Home

>

Reprappers

>

Topic

Auto-Leveling + Z-Axis-Leveling [Prusa i3]

Posted by Ano

|

Auto-Leveling + Z-Axis-Leveling [Prusa i3] January 17, 2015 06:43PM |

Registered: 9 years ago Posts: 119 |

Hi folks,

I'm getting my printer kit in some weeks and am really excited about it =) To dive into the whole printing thing, I read on the wiki, the forum and looked up some things on thingiverse.

That's when I saw something I would like to ask:

Apparently the whole bed and x-axis leveling is causing some headaches, so I wanted to read about some auto-leveling strategies others came up with. The solution with a switch mounted

onto a servo near to the extruder hot end seems working well, but I just don't like the idea of getting weight onto it, that will have no more purpose while the printing process is running.

Then I saw this post: http://www.thingiverse.com/thing:273805

He is attaching his bed-level switch not to the extruder part, but to the z-axis rod. The extruder is lowered until it sits on the bed. Then it's lowered even more which will only cause an attachment

on the shaft to be lowered (cause the extruder still sits on the bed and can't be lowered more) which then activates a microswitch.

Another thing I saw was this anti-wobble unit:

http://www.thingiverse.com/thing:141479

Which essentially trys to decouple the x-axis shaft from the z-axis threaded rod. The x-axis shaft is only mounted to the z-axis shaft, but not to the z-axis threaded rod. The z-axis lifting is achieved by

a second unit that is placed under the x-axis attachment that just pushes it up. But when lowering it too much, the extruder touches the bed. When lowering it further, the extruder and the

x-axis shafts will stay in place (because the extruder is still on the bed) and only the wobble-units are lowering.

Wouldn't it be possible to level the x-axis (i mean left side and right side steppers for identical height of the horizontal extruder shaft) with this combination? Add some switches on the

very bottom of the z-axis. Then lower the x-axis shaft until the extruder sit's on the heat bed. Lower it further. The extruder will just stay on the heatbed, as his horizontal shaft is not connected to the

(vertical) z-axis threaded rod. The anti-wobble parts will lower further until they hit the switches on the bottom. Now both anti-wobble units are on the exact same height and can be raised again.

Shouldn't this work?

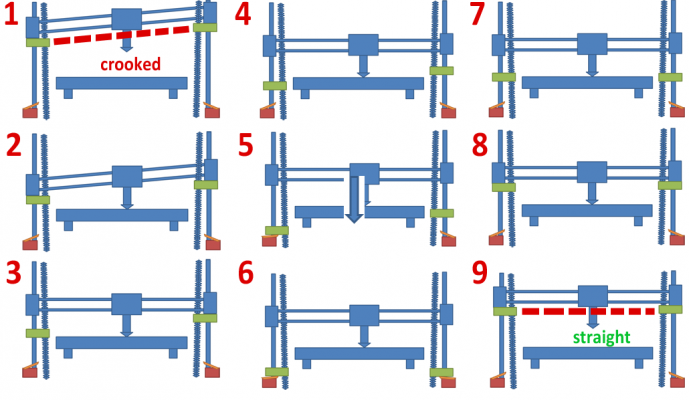

To clarify my thought, see sketch:

Edited 1 time(s). Last edit at 01/17/2015 06:50PM by Ano.

I'm getting my printer kit in some weeks and am really excited about it =) To dive into the whole printing thing, I read on the wiki, the forum and looked up some things on thingiverse.

That's when I saw something I would like to ask:

Apparently the whole bed and x-axis leveling is causing some headaches, so I wanted to read about some auto-leveling strategies others came up with. The solution with a switch mounted

onto a servo near to the extruder hot end seems working well, but I just don't like the idea of getting weight onto it, that will have no more purpose while the printing process is running.

Then I saw this post: http://www.thingiverse.com/thing:273805

He is attaching his bed-level switch not to the extruder part, but to the z-axis rod. The extruder is lowered until it sits on the bed. Then it's lowered even more which will only cause an attachment

on the shaft to be lowered (cause the extruder still sits on the bed and can't be lowered more) which then activates a microswitch.

Another thing I saw was this anti-wobble unit:

http://www.thingiverse.com/thing:141479

Which essentially trys to decouple the x-axis shaft from the z-axis threaded rod. The x-axis shaft is only mounted to the z-axis shaft, but not to the z-axis threaded rod. The z-axis lifting is achieved by

a second unit that is placed under the x-axis attachment that just pushes it up. But when lowering it too much, the extruder touches the bed. When lowering it further, the extruder and the

x-axis shafts will stay in place (because the extruder is still on the bed) and only the wobble-units are lowering.

Wouldn't it be possible to level the x-axis (i mean left side and right side steppers for identical height of the horizontal extruder shaft) with this combination? Add some switches on the

very bottom of the z-axis. Then lower the x-axis shaft until the extruder sit's on the heat bed. Lower it further. The extruder will just stay on the heatbed, as his horizontal shaft is not connected to the

(vertical) z-axis threaded rod. The anti-wobble parts will lower further until they hit the switches on the bottom. Now both anti-wobble units are on the exact same height and can be raised again.

Shouldn't this work?

To clarify my thought, see sketch:

Edited 1 time(s). Last edit at 01/17/2015 06:50PM by Ano.

|

Re: Auto-Leveling + Z-Axis-Leveling [Prusa i3] January 19, 2015 10:35AM |

Registered: 11 years ago Posts: 110 |

Hmmm... very interesting idea, but it may be harder to implement than you think. I think the biggest challenge would be in wiring the two switches. Plenty of electronics packages will accept Zmin and Zmax switches, but I don't know of any that would accept two Zmin switches like this. Wiring them in series isn't an option, because the first switch triggered will be the only one recognized. That de-coupling setup does make for a nice safety feature though, by minimizing any potential damage from a head-crash.

I use auto bed leveling on two of my printers, a Prusa Mendel i2 and a Lulzbot Taz clone. Both have probes with endstop switches attached to the carriage. The Prusa uses a servo and the Taz uses a mechanical slide to deploy the probe (created by 1013, LINK HERE). With geared extruders and steppers mounted on both carriages, the additional weight from the servo and endstop switch is negligible to me. Unless you have a large printer, capable of actually achieving maximum speeds, along with high acceleration and jerk settings, I doubt that you'd see a difference in print quality. Even with a Bowden setup and remote extruders, I wouldn't let the weight (maybe 50g?) deter you from a conventional bed leveling setup.

If you're interested in using the hotend itself as a probe, you may want to take a look at what the Smartrap folks are doing. Their design has evolved from a servo-deployed probe to one that uses the hotend itself. It's mounted on a pivot, with a spring to hold it in place and an endstop switch integrated into the hinge. There's a forum dedicated to the Smartrap, and a nice illustration of the bed-probing setup Here. There's a video of it in action on the Thingiverse Page as well.

Which kit did you go with??

I use auto bed leveling on two of my printers, a Prusa Mendel i2 and a Lulzbot Taz clone. Both have probes with endstop switches attached to the carriage. The Prusa uses a servo and the Taz uses a mechanical slide to deploy the probe (created by 1013, LINK HERE). With geared extruders and steppers mounted on both carriages, the additional weight from the servo and endstop switch is negligible to me. Unless you have a large printer, capable of actually achieving maximum speeds, along with high acceleration and jerk settings, I doubt that you'd see a difference in print quality. Even with a Bowden setup and remote extruders, I wouldn't let the weight (maybe 50g?) deter you from a conventional bed leveling setup.

If you're interested in using the hotend itself as a probe, you may want to take a look at what the Smartrap folks are doing. Their design has evolved from a servo-deployed probe to one that uses the hotend itself. It's mounted on a pivot, with a spring to hold it in place and an endstop switch integrated into the hinge. There's a forum dedicated to the Smartrap, and a nice illustration of the bed-probing setup Here. There's a video of it in action on the Thingiverse Page as well.

Which kit did you go with??

|

Re: Auto-Leveling + Z-Axis-Leveling [Prusa i3] January 19, 2015 02:21PM |

Registered: 9 years ago Posts: 119 |

Hm. I don't know anything about wiring yet, cause my printer kit is still on the way =) I ordered the Prusa i3 Rework Kit from Replikeo: http://www.replikeo.com/

(pretty cheap, not the cheapest because about 100 Dollars shipping fee + VAT, but the support seems to be really fast at responding to emails, tried it about 4 times and every time they answered in about 30mins)

Seems like a good setup, a few reviews were quite positive, and the build can be modded quite nicely =)

The idea with using the nozzle came to me, too. But I thought about using it as a capacitive sensor. Like attaching a sensing circuit directly to the nozzle, using the nozzle as the sensor surface. That's a thing i would like

to try, even if I don't know how the circuit could be attached to work.

After the idea described in this thread I saw a "normal" version of a capacitive sensor which I think will be my choice to start with:

Source: ".xack." 's build from this thread: http://forums.reprap.org/read.php?336,388217

Edited 1 time(s). Last edit at 01/19/2015 02:23PM by Ano.

(pretty cheap, not the cheapest because about 100 Dollars shipping fee + VAT, but the support seems to be really fast at responding to emails, tried it about 4 times and every time they answered in about 30mins)

Seems like a good setup, a few reviews were quite positive, and the build can be modded quite nicely =)

The idea with using the nozzle came to me, too. But I thought about using it as a capacitive sensor. Like attaching a sensing circuit directly to the nozzle, using the nozzle as the sensor surface. That's a thing i would like

to try, even if I don't know how the circuit could be attached to work.

After the idea described in this thread I saw a "normal" version of a capacitive sensor which I think will be my choice to start with:

Source: ".xack." 's build from this thread: http://forums.reprap.org/read.php?336,388217

Edited 1 time(s). Last edit at 01/19/2015 02:23PM by Ano.

|

Re: Auto-Leveling + Z-Axis-Leveling [Prusa i3] December 16, 2015 05:08AM |

Registered: 8 years ago Posts: 1 |

|

Re: Auto-Leveling + Z-Axis-Leveling [Prusa i3] December 16, 2015 06:31AM |

Registered: 8 years ago Posts: 3,525 |

When I get time to print it, I've designed an x carriage for the i3 with a hinge, spring and microswitch to act as z min probe using the nozzle. If the repeatability of it is good and the nozzle clean, it should give more useful bed levelling as it's nozzle based so no offsets etc.. Will keep you posted and publish stls if it works.

|

Re: Auto-Leveling + Z-Axis-Leveling [Prusa i3] December 16, 2015 06:46AM |

Registered: 8 years ago Posts: 3,525 |

As for the two z motors they could be independently controlled to effect a degree of x axis bed tilt correction but this would require quite a bit of firmware change and does nothing for y tilt. I feel it's best to have one z motor perhaps larger or geared and pulleys and belts to drive the two z screws. If you set both left and right square to the bed then tighten the pulleys on they should stay in balance. Apparently the way an i3 is designed with two motors they gradually go out of alignment when both motors stop one can settle one step clockwise the other one step anticlockwise.

As many people who have gained some experience say the best method is to use screws to set the bed level manually then not move the printer around. It's simple and effective. Initially I used a capacitative sensor with 5v voltage regulator for the signal pin as manual levelling seemed like a dark art, it isn't, lower the bed a little at each corner manually, then move the nozzle to each of the four corners at z=0 and turn the screw so that it touches the nozzle.

As many people who have gained some experience say the best method is to use screws to set the bed level manually then not move the printer around. It's simple and effective. Initially I used a capacitative sensor with 5v voltage regulator for the signal pin as manual levelling seemed like a dark art, it isn't, lower the bed a little at each corner manually, then move the nozzle to each of the four corners at z=0 and turn the screw so that it touches the nozzle.

Sorry, only registered users may post in this forum.