Home

>

Reprappers

>

Topic

Mendel Extruder stepper motor gear or no gear that is the question?

Posted by BodgeIt

Mendel Extruder stepper motor gear or no gear that is the question? January 18, 2010 07:55AM |

Registered: 15 years ago Posts: 478 |

Mendel Extruder stepper motor gear or no gear that is the question?

I have made the Mendel Extruder body to scale.

On fitting the stepper with a Conrad serrated gear (its not really a gear but a drive shaft connector)

Fitting is too tight.

Now looking through all the Mendel stuff I see no mention of a gear.

I cant find anything indicating what you fit or do to a Mendel extruder stepper motor shaft.

If you have already built this part what did you do at this point?

I think if a gear is neded it should be in the BOM or if I need to Dremel the shaft of the motor some place it shoud say this in prepration of materials.

I dont want to Dremel the shaft if that is not how you build the Mendel extruder.

Thou ~I cant imagine getting a gear smaller that that on the Conrad coupler.

Edited 1 time(s). Last edit at 01/18/2010 08:07AM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

I have made the Mendel Extruder body to scale.

On fitting the stepper with a Conrad serrated gear (its not really a gear but a drive shaft connector)

Fitting is too tight.

Now looking through all the Mendel stuff I see no mention of a gear.

I cant find anything indicating what you fit or do to a Mendel extruder stepper motor shaft.

If you have already built this part what did you do at this point?

I think if a gear is neded it should be in the BOM or if I need to Dremel the shaft of the motor some place it shoud say this in prepration of materials.

I dont want to Dremel the shaft if that is not how you build the Mendel extruder.

Thou ~I cant imagine getting a gear smaller that that on the Conrad coupler.

Edited 1 time(s). Last edit at 01/18/2010 08:07AM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 18, 2010 09:01AM |

Admin Registered: 17 years ago Posts: 7,879 |

It uses splines cut into the motor shaft with a Dremel and a jig I believe.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 18, 2010 09:33AM |

Registered: 15 years ago Posts: 478 |

I may have been a little hasty with my comments as I have just obeyed the instructions verbatim and with out splines or any gear it looks like it might work.. If I ever finish threading the ABS through... even without the ABS going into the other guide hole the stepper is being turned when threading it thru.

May be its a case of a little knowledge was too much knowledge as there is no need for a gear or splines on the shaft.. I think for those with the little knowledge it should clarify this point in the instructions.

Well thats what I think now unless someone knows better??

I know better now it fails to work without a gear or splines.

So I guess its splines as even the Conrad Gear is too big to fit.. Thanks Nophead

Edited 2 time(s). Last edit at 01/18/2010 09:57AM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

May be its a case of a little knowledge was too much knowledge as there is no need for a gear or splines on the shaft.. I think for those with the little knowledge it should clarify this point in the instructions.

Well thats what I think now unless someone knows better??

I know better now it fails to work without a gear or splines.

So I guess its splines as even the Conrad Gear is too big to fit.. Thanks Nophead

Edited 2 time(s). Last edit at 01/18/2010 09:57AM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 18, 2010 10:25PM |

Admin Registered: 17 years ago Posts: 1,791 |

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 18, 2010 11:54PM |

Registered: 14 years ago Posts: 65 |

The automated Dremmel method is at [objects.reprap.org]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 19, 2010 01:33AM |

Registered: 14 years ago Posts: 458 |

SebastienBailard Wrote:

-------------------------------------------------------

> It uses splines cut into the motor shaft with a

> Dremel and a jig I believe.

>

> This sounds like something we need to automate

> further.

It shouldn't need to be something we automate, we should be able to use any sized Spur Gear or splined sleeve we like and adjust the bearing close to it, then tension it up.

There are available toothed pulleys with grub screws, so it would be a good idea to use that than relying on using a Dremel or rotary tool (or file) to do no more than put a flat onto the shaft.

-------------------------------------------------------

> It uses splines cut into the motor shaft with a

> Dremel and a jig I believe.

>

> This sounds like something we need to automate

> further.

It shouldn't need to be something we automate, we should be able to use any sized Spur Gear or splined sleeve we like and adjust the bearing close to it, then tension it up.

There are available toothed pulleys with grub screws, so it would be a good idea to use that than relying on using a Dremel or rotary tool (or file) to do no more than put a flat onto the shaft.

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 19, 2010 07:25AM |

Admin Registered: 17 years ago Posts: 7,879 |

The problem is adding a pulley increases the torque required and reduces the resolution. The torque is already on the high side, requiring a high torque motor, and the resolution is already too low.

That is why I rejected this otherwise nice and simple design and went for a geared solution.

Edited 1 time(s). Last edit at 01/19/2010 07:25AM by nophead.

[www.hydraraptor.blogspot.com]

That is why I rejected this otherwise nice and simple design and went for a geared solution.

Edited 1 time(s). Last edit at 01/19/2010 07:25AM by nophead.

[www.hydraraptor.blogspot.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 19, 2010 02:06PM |

Registered: 15 years ago Posts: 478 |

Was distracted today by paper work ~ so have not cut any splines yet with my semi automatic spline cutter...

I did managed to do a PCB toner transfer without the use of water or the need to rub off wet paper gently.

I have set the temprature of ARNIE PID to 48C waiting for the etchant to get up to temprature before I pop a Single sided Arduino in to etch.

Its looks good so far though May try cutting splines while I wait..

Edited 1 time(s). Last edit at 01/19/2010 02:10PM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

I did managed to do a PCB toner transfer without the use of water or the need to rub off wet paper gently.

I have set the temprature of ARNIE PID to 48C waiting for the etchant to get up to temprature before I pop a Single sided Arduino in to etch.

Its looks good so far though May try cutting splines while I wait..

Edited 1 time(s). Last edit at 01/19/2010 02:10PM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 20, 2010 09:57PM |

Registered: 16 years ago Posts: 536 |

Just a heads up - I also built a couple of the Mendel splined extruders, and I wasn't able to get enough torque out of the surplus steppers I had around. They were pretty weak Nema 17's though.

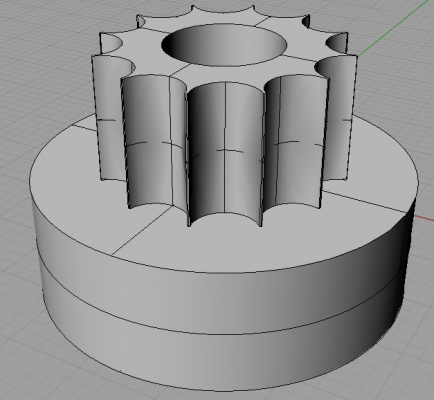

Now I'm experimenting with a geared version; although my printed gears are not quite ready for primetime yet. Looks like I'm going to have some issues transferring the output torque from the driven gear to the pinchwheel axle without destroying the gear hub, but I'm working on it. Here's a photo of my first try, which doesn't work yet:

Edited 1 time(s). Last edit at 01/20/2010 09:57PM by Wade.

Now I'm experimenting with a geared version; although my printed gears are not quite ready for primetime yet. Looks like I'm going to have some issues transferring the output torque from the driven gear to the pinchwheel axle without destroying the gear hub, but I'm working on it. Here's a photo of my first try, which doesn't work yet:

Edited 1 time(s). Last edit at 01/20/2010 09:57PM by Wade.

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 21, 2010 04:50AM |

Admin Registered: 17 years ago Posts: 7,879 |

Hi Wade,

Those gears look nice.

The only way I can think of to make the hub strong enough is to have metal insert made from hex bar, as I did here: [hydraraptor.blogspot.com]

Edited 1 time(s). Last edit at 01/21/2010 08:06AM by nophead.

[www.hydraraptor.blogspot.com]

Those gears look nice.

The only way I can think of to make the hub strong enough is to have metal insert made from hex bar, as I did here: [hydraraptor.blogspot.com]

Edited 1 time(s). Last edit at 01/21/2010 08:06AM by nophead.

[www.hydraraptor.blogspot.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 21, 2010 01:24PM |

Registered: 14 years ago Posts: 800 |

i do like the idea of a geared extruder my self, thought i have noticed they are not too common. i am planing on making one for my project

[mike-mack.blogspot.com]

[mike-mack.blogspot.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 21, 2010 05:54PM |

Registered: 15 years ago Posts: 478 |

I think that if I can get my extruder to work just good enough.

Its first job will be to print the more complicated extruder block required for a geared extruder and the two gears.

The extruder drive is the key component that is I think the most dificult component to scratch build as it requires more far more acurate parts to work perfectly.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Its first job will be to print the more complicated extruder block required for a geared extruder and the two gears.

The extruder drive is the key component that is I think the most dificult component to scratch build as it requires more far more acurate parts to work perfectly.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 22, 2010 12:35PM |

Registered: 16 years ago Posts: 536 |

With some better printed gears, I managed to get 5.5 kg of pull on the filament before the pinchwheel started slipping, details here:

[objects.reprap.org]

Wade

[objects.reprap.org]

Wade

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 22, 2010 01:16PM |

Registered: 15 years ago Posts: 478 |

Thank you that looks like a very neat solution to increasing the extruder Torque.

Do you have any maximum torque figures for an unmodified extruder?

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Do you have any maximum torque figures for an unmodified extruder?

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 22, 2010 02:03PM |

Admin Registered: 17 years ago Posts: 7,879 |

Actually the gear ratio to get the torque is significantly less than the gear ratio needed to get the resolution. People seem to be overlooking the resolution but how can you expect to build an accurate object if the extruder step size is a few mm of filament?

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 22, 2010 02:14PM |

Registered: 16 years ago Posts: 536 |

Yeah, the 0.5 mm extruded filament length resolution on that one works out to about 0.7 mm; but my current extruder can't start or stop in less than 10 mm, so I don't think it's too much of an issue, yet. This should still be way better than the old one. For now I just have Skeinforge tweaked to minimize starts and stops. Plus most of my extruders so far seem to act like low pass filters - as long as the average flow rate is about right, they seem to work OK.

8 times microstepping should get me right down to 0.1 mm though - that'd be just about right. Have to put together a microstepping stepper driver. For this test I've just been using an extruder controller in stepper mode.

The pinchwheel gear teeth on this one cause speed stability problems though, I think I'll try something similar to Nophead's hobbed pinch wheel next.

Wade

8 times microstepping should get me right down to 0.1 mm though - that'd be just about right. Have to put together a microstepping stepper driver. For this test I've just been using an extruder controller in stepper mode.

The pinchwheel gear teeth on this one cause speed stability problems though, I think I'll try something similar to Nophead's hobbed pinch wheel next.

Wade

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 22, 2010 02:36PM |

Registered: 15 years ago Posts: 264 |

I have to agree with nophead. Calculating for my extruder, 200/steps per revolution with 20 mm circumfrence gives gives .1 mm/step feeding into the heater, but that gets reduced from 3 mm to .33 mm diameter, meaning I get about 10 mm of thread per step of the extruder motor. With my feedrate of .1 mm/step I'm taking 100 feed steps for each flow step. This seems way out of whack. Yet I don't see any evidence of a problem. Wade might be right that the extruder acts as a big low-pass filter.

So, I think if we are gearing things we should aim for something around a 100:1 ratio. I think we should be able to find some very cheap motors to drive it at that point as well.

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

So, I think if we are gearing things we should aim for something around a 100:1 ratio. I think we should be able to find some very cheap motors to drive it at that point as well.

Darwin clone, Gen 2 electronics, Arduino Duemilanove w/ AtMega328, 5D Firmware, Pinchwheel extruder

[www.codeerrors.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? January 22, 2010 03:33PM |

Registered: 15 years ago Posts: 478 |

Absolutely right about resolution I agree.

Just getting an extruder to extrude reliably needed as a stepping stone.

Towards that goal of improving the extruder resolution.

As it allows the printing of a more complex worm gear extruder head parts.

Thinking about worm gears and where to get some to play with.

OO gauge trains and Minic cars though they might be too small.

As I had Minic I don't know the drive mechanism for Scalextric cars was it also a worm drive?

Using Mecano you can still buy (32b) Narrow Worm Gear 7/16" Dia Brass (Meshes With 27d) to get a 60:1 ratio that would give 2800 steps a rev using a 7.5 degree stepper giving 0.0056mm per step.

So each step would produce 0.158^3mm of plastic extruded I think..

Edited 1 time(s). Last edit at 01/22/2010 03:34PM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Just getting an extruder to extrude reliably needed as a stepping stone.

Towards that goal of improving the extruder resolution.

As it allows the printing of a more complex worm gear extruder head parts.

Thinking about worm gears and where to get some to play with.

OO gauge trains and Minic cars though they might be too small.

As I had Minic I don't know the drive mechanism for Scalextric cars was it also a worm drive?

Using Mecano you can still buy (32b) Narrow Worm Gear 7/16" Dia Brass (Meshes With 27d) to get a 60:1 ratio that would give 2800 steps a rev using a 7.5 degree stepper giving 0.0056mm per step.

So each step would produce 0.158^3mm of plastic extruded I think..

Edited 1 time(s). Last edit at 01/22/2010 03:34PM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Re: Mendel Extruder stepper motor gear or no gear that is the question? March 16, 2010 01:38PM |

How about something like this:

Made by chain drilling a ring of holes in to the end of a bar, then turning off the material around the holes to leave a pointy spline.

We have used this technique for making friction drive gears in industry.

It is equally possible to leave a cheek on either side of the spline then use a plain bearing in-between the cheeks to hold the filament against the spline.

Si

Made by chain drilling a ring of holes in to the end of a bar, then turning off the material around the holes to leave a pointy spline.

We have used this technique for making friction drive gears in industry.

It is equally possible to leave a cheek on either side of the spline then use a plain bearing in-between the cheeks to hold the filament against the spline.

Si

Re: Mendel Extruder stepper motor gear or no gear that is the question? March 17, 2010 05:59PM |

Registered: 16 years ago Posts: 536 |

I tried an 11 tooth spur gear purchased from SDP-SI, and while it worked, there was noticeable acceleration and deceleration of the filament as each tooth was engaged.

Making a worm gear style pinchwheel (like Nophead's designs) worked out much better - smooth operation, great pull (16 kg on PLA), and easy to make - all it takes is a hand drill, file, and an M3 tap, plus a few skate bearings and a vice (or a Reprap).

Details on the wiki:

[objects.reprap.org]

Wade

Making a worm gear style pinchwheel (like Nophead's designs) worked out much better - smooth operation, great pull (16 kg on PLA), and easy to make - all it takes is a hand drill, file, and an M3 tap, plus a few skate bearings and a vice (or a Reprap).

Details on the wiki:

[objects.reprap.org]

Wade

Sorry, only registered users may post in this forum.