Home

>

Reprappers

>

Topic

V-Slot is totally solid, reliable, and modular

Posted by MrDoctorDIV

|

V-Slot is totally solid, reliable, and modular July 29, 2014 07:35PM |

Registered: 10 years ago Posts: 790 |

I got more V-Slot stuffs today and I'm quite giddy and liken to a child on Christmas with just how much more it is in feel than watching things move in how-to's and whatnaught. Anyways. V-Slot. Especially the Polycarbonate wheels. Sacred golden calf it's as good as it gets. Easy to set up and once set up properly glides like melted butter with absolutely no give or bending or anything like that. Did I mention butter? Also, the corner connectors are rock solid as well. The only things that gave were the V-Slots themselves due to being 1500mm [pre-cut] and only bent on the thinner axis. I didn't notice any give along the thicker axis. Linear rods aren't even in the same tier, a comparison would lack any real meaning.

Edited 2 time(s). Last edit at 07/29/2014 07:38PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Edited 2 time(s). Last edit at 07/29/2014 07:38PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 12:26PM |

Registered: 10 years ago Posts: 790 |

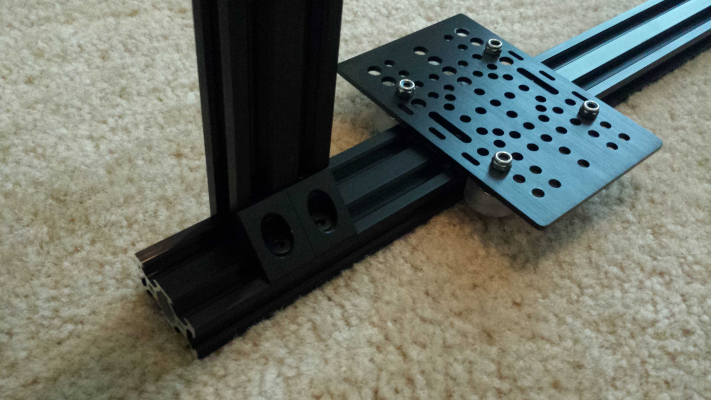

Can we say large format printer?

Okay, so maybe it's not the largest, but I'm pretty sure it doesn't fit in the "desktop" category of 3D printers. I needed to make sure that I didn't have to tell people my maximum build height 30% of the time.

I chose OpenBuild's hardest, sturdiest wheel for the carriage as I wanted to remove all play in the carriage. I was tired of linear rails bouncing around at even 300mm lengths.

I'll put it to you like this: I can sit on the carriage and I feel no play or bending [difficult to look while I'm sitting on it].

It's as solid as a rock, yet moves with very low friction, and negligible static friction. I can move it by hand the smallest amount and the whole carriage moves with it, no matter where I put the pressure. Never again will I use linear rails. I weighed many parts and combinations of parts, the V-Slot is actually less than half the weight than if I used linear rails. It's by no comparison more rigid and stable. If you order your rails from Misumi [meaning high quality, precision cut] than it's actually cheaper as well, not by half, but more than just a little. In other words, I can't find a single reason to use a linear rail for larger format printers. Even for small ones I struggle to reason in a linear rail. Anyways. My current build progress. I'll be working on the CoreXY gantry next as I wait for OpenBuilds to restock [I guess that's one reason for linear rails] on some remaining hardware.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Okay, so maybe it's not the largest, but I'm pretty sure it doesn't fit in the "desktop" category of 3D printers. I needed to make sure that I didn't have to tell people my maximum build height 30% of the time.

I chose OpenBuild's hardest, sturdiest wheel for the carriage as I wanted to remove all play in the carriage. I was tired of linear rails bouncing around at even 300mm lengths.

I'll put it to you like this: I can sit on the carriage and I feel no play or bending [difficult to look while I'm sitting on it].

It's as solid as a rock, yet moves with very low friction, and negligible static friction. I can move it by hand the smallest amount and the whole carriage moves with it, no matter where I put the pressure. Never again will I use linear rails. I weighed many parts and combinations of parts, the V-Slot is actually less than half the weight than if I used linear rails. It's by no comparison more rigid and stable. If you order your rails from Misumi [meaning high quality, precision cut] than it's actually cheaper as well, not by half, but more than just a little. In other words, I can't find a single reason to use a linear rail for larger format printers. Even for small ones I struggle to reason in a linear rail. Anyways. My current build progress. I'll be working on the CoreXY gantry next as I wait for OpenBuilds to restock [I guess that's one reason for linear rails] on some remaining hardware.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 02:49PM |

Registered: 10 years ago Posts: 770 |

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 07:08PM |

Registered: 10 years ago Posts: 790 |

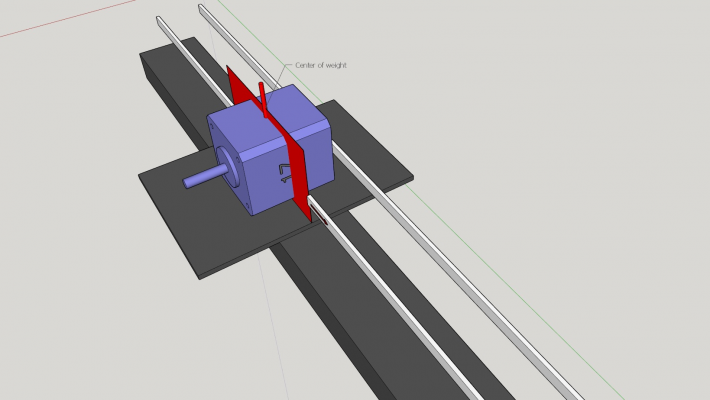

A question to the public:

H-bot's drawback is simply a racking of the gantry, correct? The only problem that CoreXY overcomes is the racking of the gantry?

So if two situations were implemented on an H-bot-- 1, that the attached belt be attached and aligned on the center of the gantry's weight; 2, that the gantry be of such tolerance as to not rack even when attempting to force it to do so by hand in rotational forces-- would that then remove the point of CoreXY? Would H-bot then have an advantage in its simplicity?

Edited 1 time(s). Last edit at 07/31/2014 08:57PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

H-bot's drawback is simply a racking of the gantry, correct? The only problem that CoreXY overcomes is the racking of the gantry?

So if two situations were implemented on an H-bot-- 1, that the attached belt be attached and aligned on the center of the gantry's weight; 2, that the gantry be of such tolerance as to not rack even when attempting to force it to do so by hand in rotational forces-- would that then remove the point of CoreXY? Would H-bot then have an advantage in its simplicity?

Edited 1 time(s). Last edit at 07/31/2014 08:57PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 08:46PM |

Registered: 10 years ago Posts: 1,381 |

Quote

MrDoctorDIV

The only problem that CoreXY overcomes is the rotating of the gantry?

To be clear:

Rotating = anti-racking?

So I can better understand, please provide a drawing of what you mean with your two points concerning the H-bot.

Most use a rough rule of thumb of 2:1 ratio of the cantilever length to bearing spread to help prevent racking, and an anti-racking cabling system is employed when the ratio, or other variables are exceeded.

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 08:56PM |

Registered: 10 years ago Posts: 790 |

This is the clearest writing I've found recently that talks about it.

And yes, by rotation I mean racking.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

And yes, by rotation I mean racking.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 08:59PM |

Registered: 10 years ago Posts: 1,381 |

Quote

MrDoctorDIV

Polycarbonate wheels

Delrin would be a better choice for a bearing material than Polycarbonate. Delrin is pretty close to an aluminum equivalent but with lubricious qualities, and the greater the impact force the better Delrin performs relative to competing plastics.

Don't run out, and make another purchase, as ymmv, and have great success with the PC wheels. But do pay attention to the bearing performance and let us know how things progress.

Note: clean the bearing surface often, as atmospheric elements will form a scale of grime. If you have some igus bearings or filament, or Teflon, rub it into the aluminum bearing ways to improve the efficiency, and reduce wear.

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 09:03PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 09:20PM |

Registered: 10 years ago Posts: 790 |

Situation 1:

If the attached belt is attached at the center of weight, or near it.

Situation 2:

Tolerances are tight enough that any attempt to create a racking of the carriage results in no visible/audible racking [in building and tightening this, I found I could hear racking even when I couldn't see the movement].

Edit: To note, in actual testing I used both hands to create the forces, and not light pressure either [coming from the guy who sat on his carriage to make sure it was sturdy enough].

I plan to get some silicone spray to lube the extrusions.

Edited 2 time(s). Last edit at 07/31/2014 09:34PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

If the attached belt is attached at the center of weight, or near it.

Situation 2:

Tolerances are tight enough that any attempt to create a racking of the carriage results in no visible/audible racking [in building and tightening this, I found I could hear racking even when I couldn't see the movement].

Edit: To note, in actual testing I used both hands to create the forces, and not light pressure either [coming from the guy who sat on his carriage to make sure it was sturdy enough].

I plan to get some silicone spray to lube the extrusions.

Edited 2 time(s). Last edit at 07/31/2014 09:34PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 09:41PM |

Registered: 10 years ago Posts: 1,381 |

OK, Tks for the pics! Terms need to be defined, the carriage is what translates along the gantry, i.e. the Y-axis, and the gantry translates along the X-axis.

The carriage is not going to rack as it appears to not come close to the 2:1 ratio, but the gantry could rack, as the bearings violate the general rule of thumb of 2:1.

My main concern would not be the belt configuration of the H-bot, but of the bearing spacing along the Y-axis of the gantry.

I would choose the Core-XY over the H-bot because both motors are placing tension on the belts in the direction of the desired motion. Based on the pics in the link shown of the gantry bearing spread along the X-axis, neither are rigorously designed.

Edited 2 time(s). Last edit at 07/31/2014 09:49PM by A2.

The carriage is not going to rack as it appears to not come close to the 2:1 ratio, but the gantry could rack, as the bearings violate the general rule of thumb of 2:1.

My main concern would not be the belt configuration of the H-bot, but of the bearing spacing along the Y-axis of the gantry.

I would choose the Core-XY over the H-bot because both motors are placing tension on the belts in the direction of the desired motion. Based on the pics in the link shown of the gantry bearing spread along the X-axis, neither are rigorously designed.

Edited 2 time(s). Last edit at 07/31/2014 09:49PM by A2.

|

Re: V-Slot is totally solid, reliable, and modular July 31, 2014 09:59PM |

Registered: 10 years ago Posts: 790 |

The gantry* [thanks for the clarification, have yet to see one] moves as a whole when any force, small distances included, is applied. It takes a some amount of racking force to get even half a mm of racking, a fair amount to get 1mm. I plan to fine tune the bearing positions to lessen that. The eccentric spacers make that quite easy, just time consuming to isolate where it's happening, why, and moving it the right amount. I really like the eccentric spacers because it's solid movement, not spring. A spring can be overcome, and variably so, by forces; eccentrics only as much as the rigidness of the whole piece.This is going to be my larger format, high speed printer. I'll be gutting and rebuilding my current printer into a fine, small printer. As of right now I believe* I can deal with a single mm of racking on a class 2 lever.

Thanks for the help!

Edited 4 time(s). Last edit at 07/31/2014 10:05PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Thanks for the help!

Edited 4 time(s). Last edit at 07/31/2014 10:05PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular August 01, 2014 04:44PM |

Registered: 9 years ago Posts: 11 |

pretty neat stuff

Have you seen any information regarding tolerances for this extrusion?

In particular, Flatness, Straightness, & Twist?

I know that even the best extrusion houses struggle with this.

80/20 is 80/20 but they follow industry standard tolerances. (see pic)

If the V slot is machined in post extrusion this can be minimized to some extent.

Do you see any machine marks on the V or is it as extruded?

Our supplier will usually let us go to 1/2 standard tolerances, but it costs more.

All that aside it really only matters when the plastic hits the glass.

Looking forward to your opinions.

thanks,

Edited 1 time(s). Last edit at 08/01/2014 04:45PM by joeb1.

Have you seen any information regarding tolerances for this extrusion?

In particular, Flatness, Straightness, & Twist?

I know that even the best extrusion houses struggle with this.

80/20 is 80/20 but they follow industry standard tolerances. (see pic)

If the V slot is machined in post extrusion this can be minimized to some extent.

Do you see any machine marks on the V or is it as extruded?

Our supplier will usually let us go to 1/2 standard tolerances, but it costs more.

All that aside it really only matters when the plastic hits the glass.

Looking forward to your opinions.

thanks,

Edited 1 time(s). Last edit at 08/01/2014 04:45PM by joeb1.

|

Re: V-Slot is totally solid, reliable, and modular August 05, 2014 07:42PM |

Registered: 10 years ago Posts: 790 |

The V-Slot is anodized normally, and I have the black anodized, so that's not visible to me. They certainly talk up the smoothness and precision of the grooves. I notice that it is sharp on the internal corners along the whole length. I've nearly punctured myself on the corners a few times. When I got my frame built and aligned the gantry glides evenly smooth along the whole length. I don't have any real scientific basis, but they seem straight to me. On my Solidoodle there is some rotation and wobble, but parts seem to fit and form fine. This build being much more rigid and tight and stable, I can't imagine that anything problems I have are going to be noticeable. I can't wait to get this finished so I can ditch my current plastic shaping old bucket.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular August 06, 2014 01:36PM |

Admin Registered: 11 years ago Posts: 3,096 |

I read you think about silicone lube to lube the extrusions, I have great experiences with Teflon spray/PTFE spray.

Oh, and, nice socks

http://www.marinusdebeer.nl/

Oh, and, nice socks

http://www.marinusdebeer.nl/

|

Re: V-Slot is totally solid, reliable, and modular August 06, 2014 02:06PM |

Registered: 10 years ago Posts: 790 |

I will certainly take a look at Teflon then.

Oh, and, thanks

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Oh, and, thanks

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular August 06, 2014 08:01PM |

Admin Registered: 11 years ago Posts: 3,096 |

With linear ball-bearings PTFE spray may not be a good choice, as the balls of the bearing will probably slip instead of roll.

However, with all other applications I've used the PTFE spray with, the lube stayed on longer than silicone lube.

In the future I've gotten sintered bronze bushings, which don't need any lubrication at all. The only part I will use the PTFE lube for now is the nut on my leadscrew for the Z-stage.

Not sure if PTFE lube is right in every application, but it is in a lot of them. I even use it on my bike chain, and noticed a better slide than with the usual chain grease I used. Less dirt sticks to the parts and this lowers the friction wear, but on the other side, the lube layer goes off a little quicker. Might be because of the lower viscosity compared to chain grease.

http://www.marinusdebeer.nl/

However, with all other applications I've used the PTFE spray with, the lube stayed on longer than silicone lube.

In the future I've gotten sintered bronze bushings, which don't need any lubrication at all. The only part I will use the PTFE lube for now is the nut on my leadscrew for the Z-stage.

Not sure if PTFE lube is right in every application, but it is in a lot of them. I even use it on my bike chain, and noticed a better slide than with the usual chain grease I used. Less dirt sticks to the parts and this lowers the friction wear, but on the other side, the lube layer goes off a little quicker. Might be because of the lower viscosity compared to chain grease.

http://www.marinusdebeer.nl/

|

Re: V-Slot is totally solid, reliable, and modular August 07, 2014 12:41AM |

Registered: 10 years ago Posts: 790 |

Thanks for the added info. If I ever use linear rails again I'll keep that in mind if I decided to use an extra lubricant. Being how V-Wheels are, it could only help.

Something I just found that might help others using V-Slot:

If you put a precision shim [1mm thick, same one included in the kit available separate at 25 cents/pc] between the two bearings inside the wheel, you can then tighten the wheel as much as you want and it will still roll at its smoothest. Otherwise, if you tighten them too much, which is hardly tight for what I want, they will have much increased friction, too much will stop all movement.

Edited 1 time(s). Last edit at 08/07/2014 12:57AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Something I just found that might help others using V-Slot:

If you put a precision shim [1mm thick, same one included in the kit available separate at 25 cents/pc] between the two bearings inside the wheel, you can then tighten the wheel as much as you want and it will still roll at its smoothest. Otherwise, if you tighten them too much, which is hardly tight for what I want, they will have much increased friction, too much will stop all movement.

Edited 1 time(s). Last edit at 08/07/2014 12:57AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular August 07, 2014 07:14PM |

Registered: 10 years ago Posts: 240 |

Quote

MrDoctorDIV

If you put a precision shim [1mm thick, same one included in the kit available separate at 25 cents/pc] between the two bearings inside the wheel, you can then tighten the wheel as much as you want and it will still roll at its smoothest. Otherwise, if you tighten them too much, which is hardly tight for what I want, they will have much increased friction, too much will stop all movement.

That is how the Mini V-wheels are assembled, I'm of surprised the others don't use the shim.

I use the mini wheels on the Griffin and they work fantastic.

|

Re: V-Slot is totally solid, reliable, and modular August 07, 2014 11:13PM |

Registered: 10 years ago Posts: 790 |

Haha! Well, that's funny! Just got around to actually watching the how to install video. Shows it right there. Just call me Billy from now on. I thought the washer was for the aluminum spacer being a different width so it wouldn't tip. But I still need the extra spacers I ordered for my pulleys and how I have everything spaced. Wow.. smartest guy ever. Can't count how many times I've reinvented the wheel [or V-Wheel for this matter] only to discover it's already been invented.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular August 08, 2014 05:59AM |

Registered: 10 years ago Posts: 903 |

I made the same incorrect assumption about the washers at first on my mini-V wheels. Even with the "precision spacer" between the bearings, several of mine are still "crunchy" when I turn them with any kind of tension on the nylock nut.....

|

Re: V-Slot is totally solid, reliable, and modular August 09, 2014 07:31PM |

Registered: 10 years ago Posts: 240 |

|

Re: V-Slot is totally solid, reliable, and modular August 09, 2014 10:08PM |

Registered: 10 years ago Posts: 231 |

|

Re: V-Slot is totally solid, reliable, and modular August 09, 2014 10:55PM |

Registered: 10 years ago Posts: 790 |

When I remove the bearings I take the same screw and give it sideways pressure like a lever. Just pull out while keeping it sideways. Gripping the screw is the hardest part.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular September 12, 2014 05:01PM |

Registered: 11 years ago Posts: 38 |

Quote

vreihen

several of mine are still "crunchy" when I turn them with any kind of tension on the nylock nut.....

Vreihen (and whoever else may apply),

could you elaborate on "crunchy?" I recently bought a set of v-slot and wheel kits to test it out to make a new large format printer for myself. I like the setup, but I'm hesitant to stick with them as linear rails because I'm not experiencing very smooth motion. As I move the carriage up and down the rails by hand it feels like the wheels are getting caught in a divot, causing the movement to be jumpy and uneven. I don't think this will fly under operating conditions, so I'm hoping its something defective or not assembled correctly. I need to spend a little more time playing with it to find out what it might be. It seems to get caught at regular intervals of one wheel rotation, so it's not something on the rail.

Has anybody else had this problem with the v-slot wheels?

|

Re: V-Slot is totally solid, reliable, and modular September 12, 2014 05:41PM |

Registered: 10 years ago Posts: 231 |

Quote

stoof

Vreihen (and whoever else may apply),

could you elaborate on "crunchy?" I recently bought a set of v-slot and wheel kits to test it out to make a new large format printer for myself. I like the setup, but I'm hesitant to stick with them as linear rails because I'm not experiencing very smooth motion. As I move the carriage up and down the rails by hand it feels like the wheels are getting caught in a divot, causing the movement to be jumpy and uneven. I don't think this will fly under operating conditions, so I'm hoping its something defective or not assembled correctly. I need to spend a little more time playing with it to find out what it might be. It seems to get caught at regular intervals of one wheel rotation, so it's not something on the rail.

Has anybody else had this problem with the v-slot wheels?

I've got several of the mini wheels and have been experimenting with them in a new printer build and haven't had any problem with them. When adjusted properly they move very smoothly and with no play whatsoever. I have a long 1500mm length of v-slot and I can put a mini v carriage on one end tip it up and it freely moves to the other end and vice-versa.

|

Re: V-Slot is totally solid, reliable, and modular September 12, 2014 05:41PM |

Registered: 10 years ago Posts: 231 |

|

Re: V-Slot is totally solid, reliable, and modular September 12, 2014 08:04PM |

Registered: 10 years ago Posts: 790 |

I haven't done much more, just added two parts to the bed movement. Car needing repairs has stopped progress.

The wheels can get debri or cuts/indents that may be causing the bumps. I had a few of those, I just take two fingers and run them across each wheel as I move it along and feel for where it's happening. Nothing I couldn't fix yet, and only twice. Super buttery smooth otherwise.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

The wheels can get debri or cuts/indents that may be causing the bumps. I had a few of those, I just take two fingers and run them across each wheel as I move it along and feel for where it's happening. Nothing I couldn't fix yet, and only twice. Super buttery smooth otherwise.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular September 13, 2014 10:55AM |

Registered: 10 years ago Posts: 903 |

Quote

stoof

could you elaborate on "crunchy?"

Some of my MINI V-slot wheels turn "crunchy" when assembled and torqued, sort of like they are lacking lubrication or have a speck or two of sand on the bearings. I have read other people complaining about the problem, which may be limited to one batch of the mini-V wheels. The problem doesn't seem to cause any problems on my delta printer, and there are no signs of flat-spotting on the wheels to hint that they were skidding on the extrusions.....

|

Re: V-Slot is totally solid, reliable, and modular September 13, 2014 11:46AM |

Registered: 10 years ago Posts: 790 |

And you've watched the actual instructions on putting them together? I know I had to go back and fix all my wheels as I apparently did it wrong at first.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: V-Slot is totally solid, reliable, and modular September 13, 2014 04:28PM |

Registered: 10 years ago Posts: 231 |

Quote

vreihen

Quote

stoof

could you elaborate on "crunchy?"

Some of my MINI V-slot wheels turn "crunchy" when assembled and torqued, sort of like they are lacking lubrication or have a speck or two of sand on the bearings. I have read other people complaining about the problem, which may be limited to one batch of the mini-V wheels. The problem doesn't seem to cause any problems on my delta printer, and there are no signs of flat-spotting on the wheels to hint that they were skidding on the extrusions.....

Are you using their plates, or did you print your own? I found that when printing my plates/gantrys, if the holes are just slightly too close together, the eccentric spacer can rub on the v-slot at certain points of it's rotation.

Sorry, only registered users may post in this forum.