Home

>

Reprappers

>

Topic

Initial review of 3dPrinterCzar Prusa i3 kit with kids

Posted by mappler

|

Initial review of 3dPrinterCzar Prusa i3 kit with kids April 25, 2014 08:48AM |

Registered: 10 years ago Posts: 61 |

My kids (10 & 12) and I have been building the Prusa i3 from 3dPrinterCzar. I spent a lot of time deciding on which one to buy, so I thought I would provide some initial build thoughts in case someone else is making similar decisions about building with children.

The parts came packaged extremely well. The cardboard box appeared to have a "rough" journey. However, all delicate parts were well packaged in foam, and there appeared to be no damage to anything inside the box, including the glass. Build directions and a build video are available online for the physical portions of the build.

However, all delicate parts were well packaged in foam, and there appeared to be no damage to anything inside the box, including the glass. Build directions and a build video are available online for the physical portions of the build.

The parts included are of excellent quality. All tools you require for the physical construction are also included in the package. This is particularly nice for the metric tape measure and metric allen wrenches, as these are not always available in your typical USA toolbox!

Building the kit with children is very doable. They are enjoying the assembly and learning quite a bit. I do not think they would be successful without supervision, but they are able to progress without significant frustration. The build video helps a LOT to follow along with the build instructions, particularly for the kids who like the visual learning. They are able to learn about measuring screw lengths, attaching things with set screws onto motors, leaving bolts loose until you have things assembled, and working with instructions that aren't written for 10 & 12 year olds!! They are also getting an appreciation for the purpose and use of each part of the printer as they assemble it.

Next we are on to the electronics, which is our more comfortable area (lots of Raspberry Pi and electronics experimentation experience). I can't comment on the build time so far, but I blame that on the children.. They are a LOT slower and we have had to break the build up into several build sessions. I suspect electronics assembly will go quickly for us.

They are a LOT slower and we have had to break the build up into several build sessions. I suspect electronics assembly will go quickly for us.

-Matt

The parts came packaged extremely well. The cardboard box appeared to have a "rough" journey.

However, all delicate parts were well packaged in foam, and there appeared to be no damage to anything inside the box, including the glass. Build directions and a build video are available online for the physical portions of the build.

However, all delicate parts were well packaged in foam, and there appeared to be no damage to anything inside the box, including the glass. Build directions and a build video are available online for the physical portions of the build. The parts included are of excellent quality. All tools you require for the physical construction are also included in the package. This is particularly nice for the metric tape measure and metric allen wrenches, as these are not always available in your typical USA toolbox!

Building the kit with children is very doable. They are enjoying the assembly and learning quite a bit. I do not think they would be successful without supervision, but they are able to progress without significant frustration. The build video helps a LOT to follow along with the build instructions, particularly for the kids who like the visual learning. They are able to learn about measuring screw lengths, attaching things with set screws onto motors, leaving bolts loose until you have things assembled, and working with instructions that aren't written for 10 & 12 year olds!! They are also getting an appreciation for the purpose and use of each part of the printer as they assemble it.

Next we are on to the electronics, which is our more comfortable area (lots of Raspberry Pi and electronics experimentation experience). I can't comment on the build time so far, but I blame that on the children..

They are a LOT slower and we have had to break the build up into several build sessions. I suspect electronics assembly will go quickly for us.

They are a LOT slower and we have had to break the build up into several build sessions. I suspect electronics assembly will go quickly for us. -Matt

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 04, 2014 08:20PM |

Registered: 10 years ago Posts: 61 |

We've had a whirlwind weekend of building and have printed our first objects!

The electronics portion of the assembly went very well. The children both enjoyed crimping connectors and figuring out the Arduino. My kids had worked with the Raspberry Pi, but not the Arduino, so they enjoyed learning another board.

The computer portion & calibration was another story. This is the part where the kids got very bored. When they were able to work with their hands, their interest level was very high. Once it was a matter of testing and watching, they were not as interested. As is to be expected, we had a lot of issues calibrating and figuring out how the Marlin firmware configuration works. So, although this was "against my rules", I spent some time solo getting calibration worked out.

Now, they are printing their first objects with decent success. I suspect our first spool of filament will go very quickly!!!

Overall, a great kit and definitely a project that is doable with children.

The electronics portion of the assembly went very well. The children both enjoyed crimping connectors and figuring out the Arduino. My kids had worked with the Raspberry Pi, but not the Arduino, so they enjoyed learning another board.

The computer portion & calibration was another story. This is the part where the kids got very bored. When they were able to work with their hands, their interest level was very high. Once it was a matter of testing and watching, they were not as interested. As is to be expected, we had a lot of issues calibrating and figuring out how the Marlin firmware configuration works. So, although this was "against my rules", I spent some time solo getting calibration worked out.

Now, they are printing their first objects with decent success. I suspect our first spool of filament will go very quickly!!!

Overall, a great kit and definitely a project that is doable with children.

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 08, 2014 02:50PM |

Registered: 9 years ago Posts: 24 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 09, 2014 08:21AM |

Registered: 10 years ago Posts: 61 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 09, 2014 08:25AM |

Registered: 9 years ago Posts: 24 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 29, 2014 09:44PM |

Registered: 9 years ago Posts: 25 |

hi Im in the process of building the prusa from 3dprinterczar at the mo and I am having some issue with how far forward or backward to place the y axis and where to place the y endstop

did you find any issues with this, I've tried placing it where the instructions say to but it blocks the movement if the heatbed. Can you put up some pics of how you have done yours?

did you find any issues with this, I've tried placing it where the instructions say to but it blocks the movement if the heatbed. Can you put up some pics of how you have done yours?

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 29, 2014 09:45PM |

Registered: 9 years ago Posts: 25 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 29, 2014 09:48PM |

Registered: 9 years ago Posts: 25 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 30, 2014 01:37PM |

Registered: 9 years ago Posts: 24 |

Hi there, I just got back from being away for a while out of uk, I will be able to send pics on Monday night for your Y axis issues. Basically, mine is set about an inch back in the slot for now as that seems to give me the best overall end to end range of travel on the Y axis. Ive put my endstop on the back of the right hand (looking from the back) smooth rod slight inclined to the right so the black plastic arm of the sliding tray of the heatbed hits it. This is only a temporary measure for now to get me up and running and the first thing Im going to make is a better endstop bracket to fit on the Y motor bracket and that will give me the full Y axis range. Ive also got plans for better positions for th X and Z endstops. One of the biggest problems I had was keeping the two m5 nuts on the z axis screw threads engaged in the x axis brackets but I ve got that one sorted now and will post pics for that as well.

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 31, 2014 06:53PM |

Registered: 9 years ago Posts: 25 |

think i might do the same, get it running with a bit of the print area unreachable

however ive designed this extension to fit onto the back of the chassis and it can be tightened on with nuts on each side of it take a look and you think it'll work for you then belt away

please do put up the pics ill find them helpful

however ive designed this extension to fit onto the back of the chassis and it can be tightened on with nuts on each side of it take a look and you think it'll work for you then belt away

please do put up the pics ill find them helpful

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 31, 2014 06:55PM |

Registered: 9 years ago Posts: 25 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 31, 2014 08:21PM |

Registered: 11 years ago Posts: 973 |

jut a note on home postions and stops if you design something with the x going right and y going away from you and your endstops z and y not it correct place you may get mirrored prints

Edited 1 time(s). Last edit at 05/31/2014 08:28PM by chris33.

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Edited 1 time(s). Last edit at 05/31/2014 08:28PM by chris33.

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids May 31, 2014 10:02PM |

Registered: 9 years ago Posts: 25 |

not seeing the diagram and question you did here on the forum but i saw it my email so

the design is with the x axis going from the origin to the right

the bottom left corner is under the thin upright with 2 small holes at the top with the 2 larger cut outs running to the right

Ive only started using solidworks and havent started to use a g code program yet, thinking of using cura, so I'm wasn't really thinking of orientation when designing it

thanks for the note chriss, il keep it in mind

the design is with the x axis going from the origin to the right

the bottom left corner is under the thin upright with 2 small holes at the top with the 2 larger cut outs running to the right

Ive only started using solidworks and havent started to use a g code program yet, thinking of using cura, so I'm wasn't really thinking of orientation when designing it

thanks for the note chriss, il keep it in mind

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 01, 2014 06:56AM |

Registered: 11 years ago Posts: 973 |

I have my x going from left to right left being 0 then y i have from 0 comes towards you obviousy z doesnt matter thats can be either max or min depends how you like it parked

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 01, 2014 07:05PM |

Registered: 9 years ago Posts: 24 |

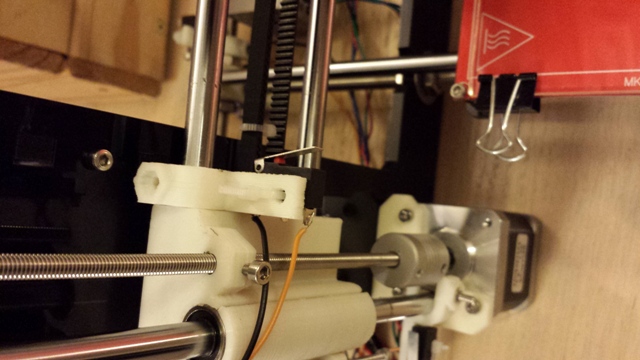

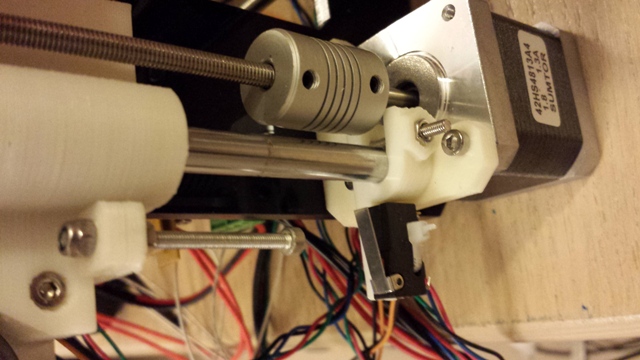

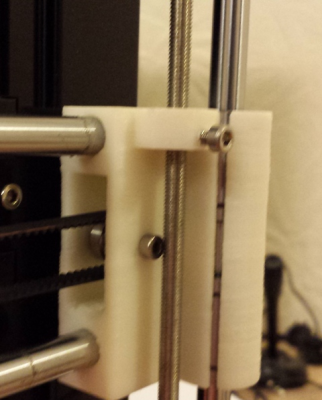

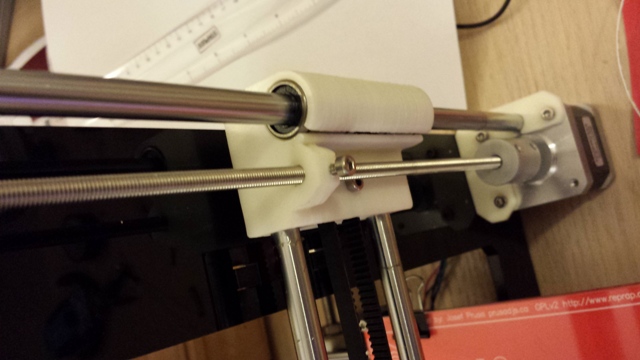

Hi there, here are the pics of my end stop positions and the frame position I use to get 180 mm of Y Axis travel for now. I'm going to make a new Y end stop microswitch holder, it will be an integral part of the motor mount at the back which should then give the full 200 mm of travel.

I did my first print tonight to check my calibration settings in the firmware (they are set to {80,80,4000,569}) and the last pic is of the 20mm cube I did. it measures 19.85 X Axis, 19.9 Y Axis and 20.02 Z axis so I'm pretty satisfied with that for a first print :-)

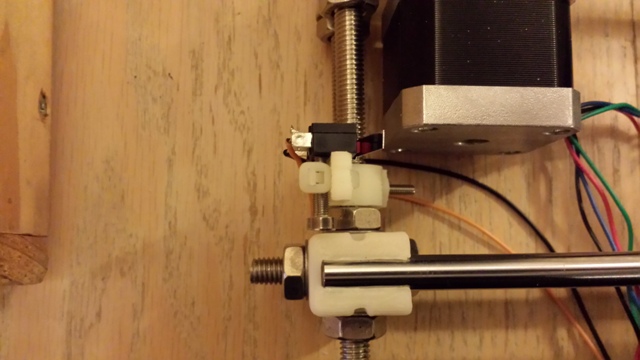

First pic is Frame position:

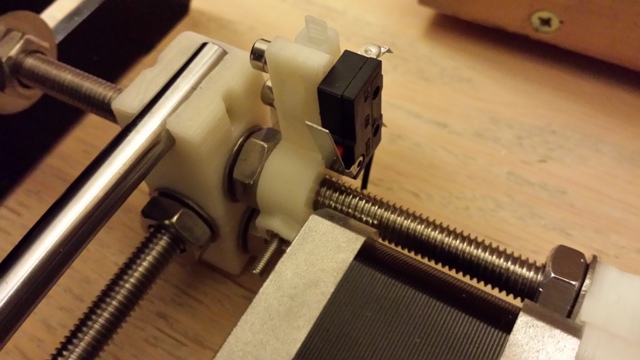

This pic shows the temp Y end stop position at the rear near the motor mount on the right hand side looking from the rear of the printer:

Another pic of the Y end stop, This position allows me to get 180 mm of travel when the microswitch is activated by the plastic frame that holds the heated bed:

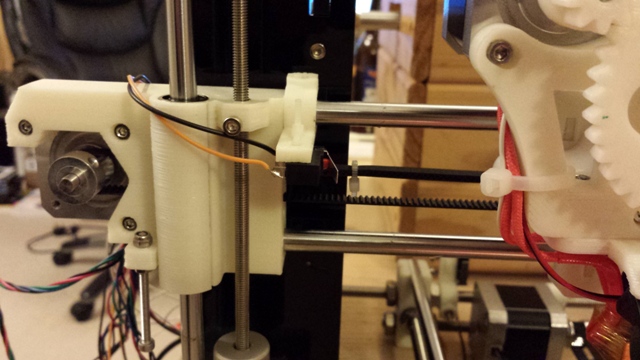

Here are a couple of pics of the X axis end stop which I may mod later:

Here is a pic of my Z End Stop mounting and a striker bolt I attached to the X Axis:

First print tonight! I had some trouble getting it to stick to the glass but it seemed to work eventually:

I did my first print tonight to check my calibration settings in the firmware (they are set to {80,80,4000,569}) and the last pic is of the 20mm cube I did. it measures 19.85 X Axis, 19.9 Y Axis and 20.02 Z axis so I'm pretty satisfied with that for a first print :-)

First pic is Frame position:

This pic shows the temp Y end stop position at the rear near the motor mount on the right hand side looking from the rear of the printer:

Another pic of the Y end stop, This position allows me to get 180 mm of travel when the microswitch is activated by the plastic frame that holds the heated bed:

Here are a couple of pics of the X axis end stop which I may mod later:

Here is a pic of my Z End Stop mounting and a striker bolt I attached to the X Axis:

First print tonight! I had some trouble getting it to stick to the glass but it seemed to work eventually:

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 03, 2014 08:13AM |

Registered: 10 years ago Posts: 61 |

Sorry, I just got back after some time away. cleary, I had the same exact problem with the y-axis. I'll take some pictures this evening and post them for you if you still have this issue.

First I worked out where I needed the lower chassis mounted on the top chassis to make sure I could get the entire length of travel of the heated bed under the print nozzle. My initial setup only gave me like 100mm of travel, which was not acceptable. Now I think I have around 185mm and I'm pretty happy with it.

The second issue was the placement of the y-axis endstop. I'm still not happy with my solution. Have you tried out your y-axis endstop extension? Does it work? If it does, I may switch to your design.

Thanks,

-Matt

First I worked out where I needed the lower chassis mounted on the top chassis to make sure I could get the entire length of travel of the heated bed under the print nozzle. My initial setup only gave me like 100mm of travel, which was not acceptable. Now I think I have around 185mm and I'm pretty happy with it.

The second issue was the placement of the y-axis endstop. I'm still not happy with my solution. Have you tried out your y-axis endstop extension? Does it work? If it does, I may switch to your design.

Thanks,

-Matt

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 03, 2014 12:27PM |

Registered: 9 years ago Posts: 25 |

its a right pain in the old bag alright

i did notice how the instructions were lacking for the endstops, me thinks this is why

havnt got my machine up and running yet i messed up 4 crimps and now im 4 short so im on a mission to get them, not too easy to find around town or from a supplier thats not in china. Really dont fancy waiting 10 to 25 working days for these, ya would think maplins would have them but it seems these are the only ones they dont have

the extension will probably the first thing il print after calibration, probably a week or 2 from now. Il keep ya posted on how it goes, in the mean time if ya want to give it a shot belt away

i did notice how the instructions were lacking for the endstops, me thinks this is why

havnt got my machine up and running yet i messed up 4 crimps and now im 4 short so im on a mission to get them, not too easy to find around town or from a supplier thats not in china. Really dont fancy waiting 10 to 25 working days for these, ya would think maplins would have them but it seems these are the only ones they dont have

the extension will probably the first thing il print after calibration, probably a week or 2 from now. Il keep ya posted on how it goes, in the mean time if ya want to give it a shot belt away

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 03, 2014 06:03PM |

Registered: 9 years ago Posts: 24 |

After printing my first calibration cube I tried again the next night to move on to designing and printing a better solution to the Y end stop. But I now have a problem with the extruder head thermistor which is giving max temp readings of about 220 deg C at room temp (even 2 hours after no power being applied!). I swapped the thermistor connections over (swapped bed to extruder and vice versa) and the indicated problem switched with the duff thermistor, so I know its knackered and a new one (2 actually) is on the way from ebay for £1.85. I didn't realise they were just 1.09 from Maplins otherwise I'd have been down there tonight. So, I cant print a new Y end stop just yet until I'm up and running again, but as I have 180 mm of travel anyway then its not critical for anything I need to print just yet.

Another problem I had was keeping the Z axis m5 nuts in the X axis blocks, they were very loose and after a full range travel check one of them had always come out of the holder and the whole X axis bar was moving on just one of the nuts. My solution was simple (see photos) I drilled a 2.5 mm hole in both of the X axis blocks and screwed an M3 bolt into them to hold the nuts firmly in place. Works a treat!

Edited 1 time(s). Last edit at 06/03/2014 06:05PM by vince31.

Another problem I had was keeping the Z axis m5 nuts in the X axis blocks, they were very loose and after a full range travel check one of them had always come out of the holder and the whole X axis bar was moving on just one of the nuts. My solution was simple (see photos) I drilled a 2.5 mm hole in both of the X axis blocks and screwed an M3 bolt into them to hold the nuts firmly in place. Works a treat!

Edited 1 time(s). Last edit at 06/03/2014 06:05PM by vince31.

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 03, 2014 06:43PM |

Registered: 10 years ago Posts: 61 |

I have attached 3 pictures to this message. Photo 1 shows how I placed the Y-axis endstop. I zip tied the switch directly to the precision rod on the same side as the SINGLE bearing. It is set up so that the bearing itself hits it. This has worked very well so far, but I am concerned it will start to slide. Homing makes very gentle contact with it, so no issues so far. I would like a better endstop solution there, but no issues so far.

Picture 2 shows the location of my Y-chassis in the upright frame. This was a "trial and error" fit.

Picture 3 shows the cork I put on the bottom of the heated bed. I could not get to ABS temperatures without this piece of cork board.

-Matt

Picture 2 shows the location of my Y-chassis in the upright frame. This was a "trial and error" fit.

Picture 3 shows the cork I put on the bottom of the heated bed. I could not get to ABS temperatures without this piece of cork board.

-Matt

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 06, 2014 04:53PM |

Registered: 9 years ago Posts: 25 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 06, 2014 04:54PM |

Registered: 9 years ago Posts: 25 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 08, 2014 03:12PM |

Registered: 9 years ago Posts: 24 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 09, 2014 07:32AM |

Registered: 10 years ago Posts: 61 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 10, 2014 03:05PM |

Registered: 9 years ago Posts: 24 |

Here is a pic of my new Y end stop holder integrated with the motor mount. Works great and gives me full 200mm travel

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 10, 2014 04:31PM |

Registered: 10 years ago Posts: 61 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 10, 2014 04:57PM |

Registered: 9 years ago Posts: 25 |

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 10, 2014 05:00PM |

Registered: 9 years ago Posts: 25 |

did any of you guys experience issues with the z axis at 4000 steps/mm

thats what i calculated it to be, i gather we all have the same with the 3dprinterczar model

mine works fine up until 2800 steps/mm and then after set at more it starts misbehaving

going to start getting my currents all properly set and adjust max feed rates and acceleration which should probably find the root of the problem

thats what i calculated it to be, i gather we all have the same with the 3dprinterczar model

mine works fine up until 2800 steps/mm and then after set at more it starts misbehaving

going to start getting my currents all properly set and adjust max feed rates and acceleration which should probably find the root of the problem

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 10, 2014 05:05PM |

Registered: 9 years ago Posts: 24 |

Here is the STL file for the Y axis end stop

y_axis_with_end_stop.stl

I had to swap over my Y axis motor to the other side of the bracket, so then had to then swap over the motor direction of travel in the firmware too. Also had to adjust the tension on the drive belt due to the mounting holes being slightly in a different position. Hope you guys get it up and running soon. Redesigning my Z axis End stop now! lol

Edited 1 time(s). Last edit at 06/10/2014 05:09PM by vince31.

y_axis_with_end_stop.stl

I had to swap over my Y axis motor to the other side of the bracket, so then had to then swap over the motor direction of travel in the firmware too. Also had to adjust the tension on the drive belt due to the mounting holes being slightly in a different position. Hope you guys get it up and running soon. Redesigning my Z axis End stop now! lol

Edited 1 time(s). Last edit at 06/10/2014 05:09PM by vince31.

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 10, 2014 05:19PM |

Registered: 9 years ago Posts: 24 |

ecleary,

My z axis is fine at 4000 steps per unit, in fact it has to be 4000 steps to move 1mm due to the thread pitch on the m5 threaded rods. If you turn it down to 2800 then you wont get 1 mm of travel on the Z Axis I dont think.

I remember that I had to turn down the Z axis homing speed though to 2.5 in the firmware as follows:

#define HOMING_FEEDRATE {50*60, 50*60, 2.5*60, 0} // set the homing speeds (mm/min)

Edited 1 time(s). Last edit at 06/10/2014 05:21PM by vince31.

My z axis is fine at 4000 steps per unit, in fact it has to be 4000 steps to move 1mm due to the thread pitch on the m5 threaded rods. If you turn it down to 2800 then you wont get 1 mm of travel on the Z Axis I dont think.

I remember that I had to turn down the Z axis homing speed though to 2.5 in the firmware as follows:

#define HOMING_FEEDRATE {50*60, 50*60, 2.5*60, 0} // set the homing speeds (mm/min)

Edited 1 time(s). Last edit at 06/10/2014 05:21PM by vince31.

|

Re: Initial review of 3dPrinterCzar Prusa i3 kit with kids June 10, 2014 05:58PM |

Registered: 9 years ago Posts: 25 |

Yep i got that it needed to be 4000 i was just messing around with different figures to see where the motor started having issues

I'll try your homing settings, i did have it running at 4000 steps/mm at a low speed on pronterface but it jibbed out when i went to home it, i gather a high speed for z axis movement isn't required seeing as it only moves a small bit at a time

here's a q" why is it in the firmware the settings are saved as mathematical functions such as 2.5*60 rather than just 150? does it make a difference?

Probably not im sure

Edited 1 time(s). Last edit at 06/10/2014 05:59PM by ecleary.

I'll try your homing settings, i did have it running at 4000 steps/mm at a low speed on pronterface but it jibbed out when i went to home it, i gather a high speed for z axis movement isn't required seeing as it only moves a small bit at a time

here's a q" why is it in the firmware the settings are saved as mathematical functions such as 2.5*60 rather than just 150? does it make a difference?

Probably not im sure

Edited 1 time(s). Last edit at 06/10/2014 05:59PM by ecleary.

Sorry, only registered users may post in this forum.