Home

>

Reprappers

>

Topic

How to get extruded ABS to stick to print bed?

Posted by avh.on1

|

How to get extruded ABS to stick to print bed? April 02, 2013 09:01PM |

Registered: 12 years ago Posts: 15 |

My just-finished Prusa has an irritating problem: extruded ABS filament will not stick to the print bed. Instead, it touches the bed, curls up, gets stuck on the nozzle, and makes a giant blob. The first two times I tried printing, this wasn't a proble, I got two good 1 cm cubes, on seperate prints. Since then, every print I have tried has had the same problem.

My question, then is: What is necessary to get the first layer to stick to the print bed?

My printer does not have a heated print bed, although I could add one if it is necessary. All prints that I have attempted so far, including the two cubes and the blobs, were printed on blue painter's tape on a plywood bed.

The reprap wiki has this line on the ABS page:

My question, then is: What is necessary to get the first layer to stick to the print bed?

My printer does not have a heated print bed, although I could add one if it is necessary. All prints that I have attempted so far, including the two cubes and the blobs, were printed on blue painter's tape on a plywood bed.

The reprap wiki has this line on the ABS page:

Has anyone tried this? Does it work, and how should it be done? Is the problem my surface? Or do I just need to get a heated print bed?Quote

On a cold bed ABS can be printed on masking tape by putting a thin layer of super-glue (cyanoacrylate) on the tape before printing.

|

Re: How to get extruded ABS to stick to print bed? April 03, 2013 01:43AM |

Registered: 11 years ago Posts: 112 |

|

Re: How to get extruded ABS to stick to print bed? April 03, 2013 03:49AM |

Registered: 11 years ago Posts: 1,592 |

Yes, I heated bed seems to be the standard these days for reliable adhesion but....

I find that one of the most critical parameters in "bed sticking", is the gap between nozzle and bed. A gap of 0.1mm (1 thickness of copier paper) is, I reckon an absolute MAX gap - ideally, half of that if you can attain it.

I find that one of the most critical parameters in "bed sticking", is the gap between nozzle and bed. A gap of 0.1mm (1 thickness of copier paper) is, I reckon an absolute MAX gap - ideally, half of that if you can attain it.

|

Re: How to get extruded ABS to stick to print bed? April 03, 2013 04:45PM |

Registered: 12 years ago Posts: 15 |

|

Re: How to get extruded ABS to stick to print bed? April 04, 2013 01:55AM |

Registered: 11 years ago Posts: 114 |

|

Re: How to get extruded ABS to stick to print bed? April 11, 2013 08:29AM |

Well about that super glue myth..

I here by conform that it works.

I have a cold bed, printing abs 250C´ (im going to try colder), heat resistance electrical tape surace (for elektrical transformers from work) and it sticks.

just put some liquid glue on the place it is going to print, as soon as it prints on the glue the glue seam to harden.

Let this message help those who have no heated bed, or its broken.

sorry for the bad english (im dutch).

I here by conform that it works.

I have a cold bed, printing abs 250C´ (im going to try colder), heat resistance electrical tape surace (for elektrical transformers from work) and it sticks.

just put some liquid glue on the place it is going to print, as soon as it prints on the glue the glue seam to harden.

Let this message help those who have no heated bed, or its broken.

sorry for the bad english (im dutch).

|

Re: How to get extruded ABS to stick to print bed? April 11, 2013 12:47PM |

Registered: 11 years ago Posts: 544 |

|

Re: How to get extruded ABS to stick to print bed? April 12, 2013 04:28PM |

Registered: 11 years ago Posts: 477 |

|

Re: How to get extruded ABS to stick to print bed? July 22, 2013 08:08PM |

Registered: 11 years ago Posts: 246 |

In case anyone is looking for a good alternative to a heated bed for ABS, printing on a cold acrylic sheet works really well. Unfortunately, sometimes it works too well and you can't get the part off the print bed...

I am currently experimenting with acrylic as a print bed for ABS and so far it is working quite well. I have also tried sanding the surface of the acrylic to reduce adhesion. I found that if you sand the surface with really fine sandpaper, it looses a bit too much adhesion. I had to heat my sanded acrylic bed to about 80C to prevent warping, but this induced warping of the acrylic sheet so I am going to have to try to superglue the sanded acrylic to a sheet of glass to keep it flat at higher temps. We'll see how it goes

Also, has anyone tried polypropylene as a bed material?

Eric

Edited 1 time(s). Last edit at 07/22/2013 08:09PM by RP Iron Man.

I am currently experimenting with acrylic as a print bed for ABS and so far it is working quite well. I have also tried sanding the surface of the acrylic to reduce adhesion. I found that if you sand the surface with really fine sandpaper, it looses a bit too much adhesion. I had to heat my sanded acrylic bed to about 80C to prevent warping, but this induced warping of the acrylic sheet so I am going to have to try to superglue the sanded acrylic to a sheet of glass to keep it flat at higher temps. We'll see how it goes

Also, has anyone tried polypropylene as a bed material?

Eric

Edited 1 time(s). Last edit at 07/22/2013 08:09PM by RP Iron Man.

|

Re: How to get extruded ABS to stick to print bed? July 22, 2013 09:35PM |

Registered: 11 years ago Posts: 364 |

i have tried superglue on kypton tape before i got abs juice.. It works really well but is a health hazard if you turn on the hot bed.... The gas emitted from the hot bed will cause a burning sensation in your eyes.. also the super glue works too well and is hard to take the parts out .... I used to tear the kypton tape almost everytime i pulled the parts out .. And i used it only to glue the corners of the parts so that they wont warp ...

conclusion dont use it ....

conclusion dont use it ....

|

Re: How to get extruded ABS to stick to print bed? July 22, 2013 10:22PM |

Registered: 11 years ago Posts: 246 |

Thanks for the tip. You probably just saved my life  It is important to be safe when experimenting with stuff...

It is important to be safe when experimenting with stuff...

A little while ago, I was using UHU Glue Stick (Non-Toxic!) on heated glass and it was working really well. Unfortunately, my glass broke and I switched over to UHU Stick on Borosilicate glass with less than satisfactory results. I am not sure what else I changed as it is odd that UHU glue stick would work with float glass but not boro glass I have to get back to this.

I have to get back to this.

BTW, I just tried printing ABS on a polypropylene sheet and it does not work very well The glass transition of PP is wayyyyyyyyyy too low and it seems warp when it comes into contact with the hot extruded ABS. Then again, I was using a 2mm sheet that I cut out of a PP box using my laser cutter. I think a thicker sheet of PP would help. Today I also tried printing ABS on a heated plate of laser raster engraved glass (results in a surface almost identical to sand-blasted glass) at several temps up to 140C but it performed about as well as plain glass... Nothing I try seems to be working!

The glass transition of PP is wayyyyyyyyyy too low and it seems warp when it comes into contact with the hot extruded ABS. Then again, I was using a 2mm sheet that I cut out of a PP box using my laser cutter. I think a thicker sheet of PP would help. Today I also tried printing ABS on a heated plate of laser raster engraved glass (results in a surface almost identical to sand-blasted glass) at several temps up to 140C but it performed about as well as plain glass... Nothing I try seems to be working!

So far only acrylic seems to have some potential. I have tried plain acrylic, sanded acrylic, and laser raster engraved acrylic. The plain acrylic sticks too well even at room temp, while the sanded acrylic and engraved acrylic sheets seem to have much less adhesion. Unfortunately, as I mentioned before, I have to heat the sheets to get satisfactory adhesion, which leads to the warping of the acrylic surface; a problem that cannot be fixed with super glue due to the health concerns.

As much as I hate to say this, I think I am going to try imitating the scored acrylic print bed that Makerbot uses in their Cupcake printer. Hopefully this will reduce some of the adhesion of plain acrylic just enough so that I can still print ABS onto it at room temp. This way I can use a 6mm acrylic sheet at room temp and I won't have to worry about it warping.

If this doesn't work, I will have to try to get the UHU glue stick on heated glass working again...We'll see how this turns out.

Eric

It is important to be safe when experimenting with stuff...

It is important to be safe when experimenting with stuff... A little while ago, I was using UHU Glue Stick (Non-Toxic!) on heated glass and it was working really well. Unfortunately, my glass broke and I switched over to UHU Stick on Borosilicate glass with less than satisfactory results. I am not sure what else I changed as it is odd that UHU glue stick would work with float glass but not boro glass

I have to get back to this.

I have to get back to this.BTW, I just tried printing ABS on a polypropylene sheet and it does not work very well

The glass transition of PP is wayyyyyyyyyy too low and it seems warp when it comes into contact with the hot extruded ABS. Then again, I was using a 2mm sheet that I cut out of a PP box using my laser cutter. I think a thicker sheet of PP would help. Today I also tried printing ABS on a heated plate of laser raster engraved glass (results in a surface almost identical to sand-blasted glass) at several temps up to 140C but it performed about as well as plain glass... Nothing I try seems to be working!

The glass transition of PP is wayyyyyyyyyy too low and it seems warp when it comes into contact with the hot extruded ABS. Then again, I was using a 2mm sheet that I cut out of a PP box using my laser cutter. I think a thicker sheet of PP would help. Today I also tried printing ABS on a heated plate of laser raster engraved glass (results in a surface almost identical to sand-blasted glass) at several temps up to 140C but it performed about as well as plain glass... Nothing I try seems to be working!So far only acrylic seems to have some potential. I have tried plain acrylic, sanded acrylic, and laser raster engraved acrylic. The plain acrylic sticks too well even at room temp, while the sanded acrylic and engraved acrylic sheets seem to have much less adhesion. Unfortunately, as I mentioned before, I have to heat the sheets to get satisfactory adhesion, which leads to the warping of the acrylic surface; a problem that cannot be fixed with super glue due to the health concerns.

As much as I hate to say this, I think I am going to try imitating the scored acrylic print bed that Makerbot uses in their Cupcake printer. Hopefully this will reduce some of the adhesion of plain acrylic just enough so that I can still print ABS onto it at room temp. This way I can use a 6mm acrylic sheet at room temp and I won't have to worry about it warping.

If this doesn't work, I will have to try to get the UHU glue stick on heated glass working again...We'll see how this turns out.

Eric

|

Re: How to get extruded ABS to stick to print bed? July 22, 2013 10:37PM |

Registered: 17 years ago Posts: 392 |

Just as a test, you might want to try repeated ABS rafts on window glass. Each attempt to extrude ABS on glass seems to remove some of the oil or contamination on the glass, and after several passes, it might stick. I've had it stick so well it literally chipped some glass off when I tried to pry off a part that had not cooled down enough.

Printing a big square raft would be a good way to try this.

Yvan

Singularity Machine

Printing a big square raft would be a good way to try this.

Yvan

Singularity Machine

|

Re: How to get extruded ABS to stick to print bed? July 22, 2013 11:06PM |

Registered: 11 years ago Posts: 246 |

@Yvan

Thanks for the advice. I'll be sure to try this.

I have tried wiping glass with acetone to remove contaminates but I still get poor results. Are you wiping the bed with acetone between your prints? It could be that some ABS left over from the print is dissolved in the acetone when you wipe the bed, thus creating an ABS glue mixture on the glass which would be responsible for the strong adhesion.

I briefly tried ABS glue but I had trouble applying an even coating to the glass. At first I would apply the ABS glue mixture and it would be too thick, so I would wipe the bed with acetone and end up removing all of the ABS from the glass I will try this again with a sheet of glass at room temp and see how it turns out.

I will try this again with a sheet of glass at room temp and see how it turns out.

BTW, its not that I haven't been able to get ABS to stick reliably to anything. I am just trying to find the perfect print bed that ABS sticks to when hot but pops off easily when cooled. Also, I am trying to find a method that will work at temps below 100C as it is a PITA getting the bed to 130C to print the first layer. Also, high bed temps really kill my overhangs close to the bed. I think Acrylic has the most potential so far for a low temp ABS print bed. However, much more experimentation is required.

Thanks for the help

Eric

Thanks for the advice. I'll be sure to try this.

I have tried wiping glass with acetone to remove contaminates but I still get poor results. Are you wiping the bed with acetone between your prints? It could be that some ABS left over from the print is dissolved in the acetone when you wipe the bed, thus creating an ABS glue mixture on the glass which would be responsible for the strong adhesion.

I briefly tried ABS glue but I had trouble applying an even coating to the glass. At first I would apply the ABS glue mixture and it would be too thick, so I would wipe the bed with acetone and end up removing all of the ABS from the glass

I will try this again with a sheet of glass at room temp and see how it turns out.

I will try this again with a sheet of glass at room temp and see how it turns out.BTW, its not that I haven't been able to get ABS to stick reliably to anything. I am just trying to find the perfect print bed that ABS sticks to when hot but pops off easily when cooled. Also, I am trying to find a method that will work at temps below 100C as it is a PITA getting the bed to 130C to print the first layer. Also, high bed temps really kill my overhangs close to the bed. I think Acrylic has the most potential so far for a low temp ABS print bed. However, much more experimentation is required.

Thanks for the help

Eric

|

Re: How to get extruded ABS to stick to print bed? July 23, 2013 12:14AM |

Registered: 17 years ago Posts: 392 |

I am using the Lazy Slob Methodology of Printing Surface Management. It involves just... well.. nothing at all really... no acetone, nothing. Strangely enough it has worked with at least 4 pieces of randomly sourced glass(broke a few because the ABS stuck so well while still warm) and now three different rolls of filament from three suppliers. Not an expert, but it seems to be a trend. The pieces usually just slide off or pop off after a few minutes of cooling.

I keep the bed temp around 105°, well below the temp required to sag overhangs. This number is uncaliberated, so it is only aproximate. I suspect is is on the low side due to thermistor placement.

Apparently people are using carbon fibre as a printing surface. That effectively means epoxy is in contact with the extrudate. The carbon fibre is inside the epoxy, unless something goes really wrong with the saturation process!

Yvan

Singularity Machine

I keep the bed temp around 105°, well below the temp required to sag overhangs. This number is uncaliberated, so it is only aproximate. I suspect is is on the low side due to thermistor placement.

Apparently people are using carbon fibre as a printing surface. That effectively means epoxy is in contact with the extrudate. The carbon fibre is inside the epoxy, unless something goes really wrong with the saturation process!

Yvan

Singularity Machine

|

Re: How to get extruded ABS to stick to print bed? July 23, 2013 02:21AM |

Registered: 11 years ago Posts: 364 |

|

Re: How to get extruded ABS to stick to print bed? July 23, 2013 02:44AM |

Registered: 11 years ago Posts: 246 |

@ ekaggrat

This is something I have considered, though I imagine that there would be problems with it. First of all, thermoplastics adhere to themselves VERY well. Extruding ABS at above 200C onto a cold ABS print bed would most likely result in a part that is completely fused to the bed. The ABS print bed would essentially be a solid raft so you could print one yourself It would be an interesting experiment.

It would be an interesting experiment.

Eric

This is something I have considered, though I imagine that there would be problems with it. First of all, thermoplastics adhere to themselves VERY well. Extruding ABS at above 200C onto a cold ABS print bed would most likely result in a part that is completely fused to the bed. The ABS print bed would essentially be a solid raft so you could print one yourself

It would be an interesting experiment.

It would be an interesting experiment.Eric

|

Re: How to get extruded ABS to stick to print bed? July 23, 2013 11:48AM |

Registered: 11 years ago Posts: 342 |

lotw Wrote:

-------------------------------------------------------

> With pretty much everything but PLA you will need

> a heated print bed. That maybe not enough though,

> kapton tape, PET tape, ABS Juice, or hairspray may

> also be needed. I usually print directly to glass

> using just hairspray and heated bed.

+1 on the hairspray on glass. The glass needs to be super clean before applying the spray though. I clean with isopropyl alcohol (which I guess is one step below acetone) until the glass squeaks. After letting the alcohol evaporate, I hold the glass vertically an spray with aqua net hair spray about eight to ten inches away from the glass, spraying from bottom to top in an even coat. Don't spray so heavy that it runs. I then hold the glass at an angle to my desk light. You should see little bumps. If there are smooth places I start over again (think it might be oil still on the glass). I lay it horizontal under a six inch desk fan angled down to let it dry. I then apply atleast one more coat, but sometimes I do three. I only print once on this and have never had a part come unstuck.

I worry acetone may have other contaminates in it. That’s why I use isopropyl alcohol. I don't think you want to use rubbing alcohol.

Edit: Oh, and to get the parts off... I stand the plate up and let that 6" desk fan blow on the bottom of the glass. I usually hear a crack and then I strike the part with a weighted tool. Don't hit your glass! If this doesn't work or the part is too small or delicate for striking, I stick the cooled part and glass into the freezer for about five to fifteen minutes depending on part size and pull them right off the glass. Thanks to nophead for the freezer idea, don't know why I didn't think of it. Hello, the plastic and the glass will shrink at different rates causing the plastic to un-adhere.

Edited 1 time(s). Last edit at 07/23/2013 12:03PM by appdev007.

-------------------------------------------------------

> With pretty much everything but PLA you will need

> a heated print bed. That maybe not enough though,

> kapton tape, PET tape, ABS Juice, or hairspray may

> also be needed. I usually print directly to glass

> using just hairspray and heated bed.

+1 on the hairspray on glass. The glass needs to be super clean before applying the spray though. I clean with isopropyl alcohol (which I guess is one step below acetone) until the glass squeaks. After letting the alcohol evaporate, I hold the glass vertically an spray with aqua net hair spray about eight to ten inches away from the glass, spraying from bottom to top in an even coat. Don't spray so heavy that it runs. I then hold the glass at an angle to my desk light. You should see little bumps. If there are smooth places I start over again (think it might be oil still on the glass). I lay it horizontal under a six inch desk fan angled down to let it dry. I then apply atleast one more coat, but sometimes I do three. I only print once on this and have never had a part come unstuck.

I worry acetone may have other contaminates in it. That’s why I use isopropyl alcohol. I don't think you want to use rubbing alcohol.

Edit: Oh, and to get the parts off... I stand the plate up and let that 6" desk fan blow on the bottom of the glass. I usually hear a crack and then I strike the part with a weighted tool. Don't hit your glass! If this doesn't work or the part is too small or delicate for striking, I stick the cooled part and glass into the freezer for about five to fifteen minutes depending on part size and pull them right off the glass. Thanks to nophead for the freezer idea, don't know why I didn't think of it. Hello, the plastic and the glass will shrink at different rates causing the plastic to un-adhere.

Edited 1 time(s). Last edit at 07/23/2013 12:03PM by appdev007.

|

Re: How to get extruded ABS to stick to print bed? December 25, 2013 01:54AM |

Registered: 10 years ago Posts: 2 |

ive had pretty good luck with paper. i tape a full sheet to the 8x8 glass plate i place on my heat bed. the paper is pulled taught and then the glass is put on the heat bed. to get the print off, i put the part of the print that has paper (if the paper ends up stuck) on a sponge or something wet, then the paper rubs off very easily. i hope this can be of any help

|

Re: How to get extruded ABS to stick to print bed? December 25, 2013 04:44PM |

Registered: 10 years ago Posts: 329 |

|

Re: How to get extruded ABS to stick to print bed? December 25, 2013 06:15PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: How to get extruded ABS to stick to print bed? December 25, 2013 10:42PM |

Registered: 10 years ago Posts: 55 |

So I guess I started with something that worked great from day one with no problems, and just assumed that the world did this every time. I have only ever printed ABS and have never had a problem with it. I use a heated bed which I put to 110C for the first layer and then 90C for the rest. I have a 3mm glass sheet on top of it. I put blue masking tape made by 3M on the glass. When the print is done I have the bed maintain the 90C temp(if I am not around for a few hours it will sit at that temp until I get home), and I just pull up the edge of the tape with my right hand. When the tape that I am pulling up reaches the print I use my left hand to tilt it to the left, just like the tape is trying to push it. The whole thing comes up and I smooth the same piece of tape down and use it again. I have reproduced the same print over and over now 10 times without even changing the piece of tape I am printing on, and this stuff is a hell of a lot cheaper than Kapton! and easier than the ABS wipe or having to smell the hair spray! The only thing you could possibly call a drawback is that I only have 2 inch wide tape, so the bottom of the print shows the seam between the side-by-side pieces of tape on the bed. That part is always on the bottom, so no big deal. After reading all of the above I can't recommend enough that all of you give this a try!! I have learned so much from this forum I would be super excited if I helped anyone else!

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 03:16AM |

Registered: 11 years ago Posts: 1,171 |

Quote

uncle_bob

Well since we are dredging up fossil threads. ....

Hair spray on glass works just fine. It's far more "level" than anything you can do with tape. If you want a thin first layer it's the right way to go. It's about as cheap as anything else.

What hair spray do you use?

I would imagine it matters with hundreds of brands and types. Probably many use different chemicals.

I never have any issues with ABS sticking (PET film with ABS juice) but after the first few uses it gets bubbles and ripples from where other parts were printed and this leaves a mark on the next part printed. I am looking to have the bottom layer as smooth as the rest.

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 08:28AM |

Registered: 10 years ago Posts: 770 |

I just use a clean glass bed heated to 110c and right before the print I put a thin layer of the purple elmers glue stick down and it holds great!

Clean up is just warm water and wipe it off, no scrubbing or anything.

Normally I can get 5-8 prints before I build up enough glue to need cleaning.

Clean up is just warm water and wipe it off, no scrubbing or anything.

Normally I can get 5-8 prints before I build up enough glue to need cleaning.

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 12:33PM |

Registered: 10 years ago Posts: 1,433 |

Oddly enough there are a fairly limited number of things they put in hair spray. The reason the stuff works is that the main useful ingredients are water soluble plastics. If you see things like polyester-5 and polyurethane-6 on the list of ingredients, you've probably got the right stuff.

I've been using the Official Rep Rap Hairspray (trademark pending I'm sure). It's Garnier Fructis Style Extreme Control Anit-Humidity Hairspray With Natural Bamboo Extract Provides 24 Hr Bounce-Back Hold. The important thing on the label is "Extreme 5". Walmart sells it in the stores (but not on the web site??) for about $3.40 an 8.25 oz can. I'm sure it's nothing unique. The only real advantage it has is that it's about the closest thing you can find to spray paint in the hairspray aisle.

I've been using the Official Rep Rap Hairspray (trademark pending I'm sure). It's Garnier Fructis Style Extreme Control Anit-Humidity Hairspray With Natural Bamboo Extract Provides 24 Hr Bounce-Back Hold. The important thing on the label is "Extreme 5". Walmart sells it in the stores (but not on the web site??) for about $3.40 an 8.25 oz can. I'm sure it's nothing unique. The only real advantage it has is that it's about the closest thing you can find to spray paint in the hairspray aisle.

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 12:57PM |

Registered: 11 years ago Posts: 246 |

Quote

Floyd

I just use a clean glass bed heated to 110c and right before the print I put a thin layer of the purple elmers glue stick down and it holds great!

Clean up is just warm water and wipe it off, no scrubbing or anything.

Normally I can get 5-8 prints before I build up enough glue to need cleaning.

Yeah, me too. Elmer's glue works so well! The parts also pop off the bed by themselves once it cools

Eric

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 01:30PM |

Registered: 11 years ago Posts: 730 |

I stopped using hairspray on bare glass because it shrinks the bottom layers by a considerable amount. I had a part with holes 32mm apart, on the bottom the distance shrinked to 31mm.

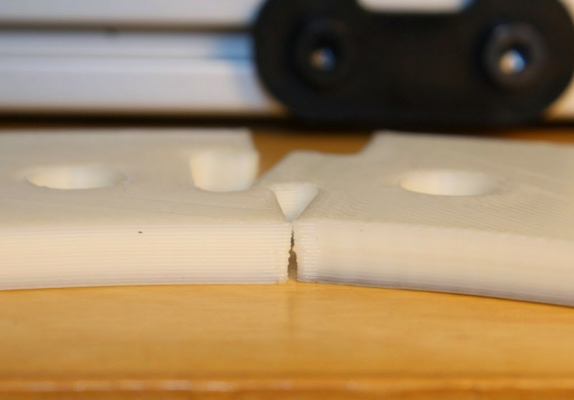

Here's what it does to perimeter walls:

This has also been witnessed by the Lulzbot people who stopped using and recommending the hairspray method.

Your mixture was too thick! Following Lulzbot instructions, mine is still liquid. I wipe it on the bed with a paper towel, it does not leave any visible residue. On my glass bed, you can't even see there's anything over the PET tape. But it is there, and very effective.

Here's what it does to perimeter walls:

This has also been witnessed by the Lulzbot people who stopped using and recommending the hairspray method.

Quote

RP Iron Man

I briefly tried ABS glue but I had trouble applying an even coating to the glass. At first I would apply the ABS glue mixture and it would be too thick, so I would wipe the bed with acetone and end up removing all of the ABS from the glass

Your mixture was too thick! Following Lulzbot instructions, mine is still liquid. I wipe it on the bed with a paper towel, it does not leave any visible residue. On my glass bed, you can't even see there's anything over the PET tape. But it is there, and very effective.

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 01:37PM |

Registered: 10 years ago Posts: 770 |

Quote

RP Iron Man

Yeah, me too. Elmer's glue works so well! The parts also pop off the bed by themselves once it cools

Its actually scared my wife a few times when you get a loud "snap" when you have a part with a large base break loose during cooling.

I dont know why people bother with ABS slurry and wiping that junk on there with tape and all. glue stick has not let me down so far with ABS.

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 05:32PM |

Registered: 10 years ago Posts: 1,433 |

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 05:46PM |

Registered: 11 years ago Posts: 1,171 |

|

Re: How to get extruded ABS to stick to print bed? December 26, 2013 06:39PM |

Registered: 11 years ago Posts: 730 |

Sorry, only registered users may post in this forum.