Home

>

Reprappers

>

Topic

GT9S exrtuder problem

Posted by vagran

|

GT9S exrtuder problem January 25, 2015 06:24AM |

Registered: 9 years ago Posts: 10 |

Hi,

I have just built my first 3d printer which is RepRap Mendel Prusa i2. I really wanted to have best quality prints, so I used GT9S extruder which was looking as state of the art. Has anyone used it?

I cannot make it work. After some extruding (several millimeters of filament) it jams. When pushing filament it seems to be too soft in the tube with the radiator, and becomes thicker until it is completely jammed. I have experimented with hot end temperature and the lower fan rotation speed with no luck (also at full fan speed the head is unable to warm more than ~150C). I have 0.35mm nozzle and 1.75mm ABS. Is such problem common for all heads or is specific to this one? I am newbie in 3d printing, any advise would be useful.

Edited 1 time(s). Last edit at 01/25/2015 06:31AM by vagran.

I have just built my first 3d printer which is RepRap Mendel Prusa i2. I really wanted to have best quality prints, so I used GT9S extruder which was looking as state of the art. Has anyone used it?

I cannot make it work. After some extruding (several millimeters of filament) it jams. When pushing filament it seems to be too soft in the tube with the radiator, and becomes thicker until it is completely jammed. I have experimented with hot end temperature and the lower fan rotation speed with no luck (also at full fan speed the head is unable to warm more than ~150C). I have 0.35mm nozzle and 1.75mm ABS. Is such problem common for all heads or is specific to this one? I am newbie in 3d printing, any advise would be useful.

Edited 1 time(s). Last edit at 01/25/2015 06:31AM by vagran.

|

Re: GT9S exrtuder problem January 25, 2015 07:45AM |

Registered: 9 years ago Posts: 10 |

May be that's a stupid question but I have found that some PTFE tubing is used for hot-end insulation. In my hot-end there is no any PTFE tube, just the steel tube with radiator. Should it have PTFE tube inside? It has inner diameter ~2mm which I believe is not enough to place additional tube inside for 1.75 mm filament. Is it possible that the head is capable to work without PTFE?

|

Re: GT9S exrtuder problem January 25, 2015 03:08PM |

Registered: 9 years ago Posts: 56 |

I don't have such a head myself, but from what I know:

First, you don't need PTFE. This is used in plastic hot ends as far as I remember. Not metal heads.

Second, the fan should cool the upper part of the hotend, so that it's not hot (it's not good for the filament to get hot too early). Only the bottom of the hotend should reach a high temperature, which is where the thermistor is placed (so you get accurate reading). The hotend could get jammed if the filament is melting too early (too far from the nozzle), but also if it doesn't melt properly. You definitely don't want to push any ABS through a hotend that reads 150C. Maybe the fan is not mouted correctly?

Cheers.

First, you don't need PTFE. This is used in plastic hot ends as far as I remember. Not metal heads.

Second, the fan should cool the upper part of the hotend, so that it's not hot (it's not good for the filament to get hot too early). Only the bottom of the hotend should reach a high temperature, which is where the thermistor is placed (so you get accurate reading). The hotend could get jammed if the filament is melting too early (too far from the nozzle), but also if it doesn't melt properly. You definitely don't want to push any ABS through a hotend that reads 150C. Maybe the fan is not mouted correctly?

Cheers.

|

Re: GT9S exrtuder problem January 26, 2015 03:43AM |

Registered: 9 years ago Posts: 10 |

Thanks for the answer!

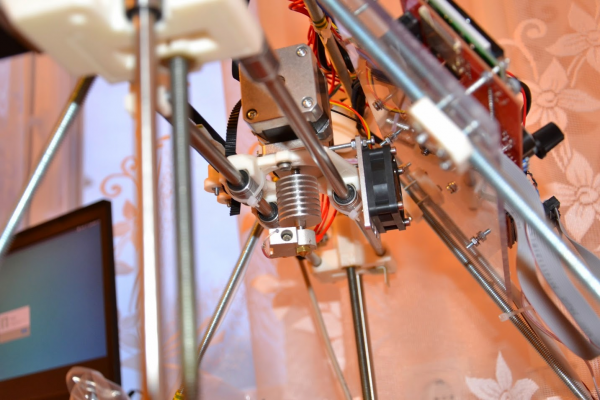

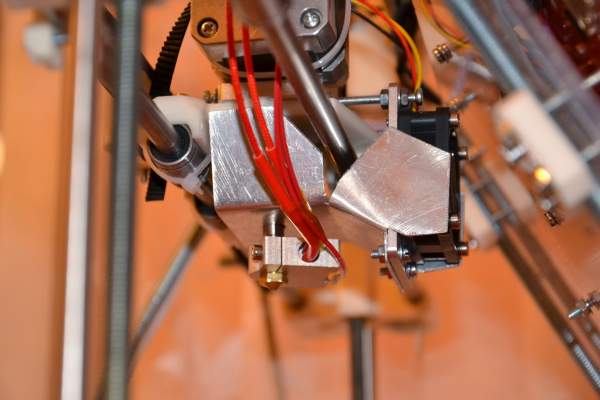

Actually, yes, I have non-original fan mounting. Here are the pictures:

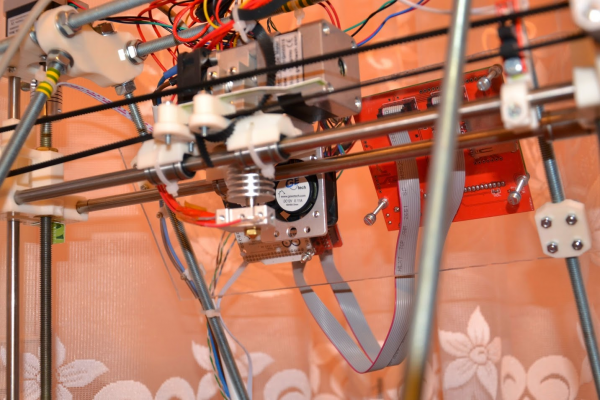

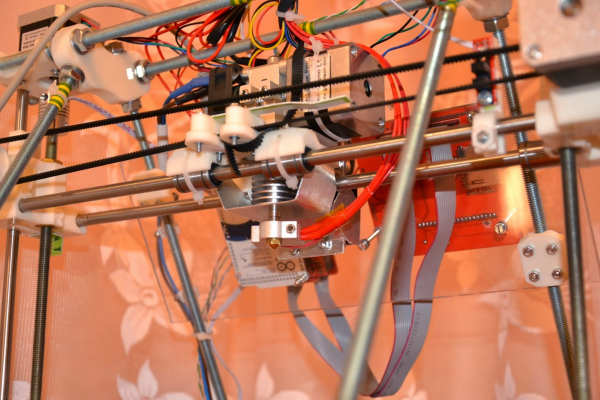

That was initially done because this head in its original assembly does not fit into RepRap carriage design, I was unable to mount it. However there is another problem. After I encountered the problem with the extrusion I also suspected it could be caused by changed fan placement so I unmounted the head, and properly assembled it. Then I tried to test it separately in original assembly. (Like this:

What I found is that even with the lower fan switched off, the head is unable to heat more than 150C because of heat leak through the fan mounting plate. Obviously the power on 12V is not enough to work in such assembly (PSU is able to feed the necessary current). So I am very confused with this head, it seems to be designed non-working, but cost is significant part of the whole printer Or I am doing something completely wrong. I also tried to find some feedback for this head from other users, but nothing found, it looks like I am the first one who tries to use it

Or I am doing something completely wrong. I also tried to find some feedback for this head from other users, but nothing found, it looks like I am the first one who tries to use it

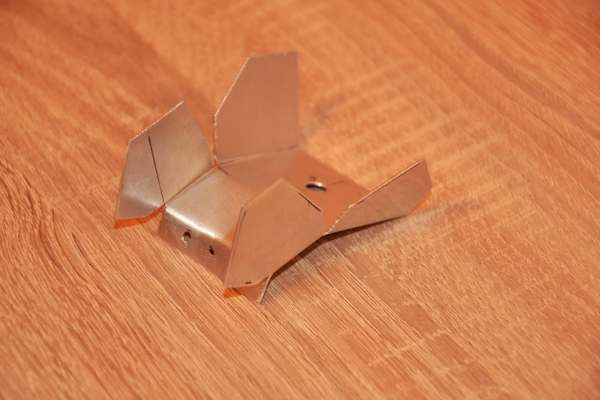

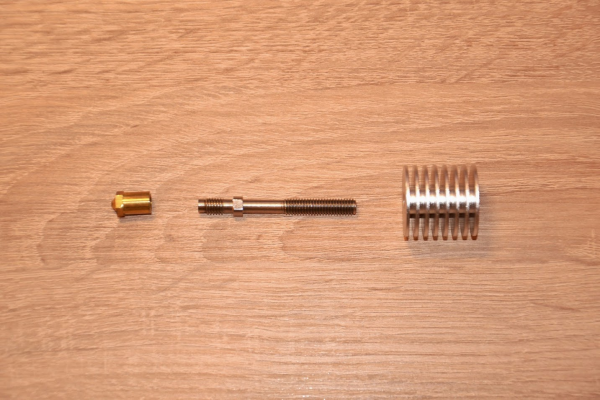

Here is the jammed filament:

Piece of the filament which was near hot end was swelled till 2mm diameter (inner diameter of the steel tube) under the pressure of the extruder. As I understand it is because the steel tube was not cold enough. But as I written before, powering the fan harder prevents from nozzle heating up to necessary temperature. (However I do not fully understand how it should work properly, anyway on some piece of the tube there will be transition from high temperature near nozzle to low temperature). Now I have an idea to make some kind of shield between the tube radiator and the heating block, so that the fan airflow will not cool down the heating block, thus it might be possible to power the fan harder and still maintaining proper nozzle temperature.

Actually, yes, I have non-original fan mounting. Here are the pictures:

That was initially done because this head in its original assembly does not fit into RepRap carriage design, I was unable to mount it. However there is another problem. After I encountered the problem with the extrusion I also suspected it could be caused by changed fan placement so I unmounted the head, and properly assembled it. Then I tried to test it separately in original assembly. (Like this:

What I found is that even with the lower fan switched off, the head is unable to heat more than 150C because of heat leak through the fan mounting plate. Obviously the power on 12V is not enough to work in such assembly (PSU is able to feed the necessary current). So I am very confused with this head, it seems to be designed non-working, but cost is significant part of the whole printer

Or I am doing something completely wrong. I also tried to find some feedback for this head from other users, but nothing found, it looks like I am the first one who tries to use it

Or I am doing something completely wrong. I also tried to find some feedback for this head from other users, but nothing found, it looks like I am the first one who tries to use it

Here is the jammed filament:

Piece of the filament which was near hot end was swelled till 2mm diameter (inner diameter of the steel tube) under the pressure of the extruder. As I understand it is because the steel tube was not cold enough. But as I written before, powering the fan harder prevents from nozzle heating up to necessary temperature. (However I do not fully understand how it should work properly, anyway on some piece of the tube there will be transition from high temperature near nozzle to low temperature). Now I have an idea to make some kind of shield between the tube radiator and the heating block, so that the fan airflow will not cool down the heating block, thus it might be possible to power the fan harder and still maintaining proper nozzle temperature.

|

Re: GT9S exrtuder problem January 26, 2015 04:07AM |

Registered: 9 years ago Posts: 1,011 |

Try to mount the fan on the side, between the two rods, with a paper made temporary duct, and print a proper fan duct

Edited 1 time(s). Last edit at 01/26/2015 04:09AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Edited 1 time(s). Last edit at 01/26/2015 04:09AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: GT9S exrtuder problem January 26, 2015 04:16AM |

Registered: 9 years ago Posts: 10 |

Which side do you mean? Like in the original head design? Then, as I said, the head is unable to heat more than 150C because of heat leak through the fan mounting plate. However, I think, it is possible not to screw the plate to the heating block and insert some heat insulation between the plate and the heating block. But I will firstly try to make a fan duct from metal sheet - it is easier for me because I can leave my current head mounting as is, and also it will be additional radiator area for the tube cooling. I will make a post about the result.

|

Re: GT9S exrtuder problem January 26, 2015 07:54AM |

Registered: 10 years ago Posts: 553 |

Quote

vagran

Which side do you mean? Like in the original head design? Then, as I said, the head is unable to heat more than 150C because of heat leak through the fan mounting plate. However, I think, it is possible not to screw the plate to the heating block and insert some heat insulation between the plate and the heating block. But I will firstly try to make a fan duct from metal sheet - it is easier for me because I can leave my current head mounting as is, and also it will be additional radiator area for the tube cooling. I will make a post about the result.

It appears that you may be able to mount a Lulzbot Budaschnozzle directly to that extruder, you may have to change the way the extruder mounts a bit or you can get a J-Head and mounting plate and use that. An E3D or Hexagon should have no trouble with ABS but I've never seen your hotend before. If you aren't printing Polycarbonate or anything else that requires temperatures above 240C, I would suggest you get a Buda or J-Head. It will make your life much easier and both should be compatible with that extruder, you'll just need the correct parts to attach them.

Please add your printer design to [reprap.org]

|

Re: GT9S exrtuder problem January 26, 2015 08:09AM |

Registered: 9 years ago Posts: 1,011 |

The problem you have is that your heatsink does not recieve enough air cooling. Actualy, your fan is far away from the heatsink, 1/3 blind behind a X rod. That means two things. First, the airflow does not reach enough the heatsink. Second, the airflow cools down the heatblock too much. You need to place the fan between the two X rods or horizontaly, and conduct the airflow to the heatsink only with a fan duct. Do a temporary mount and duct with paper/cardboard and adhesive, then print proper fan mount and fan duct

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: GT9S exrtuder problem January 27, 2015 03:27AM |

Registered: 9 years ago Posts: 10 |

Fixed the problem by creating a shield which covers heating block from the air flow so now the fan can be powered fully and this does not prevent the nozzle from heating. Also it acts as additional radiator. The tube is now cold. No more problems with the extrusion.

The fan is powerful enough so neither increased distance from the radiator nor partial blinding by X-rod nor non-fully enclosed duct prevents it from enough cooling of the tube.

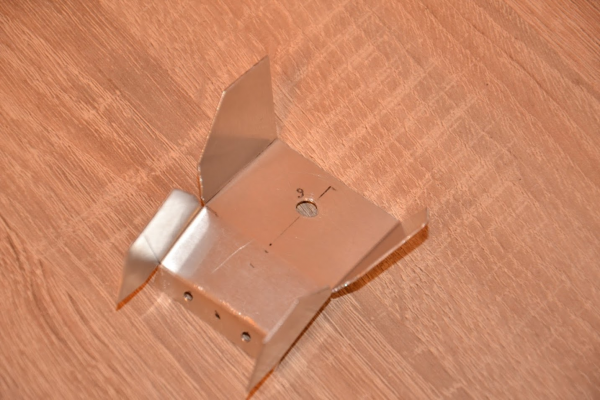

Here are the hot-end parts. Thread is M6.

So be warned that GT9S is not working out-of-the-box. You will need at least to disconnect fan mounting plate from the heating block to eliminate heat leakage and to insulate the heating block from the air flow.

Edited 1 time(s). Last edit at 01/27/2015 03:28AM by vagran.

The fan is powerful enough so neither increased distance from the radiator nor partial blinding by X-rod nor non-fully enclosed duct prevents it from enough cooling of the tube.

Here are the hot-end parts. Thread is M6.

So be warned that GT9S is not working out-of-the-box. You will need at least to disconnect fan mounting plate from the heating block to eliminate heat leakage and to insulate the heating block from the air flow.

Edited 1 time(s). Last edit at 01/27/2015 03:28AM by vagran.

|

Re: GT9S exrtuder problem January 27, 2015 03:39AM |

Registered: 9 years ago Posts: 10 |

It might be useful to add link to this topic in the article on the Wiki about this head: [reprap.org]

I tried but I do not have enough permissions to add external links.

I tried but I do not have enough permissions to add external links.

Sorry, only registered users may post in this forum.