Wilson TS build log

Posted by TheHackerArtist

|

Re: Wilson TS build log July 08, 2014 12:40PM |

Registered: 13 years ago Posts: 134 |

test 1...2...

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

|

Re: Wilson TS build log July 08, 2014 01:24PM |

Registered: 10 years ago Posts: 553 |

I've used these and they worked quite nicely on my older Kossel - [www.tridprinting.com]

|

Re: Wilson TS build log July 08, 2014 07:06PM |

Registered: 9 years ago Posts: 67 |

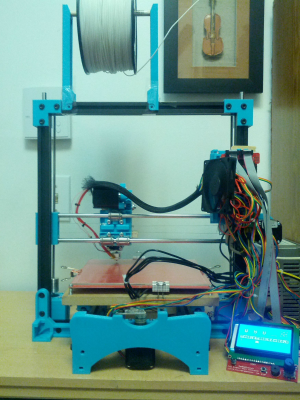

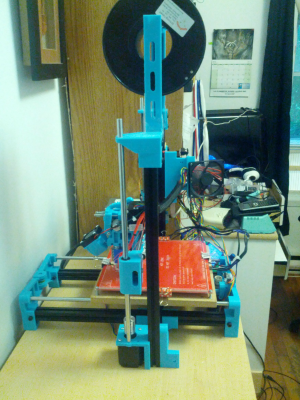

Hi Everyone,

I've been busy lately, sorry for the lack of updates. I work 2 jobs so the time I can commit to the build is limitted

Marty, happy to hear you hop into the discussion! I'd be curious to see a video of the modifications you brought to the design, even though I'm using a fishing wire, adding a tensionner is as important, if not more.

I'm waiting on 100lbs Dynemma wire, I'll revamps the build once that arrives.

I adjusted the limit switches so they are aligned with the limits of the bed and checked the stepper motor movements.

I travel a distance of 74.6mm in x and Y when I should travel a distance of 60mm and the z axis travel 1.2mm rather then 10mm. That's easily fixed.

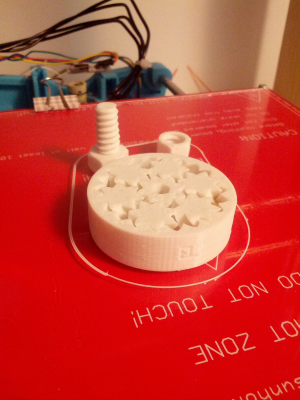

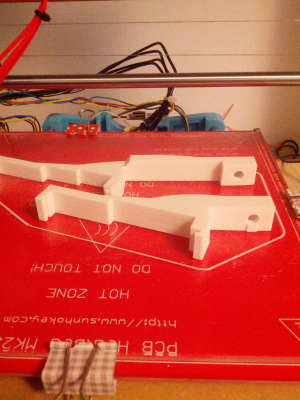

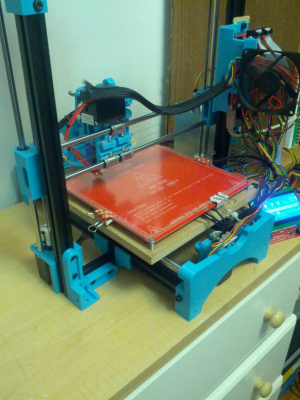

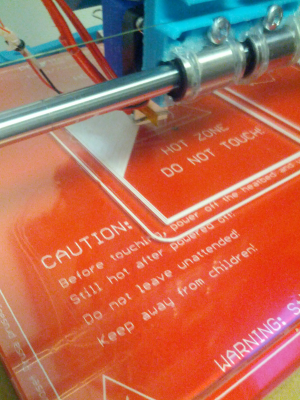

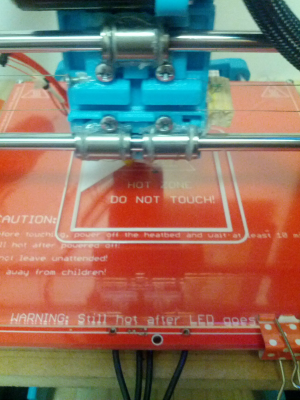

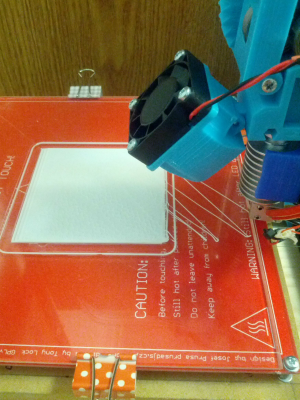

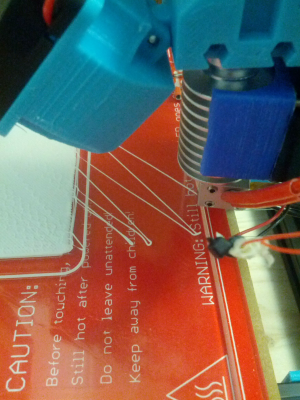

Here are some pictures:

The Z frame wobble significantly. I'll re-tighten the nuts and fix everything on a piece of wood. That should help.

I've been busy lately, sorry for the lack of updates. I work 2 jobs so the time I can commit to the build is limitted

Marty, happy to hear you hop into the discussion! I'd be curious to see a video of the modifications you brought to the design, even though I'm using a fishing wire, adding a tensionner is as important, if not more.

I'm waiting on 100lbs Dynemma wire, I'll revamps the build once that arrives.

I adjusted the limit switches so they are aligned with the limits of the bed and checked the stepper motor movements.

I travel a distance of 74.6mm in x and Y when I should travel a distance of 60mm and the z axis travel 1.2mm rather then 10mm. That's easily fixed.

Here are some pictures:

The Z frame wobble significantly. I'll re-tighten the nuts and fix everything on a piece of wood. That should help.

|

Re: Wilson TS build log July 09, 2014 11:36AM |

Registered: 13 years ago Posts: 134 |

Lookin' Good.

Maybe a duel-frame for the Z like Lulzbot's Taz

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

Maybe a duel-frame for the Z like Lulzbot's Taz

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

|

Re: Wilson TS build log July 09, 2014 09:55PM |

Registered: 9 years ago Posts: 67 |

Well, My Power supply refuses to open, no mater where I plug it.

It shut down on me just when I tested the Z axis movement with my updated firmware.

I guess I can`t blame it. It must have been sitting in my basement for a decade before I used it for this build...

Time to get a new power supply!

It shut down on me just when I tested the Z axis movement with my updated firmware.

I guess I can`t blame it. It must have been sitting in my basement for a decade before I used it for this build...

Time to get a new power supply!

|

Re: Wilson TS build log July 09, 2014 09:58PM |

Registered: 9 years ago Posts: 67 |

|

Re: Wilson TS build log July 12, 2014 01:25AM |

Registered: 9 years ago Posts: 67 |

Got a new power supply

My axis all move the right distance. yeah!

I got the bed level

I ran a dry run. aka no filament was in the extruder. and the movements were fine and it ran the job till completion

I re-tightened Y-Z frame connection and it wobble less but it still wobbles. A peice of PLA has just so much flexural rigidity. With a leverage arm of 300mm, there`s bond to be noticeable deformations. That`s just physics, it seems. Marty, have you noticed some wobble on your Wilson?

I don't think fixing everything to a piece of wood will solve the issue but ll do it anyways, It`s practical to have the printer on a platform. I`ll need to add a piece that connects higher on the Z axis, when to time comes.

Now I need to test the extrusion and calibrate that.

I`ll try to get a video up when everything is up and running.

Oh and random question. Is there a way to get G-Code on the SD card of the printer through Repetier host or do I need to plug the card in my computer? I don`t have an SD card reader on my computer

Thanks!

My axis all move the right distance. yeah!

I got the bed level

I ran a dry run. aka no filament was in the extruder. and the movements were fine and it ran the job till completion

I re-tightened Y-Z frame connection and it wobble less but it still wobbles. A peice of PLA has just so much flexural rigidity. With a leverage arm of 300mm, there`s bond to be noticeable deformations. That`s just physics, it seems. Marty, have you noticed some wobble on your Wilson?

I don't think fixing everything to a piece of wood will solve the issue but ll do it anyways, It`s practical to have the printer on a platform. I`ll need to add a piece that connects higher on the Z axis, when to time comes.

Now I need to test the extrusion and calibrate that.

I`ll try to get a video up when everything is up and running.

Oh and random question. Is there a way to get G-Code on the SD card of the printer through Repetier host or do I need to plug the card in my computer? I don`t have an SD card reader on my computer

Thanks!

|

Re: Wilson TS build log July 12, 2014 03:28AM |

Registered: 9 years ago Posts: 67 |

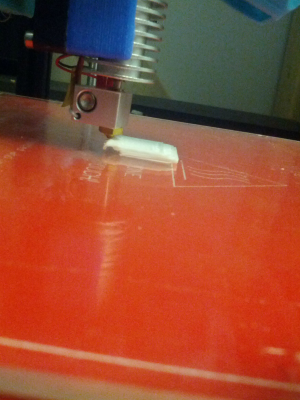

Hmmm, My first test run gave me pecular results

So, the file I was trying to print is attached. It`s just a 20mm cube. G code is too large to be attached, sorry

What happened:

The rim around the cube didnt print out because I had retracted the filament a bit but it started coming out just when the cube started printing so thats good.

First 4 layers were good although some minor adjustments need to happen. The perimeter and infill printed out perfectly fine.

Then the next three layers shifted a few millimeters every time in the positive Y axis I have no clue why!

I have no clue why!

Check out the pictures:

Any clue why that happened?

It seems like the issue is in the G-code generated...could that be?

So, the file I was trying to print is attached. It`s just a 20mm cube. G code is too large to be attached, sorry

What happened:

The rim around the cube didnt print out because I had retracted the filament a bit but it started coming out just when the cube started printing so thats good.

First 4 layers were good although some minor adjustments need to happen. The perimeter and infill printed out perfectly fine.

Then the next three layers shifted a few millimeters every time in the positive Y axis

I have no clue why!

I have no clue why!Check out the pictures:

Any clue why that happened?

It seems like the issue is in the G-code generated...could that be?

|

Re: Wilson TS build log July 12, 2014 12:35PM |

Registered: 13 years ago Posts: 134 |

Glad to hear you're up and runnin' albeit w/so-so quality. Have you seen Tom Sanlanderer's page yet? (not sure if I mentioned this yet)

Ist off I think you're not close enough to the bed when printing. The plastic doesn't look "squished" enough.

The Y problem - do you need to adjust your Y stepper trimpot a little, or is the belt catching on something?

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

Ist off I think you're not close enough to the bed when printing. The plastic doesn't look "squished" enough.

The Y problem - do you need to adjust your Y stepper trimpot a little, or is the belt catching on something?

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

|

Re: Wilson TS build log July 13, 2014 01:28AM |

Registered: 9 years ago Posts: 67 |

Hey BoriSpider!

I have not seen Tom Sanlanderer's channel no, thanks a lot for the link, there seems to be many useful videos there!

You're right for the Z height, I adjusted that and printed a larger cube, 80mm. It was more "squished" as you describe.

had the same Y axis shift problem though, even worse actually, during the final infill it just went outside the bound of the printer. I shut everything down.

I don't know about the tripot... there would be a constant add up of error in that case, no? Also, I tested the movement before, manually, and that was fine. Here it's only when there's a switch in Z height or a switch from "perimeter" to "infill" that the shift happens

But I'll mess around with it none the less, maybe it's slipping at higher accelerations.

No belts in my build =P but no, the fishing wire isn't catching on anything. There's a bit of slack and I knew I had to adjust that before I started printing. I just wanted to get it printing ASAP! but even that should be a constant systematic error when there is a change in direction, not the issue seen here...

It seems like it's software really. I don't know. But, then again, why would I have issues when thousands of other using the same software don't. Doesn't seem logical...

I'll try messing around with the tri-pot and checking the mechanics.

Maybe it has to do with the acceleration and jerk settings for my steppers

I just received the new 100lbs fishing rope today so I'll change that and re-tighten everything

I'll try things and keep you updated.

I have not seen Tom Sanlanderer's channel no, thanks a lot for the link, there seems to be many useful videos there!

You're right for the Z height, I adjusted that and printed a larger cube, 80mm. It was more "squished" as you describe.

had the same Y axis shift problem though, even worse actually, during the final infill it just went outside the bound of the printer. I shut everything down.

I don't know about the tripot... there would be a constant add up of error in that case, no? Also, I tested the movement before, manually, and that was fine. Here it's only when there's a switch in Z height or a switch from "perimeter" to "infill" that the shift happens

But I'll mess around with it none the less, maybe it's slipping at higher accelerations.

No belts in my build =P but no, the fishing wire isn't catching on anything. There's a bit of slack and I knew I had to adjust that before I started printing. I just wanted to get it printing ASAP! but even that should be a constant systematic error when there is a change in direction, not the issue seen here...

It seems like it's software really. I don't know. But, then again, why would I have issues when thousands of other using the same software don't. Doesn't seem logical...

I'll try messing around with the tri-pot and checking the mechanics.

Maybe it has to do with the acceleration and jerk settings for my steppers

I just received the new 100lbs fishing rope today so I'll change that and re-tighten everything

I'll try things and keep you updated.

|

Re: Wilson TS build log July 13, 2014 11:22AM |

Registered: 13 years ago Posts: 134 |

Oh yeah, forgot about the fishing line.

The only other thing I can think of checking is make sure the spool isn't slipping on the motor.

That new bottom layer looks better.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

The only other thing I can think of checking is make sure the spool isn't slipping on the motor.

That new bottom layer looks better.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

|

Re: Wilson TS build log July 14, 2014 02:25PM |

Registered: 9 years ago Posts: 67 |

Yesssss! It didn`t shift in the Y axis.

The issue was my first guess =)

I just reduced the acceleration to max 1000 ( VS 9000) I`m curious to do an analysys of the force incured at 9000mm/s2 VS 1000mm/s2 and see if the actualy holdlign torque is as adversised...

Edited 1 time(s). Last edit at 07/14/2014 02:28PM by TheHackerArtist.

The issue was my first guess =)

I just reduced the acceleration to max 1000 ( VS 9000) I`m curious to do an analysys of the force incured at 9000mm/s2 VS 1000mm/s2 and see if the actualy holdlign torque is as adversised...

Edited 1 time(s). Last edit at 07/14/2014 02:28PM by TheHackerArtist.

|

Re: Wilson TS build log July 14, 2014 02:40PM |

Registered: 9 years ago Posts: 67 |

|

Re: Wilson TS build log August 07, 2014 01:54AM |

Registered: 9 years ago Posts: 67 |

I have successfully printed a few peices over that last couple of weeks. I ended up using a thrid power supply I salvaged from an old computer I had lying around while waiting from a legit 30A 12V power supply which I received yesterday

I found my optimal extrusion temperature to be 186°C by printing out a calibration rectangular tube. This was my first succesful printm

I then printed caps for a bearing to act as a guide for the filament I will soon be switching with the 100lbs wire. I was impressed at how well it press fitted. But I stumbled upon some V-grooved bearing on ebay and ordered 20 so Ill be using that instead.

I then had two terrible extruder jam, I had to dissassemble the entire nozzle twice. the first time I had to pull the filament out with plyers as it snaped inside the nozzle as I tried pulling it out initially. The second time around I was wiser and just dipped the heat sink part of the hot end in hot water and pulled the jamed filament out more easily.

Turns out the problem was that, I got myself a new laptop and although I had saved my slic3r setting, I forgot to select them while in reptier host so it was over extruding plastic with the default settings. Pressure build up in the nozzle and jammed it. I won't count those as extruder jams since they were cause by software misconfigs. I'm really satified with the J-head so far.

After all that was corrected I made a few good prints, finally got my smart controller holder!

Nut and bolt fitted like mom and dad but the gear bearing failed to work, I'll blame that on the fact that the first layer was too squished, I should have added a brim or raised my initial Z height.

Next up :

I bought myself a dual mk8 extruder clone, I'll be designing a holder for that and reprinting the Z axis X carriage holder so the two rods are oriented next to each other as opposed to on top of each other.

I will reprint the Y - GT2 pulley holder and include a tensioner because although my drilled screw gives the build some style it's sketchy and my wire is somewhat loose.

it's sketchy and my wire is somewhat loose.

I'll print some spool inner holder ( I'll still be covering it with PVC tubing because it hase a consistance surface) so that should help with keeping things concentric and coaxial.

I will be making a new Z height adjustement system because its anoying and innacurate as it is. And ultimatly I'd like to get a distance sensor so I can calibrate the Z height and bed leveling automatically. anobody know if this has been done before or know of any cheap yet acurate distance sensors within in a range of 500 microns +/- 10 microns ?

I'll order someT-slot cube and/or gusset conectors to add structural rigidity in the conections between the T-slots. I think it'll be a good investement as it will add some swag and reduce Z-woble

TheHackerArtist

I found my optimal extrusion temperature to be 186°C by printing out a calibration rectangular tube. This was my first succesful printm

I then printed caps for a bearing to act as a guide for the filament I will soon be switching with the 100lbs wire. I was impressed at how well it press fitted. But I stumbled upon some V-grooved bearing on ebay and ordered 20 so Ill be using that instead.

I then had two terrible extruder jam, I had to dissassemble the entire nozzle twice. the first time I had to pull the filament out with plyers as it snaped inside the nozzle as I tried pulling it out initially. The second time around I was wiser and just dipped the heat sink part of the hot end in hot water and pulled the jamed filament out more easily.

Turns out the problem was that, I got myself a new laptop and although I had saved my slic3r setting, I forgot to select them while in reptier host so it was over extruding plastic with the default settings. Pressure build up in the nozzle and jammed it. I won't count those as extruder jams since they were cause by software misconfigs. I'm really satified with the J-head so far.

After all that was corrected I made a few good prints, finally got my smart controller holder!

Nut and bolt fitted like mom and dad but the gear bearing failed to work, I'll blame that on the fact that the first layer was too squished, I should have added a brim or raised my initial Z height.

Next up :

I bought myself a dual mk8 extruder clone, I'll be designing a holder for that and reprinting the Z axis X carriage holder so the two rods are oriented next to each other as opposed to on top of each other.

I will reprint the Y - GT2 pulley holder and include a tensioner because although my drilled screw gives the build some style

it's sketchy and my wire is somewhat loose.

it's sketchy and my wire is somewhat loose.I'll print some spool inner holder ( I'll still be covering it with PVC tubing because it hase a consistance surface) so that should help with keeping things concentric and coaxial.

I will be making a new Z height adjustement system because its anoying and innacurate as it is. And ultimatly I'd like to get a distance sensor so I can calibrate the Z height and bed leveling automatically. anobody know if this has been done before or know of any cheap yet acurate distance sensors within in a range of 500 microns +/- 10 microns ?

I'll order someT-slot cube and/or gusset conectors to add structural rigidity in the conections between the T-slots. I think it'll be a good investement as it will add some swag and reduce Z-woble

TheHackerArtist

|

Re: Wilson TS build log August 07, 2014 05:10AM |

Registered: 11 years ago Posts: 364 |

glad to see that the plastic spools worked after all.. I would love to see the chinese clone extruder working without jamming.. IMHO just avoid it . It will never give you faster speeds and will inevitabley jam with PLA because the barrel is not so good in these things. ( some of them have a ptfe sleeve which makes them work better ) ..

good luck with the MK8

good luck with the MK8

|

Re: Wilson TS build log August 07, 2014 10:21AM |

Registered: 10 years ago Posts: 27 |

Looking good Hacker! I am getting ready to start sourcing my parts. I looked back and didn't see your build area. I have decided to go with a 254x254x254. Looking possibly to use 20x40 extrusions for strength on the Z axis, and trying to figure out how to use the open builds v-slot linear rail for the X, like makerfarm's.

|

Re: Wilson TS build log August 08, 2014 01:03AM |

Registered: 9 years ago Posts: 67 |

Hey usarmy ,

Good to know others have interest in the wilson TS and thanks for folowing my build.

Will you get a custom build plate then? and still use the MK2 heat bed. Just not sure the temperature at the extrimety of the build plate will be maintained correctly...

Getting 40x20 could be a solution for a sturdier Z frame but I still think the issue is simply that PLA does not have enough flexural regidity to eliminate wobble. I'll have to actually calculate that one day... =/

Im curious so see how the linear rails will turn out, if you decide to do that in the end. IMO it's better to start with something you for sure know will work and then upgrading. Which isn't what I did with my fishing wire so don't listen to me!

You should keep a build log up and running, I and I'm sure others, would be curious to follow your project.

TheHackerArtist

Good to know others have interest in the wilson TS and thanks for folowing my build.

Will you get a custom build plate then? and still use the MK2 heat bed. Just not sure the temperature at the extrimety of the build plate will be maintained correctly...

Getting 40x20 could be a solution for a sturdier Z frame but I still think the issue is simply that PLA does not have enough flexural regidity to eliminate wobble. I'll have to actually calculate that one day... =/

Im curious so see how the linear rails will turn out, if you decide to do that in the end. IMO it's better to start with something you for sure know will work and then upgrading. Which isn't what I did with my fishing wire so don't listen to me!

You should keep a build log up and running, I and I'm sure others, would be curious to follow your project.

TheHackerArtist

|

Re: Wilson TS build log August 10, 2014 10:51PM |

Registered: 10 years ago Posts: 27 |

MakerFarm has a 10x10 heat bed, I will have to get a piece of glass or mirror for the build surface, I think the standard for the base is MDF so I will get a piece of that.

Like you said I will build the standard version, then look to add the linear rails once I can print. I am hoping to do the 20x40 extrusion right away, but am not sure if that will be an issue, so might just go with the 20x20 to get started. There is a guy in Tulsa just 30 minutes away that I can get to print parts for me, if needed. One difference is that I am going to start with a E3Dv6 right away.

I will keep a build log, thanks!

Like you said I will build the standard version, then look to add the linear rails once I can print. I am hoping to do the 20x40 extrusion right away, but am not sure if that will be an issue, so might just go with the 20x20 to get started. There is a guy in Tulsa just 30 minutes away that I can get to print parts for me, if needed. One difference is that I am going to start with a E3Dv6 right away.

I will keep a build log, thanks!

|

Re: Wilson TS build log August 12, 2014 12:22PM |

Registered: 13 years ago Posts: 134 |

I see Marty has uploaded a Wilson TS design update video.

Some great additions.

Wilson TS update 1

Edited 1 time(s). Last edit at 08/12/2014 12:25PM by BoriSpider.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

Some great additions.

Wilson TS update 1

Edited 1 time(s). Last edit at 08/12/2014 12:25PM by BoriSpider.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

|

Re: Wilson TS build log August 30, 2014 10:12PM |

Registered: 9 years ago Posts: 6 |

So I have started sourcing my parts for my wilson ts. I bought extrusion, rods, and nuts and bolts from Marty. I will post the rest of my links once I have bought everything. One of the things I haven't figured out completely yet is the heatbed. Did you have to buy extra parts to make the heatbed you bought work? Thanks.

|

Re: Wilson TS build log August 31, 2014 01:54AM |

Registered: 9 years ago Posts: 67 |

Hey Rayton, glad to here you`ve sourced your parts. Are you in Canada as well?

Will you be building it using a belt drive or a wire drive?

For the heat bed, you will need a thermistor, leds and wires to connect to it that can carry 15A to be safe and can resist up to 120 degree without melting. Its a heat bed after all! And kapton tape to secure the thermistor in the hole in the middle of the bed.

You might want to buy something like this

[www.ebay.ca]

I`ll be posting shortly with a loooot of updates on my printer. Thanks ( a bit late) for the link BoriSpider. I still don't like that there`s plastic part holding the frame. I opted for an all metal frame and It`s sturdy. really sturdy.

More to come!

Will you be building it using a belt drive or a wire drive?

For the heat bed, you will need a thermistor, leds and wires to connect to it that can carry 15A to be safe and can resist up to 120 degree without melting. Its a heat bed after all! And kapton tape to secure the thermistor in the hole in the middle of the bed.

You might want to buy something like this

[www.ebay.ca]

I`ll be posting shortly with a loooot of updates on my printer. Thanks ( a bit late) for the link BoriSpider. I still don't like that there`s plastic part holding the frame. I opted for an all metal frame and It`s sturdy. really sturdy.

More to come!

|

Re: Wilson TS build log August 31, 2014 11:38AM |

Registered: 13 years ago Posts: 134 |

YW THA.

Hey Rayton, how are the parts from Marty, if you received them already?

When I'm ready I was thinking on going that rout too. He has a nice hardware kit

up now with extrusions, rods, fasteners, and bearings.

Marty might as well put together a whole kit. Well maybe minus hotend, controller board,

motors.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

Hey Rayton, how are the parts from Marty, if you received them already?

When I'm ready I was thinking on going that rout too. He has a nice hardware kit

up now with extrusions, rods, fasteners, and bearings.

Marty might as well put together a whole kit. Well maybe minus hotend, controller board,

motors.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

|

Re: Wilson TS build log September 01, 2014 07:45AM |

Registered: 13 years ago Posts: 134 |

I see that he has done that in the past already. Guess I missed it.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

|

Re: Wilson TS build log September 01, 2014 03:48PM |

Registered: 9 years ago Posts: 6 |

The parts seem really nice to me and everything is nice and labeled. The box was well packed. I attached a few photos of the stuff I got. The threaded rods also came wrapped in bubble wrap

|

Re: Wilson TS build log September 07, 2014 01:38PM |

Registered: 9 years ago Posts: 6 |

If I bought these two parts

thermistor

and

bed

Would I have everything I need to have a working heatbed? Did you buy stuff like this Hackerartist, or did you buy different components?

Do you think this would be a better solution?

Bed and thermistor

I don't think either of these come with an led/resistor, but it seems those components are not necessary. Thank you so much for the help and sorry about all the questions.

I also found this youtube channel which has some helpful videos with stuff like assembling the heatbed and hotend.

elderfarrer

thermistor

and

bed

Would I have everything I need to have a working heatbed? Did you buy stuff like this Hackerartist, or did you buy different components?

Do you think this would be a better solution?

Bed and thermistor

I don't think either of these come with an led/resistor, but it seems those components are not necessary. Thank you so much for the help and sorry about all the questions.

I also found this youtube channel which has some helpful videos with stuff like assembling the heatbed and hotend.

elderfarrer

|

Re: Wilson TS build log September 08, 2014 12:10AM |

Registered: 13 years ago Posts: 134 |

TheHackerArtist I just caught your great video on YouTube. Nice setup there.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

|

Re: Wilson TS build log September 18, 2014 12:49AM |

Registered: 9 years ago Posts: 67 |

|

Re: Wilson TS build log September 18, 2014 01:02AM |

Registered: 9 years ago Posts: 67 |

Hey BoriSpider! Thanks.

Have you begun putting your printer together?

I have a new video I just uploaded with all the changes I made. I'm no video-tacking expert so its not the best, sorry about that.

You can find my channel here

Its pretty geared up in terms of cooling now! And I have really good finishes. Only problem is at higher speeds it makes tiny rimples while printing a hollow rectangular prism, every time it changes direction. This is due to the system oscilating. My guess is that the fishing rope is still a bit too springy. I have ordered braided 7x7 stainless steel wire. That should solve the issue, I hope.

I have a video of a printed part to show off quality uploading right now, so that should be up by the time you check the channel.

Have you begun putting your printer together?

I have a new video I just uploaded with all the changes I made. I'm no video-tacking expert so its not the best, sorry about that.

You can find my channel here

Its pretty geared up in terms of cooling now! And I have really good finishes. Only problem is at higher speeds it makes tiny rimples while printing a hollow rectangular prism, every time it changes direction. This is due to the system oscilating. My guess is that the fishing rope is still a bit too springy. I have ordered braided 7x7 stainless steel wire. That should solve the issue, I hope.

I have a video of a printed part to show off quality uploading right now, so that should be up by the time you check the channel.

|

Re: Wilson TS build log September 18, 2014 01:46AM |

Registered: 9 years ago Posts: 67 |

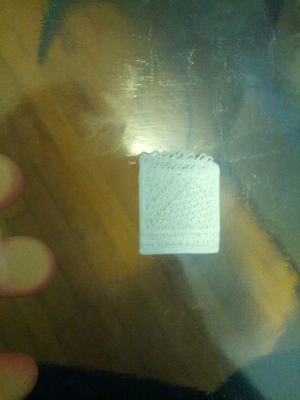

Here are some high res pics!

Print details

Marvin Key Chain height : 22mm

Layer height : 0.2mm

Material : White PLA

Edited 2 time(s). Last edit at 09/18/2014 08:51AM by TheHackerArtist.

Print details

Marvin Key Chain height : 22mm

Layer height : 0.2mm

Material : White PLA

Edited 2 time(s). Last edit at 09/18/2014 08:51AM by TheHackerArtist.

|

Re: Wilson TS build log September 18, 2014 09:50AM |

Registered: 13 years ago Posts: 134 |

Hi TheHackerArtist, some great prints you got there.

Back when I found you on YouTube I sub'd you. My page

didn't show anything new from you so I'll go now and watch.

My printer is "in the shop" right now so when it's up and running

and the cash is flowing I'll start sourcin' my TS.

You hear of (I could be wrong about the name) Spectra line??

The Bukobots use something like it. Might be worth looking into.

Maybe too pricey but future upgrade?

DeezMaker(BukoBot) has a Prusa upgrade kit. you might be able use on your bot.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

Back when I found you on YouTube I sub'd you. My page

didn't show anything new from you so I'll go now and watch.

My printer is "in the shop" right now so when it's up and running

and the cash is flowing I'll start sourcin' my TS.

You hear of (I could be wrong about the name) Spectra line??

The Bukobots use something like it. Might be worth looking into.

Maybe too pricey but future upgrade?

DeezMaker(BukoBot) has a Prusa upgrade kit. you might be able use on your bot.

__________________________________________________________________________

"I like to be, what I like to see, in you and me.

I am the Stallion, Mang."

ISTAR Scope Club

Sorry, only registered users may post in this forum.

....Not sure why.

....Not sure why.