Home

>

Reprappers

>

Topic

Extruder Design - optimal depth of teeth biting into filament

Posted by dgm3333

|

Extruder Design - optimal depth of teeth biting into filament August 11, 2013 04:59PM |

Registered: 15 years ago Posts: 40 |

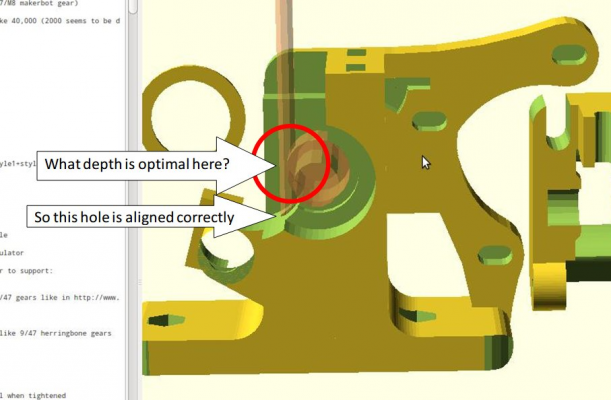

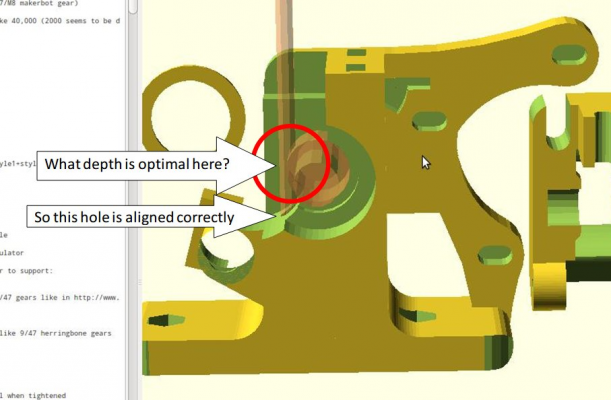

My question is, when people get optimal output, how deeply to the teeth of the drive gears bite=cut into the filament to get maximum extrusion force without slipping or breaking? I'm wondering if there is an optimal 'bite depth'. I'm using 3mm ABS filament, but also plan to try nylon at some stage, so any info for this too.

I'm about to print a new extruder body to make use of a hyena-mini.

I've modified a wades extruder (http://www.thingiverse.com/thing:18379) to take a hyena-mini drive gear, because I wanted to trial the larger diameter as my current 8mm hobbed bolt fairly regularly shreds the filament and ruins the print (as well as figuring it would be a fun project). The hyena/mini is pretty similar to a Makerbot (currently MK7/MK8) drive gear. See [reprap.org] for various examples.

I know the depth will vary with idler pressure, density/softness of the filament, and diameter of the filament but I'm wondering where to optimally place the filament guide hole to optimise grip without breaking or shredding the filament.

Obviously if the teeth bite only 0.1mm into the filament it won't have enough grip to move the filament (and will probably just shred it and slip), conversely if it bites 3mm into the filament it would cut through entirely and break the filament, so there must be an optimal bite depth somewhere in between. Also the deeper the bite, the harder for the motor to drive the toothed shaft, which is likely to contribute to it skipping/stalling, and also reduce the ultimate force which can be used for pushing the filament through the hot-end.

My previous extruders have had a bite of approx 0.5mm for a dremmel hobbed bolt, and 0.3mm for a shaft hobbed with a tap, but I didn't optomize these, as I just drilled the filament hole in the extruder body by eye, and relied on a slightly oversized hole and the idler to correct any error.

However I'd like to be a bit more scientific printing my next one.

Any help would be most appreciated.

Thanks

David

Edited 1 time(s). Last edit at 08/11/2013 05:20PM by dgm3333.

I'm about to print a new extruder body to make use of a hyena-mini.

I've modified a wades extruder (http://www.thingiverse.com/thing:18379) to take a hyena-mini drive gear, because I wanted to trial the larger diameter as my current 8mm hobbed bolt fairly regularly shreds the filament and ruins the print (as well as figuring it would be a fun project). The hyena/mini is pretty similar to a Makerbot (currently MK7/MK8) drive gear. See [reprap.org] for various examples.

I know the depth will vary with idler pressure, density/softness of the filament, and diameter of the filament but I'm wondering where to optimally place the filament guide hole to optimise grip without breaking or shredding the filament.

Obviously if the teeth bite only 0.1mm into the filament it won't have enough grip to move the filament (and will probably just shred it and slip), conversely if it bites 3mm into the filament it would cut through entirely and break the filament, so there must be an optimal bite depth somewhere in between. Also the deeper the bite, the harder for the motor to drive the toothed shaft, which is likely to contribute to it skipping/stalling, and also reduce the ultimate force which can be used for pushing the filament through the hot-end.

My previous extruders have had a bite of approx 0.5mm for a dremmel hobbed bolt, and 0.3mm for a shaft hobbed with a tap, but I didn't optomize these, as I just drilled the filament hole in the extruder body by eye, and relied on a slightly oversized hole and the idler to correct any error.

However I'd like to be a bit more scientific printing my next one.

Any help would be most appreciated.

Thanks

David

Edited 1 time(s). Last edit at 08/11/2013 05:20PM by dgm3333.

|

Re: Extruder Design - optimal depth of teeth biting into filament August 22, 2013 05:09PM |

Registered: 11 years ago Posts: 342 |

|

Re: Extruder Design - optimal depth of teeth biting into filament August 27, 2013 01:40PM |

Registered: 10 years ago Posts: 474 |

I have built my own extruder is quite large very reliable it is okay for me because I built the machine around it machine is large and strong one of the things I took into consideration when designing it was diameter of drive wheel which makes a big difference if you think of it a small diameter you may only have one tooth engaging dead center the next one's next to it is barely touching it if you have a larger diameter will get more teeth engaging the filament my drive wheel is quite large over 1 inch in diameter I didn't make it I used one that is made for a wire feed for mig welder because of the diameter you need have a high gear reduction I use 100 to 1 you can buy Nema 17 gearmotors with one hundred to one gearbox you might be able to make something small enough but it would be heavy compared to reprap standards I suppose if it was a remote extruder would be okay but I don't suggest running remote extruder's because of bad print quality

|

Re: Extruder Design - optimal depth of teeth biting into filament August 28, 2013 04:44PM |

Registered: 15 years ago Posts: 40 |

Reposted on Developer Forum

Sorry, only registered users may post in this forum.