|

Prusa I3 Fine Tuning May 28, 2014 04:37AM |

Registered: 10 years ago Posts: 82 |

I have been struggling with the fine tuning of my Prusa I3 for some time now and have finally gotten to a result that (I think) I am pleased with and that I wanted to share. My last post on this topic was "Help with Fine Tuning Print Quality on Prusa I3" where I learned about the acceleration settings in Slic3r. These have proven to not be needed as part of the final solution, though adding a jerk limit to Marlin is part of said solution.

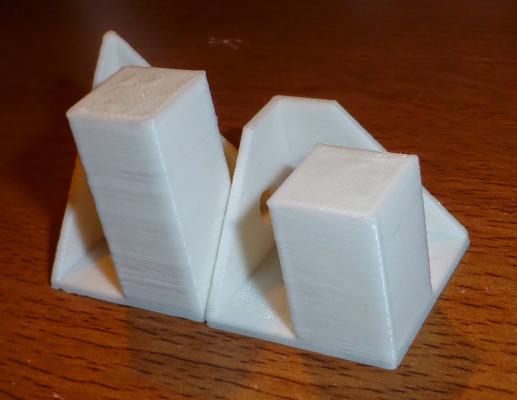

Here is a before and after print showing the results of one last tuning effort.

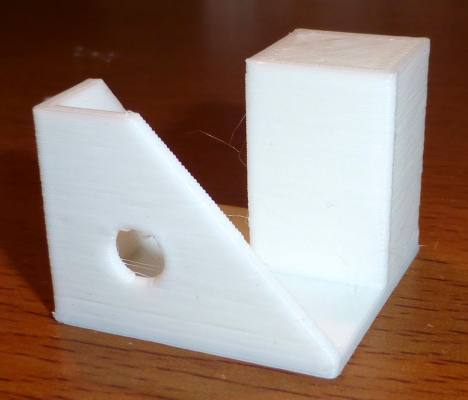

Closer image of the after shows that I still have a little work to do, particularily on the hole, but I am happy with where I finally am in terms of quality balanced with some level of speed. Of course, I have no idea what speed would be good, so am not completely sure how happy I should be!

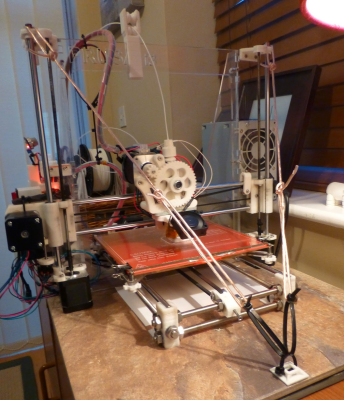

The last tuning adjustment was the addition of the frame tensioner shown below. It seems that I had some vibration that the Prusa I3 frame was not dampening. I have done several rounds of adjusting, and tightening, the frame but to no avail. The final solution was tying the whole thing to some floor tiles and adding the shown contraption to pull the bow of the printer tight.

Details on the above

Printed in PLA with a .4mm nozzle and a layer height of .32 and an infill of .2 (sliced using Slic3r)

Speeds were

Perimeters of 25mm/s

External perimiters at 70%

Infill at 45mm/s

Solid infill at 40mm/s

Travel at 80mm/s

First layer at 30%

Filament is 1.75 with a extrusion multiplier of 1.01

Extruder temp at 188 and bed at 60

Fan on auto

Retraction of 1.5mm with a 1mm lift

Retract on layer change with a wipe while retracting

In Marlin:

Default X/Y Jerk of 10mm/s

I would be interested in any comments on any of the above but in particular if anyone else has needed such a contraption and what speed other people are getting, with similar quality, on a Prusa I3. I am still working on the balance of speed versus quality and will followup later

Here is a before and after print showing the results of one last tuning effort.

Closer image of the after shows that I still have a little work to do, particularily on the hole, but I am happy with where I finally am in terms of quality balanced with some level of speed. Of course, I have no idea what speed would be good, so am not completely sure how happy I should be!

The last tuning adjustment was the addition of the frame tensioner shown below. It seems that I had some vibration that the Prusa I3 frame was not dampening. I have done several rounds of adjusting, and tightening, the frame but to no avail. The final solution was tying the whole thing to some floor tiles and adding the shown contraption to pull the bow of the printer tight.

Details on the above

Printed in PLA with a .4mm nozzle and a layer height of .32 and an infill of .2 (sliced using Slic3r)

Speeds were

Perimeters of 25mm/s

External perimiters at 70%

Infill at 45mm/s

Solid infill at 40mm/s

Travel at 80mm/s

First layer at 30%

Filament is 1.75 with a extrusion multiplier of 1.01

Extruder temp at 188 and bed at 60

Fan on auto

Retraction of 1.5mm with a 1mm lift

Retract on layer change with a wipe while retracting

In Marlin:

Default X/Y Jerk of 10mm/s

I would be interested in any comments on any of the above but in particular if anyone else has needed such a contraption and what speed other people are getting, with similar quality, on a Prusa I3. I am still working on the balance of speed versus quality and will followup later

|

Re: Prusa I3 Fine Tuning May 28, 2014 08:32AM |

Registered: 10 years ago Posts: 43 |

Looks great!

For printers I make with a home made hot end, using a block of aluminum, brass rod, and a brass nut cap, I can only run at like 15mm/sec. But with a premade jhead style hot end I can run at the default slic3r speeds.

E. J. Bantz

[3dprintercamp.com]

For printers I make with a home made hot end, using a block of aluminum, brass rod, and a brass nut cap, I can only run at like 15mm/sec. But with a premade jhead style hot end I can run at the default slic3r speeds.

E. J. Bantz

[3dprintercamp.com]

Sorry, only registered users may post in this forum.