mm's in air, but anything more it too much huh?

So who knows for sure?

What I'm trying to print is a coil type of thing. Picture here...

The plastic just droops down when it tries to print the next layer of the coil. Support structure would probably be too troublesome to remove.

|

Re: Printing in air? January 02, 2013 02:53PM |

Registered: 12 years ago Posts: 99 |

|

Re: Printing in air? January 02, 2013 03:19PM |

Registered: 12 years ago Posts: 809 |

|

Re: Printing in air? January 02, 2013 04:52PM |

Registered: 11 years ago Posts: 26 |

I have been looking into PVA, but I do not have dual extrusion at this moment. Maybe in the future if I deem it necessary I will install it.

I was thinking of cutting the thing in half vertically and printing two pieces then gluing it, but those vertical pillars will not print because they would be horizontally in air.

STL attached.

I was thinking of cutting the thing in half vertically and printing two pieces then gluing it, but those vertical pillars will not print because they would be horizontally in air.

STL attached.

|

Re: Printing in air? January 03, 2013 07:05AM |

Registered: 11 years ago Posts: 251 |

I have had a couple of occasions where parts got knocked off the bed or I have been fiddling and accidentally blocked an axis' free movement causing significant position error. The result has normally been a complete mess, but once or twice I have had a part come out with a pretty decent overhanging step in my model. There are some areas with effectively a 90 degree overhang out to like a cm away from the part.

The observation I can make is that the printer is able to print into free air only when the layer heights are very thick and speeds moderately low.

Perhaps thick layers (equal to extruder diameter) , huge amounts of cooling and very very low speed will allow you to do this?

I think thick extrusion is able to support itself better than very thin one.

Edited 1 time(s). Last edit at 01/03/2013 07:07AM by konwiddak.

The observation I can make is that the printer is able to print into free air only when the layer heights are very thick and speeds moderately low.

Perhaps thick layers (equal to extruder diameter) , huge amounts of cooling and very very low speed will allow you to do this?

I think thick extrusion is able to support itself better than very thin one.

Edited 1 time(s). Last edit at 01/03/2013 07:07AM by konwiddak.

|

Re: Printing in air? January 03, 2013 07:29AM |

Registered: 11 years ago Posts: 251 |

|

Re: Printing in air? January 03, 2013 10:25AM |

Registered: 11 years ago Posts: 26 |

^^let me know what you find out.

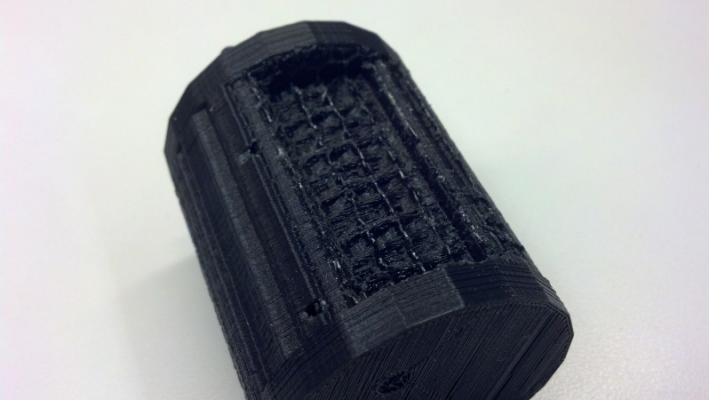

I printed my model in PLA with honeycomb support material. As you can see it is impossible to clean up. PVA support material would be the only viable option here.

Can someone please explain pattern spacing and pattern angle in slic3r?

I think I understand spacing: if I increase the spacing I will decrease the amount of support material generated correct? If I print the above model with say 5mm spacing instead of 2.5mm there will be half of it to clean up, but potentially more dodgy overhangs right?

Pattern angle I am not sure about.

I printed my model in PLA with honeycomb support material. As you can see it is impossible to clean up. PVA support material would be the only viable option here.

Can someone please explain pattern spacing and pattern angle in slic3r?

I think I understand spacing: if I increase the spacing I will decrease the amount of support material generated correct? If I print the above model with say 5mm spacing instead of 2.5mm there will be half of it to clean up, but potentially more dodgy overhangs right?

Pattern angle I am not sure about.

|

Re: Printing in air? January 03, 2013 11:53AM |

Registered: 11 years ago Posts: 251 |

|

Re: Printing in air? January 03, 2013 12:23PM |

Registered: 12 years ago Posts: 939 |

konwiddak Wrote:

-------------------------------------------------------

> The support generated by kisslicer is much easier

> to remove. I always use the coarsest option and it

> does some clever stuff printing an extremely fine

> wiry mesh that you can break away with fingers.

> Just need a small pair of needle nose pliers on

> your model.

I agree kisslicer support is the closest thing to usable I've seen, even there though in PLA you'd have a hard time getting a clean part.

In ABS support removal is a lot easier.

-------------------------------------------------------

> The support generated by kisslicer is much easier

> to remove. I always use the coarsest option and it

> does some clever stuff printing an extremely fine

> wiry mesh that you can break away with fingers.

> Just need a small pair of needle nose pliers on

> your model.

I agree kisslicer support is the closest thing to usable I've seen, even there though in PLA you'd have a hard time getting a clean part.

In ABS support removal is a lot easier.

|

Re: Printing in air? January 03, 2013 12:51PM |

Registered: 11 years ago Posts: 26 |

|

Re: Printing in air? January 03, 2013 03:43PM |

Registered: 11 years ago Posts: 251 |

My printer is my own design. Kisslicer is pretty easy to set up, but everything is called something different to what it is in other slicers! I'll go through the unclear settings:

Style Tab:

Skin thickness - This affects how thick your top and bottom surfaces are

Extrusion width - set it to slightly wider than your nozzle (I use a 0.5mm and a 0.55mm extrusion width)

De-string - enable retraction

Material:

Extruder RPM Min and Max I just left at 3 and 75

Destring Suck - This is extruder retract

Prime - This is the opposite part of the retract, should be the same as Destring suck

Extruders:

[mm/rev] this is used in the calculation of max/min extruder speed, so you can ignore it at first (just set to 1)

All the other settings are pretty self explanatory

Style Tab:

Skin thickness - This affects how thick your top and bottom surfaces are

Extrusion width - set it to slightly wider than your nozzle (I use a 0.5mm and a 0.55mm extrusion width)

De-string - enable retraction

Material:

Extruder RPM Min and Max I just left at 3 and 75

Destring Suck - This is extruder retract

Prime - This is the opposite part of the retract, should be the same as Destring suck

Extruders:

[mm/rev] this is used in the calculation of max/min extruder speed, so you can ignore it at first (just set to 1)

All the other settings are pretty self explanatory

|

Re: Printing in air? January 03, 2013 04:10PM |

Registered: 12 years ago Posts: 939 |

> Extruder RPM Min and Max I just left at 3 and 75

You'll want to set the maximum to some large number if you are printing quickly or it'll limit your maximum printing speed, basically it caps the maximum speed that plastic can be extruded, you set mm/rev to 1 then it's in mm/s. The firmware really ought to have realistic values set in it.

You'll want to set the maximum to some large number if you are printing quickly or it'll limit your maximum printing speed, basically it caps the maximum speed that plastic can be extruded, you set mm/rev to 1 then it's in mm/s. The firmware really ought to have realistic values set in it.

|

Re: Printing in air? January 03, 2013 09:05PM |

Registered: 11 years ago Posts: 26 |

Thanks for the help guys.

Couple more questions about kisslicer...

1. Under printer tab: what do you guys have for 'loop/solid infill overlap' value? I think I want the infill to hit the perimeter loops so the value should be 1.00 right?

2. Under material tab: do you guys have a value under 'wipe' ? I don't really see it necessary.

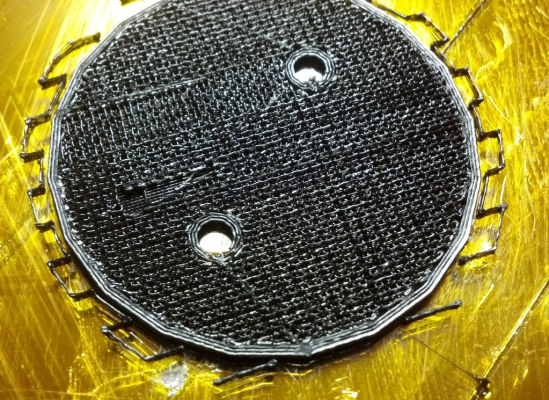

I sliced my model using kisslicer and tried to print using repetier. Here is what it was printing before I killed it because the infill was violently shaking my machine. I have the infill set at 50%. Is there a way to have it do rectilinear instead of this chain-link business? I tried with 'round infill' enabled and disabled with same results.

Looks like it's making support material on the outside, which is odd because slice3r did not do that. I would've continued with the print if I wasn't worried about it falling apart due to the vibration of the infill pattern.

Couple more questions about kisslicer...

1. Under printer tab: what do you guys have for 'loop/solid infill overlap' value? I think I want the infill to hit the perimeter loops so the value should be 1.00 right?

2. Under material tab: do you guys have a value under 'wipe' ? I don't really see it necessary.

I sliced my model using kisslicer and tried to print using repetier. Here is what it was printing before I killed it because the infill was violently shaking my machine. I have the infill set at 50%. Is there a way to have it do rectilinear instead of this chain-link business? I tried with 'round infill' enabled and disabled with same results.

Looks like it's making support material on the outside, which is odd because slice3r did not do that. I would've continued with the print if I wasn't worried about it falling apart due to the vibration of the infill pattern.

|

Re: Printing in air? January 03, 2013 09:11PM |

Registered: 12 years ago Posts: 939 |

|

Re: Printing in air? January 04, 2013 03:20PM |

Registered: 11 years ago Posts: 26 |

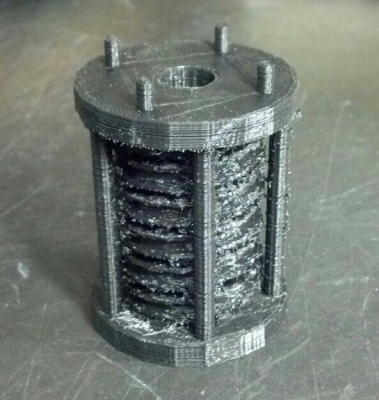

I printed the model sliced by kisslicer with 'coarse' support material. As you can see it is much better than the first one I did with slic3r, but still impossible to clean up. Yup I think I’m done trying this with PLA. Even if ABS would be easier to remove I think this particular model only PVA would do the trick in a dual extrusion setup.

|

Re: Printing in air? January 05, 2013 06:34AM |

Registered: 11 years ago Posts: 251 |

|

Re: Printing in air? January 13, 2013 03:36AM |

Registered: 11 years ago Posts: 369 |

ooo yes ... rotate the model onto its side ...

konwiddak Wrote:

-------------------------------------------------------

> You could put the model on its side, then use

> support, but limit the support to only the first

> 10mm (there is an option somewhere in kisslicer to

> do this as a one off in one of the drop down menus

> at the top of the window)

konwiddak Wrote:

-------------------------------------------------------

> You could put the model on its side, then use

> support, but limit the support to only the first

> 10mm (there is an option somewhere in kisslicer to

> do this as a one off in one of the drop down menus

> at the top of the window)

Sorry, only registered users may post in this forum.