Home

>

Reprappers

>

Topic

Mantis Electron works!

Posted by Traumflug

|

Mantis Electron works! September 24, 2014 10:06AM |

Registered: 13 years ago Posts: 7,616 |

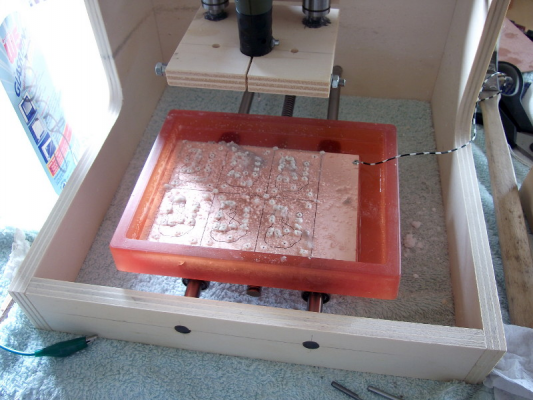

First try, great success! That's how I like it.

Experience is quite different from the weak WolfStrap. No pressing here, observing there, isolation tracks are simply of identical width everywhere. And also smaller, likely because there's less overall vibration. G0 is almost three times as fast as previously, which about halfed drilling time.

Looks like I have to build a second one to be able to print in a similarly precise fashion. Have to keep the spindle there for now, there's are pile of Gen7 orders waiting.

Experience is quite different from the weak WolfStrap. No pressing here, observing there, isolation tracks are simply of identical width everywhere. And also smaller, likely because there's less overall vibration. G0 is almost three times as fast as previously, which about halfed drilling time.

Looks like I have to build a second one to be able to print in a similarly precise fashion. Have to keep the spindle there for now, there's are pile of Gen7 orders waiting.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Mantis Electron works! September 24, 2014 12:22PM |

Registered: 12 years ago Posts: 809 |

|

Re: Mantis Electron works! September 25, 2014 08:15PM |

Registered: 9 years ago Posts: 204 |

|

Re: Mantis Electron works! September 26, 2014 05:06AM |

Registered: 13 years ago Posts: 7,616 |

Quote

Shank man

Sweet. Make you post those plans!

Design principle is the same as that of David Carr's Mantis 9.1. Changes:

- 10 mm rods instead of 8 mm.

- Linear ball bearings instead of brass bushings.

- A small piece of wood underneath each bearing for more glueing surface.

- Slightly bigger, print volume 160 x 120 x 90 mm.

During the build I found a number of minor issues (like holes being 2 mm off) and I think it's a good idea to re-do this design in FreeCAD. Currently it's made with a proprietary CAD. Let's hope FreeCAD is up to such tasks now. :-)

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Mantis Electron works! September 27, 2014 02:01PM |

Registered: 13 years ago Posts: 7,616 |

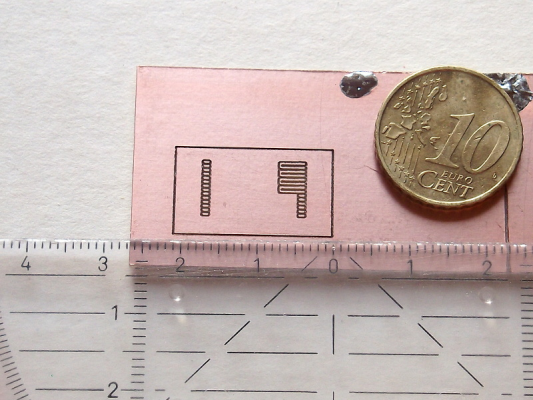

Here's a little demonstration on how precise this printer is. A TSOP-28 footprint, legs just 22 mil (0,559 mm) apart. As you can see, there's room for even finer details:

Now, which kind of extruder could take advantage of such precision?

Now, which kind of extruder could take advantage of such precision?

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Mantis Electron works! September 27, 2014 03:20PM |

Registered: 11 years ago Posts: 730 |

Cool project!

Let me know if you need help in converting the files to FreeCAD format.

In the past on the FreeCAD forum, there was an initiative to remodel parts for a popular RepRap design, and many forum members had contributed.

If you joined the FreeCAD forum, you could discuss modeling and assembly strategies with the forum regulars. In the past I modeled the TK-0 (which became TAZ) in FreeCAD for Lulzbot. AFAIK they are still using FreeCAD to design some of their parts.

Parametric assembly relationships are still not implemented in FreeCAD yet, nor is motion simulation (although some have "simulated" it by Python scripting). But assemblies can still be done.

Cheers

Norm

Quote

Traumflug

During the build I found a number of minor issues (like holes being 2 mm off) and I think it's a good idea to re-do this design in FreeCAD. Currently it's made with a proprietary CAD. Let's hope FreeCAD is up to such tasks now. :-)

Let me know if you need help in converting the files to FreeCAD format.

In the past on the FreeCAD forum, there was an initiative to remodel parts for a popular RepRap design, and many forum members had contributed.

If you joined the FreeCAD forum, you could discuss modeling and assembly strategies with the forum regulars. In the past I modeled the TK-0 (which became TAZ) in FreeCAD for Lulzbot. AFAIK they are still using FreeCAD to design some of their parts.

Parametric assembly relationships are still not implemented in FreeCAD yet, nor is motion simulation (although some have "simulated" it by Python scripting). But assemblies can still be done.

Cheers

Norm

Sorry, only registered users may post in this forum.