Home

>

Reprappers

>

Topic

Guide rails and other questions

Posted by Embed

|

Guide rails and other questions February 26, 2015 04:34PM |

Registered: 9 years ago Posts: 33 |

Finaly got time to order parts and odered a smoothie and megatronics. So my next step was guide rails and then motors. After looking I see everyone using 8mm rails. I'm planning on using this as double duty, a 3d printer and a cnc machine. The 8mm rods are very small. If I go up to 12mm do you think the mass would be too high to move with nema 17 motors?

I'm also going with a bowden design too whitch will remove some mass.

I should have researched more but didn't have time. I should have got a controller board capable of handling nema 23 steppers instead of nema 17 but too late now.

I'm also going with a bowden design too whitch will remove some mass.

I should have researched more but didn't have time. I should have got a controller board capable of handling nema 23 steppers instead of nema 17 but too late now.

|

Re: Guide rails and other questions February 26, 2015 05:36PM |

Registered: 11 years ago Posts: 335 |

It depends on what you are expecting from the machine, but I have been extremely disapointed every time I use unsupported linear shafts for milling.

Milling and 3d printing are mostly incompatible processes in a single machine. If you use belts you won't have enough rigidity for milling. If you use screws you won't have enough acceleration for printing. Nema17 stepper motors are unlikely to be a limiting component in either case.

Laser and 3d printing are better aligned from a dynamics standpoint, although the working volumes are different.

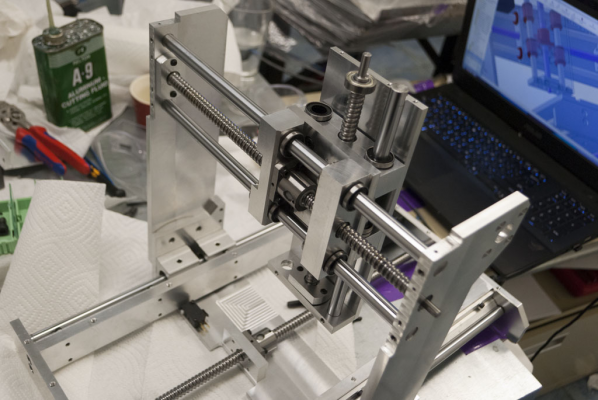

Here is a small router I've built. It looks pretty, but 12mm shafts ruin the machine and flop around like jello.

[imgur.com]

If you really want a hybrid machine you basically need to build a mill (supported rail, ballscrews). A slow 3d printer is just slow, whereas a sloppy milling machine is trash.

Milling and 3d printing are mostly incompatible processes in a single machine. If you use belts you won't have enough rigidity for milling. If you use screws you won't have enough acceleration for printing. Nema17 stepper motors are unlikely to be a limiting component in either case.

Laser and 3d printing are better aligned from a dynamics standpoint, although the working volumes are different.

Here is a small router I've built. It looks pretty, but 12mm shafts ruin the machine and flop around like jello.

[imgur.com]

If you really want a hybrid machine you basically need to build a mill (supported rail, ballscrews). A slow 3d printer is just slow, whereas a sloppy milling machine is trash.

|

Re: Guide rails and other questions February 26, 2015 05:51PM |

Registered: 9 years ago Posts: 33 |

|

Re: Guide rails and other questions February 27, 2015 03:39AM |

Registered: 9 years ago Posts: 1,011 |

There's no think, engineering a machine is all about calculation. If you don't know the formulas, don't design a machine. If you realy want to desing a machine, get some skills. CNC mills and 3D printer are ways different. A mill is a bodybuilder while the 3D printer is fitness. The mill needs mass while 3D printer do not. It can't be good on both application, and compromises will make the machine clumsy for both jobs. They don't work at the same speed. To make a good mill, it will cost you about $1000, and a correct home made 3D printer starts around $300. Building a dual function machine will also cost you much more than two separate machines. No economy here, or you'll get a bad tool. A pure CNC mill will need strong motors, if you add a 3D printer head, you'll need them to be also fast and agile, so it will be more expensive. The sames principle apply on many components. Don't waste that money on a clumsy machine. Otherhand, a CNC Mill produce a lot of dust and chips while a 3D printer needs to stay dust free. To me, one function equals one machine. Maybe start with a proper 3D printer, then save money to build a good CNC mill.Quote

Embed

I'm planning on using this as double duty, a 3d printer and a cnc machine.

If I go up to 12mm do you think the mass would be too high to move with nema 17 motors?

Edited 1 time(s). Last edit at 02/27/2015 03:41AM by Zavashier.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Guide rails and other questions February 27, 2015 10:28AM |

Registered: 11 years ago Posts: 335 |

Quote

Embed

I'm planning on milling only small acrylic and pcb boards, not metal.

The thing about CNC is that even really shitty machines can look okay at first glance. You don't realize just how frustrating they are until you actually use one.

I'd consider a machine like this to be pretty trashy and it uses 16mm rods with very small travels.

[www.ebay.com]

|

Re: Guide rails and other questions February 28, 2015 02:15AM |

Registered: 9 years ago Posts: 483 |

In addition, Nema 17 and Nema 23 are just motor frame sizes. They don't specify the torque or anything else about the motor. Drivers usually are specified by the amount of current they can deliver to the motors. There are quite a few threads on the internet about creating multi-use machines, but I don't think I've seen any that were a resounding success. My CNC router uses 25mm unsupported shafts with a build area of 50cmX50cm and I would say that they are barely adequate.

|

Re: Guide rails and other questions February 28, 2015 07:05AM |

Registered: 11 years ago Posts: 5,780 |

You're kind of building your machine backwards.

Normally you decide what the machine should do, then you figure out the mechanical stuff required to make it do that, finally you select the electronics. I'm not sure why you think you need NEMA-23 motors (why not NEMA-34?) or why you think that a smoothieboard can't drive a NEMA-23 motor (it will drive any size stepper up to 2A).

You have a lot of research to do and a lot to learn. If you don't have time to do it, maybe you should take up some other hobby that doesn't require so much time, effort, or knowledge.

Normally you decide what the machine should do, then you figure out the mechanical stuff required to make it do that, finally you select the electronics. I'm not sure why you think you need NEMA-23 motors (why not NEMA-34?) or why you think that a smoothieboard can't drive a NEMA-23 motor (it will drive any size stepper up to 2A).

You have a lot of research to do and a lot to learn. If you don't have time to do it, maybe you should take up some other hobby that doesn't require so much time, effort, or knowledge.

Sorry, only registered users may post in this forum.