Home

>

Reprappers

>

Topic

X axis mounts uneven

Posted by elwood127

|

X axis mounts uneven May 17, 2015 01:21AM |

Registered: 9 years ago Posts: 705 |

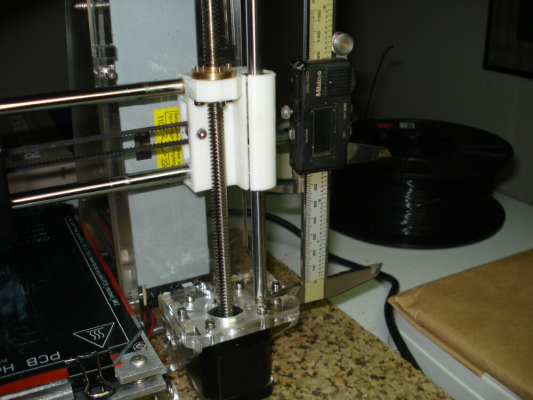

Hey all, I noticed that my build plate springs (right side) were almost completely collapsed compared to the left side springs. I put a mic on the left and right X axis mounts and found a .053 inch difference. Turned the right lead screw by hand until height matched left motor mount. Readjusted leveling screws. Measured from X axis rods to bed and am within .002 now. I think I'm going to make a gauge block that matches the motor mount height at Z home so I can check the right side more easily. If you haven't checked yours lately you may want to. Food for thought.

|

Re: X axis mounts uneven May 17, 2015 11:23AM |

Registered: 11 years ago Posts: 5,780 |

This is the problem with using two motors for the Z axis.

Using two motors does NOT make alignment easier. It does make it easier to throw the alignment off - all you need is for one of the screws to bind or for someone with curious fingers to come along and turn one of the screws.

If one motor doesn't turn with the other, the axis alignment is thrown off. Tilting the bed to compensate only ensures that the first layer will stick- it doesn't fix the axis alignment. Every part printed with a tilted X axis will be skewed. The X axis has to be aligned to the Y and Z axes, not to the bed. The bed is in turn aligned to the XY plane defined by the axes. Autotramming doesn't help - it assumes that the axes are orthogonal. If the axes are not orthogonal, you'll have a hard time doing any precision work with the printer- printed gears will bind, tight fitting lids may not work, etc.

Aligning the axes starts by setting the axes as close as you can (use metal spacers, caliper, electronic protractor, etc.), printing a rectangular solid, and measuring the diagonals in each plane. If the diagonals match, the axes in that plane are at 90 degrees. If not, make adjustments and try again. Don't print a 20mm cube. The errors may be so small that you won't be able to accurately measure them. Print a 100 mm shape. Most digital calipers can measure the diagonals of a 100 mm shape easily and accurately.

Why do they use two motors? Because it is cheaper than using a single motor and a closed loop belt to ensure that the screws are ALWAYS turned in sync. The few $ they shaved out of the price of the machine turned into hours of your effort to align and realign the axes. Was it worth the few $ saved? Only you can decide how much your time is worth.

I used the attached file to align the axes in my printer. I printed with 0.25 mm layers, 2 perimeters, and 20% infill. Before removing it from the bed, use a marker to mark the X and Y axes and left and right sides of the print. Measure the lengths of the sides and the diagonals and enter them into the spreadsheet. It will tell you the amount of error and what to adjust and how much to correct it. You can use it for any two axes in the machine by substitution.

Using two motors does NOT make alignment easier. It does make it easier to throw the alignment off - all you need is for one of the screws to bind or for someone with curious fingers to come along and turn one of the screws.

If one motor doesn't turn with the other, the axis alignment is thrown off. Tilting the bed to compensate only ensures that the first layer will stick- it doesn't fix the axis alignment. Every part printed with a tilted X axis will be skewed. The X axis has to be aligned to the Y and Z axes, not to the bed. The bed is in turn aligned to the XY plane defined by the axes. Autotramming doesn't help - it assumes that the axes are orthogonal. If the axes are not orthogonal, you'll have a hard time doing any precision work with the printer- printed gears will bind, tight fitting lids may not work, etc.

Aligning the axes starts by setting the axes as close as you can (use metal spacers, caliper, electronic protractor, etc.), printing a rectangular solid, and measuring the diagonals in each plane. If the diagonals match, the axes in that plane are at 90 degrees. If not, make adjustments and try again. Don't print a 20mm cube. The errors may be so small that you won't be able to accurately measure them. Print a 100 mm shape. Most digital calipers can measure the diagonals of a 100 mm shape easily and accurately.

Why do they use two motors? Because it is cheaper than using a single motor and a closed loop belt to ensure that the screws are ALWAYS turned in sync. The few $ they shaved out of the price of the machine turned into hours of your effort to align and realign the axes. Was it worth the few $ saved? Only you can decide how much your time is worth.

I used the attached file to align the axes in my printer. I printed with 0.25 mm layers, 2 perimeters, and 20% infill. Before removing it from the bed, use a marker to mark the X and Y axes and left and right sides of the print. Measure the lengths of the sides and the diagonals and enter them into the spreadsheet. It will tell you the amount of error and what to adjust and how much to correct it. You can use it for any two axes in the machine by substitution.

|

Re: X axis mounts uneven May 17, 2015 11:54AM |

Registered: 10 years ago Posts: 14,672 |

I can think of a few reasons why the motors might get out of sync:

1. If you have the acceleration, speed or jerk rates set too high, then the motors may miss steps. If this were happening frequently, you would notice Z axis problems in your prints, and you can solve it by reducing the corresponding settings in the firmware config file.

2. Binding of the Z axis. Should be easy to avoid.

3. Crashing the head into the bed so that the motors have to skip steps - but they won't necessarily skip steps in sync.

4. When the motors are first powered on, they will be energised in a particular phase. If they were energised in the opposite phase (or nearly so) when the printer was last turned off, then they need to jump to the correct phase - and they may jump in opposite directions. This could be avoided by having a "park" gcode command that raises Z to the next position in which the motors are energised in the same phase as when the printer is turned on. The park gcode could be run before turning the machine off, or in the end gcode of the print. Or the park command could be made a standard part of the M0 and M1 commands.

Ideally, the motors would be driven independently by the electronics, and adjusted as part of the bed compensation or Z homing routine. That would remove the need for parking.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. If you have the acceleration, speed or jerk rates set too high, then the motors may miss steps. If this were happening frequently, you would notice Z axis problems in your prints, and you can solve it by reducing the corresponding settings in the firmware config file.

2. Binding of the Z axis. Should be easy to avoid.

3. Crashing the head into the bed so that the motors have to skip steps - but they won't necessarily skip steps in sync.

4. When the motors are first powered on, they will be energised in a particular phase. If they were energised in the opposite phase (or nearly so) when the printer was last turned off, then they need to jump to the correct phase - and they may jump in opposite directions. This could be avoided by having a "park" gcode command that raises Z to the next position in which the motors are energised in the same phase as when the printer is turned on. The park gcode could be run before turning the machine off, or in the end gcode of the print. Or the park command could be made a standard part of the M0 and M1 commands.

Ideally, the motors would be driven independently by the electronics, and adjusted as part of the bed compensation or Z homing routine. That would remove the need for parking.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: X axis mounts uneven May 17, 2015 01:45PM |

Registered: 9 years ago Posts: 705 |

|

Re: X axis mounts uneven May 17, 2015 07:26PM |

Registered: 9 years ago Posts: 705 |

Hey Doc, these are my numbers. Would I change x and y offset in printer settings? Using repetier and cura.

Physical length of X axis (mm): 200.00

Physical length of Y axis (mm): 200.00

X = 101.50 Measured length of test rectangle X (mm):

Y = 100.14 Measured length of test rectangle Y (mm):

Z = 143.30 Measured length of test rectangle long diagonal (mm):

Ideal diagonal length (mm): 142.58

Ɵ : 0.58 Error angle (degrees)

Error angle (mm/m): 10.07

Error in X axis position (mm): 2.01

or

Error in Y axis position (mm): 2.01

Physical length of X axis (mm): 200.00

Physical length of Y axis (mm): 200.00

X = 101.50 Measured length of test rectangle X (mm):

Y = 100.14 Measured length of test rectangle Y (mm):

Z = 143.30 Measured length of test rectangle long diagonal (mm):

Ideal diagonal length (mm): 142.58

Ɵ : 0.58 Error angle (degrees)

Error angle (mm/m): 10.07

Error in X axis position (mm): 2.01

or

Error in Y axis position (mm): 2.01

|

Re: X axis mounts uneven May 17, 2015 08:07PM |

Registered: 11 years ago Posts: 5,780 |

Printing a rectangle shows you how the axes are aligned. If they are not orthogonal, the diagonals won't match. There is nothing you can do in Cura to compensate, though theoretically corrections could be applied in software. Until something like that is incorporated into the slicing software you have to physically adjust the positions of the axes on the machine. When adjusting the X/Y orthogonality, it is usually easier to adjust the position of one end of the Y axis, but it depends on the architecture of your machine and how the axes are attached to the frame. Generally, when adjusting either the XZ or YZ planes it is easier to move the X or Y axis. The Z axis tends to be a part of the frame that makes it hard to adjust.

Now that you understand what it takes to ensure that the axes are orthogonal, you can understand why they should be locked down solidly with no chance of misalignment.

You can use the 100 mm alignment object to calibrate the axes steps/mm, too.

Now that you understand what it takes to ensure that the axes are orthogonal, you can understand why they should be locked down solidly with no chance of misalignment.

You can use the 100 mm alignment object to calibrate the axes steps/mm, too.

|

Re: X axis mounts uneven May 17, 2015 08:38PM |

Registered: 9 years ago Posts: 119 |

On my Z axis screws I have a knob with an arrow on it. After I align my bed I move one knob so both arrows point in the same direction.

I then can at any time the printer is stopped look at the arrows to see that they both point in the same direction, missed steps on one motor will cause the arrows to not align.

I have the seen the same thing on others with a printed pointer on the screw in a position where it is not in the way such as rigth at the motor if your x axis does not come down that low.

By the way a step not allways done is to put a square on the bed and align with the z axis rails prior to aligning x axis parallel to the bed.

I then can at any time the printer is stopped look at the arrows to see that they both point in the same direction, missed steps on one motor will cause the arrows to not align.

I have the seen the same thing on others with a printed pointer on the screw in a position where it is not in the way such as rigth at the motor if your x axis does not come down that low.

By the way a step not allways done is to put a square on the bed and align with the z axis rails prior to aligning x axis parallel to the bed.

|

Re: X axis mounts uneven May 18, 2015 01:00AM |

Registered: 11 years ago Posts: 5,780 |

So you're aligning the bed perpendicular to the Z axis rails (in the X axis) and then aligning the physical X axis parallel to the bed? So next you level in the Y axis which will change the bed's X axis alignment (because the levelers almost always affect both), so you align it back the the physical X axis? In many/most machines the bed has to be releveled frequently for many reasons- it's not a stable reference. The guide rails define the axes of motion, so alignment should be done rail to rail.

The OP noticed a problem with the bed levelers, probably because he kept adjusting the bed level to try to compensate for ever worsening misalignment of the X axis caused by the screws turning out of sync. You may get the bed level enough to print on that way, but prints will be skewed.

The "best" way to ensure the X axis stays in alignment is to use a single motor and a continuous drive belt to drive both screws. My machine has been set up that way from day one, and until a recent rebuild, did not need ANY adjustment for the 2 1/2 years I was printing with it. A single motor and closed loop belt works extremely well.

Edited 1 time(s). Last edit at 05/18/2015 01:04AM by the_digital_dentist.

The OP noticed a problem with the bed levelers, probably because he kept adjusting the bed level to try to compensate for ever worsening misalignment of the X axis caused by the screws turning out of sync. You may get the bed level enough to print on that way, but prints will be skewed.

The "best" way to ensure the X axis stays in alignment is to use a single motor and a continuous drive belt to drive both screws. My machine has been set up that way from day one, and until a recent rebuild, did not need ANY adjustment for the 2 1/2 years I was printing with it. A single motor and closed loop belt works extremely well.

Edited 1 time(s). Last edit at 05/18/2015 01:04AM by the_digital_dentist.

|

Re: X axis mounts uneven May 18, 2015 01:10AM |

Registered: 9 years ago Posts: 705 |

|

Re: X axis mounts uneven May 18, 2015 03:10AM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

Printing a rectangle shows you how the axes are aligned. If they are not orthogonal, the diagonals won't match. There is nothing you can do in Cura to compensate, though theoretically corrections could be applied in software.

It isn't theoretical. RepRapFirmware running on Duet electronics supports orthogonal axis compensation.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: X axis mounts uneven May 18, 2015 07:29AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: X axis mounts uneven May 18, 2015 08:51AM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

That's very interesting! How does it work? What does it use for input?

It works by applying a transform to the commanded XYZ coordinates before moving to them. See [reprappro.com] for the calibration procedure.

Edited 1 time(s). Last edit at 05/18/2015 08:52AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: X axis mounts uneven May 18, 2015 11:39AM |

Registered: 11 years ago Posts: 5,780 |

Interesting, but it assumes that the axes will all be static- i.e. the X axis alignment isn't going to change. If you have a problem like the OPs, where the axis keeps tilting, the compensation won't work unless you keep redoing the test print and measurements.

I think it's still best to align the axes to be orthogonal and lock them down so they can't move- which generally means a single motor to drive as many screws as lift the X axis or the bed. It saves a lot of time and screwing around later.

I think it's still best to align the axes to be orthogonal and lock them down so they can't move- which generally means a single motor to drive as many screws as lift the X axis or the bed. It saves a lot of time and screwing around later.

|

Re: X axis mounts uneven May 18, 2015 12:24PM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

Interesting, but it assumes that the axes will all be static- i.e. the X axis alignment isn't going to change. If you have a problem like the OPs, where the axis keeps tilting, the compensation won't work unless you keep redoing the test print and measurements.

I think it's still best to align the axes to be orthogonal and lock them down so they can't move- which generally means a single motor to drive as many screws as lift the X axis or the bed. It saves a lot of time and screwing around later.

I agree that the bed and X axis should be kept as parallel as possible, even when orthogonal axis compensation is employed. The main benefit of orthogonal axis compensation IMO is to compensate for a Z axis that is not exactly perpendicular to the X axis, or not exactly perpendicular to the Y axis, or when the towers of a delta printer have a slight lean - as long as the misalignment is fixed and doesn't change with time. Even then,it is only needed on tall prints.

Edited 1 time(s). Last edit at 05/18/2015 12:24PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.