Home

>

Reprappers

>

Topic

How to: High precision calibration

Posted by thecrazy

|

How to: High precision calibration January 20, 2014 12:24AM |

Registered: 11 years ago Posts: 124 |

I hope you find this usefull, should have shared this over a year ago.

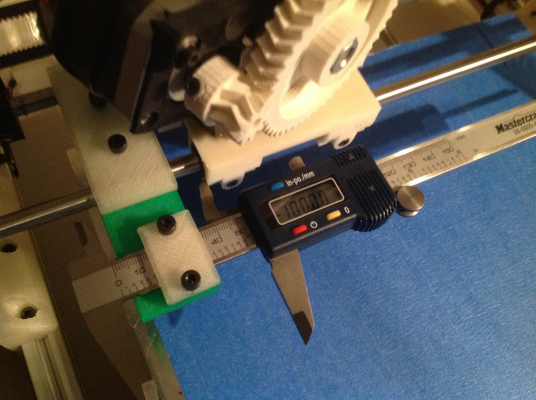

Here is a teaser of what my calibration OCD lead to:

Now I need to find a calliper with extra digits.

Unfortunatly I'm lazy about reposting stuff, so if you want the full story please head on to my blog post:

http://gearforge.blogspot.ca/2014/01/3d-printer-axis-calibration-how-to-do.html

You can get the files here (but read the post first):

[www.thingiverse.com]

Edited 5 time(s). Last edit at 01/20/2014 12:34AM by thecrazy.

Here is a teaser of what my calibration OCD lead to:

Now I need to find a calliper with extra digits.

Unfortunatly I'm lazy about reposting stuff, so if you want the full story please head on to my blog post:

http://gearforge.blogspot.ca/2014/01/3d-printer-axis-calibration-how-to-do.html

You can get the files here (but read the post first):

[www.thingiverse.com]

Edited 5 time(s). Last edit at 01/20/2014 12:34AM by thecrazy.

|

Re: How to: High precision calibration January 20, 2014 12:14PM |

Registered: 11 years ago Posts: 1,320 |

Nice idea. Should be relatively easy to try out.

I'd like to see a picture of the E axis mounting; I can't quite picture it. If I put the caliper into the slot, won't I be blocking the bolt from going through and tightening things down. What I'm gathering from this is that I mount the caliper above the extruder, and then run both the filament and the caliper through the clip you show and tighten. Then extrude, and measure how far the clip was pulled versus how much you thing you were expecting.

I'd like to see a picture of the E axis mounting; I can't quite picture it. If I put the caliper into the slot, won't I be blocking the bolt from going through and tightening things down. What I'm gathering from this is that I mount the caliper above the extruder, and then run both the filament and the caliper through the clip you show and tighten. Then extrude, and measure how far the clip was pulled versus how much you thing you were expecting.

|

Re: How to: High precision calibration January 20, 2014 01:35PM |

Registered: 11 years ago Posts: 349 |

|

Re: How to: High precision calibration January 20, 2014 10:06PM |

Registered: 11 years ago Posts: 124 |

Quote

jbernardis

Nice idea. Should be relatively easy to try out.

I'd like to see a picture of the E axis mounting; I can't quite picture it. If I put the calliper into the slot, won't I be blocking the bolt from going through and tightening things down. What I'm gathering from this is that I mount the calliper above the extruder, and then run both the filament and the calliper through the clip you show and tighten. Then extrude, and measure how far the clip was pulled versus how much you thing you were expecting.

I know, sorry, I lost the files for the E axis calibration. Including the pictures and the stl to the bracket holding the calliper. But basicly you need to design a piece that will attach the calliper to the top of the printer with the depth probe pointing down.

Then you open the calliper until the little probe comes out and you attach it to the filament that sticks out of your extruder using the last part showed in my post, its called extruder_calibration_3mm.stl.

Then you zero the calliper and when you extrude it will pull down on the depth probe which will give you your reading.

Is that any clearer?

Edited 2 time(s). Last edit at 01/20/2014 10:16PM by thecrazy.

|

Re: How to: High precision calibration January 20, 2014 10:26PM |

Registered: 11 years ago Posts: 124 |

Quote

lazzymonk

Did you know that you can interface directly with most digital callipers relatively easily. Just a thought.

I noticed there was a connector on top of my calliper. I tough it would be for something like this.

Ideally each axis would be connected to a calliper permanently and the printer would calibrate itself.

But what I think will happen instead is that printers will start using encoder strips and then estep calibration will be history.

I wonder why it hasn't happened already, were probably waiting for Canon, HP or Lexmark to beat us to it. Cause lets not fool ourselves here, the only reason we are still building printers and that Stratasys is still in business its because those guys haven't joined in on the fun yet.

At least, not publicly. What I have found out with all my years taking apart regular printers and copiers its that they are way more complex than our 3d printers. Once they start playing on our turf they will bitch slap us all out of business with a sneeze

(

|

Re: How to: High precision calibration January 21, 2014 12:30PM |

Registered: 11 years ago Posts: 256 |

Quote

thecrazy

Quote

lazzymonk

What I have found out with all my years taking apart regular printers and copiers its that they are way more complex than our 3d printers. Once they start playing on our turf they will bitch slap us all out of business with a sneeze

(

Not all of our printers...I have been planning various feedback mechanisms for some months now for my printer...(stay tuned) If HP had their way, you'd be paying $200 /lb for filament, and having to throw half of it away if it reached a certain age. If you doubt this for one second, look at the strategy they use to rip you off for printer ink. A chip in the cartridge decides when you are out of ink, not fluid levels. I try not to print documents unless I absolutely have to anymore.

|

Re: How to: High precision calibration January 21, 2014 12:40PM |

Registered: 11 years ago Posts: 349 |

just found these [www.ebay.co.uk] would make life a bit easier.

|

Re: How to: High precision calibration January 22, 2014 11:26AM |

Registered: 11 years ago Posts: 124 |

Quote

Maxx Mayhem

Quote

thecrazy

Quote

lazzymonk

What I have found out with all my years taking apart regular printers and copiers its that they are way more complex than our 3d printers. Once they start playing on our turf they will bitch slap us all out of business with a sneeze

(

Not all of our printers...I have been planning various feedback mechanisms for some months now for my printer...(stay tuned) If HP had their way, you'd be paying $200 /lb for filament, and having to throw half of it away if it reached a certain age. If you doubt this for one second, look at the strategy they use to rip you off for printer ink. A chip in the cartridge decides when you are out of ink, not fluid levels. I try not to print documents unless I absolutely have to anymore.

Yep, I know they will charge an arm and a leg for ink but we know better than buying it from them. All I want is some awesomely reliable 3D printer on the cheap that I don't have to worry about all the problems that can happen. Deskjet printers are very reliable and that's because of all the money they put behind the R&D to make it happen.

In the meant time its still a lot of fun to tinker with our DIY machines. Just not when your are trying to print something that you need right now and that's usually when it fails lol.

Edited 2 time(s). Last edit at 01/22/2014 11:27AM by thecrazy.

|

Re: How to: High precision calibration January 22, 2014 11:29AM |

Registered: 11 years ago Posts: 124 |

Not bad not bad! Can you imagine using that on all your axis and use its output to control the movement of the printer? That would be awesome.

But it would probably be better to look into implementing some encoder strips. It would be much more compact and its basically the same thing.

Edited 1 time(s). Last edit at 01/22/2014 11:29AM by thecrazy.

|

Re: How to: High precision calibration January 22, 2014 02:53PM |

Registered: 10 years ago Posts: 13 |

|

Re: How to: High precision calibration January 22, 2014 03:46PM |

Registered: 11 years ago Posts: 124 |

Quote

aknapp

Thank you for posting this!

I have been looking for a way to better calibrate my machine for more accurate prints. I really appreciate you sharing this for those of us who could use the help. I will be using this method as soon as I get the chance.

My pleasure. This community has given so much to me, I am very happy when I can contribute something.

Sorry, only registered users may post in this forum.