Home

>

Reprappers

>

Topic

Starting on a boxed reprap + mill

Posted by zzorn

|

Starting on a boxed reprap + mill March 12, 2009 09:52AM |

Registered: 16 years ago Posts: 34 |

Hi,

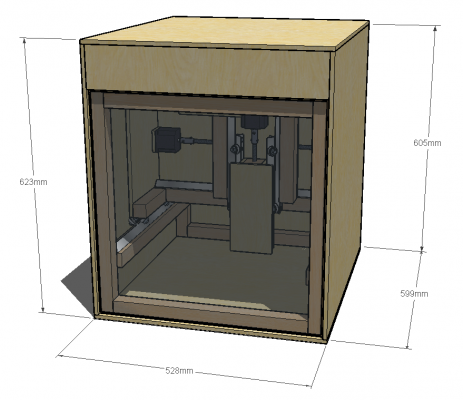

I'm starting design and implementation of a 'RepRap in a box' type machine. The goal is to create a simple design that can be easily constructed with a small amount of standard parts from a well sorted hardware store, and that is steady enough to use for milling too. By putting it in a box I hope to be able to raise the ambient temperature enough to avoid warping of the plastics too.

So far I'm doing the design in SketchUp and buying tools and materials.

Here's an initial blogpost about it: [www.zzorn.net]

You should be able to follow my RepRap related blog posts with the following feed: [www.zzorn.net]

-- zzorn

I'm starting design and implementation of a 'RepRap in a box' type machine. The goal is to create a simple design that can be easily constructed with a small amount of standard parts from a well sorted hardware store, and that is steady enough to use for milling too. By putting it in a box I hope to be able to raise the ambient temperature enough to avoid warping of the plastics too.

So far I'm doing the design in SketchUp and buying tools and materials.

Here's an initial blogpost about it: [www.zzorn.net]

You should be able to follow my RepRap related blog posts with the following feed: [www.zzorn.net]

-- zzorn

|

Re: Starting on a boxed reprap + mill March 12, 2009 07:56PM |

Registered: 15 years ago Posts: 37 |

I like the concept of keeping it all in a box. I especially like the use of the electronics' heat to heat the build box very efficient concept. I got a server rack and was easily able to fit the electronics in it (though it was pretty thin). See my pick:

very efficient concept. I got a server rack and was easily able to fit the electronics in it (though it was pretty thin). See my pick:

[forums.reprap.org]

What isn't shown is that I was easily able to fit some drawer sliders on it and it cleanly fits in an old AV rack I made years ago. This may work for your design and would save the time of making a drawer. I got a bunch of fans to put on mine and haven't really tried running it to see if heat is a problem but if you are keeping the top off the rack that 'should' help with heat dissipation.

very efficient concept. I got a server rack and was easily able to fit the electronics in it (though it was pretty thin). See my pick:

very efficient concept. I got a server rack and was easily able to fit the electronics in it (though it was pretty thin). See my pick:[forums.reprap.org]

What isn't shown is that I was easily able to fit some drawer sliders on it and it cleanly fits in an old AV rack I made years ago. This may work for your design and would save the time of making a drawer. I got a bunch of fans to put on mine and haven't really tried running it to see if heat is a problem but if you are keeping the top off the rack that 'should' help with heat dissipation.

|

Re: Starting on a boxed reprap + mill April 18, 2009 08:17AM |

Registered: 16 years ago Posts: 34 |

New design iteration of the boxed reprap out at: [www.zzorn.net]

It has some major differences from the last version, such as a completely mobile toolhead platform, and a fixed bed. The electronics were also moved on top instead of underneath.

I'll put the saw to the wood now, and start cutting out the pieces. Comments on the design are still welcome though.

It has some major differences from the last version, such as a completely mobile toolhead platform, and a fixed bed. The electronics were also moved on top instead of underneath.

I'll put the saw to the wood now, and start cutting out the pieces. Comments on the design are still welcome though.

|

Re: Starting on a boxed reprap + mill April 20, 2009 07:37AM |

Registered: 15 years ago Posts: 45 |

|

Re: Starting on a boxed reprap + mill April 21, 2009 10:34AM |

Registered: 15 years ago Posts: 42 |

|

Re: Starting on a boxed reprap + mill April 21, 2009 04:17PM |

Registered: 16 years ago Posts: 34 |

@Jeremy:

I used Google Sketchup (version 5, because newer versions didn't work for me under Wine). It's awesome for this kind of work. Very easy to use! [sketchup.google.com]

@atztek:

I'm planning to either drill holes at the top of the inverted V the rails make, and fasten them with a bolt, or alternatively attach them with bolts on each side.

It is a bit hard to get the precision accurate enough with wood (a stationary band-saw is probably useful, I used ordinary cheap power tools). Otherwise I'm not expecting any particularly difficult parts, but I'll blog more as the build progresses (currently I've cut up the pieces for the box and basic frame, next up is drilling holes and bolting them together).

I used Google Sketchup (version 5, because newer versions didn't work for me under Wine). It's awesome for this kind of work. Very easy to use! [sketchup.google.com]

@atztek:

I'm planning to either drill holes at the top of the inverted V the rails make, and fasten them with a bolt, or alternatively attach them with bolts on each side.

It is a bit hard to get the precision accurate enough with wood (a stationary band-saw is probably useful, I used ordinary cheap power tools). Otherwise I'm not expecting any particularly difficult parts, but I'll blog more as the build progresses (currently I've cut up the pieces for the box and basic frame, next up is drilling holes and bolting them together).

|

Re: Starting on a boxed reprap + mill April 21, 2009 08:14PM |

Registered: 15 years ago Posts: 42 |

|

Re: Starting on a boxed reprap + mill May 19, 2009 04:11PM |

Registered: 14 years ago Posts: 248 |

cptwinder Wrote:

-------------------------------------------------------

> That shows how long it has been since I have

> played with it. I didn't realize you could

> dimension your designs or that they had a version

> for OS X. I may have just found my 3d design

> package. I have been looking for one that was

> inexpensive and easier to use then Blender.

I personally love Sketchup (i'm not much of an artist) and the drawings can be converted to STL through scripts.

The main issue is the scaling is limited to mm, I think its to stop conflicts with the major CAD programs. Shame really as its a damn good and well thought out program.

-------------------------------------------------------

> That shows how long it has been since I have

> played with it. I didn't realize you could

> dimension your designs or that they had a version

> for OS X. I may have just found my 3d design

> package. I have been looking for one that was

> inexpensive and easier to use then Blender.

I personally love Sketchup (i'm not much of an artist) and the drawings can be converted to STL through scripts.

The main issue is the scaling is limited to mm, I think its to stop conflicts with the major CAD programs. Shame really as its a damn good and well thought out program.

|

Re: Starting on a boxed reprap + mill May 20, 2009 05:04AM |

Registered: 15 years ago Posts: 242 |

|

Re: Starting on a boxed reprap + mill May 20, 2009 06:25AM |

Registered: 16 years ago Posts: 34 |

grael Wrote:

-------------------------------------------------------

> The big challenge with a box design is access.

>

> You might consider removable panels with wingnuts

> to secure, and a basic box framework, strengthened

> by the attached panels.

Yep, that's my approach. I'm using a wooden frame and bolts to secure the sides. The whole front panel will be a door. The top panel is removable with wingnuts, and the tray under the top panel should be possible to easily lift to access the positioning robot and print head from above.

I haven't had time to work on it much in the recent weeks, but I'll get back to it eventually.

-- zzorn

-------------------------------------------------------

> The big challenge with a box design is access.

>

> You might consider removable panels with wingnuts

> to secure, and a basic box framework, strengthened

> by the attached panels.

Yep, that's my approach. I'm using a wooden frame and bolts to secure the sides. The whole front panel will be a door. The top panel is removable with wingnuts, and the tray under the top panel should be possible to easily lift to access the positioning robot and print head from above.

I haven't had time to work on it much in the recent weeks, but I'll get back to it eventually.

-- zzorn

|

Re: Starting on a boxed reprap + mill May 27, 2009 05:03PM |

I am well into putting together a similar design which I call my "plyrap" (I am sure somebody used this name already!) Mine differs in that I have cut out most of the sides of the box, to allow as much access as possible. Te basic material is 3/8 inch and 3/4 inch plywood. The z axis (hopefully!) will slide nicely up and down on 4 bits of polished drill rod, the bearings being sections cut out of "hobby shop" brass tube. The z axis motor is mounted under the z (work) platform and is raised and lowered by a single central down pointing 8mm screw, working in a captive 8mm nut 8 inches below its platform. The additional weight of the motor here is compensated for by four external counterweights attacged to it and run over pulleys at the top of the "box". The x and Y drives are like those used for home made milling machines and mounted on top of the box and likewise here the top of the box is cut out for the extruder nozzle access. May I wish you the very best of luck with your project! If I can be of any assistance to anyone working along these lines please feel free to contact me at teclightster@gmail.com or teclight@yahoo.com Paul C Pottash

|

Re: Starting on a boxed reprap + mill May 30, 2009 01:48AM |

Registered: 15 years ago Posts: 153 |

|

Re: Starting on a boxed reprap + mill May 30, 2009 08:36PM |

Registered: 14 years ago Posts: 458 |

zzorn Wrote:

-------------------------------------------------------

> New design iteration of the boxed reprap out at:

> [www.zzorn.net]

> 3.html

>

> It has some major differences from the last

> version, such as a completely mobile toolhead

> platform, and a fixed bed. The electronics were

> also moved on top instead of underneath.

>

> I'll put the saw to the wood now, and start

> cutting out the pieces. Comments on the design

> are still welcome though.

>

>

I took a look at your page, and I reckon your onto a great idea there about using the bevel gear for driving the Z axis lead screw.

I'd like to know more about how you plan on affixing the bevel gear to the lead screw

Edited 1 time(s). Last edit at 05/30/2009 08:39PM by Grogyan.

-------------------------------------------------------

> New design iteration of the boxed reprap out at:

> [www.zzorn.net]

> 3.html

>

> It has some major differences from the last

> version, such as a completely mobile toolhead

> platform, and a fixed bed. The electronics were

> also moved on top instead of underneath.

>

> I'll put the saw to the wood now, and start

> cutting out the pieces. Comments on the design

> are still welcome though.

>

>

I took a look at your page, and I reckon your onto a great idea there about using the bevel gear for driving the Z axis lead screw.

I'd like to know more about how you plan on affixing the bevel gear to the lead screw

Edited 1 time(s). Last edit at 05/30/2009 08:39PM by Grogyan.

Sorry, only registered users may post in this forum.