Home

>

Reprappers

>

Topic

Any ideas??

Posted by fatesalign

|

Any ideas?? May 16, 2015 11:10PM |

Registered: 9 years ago Posts: 158 |

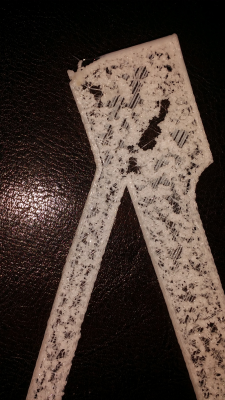

Hello everyone. My printer has been going like a champ for a few weeks now but since I put ABS in it, and even moved back to PLA, everything has been looking like this:

I have no idea why. I thought maybe it could be that the extruder isn't clean, but when I manually extrude it with repetier host, it works fine. I'm just completely lost. I've tried everything I could think of. If anyone has any ideas, please help. The first layer seems to be okay, though sometimes the width of each line varies randomly, but every layer after that is extremely spotty. It's like it works for a mm and then doesn't, works for 2mm and then doesn't Please help if anyone has any ideas. Thank you!

I have no idea why. I thought maybe it could be that the extruder isn't clean, but when I manually extrude it with repetier host, it works fine. I'm just completely lost. I've tried everything I could think of. If anyone has any ideas, please help. The first layer seems to be okay, though sometimes the width of each line varies randomly, but every layer after that is extremely spotty. It's like it works for a mm and then doesn't, works for 2mm and then doesn't Please help if anyone has any ideas. Thank you!

|

Re: Any ideas?? May 17, 2015 02:12AM |

Registered: 9 years ago Posts: 705 |

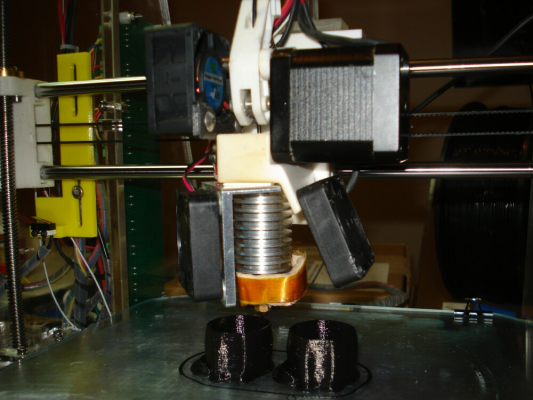

You need more flow. I'm running at 240c but until I mounted a fan where filament enters the extruder and eventually a finned hotend I couldn't raise feed rate because filament was melting above the cool zone causing jams. Since fan install I'm getting 100mm/sec movements with no jams.

|

Re: Any ideas?? May 17, 2015 01:16PM |

Registered: 9 years ago Posts: 158 |

|

Re: Any ideas?? May 17, 2015 02:46PM |

Registered: 9 years ago Posts: 286 |

You may have changed something in your slicer for abs and not switched back to all the same settings for pla.

I use cura and save my configuration for each nozzle size, i regularly swap between 0.5mm and 0.3mm nozzles, each material type, abs, pla, nylon, ninja flex.

Even down to colour if i find much difference in the way the filament behaves.

that way i can quickly load a basic configuration for what im printing and then tweak it.

Gordon

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

I use cura and save my configuration for each nozzle size, i regularly swap between 0.5mm and 0.3mm nozzles, each material type, abs, pla, nylon, ninja flex.

Even down to colour if i find much difference in the way the filament behaves.

that way i can quickly load a basic configuration for what im printing and then tweak it.

Gordon

Gordon

Currently have a tweaked mendel prusa i2

About to build a P3Steel.

[scratchpad.thisandthose.org]

Printer for hire.

[www.3dhubs.com]

Member of South London Makerspace:

[southlondonmakerspace.org]

|

Re: Any ideas?? May 17, 2015 02:46PM |

Registered: 9 years ago Posts: 158 |

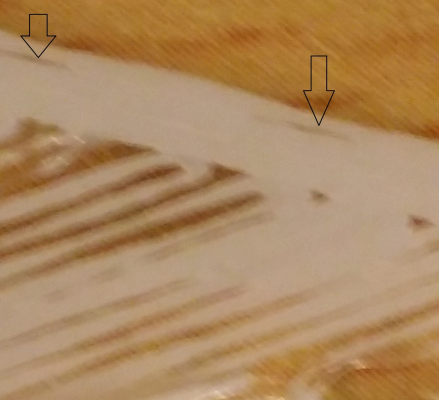

If you look in the image, the problem is that it isn't shooting out the same amount of filament each time. It prints it wide then thin then wide then thin. I know it isn't too fast or anything because it worked perfectly before. I will say that I'm using a Chinese jhead, but I just don't understand.

|

Re: Any ideas?? May 17, 2015 02:47PM |

Registered: 9 years ago Posts: 158 |

|

Re: Any ideas?? May 17, 2015 02:50PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Any ideas?? May 17, 2015 03:29PM |

Registered: 9 years ago Posts: 158 |

|

Re: Any ideas?? May 17, 2015 03:34PM |

Registered: 9 years ago Posts: 158 |

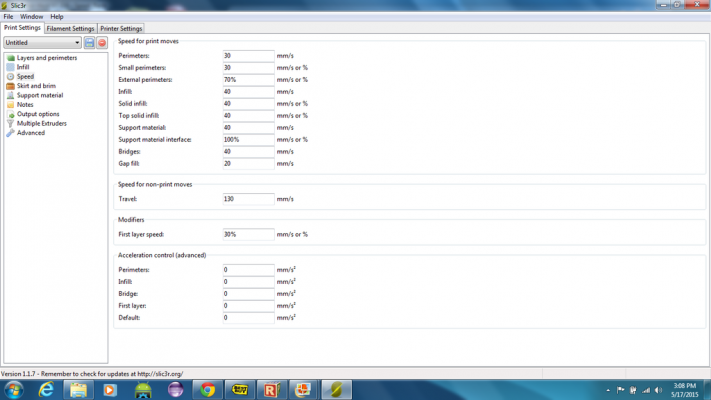

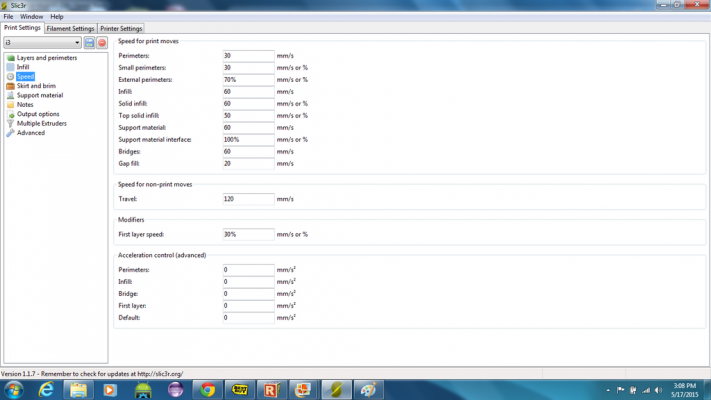

I've tried both these settings:

The second image is my normal settings.

The second image is my normal settings.

|

Re: Any ideas?? May 17, 2015 03:43PM |

Registered: 10 years ago Posts: 14,672 |

So what hot end temperatures have you tried?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Any ideas?? May 17, 2015 03:53PM |

Registered: 9 years ago Posts: 158 |

I'm using what I always did. That's what's so confusing. I was getting perfect prints from PLA. Now I get horrible prints. The temps ive tried are from 200-210. Bed temps are 55 for first layer and 50 for all others. I just don't see how it could be any of that because it used to work so well. I use the glue for adhesion.Quote

dc42

So what hot end temperatures have you tried?

Edited 1 time(s). Last edit at 05/17/2015 03:53PM by fatesalign.

|

Re: Any ideas?? May 17, 2015 04:28PM |

Registered: 9 years ago Posts: 26 |

|

Re: Any ideas?? May 17, 2015 06:59PM |

Registered: 9 years ago Posts: 158 |

|

Re: Any ideas?? May 18, 2015 03:59AM |

Registered: 8 years ago Posts: 5,232 |

Quote

but since I put ABS in it...

There might be a little ABS left in the nozzle coating the outlet, so the actual diameter is smaller now.

Try to heat up the extruder to ABS-temps and manually push some PLA through it to clear the nozzle. Or change the nozzle with a new one.

-Olaf

Edited 2 time(s). Last edit at 05/18/2015 04:02AM by o_lampe.

|

Re: Any ideas?? May 18, 2015 07:43PM |

Registered: 9 years ago Posts: 351 |

Is the hot end holding the setpoint successfully? If the power supply is maxed out running the bed and hot end, some stray air currents on the hot end or lost insulation could cause the hot end to be unable to keep up, allowing the temperature to fall below what can successfully be extruded at the speeds you're using.

Sorry, only registered users may post in this forum.