Home

>

Reprappers

>

Topic

Removing ABS print took flake of glass of the bed !

Posted by rogerclark

|

Removing ABS print took flake of glass of the bed ! January 05, 2014 02:05AM |

Registered: 10 years ago Posts: 273 |

I'm not sure if I've just got a dodgy piece of glass but...

I've been using the same piece of 5mm window glass for since I got the printer around 4 months ago, but today when I tapped a print off the bed, it took a flake of glass off with it.

I'd used ABS juice, as I'd had problems with the print not sticking as it has a few parts that stick out that are only 3mm thick.

Is this a common occurrence?

I guess I'll need to get another piece of glass, but I'll get it from a different supplier.

Edited 1 time(s). Last edit at 01/05/2014 05:38PM by rogerclark.

I've been using the same piece of 5mm window glass for since I got the printer around 4 months ago, but today when I tapped a print off the bed, it took a flake of glass off with it.

I'd used ABS juice, as I'd had problems with the print not sticking as it has a few parts that stick out that are only 3mm thick.

Is this a common occurrence?

I guess I'll need to get another piece of glass, but I'll get it from a different supplier.

Edited 1 time(s). Last edit at 01/05/2014 05:38PM by rogerclark.

|

Re: Renoving ABS print took flake of glass of the bed ! January 05, 2014 02:43AM |

Registered: 10 years ago Posts: 1,381 |

If the flake of glass was at an edge, then that is not surprising.

A micro crack from cutting the glass is a possibility.

If the flake came from the center of the pane of glass, then some thing else is going on.

Possibly the extruder die head crashed into it.

Edited 1 time(s). Last edit at 01/05/2014 06:05AM by A2.

A micro crack from cutting the glass is a possibility.

If the flake came from the center of the pane of glass, then some thing else is going on.

Possibly the extruder die head crashed into it.

Edited 1 time(s). Last edit at 01/05/2014 06:05AM by A2.

|

Re: Renoving ABS print took flake of glass of the bed ! January 05, 2014 05:39AM |

Registered: 10 years ago Posts: 273 |

@A2

The flake is not next to the edge, and I hadn't noticed any flaws in the glass prior to the print removing the fleck.

Is possible that the extruder has collided with the bed at some time, but not recently, and I can't really recall where it hit in the past as it didnt appear to do any damage at the time.

I'll try to take a photo and post it to the forum.

The flake is not next to the edge, and I hadn't noticed any flaws in the glass prior to the print removing the fleck.

Is possible that the extruder has collided with the bed at some time, but not recently, and I can't really recall where it hit in the past as it didnt appear to do any damage at the time.

I'll try to take a photo and post it to the forum.

|

Re: Renoving ABS print took flake of glass of the bed ! January 05, 2014 12:48PM |

Registered: 17 years ago Posts: 392 |

I've had the same issue a number of times. At first I also wondered about head crashes, but the physics aren't right for the damage to come from head contact. It is caused by adhesion. Each additional print job strips away contaminants on the glass until you have a bond between perfectly clean glass and hot ABS.

I've learned to let things cool more before sliding parts off. I used to pry them off and it ruined a few glass beds.

The glass I've been using for the last several months chipped right in the middle some time ago, so I've just flipped it over and kept going.

Yvan

Singularity Machine

I've learned to let things cool more before sliding parts off. I used to pry them off and it ruined a few glass beds.

The glass I've been using for the last several months chipped right in the middle some time ago, so I've just flipped it over and kept going.

Yvan

Singularity Machine

|

Re: Renoving ABS print took flake of glass of the bed ! January 05, 2014 02:53PM |

Registered: 11 years ago Posts: 560 |

I get that as well, the slightest micro scratch out in the middle of the glass will eventually cause a chip out. For me it usually first happens with prints that have a larger contact area to the build surface.

You can get these scratches from the nozzle dragging across the glass, as well as running a razor blade across the glass to clean it or scape off plastic.

I use mirror with hairspray which lasts quite awhile, and when the glass side gets too many or a big chip in it, I flip the mirror over and print on the back side for months. The back side seems to last much longer than the glass side. The mirror finish helps to more evenly distribute heat across the whole surface. Eventually the back side will start pulling off the glass.

It's not your glass supplier, it's the repeated heat/cool cycle. Even it you are not using a heated build surface, the extuder will transfer alot of heat into the glass.

I have cracked plain glass with just the heat of the nozzle during heat up before printing.

Edited 3 time(s). Last edit at 01/05/2014 02:58PM by Dirty Steve.

You can get these scratches from the nozzle dragging across the glass, as well as running a razor blade across the glass to clean it or scape off plastic.

I use mirror with hairspray which lasts quite awhile, and when the glass side gets too many or a big chip in it, I flip the mirror over and print on the back side for months. The back side seems to last much longer than the glass side. The mirror finish helps to more evenly distribute heat across the whole surface. Eventually the back side will start pulling off the glass.

It's not your glass supplier, it's the repeated heat/cool cycle. Even it you are not using a heated build surface, the extuder will transfer alot of heat into the glass.

I have cracked plain glass with just the heat of the nozzle during heat up before printing.

Edited 3 time(s). Last edit at 01/05/2014 02:58PM by Dirty Steve.

|

Re: Renoving ABS print took flake of glass of the bed ! January 05, 2014 04:37PM |

Registered: 11 years ago Posts: 490 |

The same thing happened to the piece of oven glass of someone I know. He used ABS with ABS juice on it. The scratch theory makes sense in that it provides a starting point for the break to form, but we also noticed some wavy lines going through the glass, so maybe there have been some impurities in the glass or maybe there was some stratification in the structure itself (uneven cooling after manufacture?).

|

Re: Renoving ABS print took flake of glass of the bed ! January 05, 2014 04:49PM |

Registered: 11 years ago Posts: 1,171 |

I've seen this myself when I printed directly onto glass (with no PET tape) and I think it's due to the plastic adhering very well and then shrinking. There is a special glue for glass chipping on purpose for decorative effect and this is how it works. It sticks very well to the glass, shrinks and pulls chips of glass off in a pattern as the glue is painted on in a design.

If you want to print directly to glass this is just a risk you take. Or you can switch to any of the tapes on the surface and reduce this risk to near zero.

If you want to print directly to glass this is just a risk you take. Or you can switch to any of the tapes on the surface and reduce this risk to near zero.

|

Re: Removing ABS print took flake of glass of the bed ! January 05, 2014 05:44PM |

Registered: 10 years ago Posts: 273 |

Thanks tmorris9

I had been printing onto Kapton, but having to replace the tape every couple of weeks (depending on the number of prints I was doing), was becoming a pain, so I decided to try printing directly on glass, which works fine as long as I put ABS juice on the glass every so often (not before every print).

Actually I had been printing for quiet some time without ABS juice, but recently I had issues with a few parts coming loose, so I applied more ABS juice and it looks like the adhesion was too strong.

I think the parts came loose as I unintentionally ran the printer too fast, and they shook loose; this was because I didn't understand the speed slider in KISSlicer :-(

So I think I'll continue to use glass, but with less ABS juice, and run the printer at a more reasonable speed that doesn't shake the print loose.

I had been printing onto Kapton, but having to replace the tape every couple of weeks (depending on the number of prints I was doing), was becoming a pain, so I decided to try printing directly on glass, which works fine as long as I put ABS juice on the glass every so often (not before every print).

Actually I had been printing for quiet some time without ABS juice, but recently I had issues with a few parts coming loose, so I applied more ABS juice and it looks like the adhesion was too strong.

I think the parts came loose as I unintentionally ran the printer too fast, and they shook loose; this was because I didn't understand the speed slider in KISSlicer :-(

So I think I'll continue to use glass, but with less ABS juice, and run the printer at a more reasonable speed that doesn't shake the print loose.

|

Re: Removing ABS print took flake of glass of the bed ! January 05, 2014 06:27PM |

Registered: 11 years ago Posts: 560 |

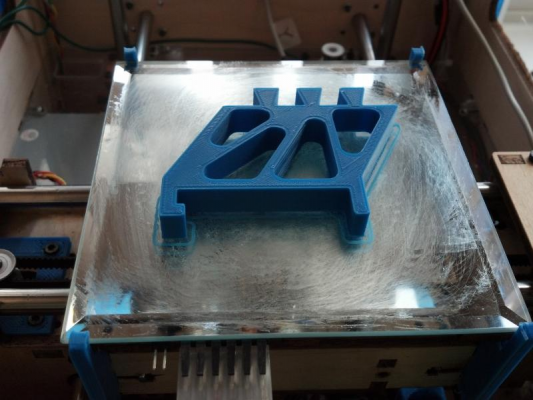

|

Re: Renoving ABS print took flake of glass of the bed ! January 05, 2014 07:59PM |

Admin Registered: 17 years ago Posts: 7,879 |

To prevent it happening I use very very very dilute ABS juice and always wipe over the whole surface between each build. It seems to happen if it gets too thick and too baked on.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Removing ABS print took flake of glass of the bed ! January 05, 2014 11:59PM |

Registered: 11 years ago Posts: 69 |

I had this happen several times with normal window glass especially when I was using ABS juice. I have since moved to using

borosilicate glass and painters tape

The standard window glass is just not set up for both the thermal stress and the stress from parts shrinking when glued.

I actually had one piece of glass that shattered while the part was cooling as it was stuck so hard.

borosilicate glass and painters tape

The standard window glass is just not set up for both the thermal stress and the stress from parts shrinking when glued.

I actually had one piece of glass that shattered while the part was cooling as it was stuck so hard.

|

Re: Removing ABS print took flake of glass of the bed ! January 06, 2014 12:51AM |

Registered: 10 years ago Posts: 273 |

Thanks guys,

I'll minimise my use of ABS juice.

Normally I can get away without applying new each time, but at the moment I'm printing some large parts that go right to the edge of the glass, and I had curling at the edge (not sure why as I double checked the bed level alignment).

Actually today another fleck of glass came off, so I'm going to turn the glass over and try it without ABS juice. I suspect however that the glass will soon totally break, so I'll get a new piece ASAP

I'll minimise my use of ABS juice.

Normally I can get away without applying new each time, but at the moment I'm printing some large parts that go right to the edge of the glass, and I had curling at the edge (not sure why as I double checked the bed level alignment).

Actually today another fleck of glass came off, so I'm going to turn the glass over and try it without ABS juice. I suspect however that the glass will soon totally break, so I'll get a new piece ASAP

|

Re: Removing ABS print took flake of glass of the bed ! January 06, 2014 09:41AM |

Registered: 11 years ago Posts: 490 |

@bytemedwb: The strange thing is that I never witnessed chipping happening with window glass, only with borosilicate. However, window glass completely shattered more than once when the stress of cooling ABS parts was too strong, even with Kapton tape applied.

That being said, the guys I work with and I usually applied extremely copious amounts of ABS juice to our build surfaces. I am back to Kapton + glue stick, which just works best for me. And if the Z height is calibrated well, the tape lasts several weeks to months.

That being said, the guys I work with and I usually applied extremely copious amounts of ABS juice to our build surfaces. I am back to Kapton + glue stick, which just works best for me. And if the Z height is calibrated well, the tape lasts several weeks to months.

|

Re: Removing ABS print took flake of glass of the bed ! January 06, 2014 04:06PM |

Registered: 11 years ago Posts: 69 |

|

Re: Removing ABS print took flake of glass of the bed ! January 07, 2014 04:08PM |

Registered: 10 years ago Posts: 273 |

I know this is a bit off of a tangent from my original posting...

But perhaps I'd be better off getting hold of a piece of machined flat steel or aluminium.

Does anyone know why this isn't widely used?

Is it that its hard to get hold of 200x200 milled flat aluminium (or steel) plate ?

I suspect it would cost around $200 for me to get one made, but it cost me $20 to get the normal 5mm window glass, and its only lasted a few months, so perhaps it would be worth investing in a metal plate.??

But perhaps I'd be better off getting hold of a piece of machined flat steel or aluminium.

Does anyone know why this isn't widely used?

Is it that its hard to get hold of 200x200 milled flat aluminium (or steel) plate ?

I suspect it would cost around $200 for me to get one made, but it cost me $20 to get the normal 5mm window glass, and its only lasted a few months, so perhaps it would be worth investing in a metal plate.??

|

Re: Removing ABS print took flake of glass of the bed ! January 07, 2014 05:19PM |

Registered: 17 years ago Posts: 392 |

The aluminium may warp with the heat, so that is tricky. It is done, but you have to take a few variables into account.

I use 3 mm glass, a bit cheaper, and I buy larger pieces that I cut down myself. Multiple print surfaces can be handy.

Still can't figure out why Nophead's trick works. There is much mystery in this. There seems to be a lot of variation, and not just depending on the source of ABS.

Now that would do it!

Yvan

Singularity Machine

I use 3 mm glass, a bit cheaper, and I buy larger pieces that I cut down myself. Multiple print surfaces can be handy.

Still can't figure out why Nophead's trick works. There is much mystery in this. There seems to be a lot of variation, and not just depending on the source of ABS.

Quote

bytemedwb

So one trick I have used for this is to pause the print after the first layer. Then, using a brush brush ABS juice over the first layer.

You will end up really stuck to the glass. But when I have done this there has been no curling.

Now that would do it!

Yvan

Singularity Machine

|

Re: Removing ABS print took flake of glass of the bed ! January 07, 2014 05:31PM |

Registered: 10 years ago Posts: 273 |

Yvan

Or perhaps thicker aluminium e.g. 5mm.

I understand that bed weight on printer types where the bed moved in Y or X, and thermal mass would cause bed heating to be slower on thicker pieces of metal.

Or is what is required some sort of machined aluminium plate with a lattice structure on the back to give rigidity, yet not have the weight of a solid plate?

What about steel or stainless steel ?Quote

The aluminium may warp with the heat, so that is tricky

Or perhaps thicker aluminium e.g. 5mm.

I understand that bed weight on printer types where the bed moved in Y or X, and thermal mass would cause bed heating to be slower on thicker pieces of metal.

Or is what is required some sort of machined aluminium plate with a lattice structure on the back to give rigidity, yet not have the weight of a solid plate?

|

Re: Removing ABS print took flake of glass of the bed ! January 08, 2014 01:14AM |

Registered: 17 years ago Posts: 392 |

I wouldn't want to stear you in the wrong direction with my limited first hand experiance concerning alternatives. Maybe it is worth starting a new topic that focuses on the alternatives?

I've been sticking to glass(no pun intended!) so as to avoid dealing with all the complexities of other materials! I'm not really satisfied with glass though, for several reason...

Yvan

Singularity Machine

I've been sticking to glass(no pun intended!) so as to avoid dealing with all the complexities of other materials! I'm not really satisfied with glass though, for several reason...

Yvan

Singularity Machine

|

Re: Removing ABS print took flake of glass of the bed ! January 08, 2014 03:35AM |

Registered: 10 years ago Posts: 273 |

Hi Yvan

No worries.

I'm building a new printer at the moment, so I'm looking around for alternatives to glass at the same time.

I'm pretty sure I can get hold of steel plate and stainless steel plate locally, but not sure about aluminium. For some reason aluminium seems to be harder to source, unless I want standard things like L shaped extrusion or very thin plate e.g. 1mm thick.

No worries.

I'm building a new printer at the moment, so I'm looking around for alternatives to glass at the same time.

I'm pretty sure I can get hold of steel plate and stainless steel plate locally, but not sure about aluminium. For some reason aluminium seems to be harder to source, unless I want standard things like L shaped extrusion or very thin plate e.g. 1mm thick.

|

Re: Removing ABS print took flake of glass of the bed ! January 09, 2014 01:21PM |

Registered: 17 years ago Posts: 392 |

I've noticed that the aluminium plate I get a hold of is not very flat. Maybe at and over 3 mm it is fairly flat in smaller sizes like 20 cm x 20 cm. Also, if it is cut to size with a hydrolic shear, that can distort it. I've been using a bandsaw to cut up to 1/2 plate, that is very good it seems. The thicker it gets the flatter it is as a rule. 1000 series of alloys are really heat conductive BTW, so they might be a good choice if they are not more expensive than 3000 series utility grade stuff.

The stainless option I'm not sure of. It is expensive, hard to cut without distorting, and a very poor conductor of heat. But then so is glass on that last point.

I've learned to keep an eye out for how the metal is cut before it is sold to me. Sometimes it ruins it!

Yvan

Singularity Machine

The stainless option I'm not sure of. It is expensive, hard to cut without distorting, and a very poor conductor of heat. But then so is glass on that last point.

I've learned to keep an eye out for how the metal is cut before it is sold to me. Sometimes it ruins it!

Yvan

Singularity Machine

|

Re: Removing ABS print took flake of glass of the bed ! January 09, 2014 05:05PM |

Registered: 10 years ago Posts: 154 |

|

Re: Removing ABS print took flake of glass of the bed ! January 09, 2014 05:20PM |

Registered: 10 years ago Posts: 273 |

@Yvan. I was thinking that I'd need to buy a plate that had been machined flat e.g. a 5mm plate.

@MrBaz. I do normally leave the plate to cool, and sometimes it still sticks. However I have not tried using a razor blade, just an normal metal scraper. I will try to use a sharp implement in future

@MrBaz. I do normally leave the plate to cool, and sometimes it still sticks. However I have not tried using a razor blade, just an normal metal scraper. I will try to use a sharp implement in future

|

Re: Removing ABS print took flake of glass of the bed ! January 09, 2014 10:23PM |

Registered: 10 years ago Posts: 154 |

This isn't a huge print by any means, so take it for what it is worth. I waited for the mirror to cool down completely. I then shimmied a razor blade under a corner and the entire thing popped right off with pretty much no effort.

Oh, and I found this 124mm square mirror at some discount Garden Ridge store for only $2. They had a very large assortment of shapes and sizes. I'll be going back for more of these $2 mirrors.

They even had large circular mirrors. Those would be great for the future Delta Bot build of mine!

Edited 3 time(s). Last edit at 01/09/2014 10:28PM by MrBaz.

Oh, and I found this 124mm square mirror at some discount Garden Ridge store for only $2. They had a very large assortment of shapes and sizes. I'll be going back for more of these $2 mirrors.

They even had large circular mirrors. Those would be great for the future Delta Bot build of mine!

Edited 3 time(s). Last edit at 01/09/2014 10:28PM by MrBaz.

|

Re: Removing ABS print took flake of glass of the bed ! January 09, 2014 11:01PM |

Registered: 17 years ago Posts: 392 |

Roger, I was thinking tests could be done on inexpensive off cuts from a local metal supplier before paying for someone to machine it flat. Depending on your budget...

I do a lot of inexpensive testing like that, and I keep the big bucks for buying in bulk or good tools.

Yvan

Singularity Machine

I do a lot of inexpensive testing like that, and I keep the big bucks for buying in bulk or good tools.

Yvan

Singularity Machine

Sorry, only registered users may post in this forum.