Home

>

Reprappers

>

Topic

Making M3 Nuts flush into a 3D printed parts: any tips and tricks?

Posted by DennyP

|

Making M3 Nuts flush into a 3D printed parts: any tips and tricks? July 26, 2014 10:03PM |

Registered: 9 years ago Posts: 50 |

Hello all,

My name is Dennis and I'm a Reprapper in Sydney currently working on a Reprap Rostock build.

This is the first experience with 3D printed parts and I've realized it's a lot more harder than it is lol.

I'm currently inserting the M3 nuts into the nut holes, however they do not fit originally; so it looks like it's a finishing job for me to do!

After using a miniature flathead screwdriver for a considerable amount of time, I've managed to fit the nuts as following:

However, it's not completely flush with the plastic.

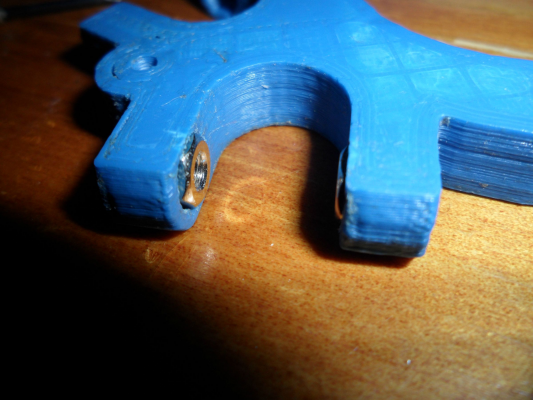

The following photo of the actual nuthole I've worked on using the screwdriver:

As you can see, it's definitely not the best.

Any seasoned pros that can give me techniques tips that would make it work for me

Cheers!

Dennis

My name is Dennis and I'm a Reprapper in Sydney currently working on a Reprap Rostock build.

This is the first experience with 3D printed parts and I've realized it's a lot more harder than it is lol.

I'm currently inserting the M3 nuts into the nut holes, however they do not fit originally; so it looks like it's a finishing job for me to do!

After using a miniature flathead screwdriver for a considerable amount of time, I've managed to fit the nuts as following:

However, it's not completely flush with the plastic.

The following photo of the actual nuthole I've worked on using the screwdriver:

As you can see, it's definitely not the best.

Any seasoned pros that can give me techniques tips that would make it work for me

Cheers!

Dennis

|

Re: Making M3 Nuts flush into a 3D printed parts: any tips and tricks? July 26, 2014 11:05PM |

Registered: 12 years ago Posts: 3 |

|

Re: Making M3 Nuts flush into a 3D printed parts: any tips and tricks? July 26, 2014 11:18PM |

Registered: 9 years ago Posts: 50 |

|

Re: Making M3 Nuts flush into a 3D printed parts: any tips and tricks? July 27, 2014 04:20AM |

Registered: 10 years ago Posts: 439 |

|

Re: Making M3 Nuts flush into a 3D printed parts: any tips and tricks? July 28, 2014 12:33PM |

Registered: 9 years ago Posts: 569 |

I had some luck using a soldering iron to heat the nut, sinking it into the plastic.

I definitely wouldn't recommend screwing it in to get a tight fit, split some of my parts that way.

EDIT: Just saw the video. In my case I used the side of the iron rather than the tip (which looked like it might hit plastic on the otherside of the nut). Also, once the nut was hot enough, you could likely flip the object over to get it flush rather than continueing to play with the iron.

Edited 1 time(s). Last edit at 07/28/2014 12:36PM by Kurzaa.

I definitely wouldn't recommend screwing it in to get a tight fit, split some of my parts that way.

EDIT: Just saw the video. In my case I used the side of the iron rather than the tip (which looked like it might hit plastic on the otherside of the nut). Also, once the nut was hot enough, you could likely flip the object over to get it flush rather than continueing to play with the iron.

Edited 1 time(s). Last edit at 07/28/2014 12:36PM by Kurzaa.

|

Re: Making M3 Nuts flush into a 3D printed parts: any tips and tricks? July 28, 2014 04:41PM |

Registered: 10 years ago Posts: 21 |

|

Re: Making M3 Nuts flush into a 3D printed parts: any tips and tricks? July 28, 2014 07:13PM |

Registered: 10 years ago Posts: 197 |

Sorry, only registered users may post in this forum.