Home

>

Reprappers

>

Topic

groove or grooveless hot end

Posted by ekaggrat

|

groove or grooveless hot end April 18, 2014 01:28AM |

Registered: 11 years ago Posts: 364 |

hi,

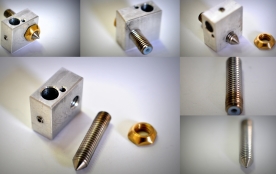

lately i have noticed that a lot of the new hotends are ditching the groove in the neck used to contain the melt zone.... Is this a correct design decision or have they made a change to make manufacturing more easy.. Also i have noticed the a lot of them have also started inserting a PTFE sleeve all the way upto the end of the nozzle .. In my experience that increases the pressure need to extrude a lot more!!..

any comments?

prometheus

argento

aluhotend

lately i have noticed that a lot of the new hotends are ditching the groove in the neck used to contain the melt zone.... Is this a correct design decision or have they made a change to make manufacturing more easy.. Also i have noticed the a lot of them have also started inserting a PTFE sleeve all the way upto the end of the nozzle .. In my experience that increases the pressure need to extrude a lot more!!..

any comments?

prometheus

argento

aluhotend

|

Re: groove or grooveless hot end April 18, 2014 02:11AM |

Registered: 10 years ago Posts: 1,381 |

Quote

ekaggrat

Is this a correct design decision or have they made a change to make manufacturing more easy.

There is nothing incorrect with a hot end design that uses a Teflon liner.

Teflon is used to insulate the filament from the barrel, which helps reduces the glass transition length.

A long glass transition length increases the force required to advance the filament.

Commonly called the plug, the glass transition zone jams more readily than rigid filament or the liquid melt.

The additional force is caused by the filament diameter increasing as it warms up, the warmed up filament tends to plug up the hot end.

The heat break that the E3D hot end uses is an attempt to throttle back the amount of heat transferred up the barrel by reducing the cross sectional area of the SS barrel.

The challenge that I see all hot ends facing is idle time. When the hot end sits idle heat will travel up, and through the filament, given enough time the glass transition zone will have expanded into the heat sink (cold zone), and causes the filament to plug. You have more heat to remove by the fan, and heat sink when the hot end sits idle, because the heat is not being removed by the melted filament.

Jammed or plugged filament is also caused by retraction, retracting either the glass-transition or melt zones into the cold zone e.g. heat sink, or thermal break, cools the plastic. The previously warm, and expanded plastic will cool at a larger diameter, and in intimate contact with the barrel wall. This increases greatly the force required to advance the filament.

A polished, and debris free barrel helps to reduce the force needed to advance the filament out of the cold zone and back into the heated block. Rough tooling marks caused by previous machining operations will greatly increase the force required to advance the filament.

A possible solution for an all metal hot end with plugged filament in the cold zone is to turn off the heat sink fan and allow the heat sink to warm up the filament. After the filament has soften sufficiently test to see if you can advance the filament. Turn the heat sink fan back on after the jam has cleared.

Barring a massively efficient method to cool an idle hot end, a slightly wasteful solution would be to allow the hot end to slowly extrude a small amount of resin to help maintain the glass transition zone below the heat sink.

Quote

ekaggrat

In my experience that increases the pressure need to extrude a lot more!!..

First I've read that the force to push a filament through a Teflon sleeve takes more force than a SS barrel.

Can you share your experience, and thoughts of why this occurred.

Edited 2 time(s). Last edit at 04/19/2014 07:47PM by A2.

|

Re: groove or grooveless hot end April 18, 2014 03:24AM |

Registered: 11 years ago Posts: 364 |

@a2

i have

i have j-head clone which had a sleeve going through till the nozzle.. the pressure to extrude 1.75 mm filament is a lot more compared to a standard j-head ... Also i have mk7 hotend,,, the pressure to extrude in that is very less.. yes but you are right the mk7 is prone to jamming if it sits for a long time or if there is machine gun retraction... also the sleeve tends to need more retraction than the stainless barrel....

i have

Quote

First I've read that the force to push a filament through a Teflon sleeve takes more force than a SS barrel.

Can you share your experience, and thoughts of why this occurred.

i have j-head clone which had a sleeve going through till the nozzle.. the pressure to extrude 1.75 mm filament is a lot more compared to a standard j-head ... Also i have mk7 hotend,,, the pressure to extrude in that is very less.. yes but you are right the mk7 is prone to jamming if it sits for a long time or if there is machine gun retraction... also the sleeve tends to need more retraction than the stainless barrel....

|

Re: groove or grooveless hot end April 19, 2014 05:27AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: groove or grooveless hot end April 19, 2014 06:28PM |

Registered: 10 years ago Posts: 9 |

|

Re: groove or grooveless hot end April 20, 2014 08:22PM |

Registered: 11 years ago Posts: 246 |

@ekaggrat

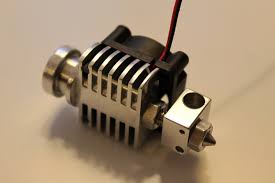

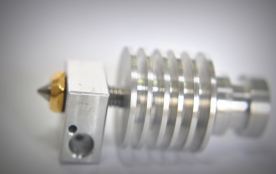

If you read closely into my design of the Prometheus Hot End you would have found out that there is a reason why I don't have a "thermal break" (machined groove) in the 1-piece nozzle and I actually designed an alternative.

Since Prometheus is a hot end with adjustable "thermal zones", the "transition-zone" has a different position on the 1-piece SS nozzle depending on the user configuration of these "thermal zones". Consequently, my customizable design cannot have a machined "thermal break" at the "transition-zone". Instead I simply use M5 threaded rod for the 3mm version and M4 threaded rod for the 1.75mm version. The result is a relatively small area to transmit heat from the "melt-zone", through the "transition-zone", to the "cold-zone". My hot end only transmits a little more heat than the E3D with the machined "thermal break" so this is not an issue.

Designs are usually more refined than they seem at first sight

As for the PTFE lined hot ends (which Prometheus is NOT since it is all-metal): usually the PTFE insert on J heads does not go all the way into the nozzle, but only lines the "transition-zone". I have to agree that it seems undesireable to insulate the filament within the "melt-zone" as this would decrease the rate of heat conduction to the plastic entering the "melt-zone" and therefore decrease the top speed of the hot end... I know that the Aluhotend has this configuration, so maybe Thejollygrimreaper can tune in and help us understand his reasons for this design decision.

As I said before, designs are usually more refined than they seem at first glance, so I am sure that Thejollygrimreaper has a good reason for that decision

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

If you read closely into my design of the Prometheus Hot End you would have found out that there is a reason why I don't have a "thermal break" (machined groove) in the 1-piece nozzle and I actually designed an alternative.

Since Prometheus is a hot end with adjustable "thermal zones", the "transition-zone" has a different position on the 1-piece SS nozzle depending on the user configuration of these "thermal zones". Consequently, my customizable design cannot have a machined "thermal break" at the "transition-zone". Instead I simply use M5 threaded rod for the 3mm version and M4 threaded rod for the 1.75mm version. The result is a relatively small area to transmit heat from the "melt-zone", through the "transition-zone", to the "cold-zone". My hot end only transmits a little more heat than the E3D with the machined "thermal break" so this is not an issue.

Designs are usually more refined than they seem at first sight

As for the PTFE lined hot ends (which Prometheus is NOT since it is all-metal): usually the PTFE insert on J heads does not go all the way into the nozzle, but only lines the "transition-zone". I have to agree that it seems undesireable to insulate the filament within the "melt-zone" as this would decrease the rate of heat conduction to the plastic entering the "melt-zone" and therefore decrease the top speed of the hot end... I know that the Aluhotend has this configuration, so maybe Thejollygrimreaper can tune in and help us understand his reasons for this design decision.

As I said before, designs are usually more refined than they seem at first glance, so I am sure that Thejollygrimreaper has a good reason for that decision

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

|

Re: groove or grooveless hot end April 20, 2014 09:35PM |

Registered: 11 years ago Posts: 364 |

@RP Iron Man

the m4pipe with 1.75mm and m5 pipe with 3mm should work fine as the wall thickness of the barrel would be less and the heat transferred would be also low... I have build two of my own hotend using the barrel from the mk7 extruder and they work great ... i also tried making one with a sleeve in it and that failed badly that's why the question of the sleeve came up ... but it could be that i may have been wrong somewhere....

maybe Thejollygrimreaper has a better explanation for the sleeve.... also the ss barrel only works good if it is mirror polished .... i tried making the barrel myself but i failed badly as i didn't have access to polishing tools...

thanks for the clarification though...

the m4pipe with 1.75mm and m5 pipe with 3mm should work fine as the wall thickness of the barrel would be less and the heat transferred would be also low... I have build two of my own hotend using the barrel from the mk7 extruder and they work great ... i also tried making one with a sleeve in it and that failed badly that's why the question of the sleeve came up ... but it could be that i may have been wrong somewhere....

maybe Thejollygrimreaper has a better explanation for the sleeve.... also the ss barrel only works good if it is mirror polished .... i tried making the barrel myself but i failed badly as i didn't have access to polishing tools...

thanks for the clarification though...

|

Re: groove or grooveless hot end April 20, 2014 09:40PM |

Registered: 11 years ago Posts: 246 |

Quote

ekaggrat

@RP Iron Man

the m4pipe with 1.75mm and m5 pipe with 3mm should work fine as the wall thickness of the barrel would be less and the heat transferred would be also low... I have build two of my own hotend using the barrel from the mk7 extruder and they work great ... i also tried making one with a sleeve in it and that failed badly that's why the question of the sleeve came up ... but it could be that i may have been wrong somewhere....

maybe Thejollygrimreaper has a better explanation for the sleeve.... also the ss barrel only works good if it is mirror polished .... i tried making the barrel myself but i failed badly as i didn't have access to polishing tools...

thanks for the clarification though...

Totally agree. Polishing is essential for all-metal hot ends. The reason all-metal hot ends have traditionally had problems (and continue to have problems) with the PLA plug causing a jam is because of the lack of polishing. Most people can't do polishing with their garage tools so it is essential to have the hot end properly manufactured.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

|

Re: groove or grooveless hot end April 20, 2014 10:11PM |

Registered: 10 years ago Posts: 1,381 |

@ekaggrat:

Polishing a 3D printer hot end barrel with sand

[www.youtube.com]

Usually, smoothing a barrel very finely requires costly equipment (namely specific reamers). Now, I did it with very basic tools: use a concrete drill bit that is 0.5 to 1 mm smaller than the inner diameter and which protrudes from the other side of the barrel. Plunge the tip of the barrel and the drill bit into a pot of sand (the finer the better, but it will get fine anyway when it gets ground). Using high speed rotation, the grains of sand are fragmented and dragged up and into the barrel, polishing nicely the inside. It obviously takes longer with stainless steel than with brass, but it did the job pretty well for me

[www.tridimake.com]

Obviously this is a hack using sand to polish the bore of a SS hot end, the presenter is fairly knowledgeable so maybe it comes out good enough.

If you search you can find abrasives that are ideally suited for polishing SS, and you could use the same technique depicted in the video to feed the abrasive medium into the barrel.

Edited 1 time(s). Last edit at 04/20/2014 10:11PM by A2.

Quote

ekaggrat

also the ss barrel only works good if it is mirror polished .... i tried making the barrel myself but i failed badly as i didn't have access to polishing tools...

Polishing a 3D printer hot end barrel with sand

[www.youtube.com]

Usually, smoothing a barrel very finely requires costly equipment (namely specific reamers). Now, I did it with very basic tools: use a concrete drill bit that is 0.5 to 1 mm smaller than the inner diameter and which protrudes from the other side of the barrel. Plunge the tip of the barrel and the drill bit into a pot of sand (the finer the better, but it will get fine anyway when it gets ground). Using high speed rotation, the grains of sand are fragmented and dragged up and into the barrel, polishing nicely the inside. It obviously takes longer with stainless steel than with brass, but it did the job pretty well for me

[www.tridimake.com]

Obviously this is a hack using sand to polish the bore of a SS hot end, the presenter is fairly knowledgeable so maybe it comes out good enough.

If you search you can find abrasives that are ideally suited for polishing SS, and you could use the same technique depicted in the video to feed the abrasive medium into the barrel.

Edited 1 time(s). Last edit at 04/20/2014 10:11PM by A2.

|

Re: groove or grooveless hot end April 20, 2014 10:21PM |

Registered: 11 years ago Posts: 246 |

Quote

A2

@ekaggrat:

Quote

ekaggrat

also the ss barrel only works good if it is mirror polished .... i tried making the barrel myself but i failed badly as i didn't have access to polishing tools...

Polishing a 3D printer hot end barrel with sand

[www.youtube.com]

Usually, smoothing a barrel very finely requires costly equipment (namely specific reamers). Now, I did it with very basic tools: use a concrete drill bit that is 0.5 to 1 mm smaller than the inner diameter and which protrudes from the other side of the barrel. Plunge the tip of the barrel and the drill bit into a pot of sand (the finer the better, but it will get fine anyway when it gets ground). Using high speed rotation, the grains of sand are fragmented and dragged up and into the barrel, polishing nicely the inside. It obviously takes longer with stainless steel than with brass, but it did the job pretty well for me

[www.tridimake.com]

Obviously this is a hack using sand to polish the bore of a SS hot end, the presenter is fairly knowledgeable so maybe it comes out good enough.

If you search you can find abrasives that are ideally suited for polishing SS, and you could use the same technique depicted in the video to feed the abrasive medium into the barrel.

Haha!

You wouldn't believe it, but this almost the exact same way that my Prometheus 1-piece nozzles are polished!

Of course the manufacturing method is more refined than your set-up, but that is the same basic idea. My manufacturer drills the internal bore to about 0.03 to 0.05mm less than the desired diameter. Then they take a rod and spray a fine abrasive onto the rod and hone/burnish the interior of the nozzles with high speed rotation! This is incredibly effective since my nozzles have a near mirror finish on the inside, and I think this is something that isn't too hard to DIY as you have shown

We just need to find a very fine abrasive and a way to evenly coat a rod with this abrasive for nice even polishing.

**Intuitive MULTI-FILAMENT 3D Printing** -- Successfully Funded on Kickstarter!

I designed the Prometheus V2 Customizable All-Metal Hot End. Buy online

Prometheus Hot End discussion thread

|

Re: groove or grooveless hot end April 20, 2014 11:46PM |

Registered: 10 years ago Posts: 1,381 |

You can make your own needle eye lap for small bores from a brass rod.

Needle eye lap:

Begin with a brass rod that is undersized of the bore.

Hammer one end of the brass rod flat, until it is a tight fit to the bore.

Using a sharp chisel, split the flat section in the middle, don't cut through the end.

The split down the middle performs the function of a spring, and the grove helps retain the abrasive.

Use Clover lapping compound, beginning with a coarse medium, and working down to a fine medium.

Don't dwell in on spot for any amount of time, or you will create a barrel shaped profile.

You can also purchase a flexible ball hone, or needle eye laps.

[www.acrolaps.com]

Edited 1 time(s). Last edit at 04/20/2014 11:47PM by A2.

Needle eye lap:

Begin with a brass rod that is undersized of the bore.

Hammer one end of the brass rod flat, until it is a tight fit to the bore.

Using a sharp chisel, split the flat section in the middle, don't cut through the end.

The split down the middle performs the function of a spring, and the grove helps retain the abrasive.

Use Clover lapping compound, beginning with a coarse medium, and working down to a fine medium.

Don't dwell in on spot for any amount of time, or you will create a barrel shaped profile.

You can also purchase a flexible ball hone, or needle eye laps.

[www.acrolaps.com]

Edited 1 time(s). Last edit at 04/20/2014 11:47PM by A2.

|

Re: groove or grooveless hot end April 21, 2014 02:15AM |

Registered: 11 years ago Posts: 364 |

|

Re: groove or grooveless hot end April 21, 2014 03:48AM |

Registered: 10 years ago Posts: 12 |

Yes -- reducing the diameter above the heating block does not change much imho, except for the shorter production time

I don't really like any tubing plunge deep in the head, because when molten filament fills it up, it produces a weld that defeats the purpose.

Sure, molten filament should "never" flow back up in the barrel, but it will happen as soon as you forget to leave the fan on for a while after printing for example (see my post).

So I better recommend a regular and well polished metal barrel and short PTFE tubing in the head (some friends of mine still like this).

I found out that polishing with sand was very efficient to remove any dirt (and metal barbs).

Blog: [tridimake.com]

Designs: [www.thingiverse.com]

Profile: [www.linkedin.com]

I don't really like any tubing plunge deep in the head, because when molten filament fills it up, it produces a weld that defeats the purpose.

Sure, molten filament should "never" flow back up in the barrel, but it will happen as soon as you forget to leave the fan on for a while after printing for example (see my post).

So I better recommend a regular and well polished metal barrel and short PTFE tubing in the head (some friends of mine still like this).

I found out that polishing with sand was very efficient to remove any dirt (and metal barbs).

Blog: [tridimake.com]

Designs: [www.thingiverse.com]

Profile: [www.linkedin.com]

|

Re: groove or grooveless hot end April 21, 2014 05:26AM |

Registered: 11 years ago Posts: 364 |

|

Re: groove or grooveless hot end May 14, 2014 10:49PM |

Registered: 11 years ago Posts: 364 |

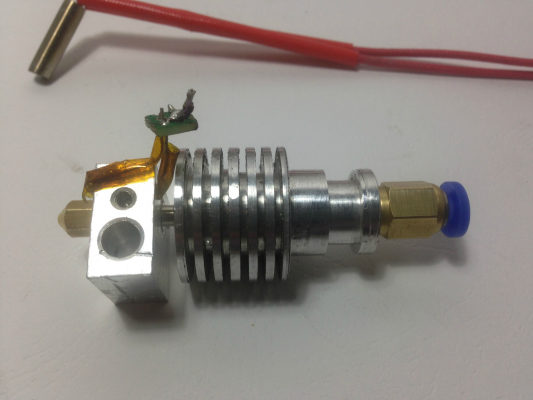

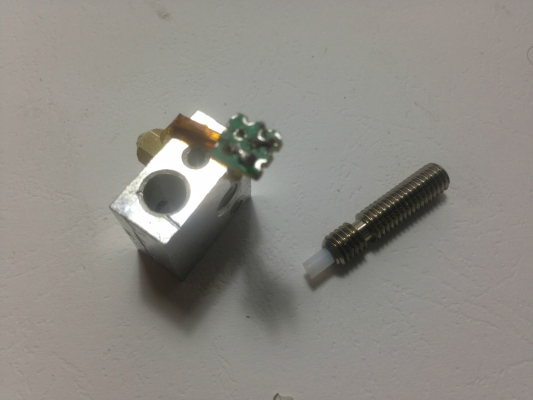

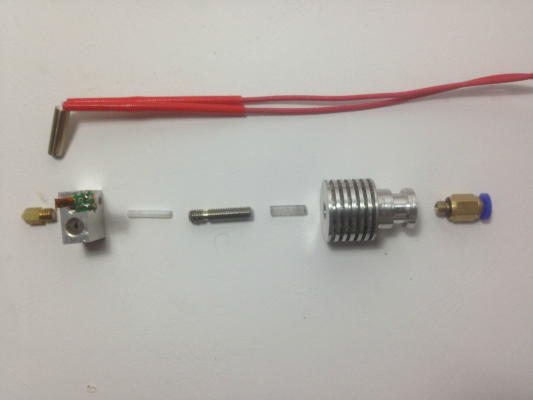

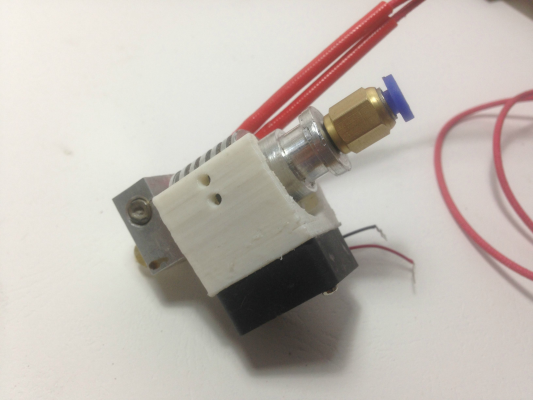

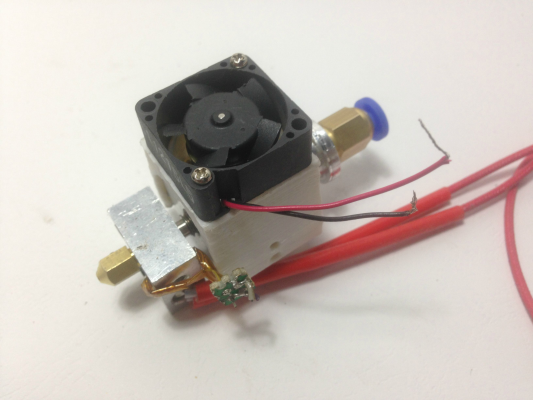

after trying to get the polishing on the inside of the stainless mirror smooth i just gave up and made one with a sleeve.... i figured out that the sleeve only in the stainless pipe didnt increase the pressure to extrude and also the problem of PLA jamming is also avoided... this is my version of a semi metal hotend ... mostly inspired from the argento and MK7 hot end

|

Re: groove or grooveless hot end May 14, 2014 11:50PM |

Registered: 10 years ago Posts: 1,381 |

A few more ideas to polish the bore:

High rpm, low feed rate, a ridged machine, and tool are the beginning of creating a fine surface finish.

SS is a gummy metal. Drilling leaves deep groves that are difficult to remove with honing.

Try reaming the hole after drilling. Reaming should be performed in the same setup as drilling. It will take some experimentation to ream without leaving tooling marks.

One thing not to do while drilling or reaming is to retract the tool at the end of the stroke while the tool is spinning.

Turn off the spindle, and if possible pass the tool through. Even retracting the tool will drag a grove into the bore.

The grove is commonly caused by a chip stuck to the cutting edge.

Burnishing (rubbing) with a hard smooth tool is another method to produce a mirror like surface.

Ball burnishing with a harden steel bearing pressed through the bore is also used to smooth the surface, arbor press or hydraulics is commonly employed.

High rpm, low feed rate, a ridged machine, and tool are the beginning of creating a fine surface finish.

SS is a gummy metal. Drilling leaves deep groves that are difficult to remove with honing.

Try reaming the hole after drilling. Reaming should be performed in the same setup as drilling. It will take some experimentation to ream without leaving tooling marks.

One thing not to do while drilling or reaming is to retract the tool at the end of the stroke while the tool is spinning.

Turn off the spindle, and if possible pass the tool through. Even retracting the tool will drag a grove into the bore.

The grove is commonly caused by a chip stuck to the cutting edge.

Burnishing (rubbing) with a hard smooth tool is another method to produce a mirror like surface.

Ball burnishing with a harden steel bearing pressed through the bore is also used to smooth the surface, arbor press or hydraulics is commonly employed.

|

Re: groove or grooveless hot end May 15, 2014 02:01AM |

Registered: 11 years ago Posts: 364 |

@A2

i drilled the hole with a 1.8mm drill ... then reamed it with a 2mm reamer and then tried polishing with the sand technique... it gets a near smooth surface but still has some grooves... maybe you are right the retracting of the reamer must be causing it... i will try again soon ... for now it is the ptfe sleeve in the barrel ..

thanks again for the feedback

i drilled the hole with a 1.8mm drill ... then reamed it with a 2mm reamer and then tried polishing with the sand technique... it gets a near smooth surface but still has some grooves... maybe you are right the retracting of the reamer must be causing it... i will try again soon ... for now it is the ptfe sleeve in the barrel ..

thanks again for the feedback

|

Re: groove or grooveless hot end May 15, 2014 11:11AM |

Registered: 11 years ago Posts: 198 |

I just drill the hole in the lathe to the final size, and polish it on the inside using the drilling macine and a swab dipped in brasso, so far this have worked fine.

The first ever hotend I made wasn't even polished on the inside, but it only saw ABS, so it probably doesn't really count

The first ever hotend I made wasn't even polished on the inside, but it only saw ABS, so it probably doesn't really count

|

Re: groove or grooveless hot end May 19, 2014 12:17PM |

Registered: 10 years ago Posts: 12 |

@ekaggrat sorry guy, I did not get the notification for your question. Anyhow I don't remember well but I think it is written in my blog post. I did not spend much time trying varieties of drill bits as I probably was lucky at the second attempt. I highly recommend a finer sand than mine but that was all what I had at the time! Also a drill bit would better be replaced by a hard stick (whatever) and proper polishing powder of course, but the idea is there I think. As for inside tubing, I really did not use any for the last year at least and will probably never get back.

Now the first attempts did gave me a few jams on retraction, but I am not really aware why it went away (probably after cleaning up very well my first mess). Best way to test is with something like this [www.youtube.com]

BTW do not ever leave the hot end slowly cooling (without the cooling fan) when there is molten filament in it, it calls for trouble (esp. carbonized PLA will stick to it). Suicide mode (auto-shutdown) must be used with a delay so it has time to cool down properly!

@A2: hey, by seeing hits on my blog coming from this community I almost feel like you are my PR agent I should spend more time here and share more, but the format is not really well suited, thanks for sharing/redirecting/helping

I should spend more time here and share more, but the format is not really well suited, thanks for sharing/redirecting/helping

Blog: [tridimake.com]

Designs: [www.thingiverse.com]

Profile: [www.linkedin.com]

Now the first attempts did gave me a few jams on retraction, but I am not really aware why it went away (probably after cleaning up very well my first mess). Best way to test is with something like this [www.youtube.com]

BTW do not ever leave the hot end slowly cooling (without the cooling fan) when there is molten filament in it, it calls for trouble (esp. carbonized PLA will stick to it). Suicide mode (auto-shutdown) must be used with a delay so it has time to cool down properly!

@A2: hey, by seeing hits on my blog coming from this community I almost feel like you are my PR agent

I should spend more time here and share more, but the format is not really well suited, thanks for sharing/redirecting/helping

I should spend more time here and share more, but the format is not really well suited, thanks for sharing/redirecting/helpingBlog: [tridimake.com]

Designs: [www.thingiverse.com]

Profile: [www.linkedin.com]

|

Re: groove or grooveless hot end May 20, 2014 08:22AM |

Admin Registered: 11 years ago Posts: 1,063 |

Quote

RP Iron Man

@ekaggrat

If you read closely into my design of the Prometheus Hot End you would have found out that there is a reason why I don't have a "thermal break" (machined groove) in the 1-piece nozzle and I actually designed an alternative.

Since Prometheus is a hot end with adjustable "thermal zones", the "transition-zone" has a different position on the 1-piece SS nozzle depending on the user configuration of these "thermal zones". Consequently, my customizable design cannot have a machined "thermal break" at the "transition-zone". Instead I simply use M5 threaded rod for the 3mm version and M4 threaded rod for the 1.75mm version. The result is a relatively small area to transmit heat from the "melt-zone", through the "transition-zone", to the "cold-zone". My hot end only transmits a little more heat than the E3D with the machined "thermal break" so this is not an issue.

Designs are usually more refined than they seem at first sight

As for the PTFE lined hot ends (which Prometheus is NOT since it is all-metal): usually the PTFE insert on J heads does not go all the way into the nozzle, but only lines the "transition-zone". I have to agree that it seems undesireable to insulate the filament within the "melt-zone" as this would decrease the rate of heat conduction to the plastic entering the "melt-zone" and therefore decrease the top speed of the hot end... I know that the Aluhotend has this configuration, so maybe Thejollygrimreaper can tune in and help us understand his reasons for this design decision.

As I said before, designs are usually more refined than they seem at first glance, so I am sure that Thejollygrimreaper has a good reason for that decision

most of the design around the Aluhotend has been through a lot of trial and error and practical testing , in the current version the ptfe goes into the brass nozzle but not all the way to the bottom which has helped a little with speed but without compromising the reliability,

the way I've done the thermal barrier has had it's share of criticism but in practical real world use it performs just like it should and so far the only way we've been able to produce a jam in the v5B is to turn the cooling fan off.

-=( blog )=- -=( thingiverse )=- -=( 3Dindustries )=- -=( Aluhotend - mostly metal hotend)=--=( Facebook )=-

|

Re: groove or grooveless hot end May 20, 2014 11:50AM |

Registered: 11 years ago Posts: 364 |

|

Re: groove or grooveless hot end September 13, 2014 11:26AM |

Registered: 12 years ago Posts: 93 |

I machined in a grove in m6 stainless rod. It makes it rather weak and prone to damage at that spot not to mention increasing costs dramatically.

The sharper the heat transition you can get the better. I am at 2mm space and temp transition from 300c to 40c this eliminates most of the plug

The advantage of this tiny transition zone is that filament retraction has less backlash. The rubbery filament acts like a rubber band which then mecessitates extra retraction in many print head designs.

Regarding Teflon tubing, it is a double edged sword. It eases filament going in but the same time it insulates and does not allow for the type of heat removal needed in the cold end.

The sharper the heat transition you can get the better. I am at 2mm space and temp transition from 300c to 40c this eliminates most of the plug

The advantage of this tiny transition zone is that filament retraction has less backlash. The rubbery filament acts like a rubber band which then mecessitates extra retraction in many print head designs.

Regarding Teflon tubing, it is a double edged sword. It eases filament going in but the same time it insulates and does not allow for the type of heat removal needed in the cold end.

Quote

RP Iron Man

@ekaggrat

If you read closely into my design of the Prometheus Hot End you would have found out that there is a reason why I don't have a "thermal break" (machined groove) in the 1-piece nozzle and I actually designed an alternative.

Since Prometheus is a hot end with adjustable "thermal zones", the "transition-zone" has a different position on the 1-piece SS nozzle depending on the user configuration of these "thermal zones". Consequently, my customizable design cannot have a machined "thermal break" at the "transition-zone". Instead I simply use M5 threaded rod for the 3mm version and M4 threaded rod for the 1.75mm version. The result is a relatively small area to transmit heat from the "melt-zone", through the "transition-zone", to the "cold-zone". My hot end only transmits a little more heat than the E3D with the machined "thermal break" so this is not an issue.

Designs are usually more refined than they seem at first sight

As for the PTFE lined hot ends (which Prometheus is NOT since it is all-metal): usually the PTFE insert on J heads does not go all the way into the nozzle, but only lines the "transition-zone". I have to agree that it seems undesireable to insulate the filament within the "melt-zone" as this would decrease the rate of heat conduction to the plastic entering the "melt-zone" and therefore decrease the top speed of the hot end... I know that the Aluhotend has this configuration, so maybe Thejollygrimreaper can tune in and help us understand his reasons for this design decision.

As I said before, designs are usually more refined than they seem at first glance, so I am sure that Thejollygrimreaper has a good reason for that decision

|

Re: groove or grooveless hot end July 14, 2015 09:41PM |

Registered: 11 years ago Posts: 82 |

I'm so glad I found this thread.

My home made all metal hotend has been working fine with ABS for the last 2 years until I decide to switch to PLA. It keeps jamming with PLA and I had no idea why. Googling and reading posts suggested polishing. So that's how I came here. Thanks very much for the suggestions folks. I will try polishing and hopefully can have my hot end working with PLA

-Thanh

My home made all metal hotend has been working fine with ABS for the last 2 years until I decide to switch to PLA. It keeps jamming with PLA and I had no idea why. Googling and reading posts suggested polishing. So that's how I came here. Thanks very much for the suggestions folks. I will try polishing and hopefully can have my hot end working with PLA

-Thanh

|

Re: groove or grooveless hot end July 15, 2015 06:16AM |

Registered: 11 years ago Posts: 364 |

|

Re: groove or grooveless hot end July 15, 2015 05:34PM |

Registered: 11 years ago Posts: 82 |

Thanks for the insight Ekaggrat. My diy hotend is just a stainless steel tube (1.98mm ID) soldered into a brass nozzle directly. Would be challenging and defeating the simplicity by adding a PTFE sleeve. I'm hoping polishing would make it a general purpose hotend which could print many materials.

Sorry, only registered users may post in this forum.