Home

>

Reprappers

>

Topic

Special Request - 25x25cm print bed

Posted by Yvan

|

Special Request - 25x25cm print bed July 14, 2013 01:51PM |

Registered: 17 years ago Posts: 392 |

Hello Everyone,

I keep on getting requests to build a printer with an oversized heated bed, about 10" by 10" or 25 cm square. It is possible alternative proportions would work as well, such as 20 cm x 30 cm

I've thought of hiring a PCB guy to make a massive 15A PCB heated bed, Prusa style, but that is a bit much for now(how would I sell them all to break even?). I could also hack two PCB beds into one big Frankenbed, about 20 by 30 cm. How would I drive all of that amperage?

The other option is a nice aluminium plate with an array of high wattage resistors. That implies more Y axis mass, and therefore a beefier Y axis stepper motor...?

Could Ramps 1.4 drive that? Don't know! I have no idea where the main restriction is for expanding the work area of the heated bed on a RepRap style machine.

Anyone have ideas to help sort out this jumble of possibilities?

Yvan

Singularity Machine

I keep on getting requests to build a printer with an oversized heated bed, about 10" by 10" or 25 cm square. It is possible alternative proportions would work as well, such as 20 cm x 30 cm

I've thought of hiring a PCB guy to make a massive 15A PCB heated bed, Prusa style, but that is a bit much for now(how would I sell them all to break even?). I could also hack two PCB beds into one big Frankenbed, about 20 by 30 cm. How would I drive all of that amperage?

The other option is a nice aluminium plate with an array of high wattage resistors. That implies more Y axis mass, and therefore a beefier Y axis stepper motor...?

Could Ramps 1.4 drive that? Don't know! I have no idea where the main restriction is for expanding the work area of the heated bed on a RepRap style machine.

Anyone have ideas to help sort out this jumble of possibilities?

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 14, 2013 03:24PM |

Registered: 11 years ago Posts: 117 |

|

Re: Special Request - 25x25cm print bed July 14, 2013 03:55PM |

Registered: 13 years ago Posts: 79 |

The ecksbot bed is 8 X 9 and uses a 2 layer aluminum bed with nichrome. With bearings, clips and control circuit it weighs ~ 900 grams. At 10” X 10” it would probably weigh a little over 1 kg. That’s all I have ever used so I don’t know what a traditional setup would weigh. I know that with 63 oz-in, motors it prints very happily using modest acceleration settings at 60mm/sec doing square grid infill. We have Sells Mendel’s printing at 120 using 84 oz-in motors. It really depends on how fast these people want to print and what acceleration settings they want to use as to how big the motor has to be.

Like jkoljo said: The main problem will be powering the bed. We use 14 amps through an independent power circuit to power our standard beds. If you want the larger bed to heat up in a timely manner you should be probably be looking at something a little higher than that.

Blog

Like jkoljo said: The main problem will be powering the bed. We use 14 amps through an independent power circuit to power our standard beds. If you want the larger bed to heat up in a timely manner you should be probably be looking at something a little higher than that.

Blog

|

Re: Special Request - 25x25cm print bed July 14, 2013 05:23PM |

Registered: 11 years ago Posts: 256 |

Yvan, if you could bump up to 30 cm square, QU-BD has a heater that will work for you. I am currently trying to source a 18 x 28 inch heater, but so far, no response from the rep of Durex industries, who makes silicon heaters of various types. They might also be able to help you with a 10 x 10 inch, and I believe you can get built in thermistors, and high or low voltage options. The questions are, will they sell one at a time, and for how much. I'll let you know what I find out this week.

|

Re: Special Request - 25x25cm print bed July 15, 2013 12:23PM |

Registered: 17 years ago Posts: 392 |

jkoljo, good suggestion. I've used electromechanical relays only a few times. I'm going to look into these solid state relays. The 12 x 12" bed from QU-BD for example can draw up to 20 amps at 12 v! Looking around a DigiKey seems to show there are only a few SS relays that can handle that, but not at 12 volts? Will have to learn more about this.

Bruce, I've been printing up one of your extruders to go with the Eckertech hot end, only one more part to go! Nichrome in an aluminium sandwich is a cool idea. Thanks for the suggestions, it all helps to give me a sense of where things are at. I might end up buying another of your power supplies just for the bed, as you suggest.

Maxx, the QU-BD bed looks very interesting! Thanks for the suggestion. The client thinks that size is very good, I have to see how it affects costs(SS relay, bigger stepper, ect.). My only concern is how to power that thing!

One thing I see now, I will have to switch to 12mm rod for this oversized machine. I can get a hold of drill rod locally, and I've seen light duty 12mm linear bearings(LM12UU) on eBay at a very low cost.

Yvan

Singularity Machine

Bruce, I've been printing up one of your extruders to go with the Eckertech hot end, only one more part to go! Nichrome in an aluminium sandwich is a cool idea. Thanks for the suggestions, it all helps to give me a sense of where things are at. I might end up buying another of your power supplies just for the bed, as you suggest.

Maxx, the QU-BD bed looks very interesting! Thanks for the suggestion. The client thinks that size is very good, I have to see how it affects costs(SS relay, bigger stepper, ect.). My only concern is how to power that thing!

One thing I see now, I will have to switch to 12mm rod for this oversized machine. I can get a hold of drill rod locally, and I've seen light duty 12mm linear bearings(LM12UU) on eBay at a very low cost.

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 16, 2013 11:33PM |

Registered: 17 years ago Posts: 392 |

Well no luck so far. I'm trying to find a way of controling this item:

12 x12" silicone heater

Seems solid state relays that can handle 12v, and more than 20 amps are rather expensive. Some I seen on DigiKey are $350 or more.

Maxx, seems one of the few good ways to make your custom sized 18 x 28" heater would be nichrome wire. Looks like I might have to do the same.

Yvan

Singularity Machine

12 x12" silicone heater

Seems solid state relays that can handle 12v, and more than 20 amps are rather expensive. Some I seen on DigiKey are $350 or more.

Maxx, seems one of the few good ways to make your custom sized 18 x 28" heater would be nichrome wire. Looks like I might have to do the same.

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 17, 2013 02:37AM |

Registered: 14 years ago Posts: 3,742 |

By an AC silicone heater then you can use a reasonably priced solid state relay.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Special Request - 25x25cm print bed July 17, 2013 03:29AM |

Registered: 11 years ago Posts: 117 |

|

Re: Special Request - 25x25cm print bed July 17, 2013 03:35AM |

Registered: 14 years ago Posts: 3,742 |

Those relays are all for AC output and the AC heater needs only 1 to 2 amps.

He is using a DC heater and therefore can NOT USE the three beefy SSR's from EBay.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

He is using a DC heater and therefore can NOT USE the three beefy SSR's from EBay.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Special Request - 25x25cm print bed July 17, 2013 09:33AM |

Registered: 11 years ago Posts: 251 |

I have a 300x300mm heat bed made from 6 100x150mm pieces of breadboard. Soldered tracks ends into threes and joined them up to make a single track running back and fourth. Will achieve 75C which is fine for PLA. Moving to 4 tracks soldered together would dramatically reduce resistance and increase power massively, 5 track wide would be very powerful.

|

Re: Special Request - 25x25cm print bed July 17, 2013 12:15PM |

Registered: 12 years ago Posts: 809 |

Yvan,

First look for something similar to this: McMaster Item # 35765K614 [www.mcmaster.com]

Or these: [www.omega.com]

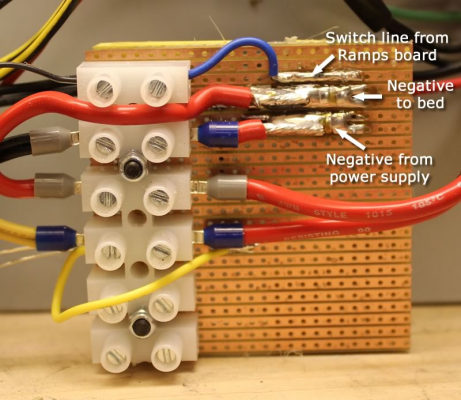

this is very easy to do. I run a 12"x12" bed. I have a thin piece of 12"x12" aluminum that I stuck a 10"x10" silicone heating pad to. One leg of the silicone pad is wired direct to AC neutral. The other leg of the silicone pad goes to an SSR. Then you wire the 110V leg of the circuit to the other side of the SSR. Lastly, you run 2 wires from RAMPS to the SSR. Make sure your polarity is correct.

Lastly, I simply attach a mirror to the aluminum heat spreader to print on.

This works for me.

[www.auberins.com]

Also, this is cheaper to run. No loss in transforming AC to DC. And you can use a smaller DC supply to run the printer.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

First look for something similar to this: McMaster Item # 35765K614 [www.mcmaster.com]

Or these: [www.omega.com]

this is very easy to do. I run a 12"x12" bed. I have a thin piece of 12"x12" aluminum that I stuck a 10"x10" silicone heating pad to. One leg of the silicone pad is wired direct to AC neutral. The other leg of the silicone pad goes to an SSR. Then you wire the 110V leg of the circuit to the other side of the SSR. Lastly, you run 2 wires from RAMPS to the SSR. Make sure your polarity is correct.

Lastly, I simply attach a mirror to the aluminum heat spreader to print on.

This works for me.

[www.auberins.com]

Also, this is cheaper to run. No loss in transforming AC to DC. And you can use a smaller DC supply to run the printer.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Special Request - 25x25cm print bed July 17, 2013 02:00PM |

Registered: 17 years ago Posts: 392 |

jkoljo, that's what I thought, then I realized there was an AC vs DC issue!

rhmorrison Wrote:

-------------------------------------------------------

> By an AC silicone heater then you can use a

> reasonably priced solid state relay.

Das ist eine gute idee! Sorry, can't help it, I like pretending I sprechen sie Deutsch....

konwiddak, Very intesting approach. I keep on thinking that something along those lines could be my backup idea, but I hadn't thought of using breadboard. If I can't find something ready made, I could get the printer going with that. When you say "soldered tracks" you mean the standard tracks on the breadboard right?

akhlut, don't make me cry with McMaster. They shipped to Canada for years, then some dummkopf mit eine stupid idee(aka terrorist) screwed it all up. Omega seems to ship to Canada, so thank you for that link!

Thanks for the overview of how you wired up your bed. Very informative for me, as electronics is not my strong suit. I will look up the SSR you linked to.

So far my thinking is to build the chassis of this machine to accept a bed slightly over 12" wide(about 30 cm). I think the bed will be the most experimental part of it for me, but I can work it out as I assemble the rest of the machine around it.

Yvan

Singularity Machine

rhmorrison Wrote:

-------------------------------------------------------

> By an AC silicone heater then you can use a

> reasonably priced solid state relay.

Das ist eine gute idee! Sorry, can't help it, I like pretending I sprechen sie Deutsch....

konwiddak, Very intesting approach. I keep on thinking that something along those lines could be my backup idea, but I hadn't thought of using breadboard. If I can't find something ready made, I could get the printer going with that. When you say "soldered tracks" you mean the standard tracks on the breadboard right?

akhlut, don't make me cry with McMaster. They shipped to Canada for years, then some dummkopf mit eine stupid idee(aka terrorist) screwed it all up. Omega seems to ship to Canada, so thank you for that link!

Thanks for the overview of how you wired up your bed. Very informative for me, as electronics is not my strong suit. I will look up the SSR you linked to.

So far my thinking is to build the chassis of this machine to accept a bed slightly over 12" wide(about 30 cm). I think the bed will be the most experimental part of it for me, but I can work it out as I assemble the rest of the machine around it.

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 17, 2013 03:07PM |

Registered: 12 years ago Posts: 809 |

Yvan,

here's a pic of the setup. It's old, but illustrative. I'll get a wiring schematic up soon.

[i.imgur.com]

I hear ya about the whole McMaster/Canada thing. Really sucks.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

here's a pic of the setup. It's old, but illustrative. I'll get a wiring schematic up soon.

[i.imgur.com]

I hear ya about the whole McMaster/Canada thing. Really sucks.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Special Request - 25x25cm print bed July 17, 2013 03:39PM |

Registered: 14 years ago Posts: 3,742 |

|

Re: Special Request - 25x25cm print bed July 17, 2013 05:22PM |

Registered: 13 years ago Posts: 79 |

If you decide to go the nichrome route we have about ¾ of a kilometer of the stuff.

Also, as per Jeremy: We also have MOSFETs that are rated to 240Amps with an internal resistance of 0.2 mOHM which means that you can run a pretty heavy duty bed without needing to heatsink the FET. MOSFET circuits are very easy to setup, they can run high currents and are very cheap.

If you ever find yourself in the Niagara region you should stop on by.

Also, as per Jeremy: We also have MOSFETs that are rated to 240Amps with an internal resistance of 0.2 mOHM which means that you can run a pretty heavy duty bed without needing to heatsink the FET. MOSFET circuits are very easy to setup, they can run high currents and are very cheap.

If you ever find yourself in the Niagara region you should stop on by.

|

Re: Special Request - 25x25cm print bed July 18, 2013 01:06AM |

Registered: 17 years ago Posts: 392 |

akhult and Bob, thanks for the photos of what you built, this seems more and more feasable all the time! This project is starting to crystalize in my mind, and the oversized heated bed no longer seems like a huge obstacle.

Bruce, your MOSFET suggestion is very interesting. I would not know where to start though. Doesn't a MOSFET need gate voltage to be quite a bit higher than the source? Wait, no, that doesn't even make sense. Need to figure out how all of this would tie in with the Arduinio/Ramps setup.

Thanks for the invite by the way. Would love to drop by, but I am not very mobile these days.

Edited 1 time(s). Last edit at 07/18/2013 01:37AM by Yvan.

Yvan

Singularity Machine

Bruce, your MOSFET suggestion is very interesting. I would not know where to start though. Doesn't a MOSFET need gate voltage to be quite a bit higher than the source? Wait, no, that doesn't even make sense. Need to figure out how all of this would tie in with the Arduinio/Ramps setup.

Thanks for the invite by the way. Would love to drop by, but I am not very mobile these days.

Edited 1 time(s). Last edit at 07/18/2013 01:37AM by Yvan.

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 18, 2013 08:20AM |

Registered: 11 years ago Posts: 117 |

|

Re: Special Request - 25x25cm print bed July 18, 2013 09:01AM |

Registered: 12 years ago Posts: 809 |

Yvan,

I think the largest obstacle is weight. Do not over-build the bed. I learned this the hard, expensive way. I now have a 12x12 hotplate that I'm still trying to figure out something to do with.

I now have a 12x12 hotplate that I'm still trying to figure out something to do with.

I've got a piece of 3003 AL, 12"x12"x0.040" thick as my heat spreader. It's bendy but not soft. I tapped and countersunk M5 screws into nylon standoffs and then used the screws to deform the metal by simply screwing them into the standoffs. Once they were in they were flush to the metal - perfect to bulldog a mirror to the heat spreader. The other benefit is that if you use long enough nylon standoffs you create a thermal break between the mounting/leveling hardware and the heated bed. This helps minimize Z changes due to heat. But you really need the mirror in this setup - it provides all the rigidity. Just make sure you place bulldog clips close to the leveling supports (3).

Also, Just as an FYI borosilicate glass is great, but expensive. I've been using cheap mirror tiles from home depot for a while now with zero issues. They cost $10 for 6.

Also, you may want to step your driver on Y up to something beefier. I've been using a DRV8825 with great success. Moving up to a 24V power supply has helped as well.

I totally forgot to post some more pics last night. Busy working on other projects.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

I think the largest obstacle is weight. Do not over-build the bed. I learned this the hard, expensive way.

I now have a 12x12 hotplate that I'm still trying to figure out something to do with.

I now have a 12x12 hotplate that I'm still trying to figure out something to do with.I've got a piece of 3003 AL, 12"x12"x0.040" thick as my heat spreader. It's bendy but not soft. I tapped and countersunk M5 screws into nylon standoffs and then used the screws to deform the metal by simply screwing them into the standoffs. Once they were in they were flush to the metal - perfect to bulldog a mirror to the heat spreader. The other benefit is that if you use long enough nylon standoffs you create a thermal break between the mounting/leveling hardware and the heated bed. This helps minimize Z changes due to heat. But you really need the mirror in this setup - it provides all the rigidity. Just make sure you place bulldog clips close to the leveling supports (3).

Also, Just as an FYI borosilicate glass is great, but expensive. I've been using cheap mirror tiles from home depot for a while now with zero issues. They cost $10 for 6.

Also, you may want to step your driver on Y up to something beefier. I've been using a DRV8825 with great success. Moving up to a 24V power supply has helped as well.

I totally forgot to post some more pics last night. Busy working on other projects.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Special Request - 25x25cm print bed July 19, 2013 02:08AM |

Registered: 17 years ago Posts: 392 |

akhlut,

Yes, I am also very concerned about the mass of the Y carriage and heated bed. I read about your attempt on your blog with the resistors. I want to avoid having to upgrade a whole chain of things to deal with the bigger heated bed. I'm thinking of building the printing surface out of carbon fibre and epoxy. Same with the Y carriage itself. I've been waiting for an excuse to work with carbon fibre for a long time. If total mass becomes a problem, I could try that!

I will look into the DRV8825 next.

Bruce, is your nichrome wire the insulated type?

Yvan

Singularity Machine

Yes, I am also very concerned about the mass of the Y carriage and heated bed. I read about your attempt on your blog with the resistors. I want to avoid having to upgrade a whole chain of things to deal with the bigger heated bed. I'm thinking of building the printing surface out of carbon fibre and epoxy. Same with the Y carriage itself. I've been waiting for an excuse to work with carbon fibre for a long time. If total mass becomes a problem, I could try that!

I will look into the DRV8825 next.

Bruce, is your nichrome wire the insulated type?

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 20, 2013 12:50PM |

Registered: 13 years ago Posts: 79 |

Yvan Wrote:

-------------------------------------------------------

> Bruce, is your nichrome wire the insulated type?

It's double wound with 2mil kapton, the same stuff that we use in our hot ends. Speaking of which: Have you got thing installed yet?

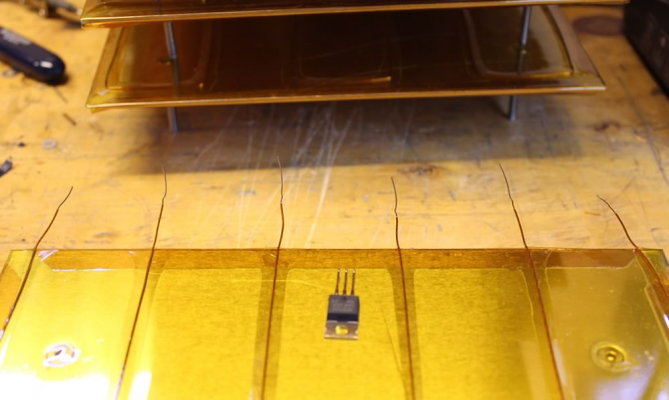

Here's a pic

I put the mosfet on the bed so you can see what it looks like.

The circuit is simple.

The terminal block is dispensable.

Blog

-------------------------------------------------------

> Bruce, is your nichrome wire the insulated type?

It's double wound with 2mil kapton, the same stuff that we use in our hot ends. Speaking of which: Have you got thing installed yet?

Here's a pic

I put the mosfet on the bed so you can see what it looks like.

The circuit is simple.

The terminal block is dispensable.

Blog

|

Re: Special Request - 25x25cm print bed July 21, 2013 02:09AM |

Registered: 17 years ago Posts: 392 |

Bruce, thanks for the photos! Duh, really simple! (simple is what I need) I like your approach. This is really giving me options in the oversized heated bed department.

The hot end has been set aside for the moment(too busy, aka life). I've finished most of the extruder assembly, still want to put a torodial groove in the idler bearing. It looks like there is just enough play in your design for me to add that mod. The extruder is clever, canted motor, angled extruder body alignment and lots of other stuff. I want to print up upgraded Z axis components before I pull the Prusa apart and install all the Ecker-stuff.

I finally just realized I made a mistake, I purchased the Mendel compatible hot end, but intend to put it in a linear bearing Prusa! Fortunately, it looks like I can easily modify the aluminium radiator plate to fit the Prusa compatible extruder I am building.

Now the distraction of the moment is sourcing ten or eleven light duty LM12UU bearings.

Yvan

Singularity Machine

The hot end has been set aside for the moment(too busy, aka life). I've finished most of the extruder assembly, still want to put a torodial groove in the idler bearing. It looks like there is just enough play in your design for me to add that mod. The extruder is clever, canted motor, angled extruder body alignment and lots of other stuff. I want to print up upgraded Z axis components before I pull the Prusa apart and install all the Ecker-stuff.

I finally just realized I made a mistake, I purchased the Mendel compatible hot end, but intend to put it in a linear bearing Prusa! Fortunately, it looks like I can easily modify the aluminium radiator plate to fit the Prusa compatible extruder I am building.

Now the distraction of the moment is sourcing ten or eleven light duty LM12UU bearings.

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 22, 2013 01:59AM |

Registered: 10 years ago Posts: 17 |

Gearing..... You can make it as heavy as you want if you gear it like an extruder head. Stepper drives a big gear, big gear has a small gear sharing that axel. Small gear drives your bed's belt. You lose speed but gain resolution and print quality. If time is not an issue then neither is weight, and quality goes up by a factor of ten.

|

Re: Special Request - 25x25cm print bed July 22, 2013 12:30PM |

Registered: 13 years ago Posts: 79 |

Quote

it looks like I can easily modify the aluminium radiator plate to fit the Prusa compatible extruder I am building.

.......Umm....... Not to challenge your innovative prowess

.......Umm....... Not to challenge your innovative prowess  but It might be prudent to bypass the possibility of alignment or cooling issues and exchange it for the proper model..... Split the postage?

but It might be prudent to bypass the possibility of alignment or cooling issues and exchange it for the proper model..... Split the postage?Blog

|

Re: Special Request - 25x25cm print bed July 22, 2013 01:44PM |

Registered: 17 years ago Posts: 392 |

Bruce Wrote:

-------------------------------------------------------

>

>

.......Umm....... Not to challenge your

.......Umm....... Not to challenge your

> innovative prowess but It might be prudent to

but It might be prudent to

> bypass the possibility of alignment or cooling

> issues and exchange it for the proper model.....

> Split the postage?

LOL! I'm operating with reduced staff right now,(aka my wife is out of town) which is why the error happened in the first place. She is much better at sourcing stuff than I am. Thank you very much for the offer, but no need for you to pay half of the shipping, it was my mistake!

Maybe I could order a few more things from you guys and get the proper hot end with that. I'll look at what I need over the next little while. Thanks for offering to take back the Mendel style hot end.

BTW, I came up with a hot end design that is very similiar to yours, but I don't need a fan at all for ABS. You guys obviously know a lot more about your design than I do, but I suspect with only slight modifications it could also run without a fan. Hence my cavalier lack of concern about fiddling around to make it fit on the Prusa! The Prusa hot end would just look nicer on the Prusa carriage though...

The Prusa hot end would just look nicer on the Prusa carriage though...

Edited 1 time(s). Last edit at 07/22/2013 01:45PM by Yvan.

Yvan

Singularity Machine

-------------------------------------------------------

>

>Quote

it looks like I can easily modify the

> aluminium radiator plate to fit the Prusa

> compatible extruder I am building.

>

>

>

.......Umm....... Not to challenge your

.......Umm....... Not to challenge your> innovative prowess

but It might be prudent to

but It might be prudent to> bypass the possibility of alignment or cooling

> issues and exchange it for the proper model.....

> Split the postage?

LOL! I'm operating with reduced staff right now,(aka my wife is out of town) which is why the error happened in the first place. She is much better at sourcing stuff than I am. Thank you very much for the offer, but no need for you to pay half of the shipping, it was my mistake!

Maybe I could order a few more things from you guys and get the proper hot end with that. I'll look at what I need over the next little while. Thanks for offering to take back the Mendel style hot end.

BTW, I came up with a hot end design that is very similiar to yours, but I don't need a fan at all for ABS. You guys obviously know a lot more about your design than I do, but I suspect with only slight modifications it could also run without a fan. Hence my cavalier lack of concern about fiddling around to make it fit on the Prusa!

The Prusa hot end would just look nicer on the Prusa carriage though...

The Prusa hot end would just look nicer on the Prusa carriage though...Edited 1 time(s). Last edit at 07/22/2013 01:45PM by Yvan.

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 23, 2013 02:24AM |

Registered: 11 years ago Posts: 730 |

Quote

Yvan

akhlut, don't make me cry with McMaster. They shipped to Canada for years, then some dummkopf mit eine stupid idee(aka terrorist) screwed it all up.

What are you guys talking about? I work for a small manufacturer in Qc and we place orders to McMaster a few times a year, last one was last week.

|

Re: Special Request - 25x25cm print bed July 23, 2013 01:31PM |

Registered: 17 years ago Posts: 392 |

NormandC Wrote:

-------------------------------------------------------

>

> What are you guys talking about? I work for a

> small manufacturer in Qc and we place orders to

> McMaster a few times a year, last one was last

> week.

You are lucky! Just for fun, try ordering from your home(or any other business in outside of the US for that matter). There is a 99.9% probability you will get a blurb -after- you finish ordering that they can't ship to due to regulations and such. Because of a guy who ordered food grade tubing aparently...

Yvan

Singularity Machine

-------------------------------------------------------

>

>Quote

Yvan

> akhlut, don't make me cry with McMaster. They

> shipped to Canada for years, then some dummkopf

> mit eine stupid idee(aka terrorist) screwed it all

> up.

>

> What are you guys talking about? I work for a

> small manufacturer in Qc and we place orders to

> McMaster a few times a year, last one was last

> week.

You are lucky! Just for fun, try ordering from your home(or any other business in outside of the US for that matter). There is a 99.9% probability you will get a blurb -after- you finish ordering that they can't ship to due to regulations and such. Because of a guy who ordered food grade tubing aparently...

Yvan

Singularity Machine

|

Re: Special Request - 25x25cm print bed July 23, 2013 01:48PM |

Registered: 11 years ago Posts: 730 |

|

Re: Special Request - 25x25cm print bed July 26, 2013 02:23PM |

Registered: 13 years ago Posts: 79 |

Quote

LOL! I'm operating with reduced staff right now,(aka my wife is out of town) which is why the error happened in the first place.

Hope she lets you live that one down…. Not that I would know anything about being in a situation like that.

Quote

Maybe I could order a few more things from you guys and get the proper hot end with that. I'll look at what I need over the next little while.

Just send me an email when you figure it out.

Fanless cooling

, “bin thar, dun that”. As a matter of fact that’s all we ever used on our cupcake, and it seemed to work great for ABS given what we knew at the time… never tried it with PLA though. Apart from the odd inexplicable jam that heatsink ran ABS faithfully without a fan. Unfortunately when we tried working with PLA on our first Mendel we got one of these >

, “bin thar, dun that”. As a matter of fact that’s all we ever used on our cupcake, and it seemed to work great for ABS given what we knew at the time… never tried it with PLA though. Apart from the odd inexplicable jam that heatsink ran ABS faithfully without a fan. Unfortunately when we tried working with PLA on our first Mendel we got one of these > <. Apparently PLA does not like to be much warmer than 45 degrees at the entrance of the inlet taper in order to extrude and retract consistently. Remember this? [www.youtube.com] . That was shortly after we started using a fan.

<. Apparently PLA does not like to be much warmer than 45 degrees at the entrance of the inlet taper in order to extrude and retract consistently. Remember this? [www.youtube.com] . That was shortly after we started using a fan.Not to put a damper on the dream, but, the problem with a fanless heatsink is that it is influenced dramatically by its environment. The actual inlet temperature depends on how close it is to the heated bed, how fast the filament is feeding and how much it is fanned by the movement of the carriage. Too many variables, I gave up. I should note: Once we added the fan the PLA flowed and those odd inexplicable jams when printing ABS went away. As an added benefit it also improved the uniformity of our prints.

Sooo……… If you can manage to come up with a fanless heatsink that can control the inlet temperature of the hot end effectively under variable printing conditions……. And not weigh more than the fan cooled option, I will tip my hat to you.

Blog

|

Re: Special Request - 25x25cm print bed July 26, 2013 05:13PM |

Registered: 17 years ago Posts: 392 |

I almost sold the Mendel compatible hot end to someone, but we ended up thinking a new J head I had is the better choice. I'm making up a lists of things to get from you guys soon.

That is a cool video you have on youtube! I almost did the same by accident when I didn't unspool enough filament once... My hobbed bolt is not the best, but it has never slipped so far...

As for the fanless hot end, it is a short term solution. I think long term I will print nylon/polycarbonate in an enclosed temp controlled box. So maybe water cooling will be the next step? Maybe my hot end never jams because the heat sink is so big? Keeps temperaturs stable? Another thing is I made up an aluminium jam nut to increase the heat flow at the inox tube to heat sink junction. Also used aluminium for the heater block, that transmits heat faster than brass. But then what do I know, it's only the second hot end I design!

BTW, your comments about the problems with fanless hot ends are very interesting.

Yvan

Singularity Machine

That is a cool video you have on youtube! I almost did the same by accident when I didn't unspool enough filament once... My hobbed bolt is not the best, but it has never slipped so far...

As for the fanless hot end, it is a short term solution. I think long term I will print nylon/polycarbonate in an enclosed temp controlled box. So maybe water cooling will be the next step? Maybe my hot end never jams because the heat sink is so big? Keeps temperaturs stable? Another thing is I made up an aluminium jam nut to increase the heat flow at the inox tube to heat sink junction. Also used aluminium for the heater block, that transmits heat faster than brass. But then what do I know, it's only the second hot end I design!

BTW, your comments about the problems with fanless hot ends are very interesting.

Yvan

Singularity Machine

Sorry, only registered users may post in this forum.