|

Multi Material extruder and one motor+servos June 05, 2015 09:41AM |

Registered: 8 years ago Posts: 69 |

Ciao,

I am working on building a very large printer for a project that I am working on which requires multi materials printing, at the moment 4, which means 4 extruders hotends.

I noticed that most of the solutions for the extruders are based on one filament/one motor or 2 filaments/1 motor in some cases but when you want to drive more filaments is one/one filaments/motor.

So I was thinking why not using servos to do the job of selecting the filaments and the motor does the traction ? And I checked that someone already thought about it, of course !!!

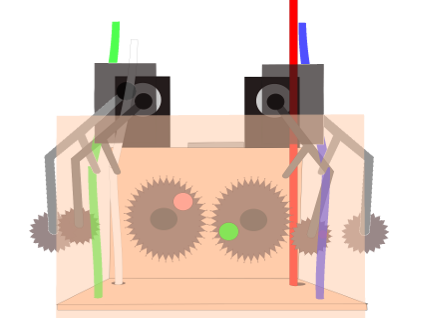

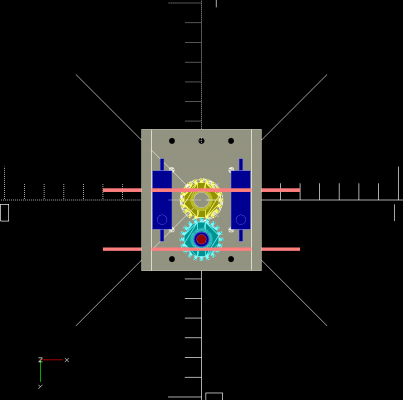

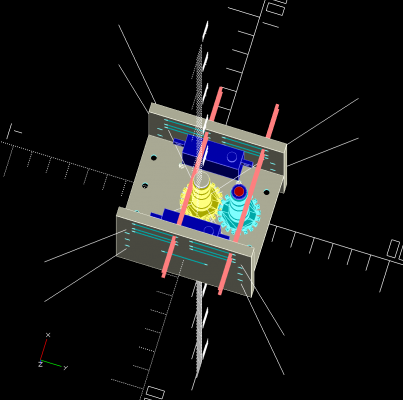

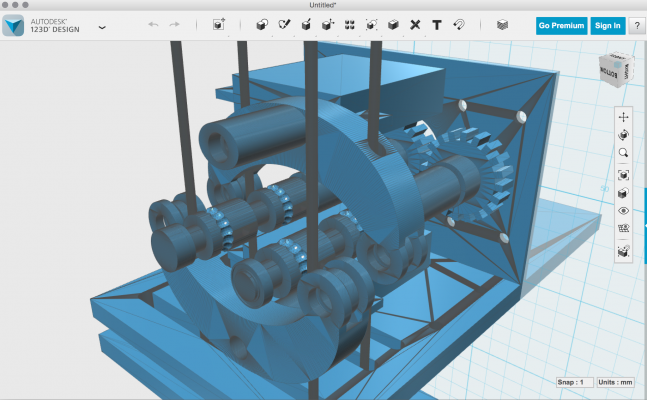

Here is an interesting design that uses one motor and 4 servos.

So wanted to share the idea and see what comes out of it, does it make sense at all?

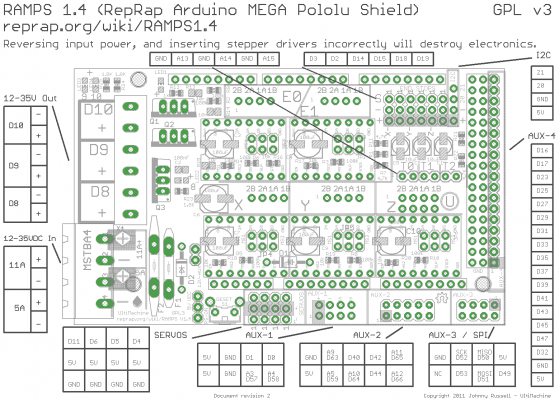

Here is the RAMPS 1.4 servos connection and here is a discussion on how to use them

Thx

Alessandro

Edited 5 time(s). Last edit at 06/05/2015 11:06AM by biskero.

I am working on building a very large printer for a project that I am working on which requires multi materials printing, at the moment 4, which means 4 extruders hotends.

I noticed that most of the solutions for the extruders are based on one filament/one motor or 2 filaments/1 motor in some cases but when you want to drive more filaments is one/one filaments/motor.

So I was thinking why not using servos to do the job of selecting the filaments and the motor does the traction ? And I checked that someone already thought about it, of course !!!

Here is an interesting design that uses one motor and 4 servos.

So wanted to share the idea and see what comes out of it, does it make sense at all?

Here is the RAMPS 1.4 servos connection and here is a discussion on how to use them

Thx

Alessandro

Edited 5 time(s). Last edit at 06/05/2015 11:06AM by biskero.

|

Re: Multi Material extruder and one motor+servos June 05, 2015 10:51AM |

Registered: 8 years ago Posts: 5,232 |

Come over here, we have a lively discussion about several Options to run multiple Filaments with one stepper.

[forums.reprap.org]

-Olaf

[forums.reprap.org]

-Olaf

|

Re: Multi Material extruder and one motor+servos June 05, 2015 02:16PM |

Registered: 9 years ago Posts: 52 |

I have an idea for this too.... but it's a little different, in that it uses solenoids, fishtailed gears, and the direction of movement is the same as the motors shaft, effectively moving the filament like an impeller.

I used each component for a reason.

Solenoids instantly activate and deactivate, which makes the change from one filament to the next more responsive.

Fish tailed gears allow the rotation to be applied without having to involve an additional plane of movement.

The orientation of the motor allows more force to be applied to the filament, and allows the activation and deactivation of the solenoids to compliment the action of the extruder motor.

I don't have a fancy animation, but i have a rudimentary drawing....

I used each component for a reason.

Solenoids instantly activate and deactivate, which makes the change from one filament to the next more responsive.

Fish tailed gears allow the rotation to be applied without having to involve an additional plane of movement.

The orientation of the motor allows more force to be applied to the filament, and allows the activation and deactivation of the solenoids to compliment the action of the extruder motor.

I don't have a fancy animation, but i have a rudimentary drawing....

|

Re: Multi Material extruder and one motor+servos June 05, 2015 02:40PM |

Registered: 8 years ago Posts: 69 |

Ciao,

looks pretty cool!

Btw the images are from the person who had the idea, I just linked them since he has done a good job.

Also your drawing would be a perfect fit for pellet feed instead of filaments which is something in the back of my mind for sometime.

Pellets are much cheaper than filaments since they do not go through the process of creating the filaments!

Alessandro

looks pretty cool!

Btw the images are from the person who had the idea, I just linked them since he has done a good job.

Also your drawing would be a perfect fit for pellet feed instead of filaments which is something in the back of my mind for sometime.

Pellets are much cheaper than filaments since they do not go through the process of creating the filaments!

Alessandro

|

Re: Multi Material extruder and one motor+servos June 06, 2015 02:21AM |

Registered: 9 years ago Posts: 52 |

I think the vertical shaft feed is better in most applications that involve multi-material extrusion simply because each different material requires varying degrees of force and a direct drive from a single extruder motor is going to have to deal with that regardless of filament or pellet status of the plastic used.

As far as pellets go, they are troublesome. They require more weight and vibration to be on the carrage, which can negatively impact print quality. If my only concern is cost, pellets make sense, but, assuming there's a small amount of wiggle room at cost, it makes more sense to process pellets into filament. It allows you to adjust characteristics of the plastic and to develop an idea of how it's going to print. Different additives and mixtures of plastics can greatly effect the properties of a filament, and, I think, if people spent more time formulating their own filament and sharing that info, it'd be better for people overall, but that's for a different thread (I would like to be involved in that discussion though.).

As far as pellets go, they are troublesome. They require more weight and vibration to be on the carrage, which can negatively impact print quality. If my only concern is cost, pellets make sense, but, assuming there's a small amount of wiggle room at cost, it makes more sense to process pellets into filament. It allows you to adjust characteristics of the plastic and to develop an idea of how it's going to print. Different additives and mixtures of plastics can greatly effect the properties of a filament, and, I think, if people spent more time formulating their own filament and sharing that info, it'd be better for people overall, but that's for a different thread (I would like to be involved in that discussion though.).

|

Re: Multi Material extruder and one motor+servos June 07, 2015 05:16AM |

Registered: 8 years ago Posts: 69 |

Ciao,

I am going to use 4 hotends for 4 materials and the software will take care of the motor.

Also from the design there are 4 servos, I am planning for 1 motor and 2 servos since a lever can be designed to have 3 state position, for example:

1st servo will engage material 1, idle and engage material 2

2nd servo will engage material 3, idle and engage material 4

There is a company from kickstarter that launched a 3d printer that uses pellets.

Alessandro

I am going to use 4 hotends for 4 materials and the software will take care of the motor.

Also from the design there are 4 servos, I am planning for 1 motor and 2 servos since a lever can be designed to have 3 state position, for example:

1st servo will engage material 1, idle and engage material 2

2nd servo will engage material 3, idle and engage material 4

There is a company from kickstarter that launched a 3d printer that uses pellets.

Alessandro

|

Re: Multi Material extruder and one motor+servos June 07, 2015 08:06AM |

Registered: 8 years ago Posts: 69 |

|

Re: Multi Material extruder and one motor+servos June 07, 2015 11:53AM |

Registered: 8 years ago Posts: 5,232 |

Nice video, but their design can only deal with 2 filaments. The amount of retraction is more or less a fixed but coincidental value.

The servo idea is much better. Also better than a solenoid. When you build the links well, you can even switch off the servo, because the servo-arm is at it´s dead point where it also has it´s maximum torque.

-Olaf

|

Re: Multi Material extruder and one motor+servos June 08, 2015 07:29PM |

Registered: 10 years ago Posts: 1,401 |

|

Re: Multi Material extruder and one motor+servos June 13, 2015 05:26AM |

Registered: 8 years ago Posts: 69 |

Ciao,

great comments.

Got 2 Turnigy TGY S712G servos at 6/7kg torque depending on voltage applied.

Need to work on a triangular lever to guide filaments without breaking them and functional to move them enough to shift from one to another.

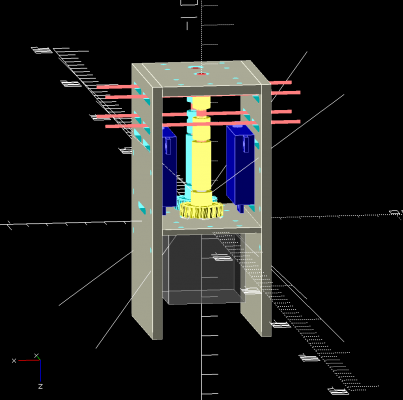

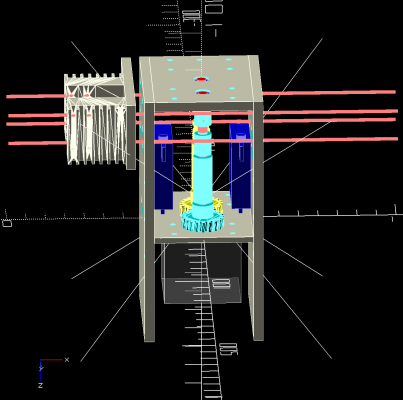

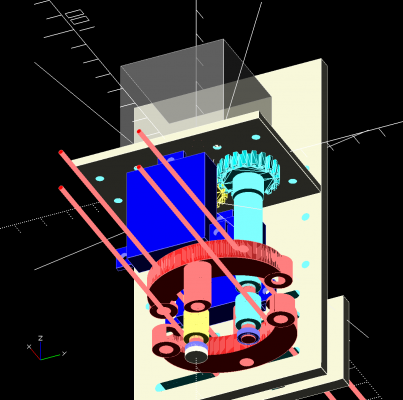

I wanted to share an initial design to have some feedback, have motor mount, 2 shafts with gears, 2 servos.

Now need to work on the lever design. Thinking on triangular shape so that it does not touch the top/bottom of the plates.

What do you think?

Alessandro

Edited 5 time(s). Last edit at 06/13/2015 11:29AM by biskero.

great comments.

Got 2 Turnigy TGY S712G servos at 6/7kg torque depending on voltage applied.

Need to work on a triangular lever to guide filaments without breaking them and functional to move them enough to shift from one to another.

I wanted to share an initial design to have some feedback, have motor mount, 2 shafts with gears, 2 servos.

Now need to work on the lever design. Thinking on triangular shape so that it does not touch the top/bottom of the plates.

What do you think?

Alessandro

Edited 5 time(s). Last edit at 06/13/2015 11:29AM by biskero.

|

Re: Multi Material extruder and one motor+servos June 13, 2015 05:17PM |

Registered: 8 years ago Posts: 69 |

Ciao,

just finished the lever design, changed a bit the idea

The bearing inside the lever arm edge is pretty small: internal diameter 5mm x external diameter 8mm x height 2.5mm, on the shaft are blue color.

One question that I have on this design is the bearings at the end of the lever can be on different plane of the MK8 ?

Currently they are a bit higher so that when the servo moves the bearing gets closer to the filament.

My guess is the I will know if the design fits when I will be able to print the parts.

Alessandro

Edited 3 time(s). Last edit at 06/13/2015 05:51PM by biskero.

just finished the lever design, changed a bit the idea

The bearing inside the lever arm edge is pretty small: internal diameter 5mm x external diameter 8mm x height 2.5mm, on the shaft are blue color.

One question that I have on this design is the bearings at the end of the lever can be on different plane of the MK8 ?

Currently they are a bit higher so that when the servo moves the bearing gets closer to the filament.

My guess is the I will know if the design fits when I will be able to print the parts.

Alessandro

Edited 3 time(s). Last edit at 06/13/2015 05:51PM by biskero.

|

Re: Multi Material extruder and one motor+servos June 14, 2015 03:41AM |

Registered: 8 years ago Posts: 5,232 |

IMHO it´s a very bad kinematic setup. You´ll kill the servos with this levers

You should use a pull/pull mechanic which compresses springs to press the lever against the hobbed bolt.

The servoarm should be in his dead-point when the filament is pressed against the gear. You could even switch off the servo then .

I sketched two Versions on a napkin .

The pull/pull version should press the filament to the gear at the servo-deadpoint, too. ( sketch is partly wrong , but I was too lazy to start another )

)

-Olaf

Edited 1 time(s). Last edit at 06/14/2015 04:04AM by o_lampe.

You should use a pull/pull mechanic which compresses springs to press the lever against the hobbed bolt.

The servoarm should be in his dead-point when the filament is pressed against the gear. You could even switch off the servo then .

I sketched two Versions on a napkin .

The pull/pull version should press the filament to the gear at the servo-deadpoint, too. ( sketch is partly wrong , but I was too lazy to start another

)

)-Olaf

Edited 1 time(s). Last edit at 06/14/2015 04:04AM by o_lampe.

|

Re: Multi Material extruder and one motor+servos June 14, 2015 04:20AM |

Registered: 8 years ago Posts: 69 |

Ciao,

thanks for the good feedback, very interesting design.

I though about the springs but wanted to use less pieces as possible.

But the servos do not have any force that goes against the lever beside moving the filament position closer to the MK8.

Also these servos have 6/7kg torque and the force to keep the filament in its engaged position, pressed between the bearing and MK8, is not that big.

These lever are pretty small, 50 mm wide, 5mm thick.

Also there are 4 positions for the servos:

1 - Servo1 engaged with left MK8, Servo2 neutral

2 - Servo1 engaged with right MK8, Servo2 neutral

3 - Servo2 engaged with left MK8, Servo1 neutral

4 - Servo2 engaged with right MK8, Servo1 neutral

So at any time there is only one lever to filament and MK8 engagement. There might be a OFF position with both Servo1 and Servo2 in neutral to position the filaments but that will be in the code.

In any case I need to experiment, maybe you are right.

Alessandro

Edited 1 time(s). Last edit at 06/14/2015 05:22AM by biskero.

thanks for the good feedback, very interesting design.

I though about the springs but wanted to use less pieces as possible.

But the servos do not have any force that goes against the lever beside moving the filament position closer to the MK8.

Also these servos have 6/7kg torque and the force to keep the filament in its engaged position, pressed between the bearing and MK8, is not that big.

These lever are pretty small, 50 mm wide, 5mm thick.

Also there are 4 positions for the servos:

1 - Servo1 engaged with left MK8, Servo2 neutral

2 - Servo1 engaged with right MK8, Servo2 neutral

3 - Servo2 engaged with left MK8, Servo1 neutral

4 - Servo2 engaged with right MK8, Servo1 neutral

So at any time there is only one lever to filament and MK8 engagement. There might be a OFF position with both Servo1 and Servo2 in neutral to position the filaments but that will be in the code.

In any case I need to experiment, maybe you are right.

Alessandro

Edited 1 time(s). Last edit at 06/14/2015 05:22AM by biskero.

|

Re: Multi Material extruder and one motor+servos June 14, 2015 05:22AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Multi Material extruder and one motor+servos June 14, 2015 05:31AM |

Registered: 8 years ago Posts: 69 |

Ciao,

I edit the previous comment with more details.

I understand what you mean but that's just to be defined in the code. It can be either way.

For me the dead-point is the neutral where no engagement is on, on both servos.

For example when you setup the filaments.

Your comment "You´ll kill the servos with this levers" make me think of the case where you switch frequently between filaments.

For my project I will not so at the moment I am ok with it, but might be a critical point to look at.

Alessandro

I edit the previous comment with more details.

I understand what you mean but that's just to be defined in the code. It can be either way.

For me the dead-point is the neutral where no engagement is on, on both servos.

For example when you setup the filaments.

Your comment "You´ll kill the servos with this levers" make me think of the case where you switch frequently between filaments.

For my project I will not so at the moment I am ok with it, but might be a critical point to look at.

Alessandro

|

Re: Multi Material extruder and one motor+servos June 14, 2015 08:34AM |

Registered: 8 years ago Posts: 5,232 |

The servo gets killed by asking constant holding force not by switching between filaments.

The deadpoint-method is the only way to make a toy-servo stand the extended duty of a 3D print. Because the holding force is lead into the output gear instead of the motor

RC-stuff usually only has 10-20min drivetime until the batteries are empty. That short duration is where the servo specification ( 6-7kg) is valid, not 24/7...

I respect it, if you want to make your own experience

-Olaf

The deadpoint-method is the only way to make a toy-servo stand the extended duty of a 3D print. Because the holding force is lead into the output gear instead of the motor

RC-stuff usually only has 10-20min drivetime until the batteries are empty. That short duration is where the servo specification ( 6-7kg) is valid, not 24/7...

I respect it, if you want to make your own experience

-Olaf

|

Re: Multi Material extruder and one motor+servos June 14, 2015 09:17AM |

Registered: 8 years ago Posts: 69 |

Ciao,

I understand your points.

I had servos holding weights for long time (robotics) and never had issues. Different servos (very high torque) from the one I plan to use so it depends from the quality of the servos.

I had issues with servos switching from one position to another many times for long time and usually is due to poor quality gears.

About the deadpoint at one time only one servo could be in that position so the issue would remain for the other servo.

Also is much more efficient from my point of view to have symmetry between the servo position and the code to manage the servos.

Let's see how it goes and thanks for the great feedback.

Alessandro

I understand your points.

I had servos holding weights for long time (robotics) and never had issues. Different servos (very high torque) from the one I plan to use so it depends from the quality of the servos.

I had issues with servos switching from one position to another many times for long time and usually is due to poor quality gears.

About the deadpoint at one time only one servo could be in that position so the issue would remain for the other servo.

Also is much more efficient from my point of view to have symmetry between the servo position and the code to manage the servos.

Let's see how it goes and thanks for the great feedback.

Alessandro

|

Re: Multi Material extruder and one motor+servos June 15, 2015 08:32AM |

Registered: 8 years ago Posts: 69 |

|

Re: Multi Material extruder and one motor+servos June 15, 2015 08:42PM |

Registered: 10 years ago Posts: 1,401 |

Alessandro,

Your biggest enemy with that setup is "glitches" if any electrical noise gets in the servo you will face failed prints. Take a look at several ABL videos and pay close attention to how much the servos glitches while in operation.

You need to plan ahead in regards of power supply, filtering and shielding (reason why I'm going with solenoids).

You might be able to use digital servos? That will take care of that problem.

Good luck with the project and keep us posted.

Edited 1 time(s). Last edit at 06/15/2015 08:47PM by ggherbaz.

Your biggest enemy with that setup is "glitches" if any electrical noise gets in the servo you will face failed prints. Take a look at several ABL videos and pay close attention to how much the servos glitches while in operation.

You need to plan ahead in regards of power supply, filtering and shielding (reason why I'm going with solenoids).

You might be able to use digital servos? That will take care of that problem.

Good luck with the project and keep us posted.

Edited 1 time(s). Last edit at 06/15/2015 08:47PM by ggherbaz.

|

Re: Multi Material extruder and one motor+servos June 16, 2015 12:16PM |

Registered: 8 years ago Posts: 69 |

Ciao,

I was just looking at these issues and also some load testing.

The servos that I got are digital but as you and Olaf point it out, these kind of servos can have problems due to the fact that are "toy" servos.

Maybe robotic servos can be more precise but did not find any yet of those small dimensions.

I am planning to do more testing as soon as I have all the pieces.

BTW will keep following your extruder too as is very promising !

Thanks

Alessandro

I was just looking at these issues and also some load testing.

The servos that I got are digital but as you and Olaf point it out, these kind of servos can have problems due to the fact that are "toy" servos.

Maybe robotic servos can be more precise but did not find any yet of those small dimensions.

I am planning to do more testing as soon as I have all the pieces.

BTW will keep following your extruder too as is very promising !

Thanks

Alessandro

|

Re: Multi Material extruder and one motor+servos July 27, 2015 02:20PM |

Registered: 8 years ago Posts: 69 |

Ciao,

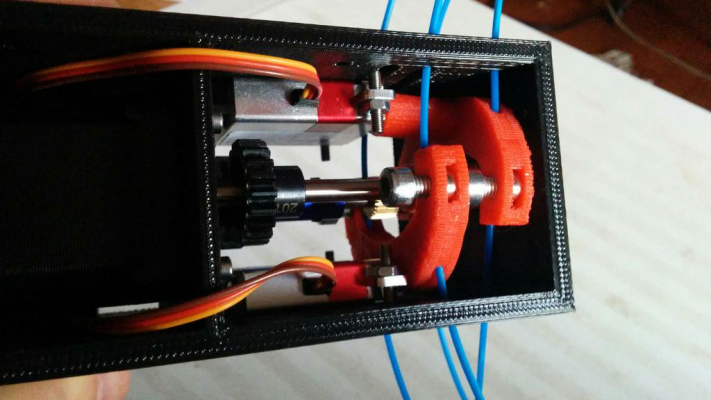

just wanted to give an update on the extruder project, here is a picture

An improvement to make is to split the structure in 2 since to screw the motor has been a challenge!!

The extension shaft for the motor and the left shaft are 5mm and are hold by very small bearings.

Tomorrow will add the servos and levers, waiting for very small and long screw for the servo.

Already tested the servos with RAMPS and some G-code custom command and everything works fine.

Need to work on some custom script to shift from one servo to another on extruding different materials.

Got help from Slic3r devs.

Alessandro

Edited 1 time(s). Last edit at 07/27/2015 02:23PM by biskero.

just wanted to give an update on the extruder project, here is a picture

An improvement to make is to split the structure in 2 since to screw the motor has been a challenge!!

The extension shaft for the motor and the left shaft are 5mm and are hold by very small bearings.

Tomorrow will add the servos and levers, waiting for very small and long screw for the servo.

Already tested the servos with RAMPS and some G-code custom command and everything works fine.

Need to work on some custom script to shift from one servo to another on extruding different materials.

Got help from Slic3r devs.

Alessandro

Edited 1 time(s). Last edit at 07/27/2015 02:23PM by biskero.

|

Re: Multi Material extruder and one motor+servos September 03, 2015 01:13PM |

Registered: 8 years ago Posts: 69 |

Ciao,

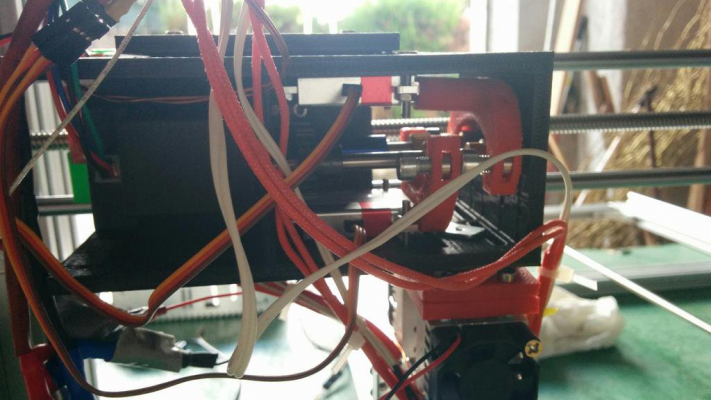

I completed the Extruder and it's working fine on first tests, so it's holding fine and pull up and down the filament with no problem.

Now I am facing an issue that ggherbaz mentioned. Basically everything works fine if the extruder is not moving.

If I move the extruder in the x direction, the servos starts to jerk left and right.

It's strange since if it was interference from the motor or other wiring, I would expect it even when I am not moving the extruder in x direction.

Instead the issue appears only when I move it, not when I extrude in a still position.

Here are couple of pics:

From the pic above, if I move left and right in the x direction (without extruding), the servos starts to move.

Any suggestions?

Alessandro

Edited 1 time(s). Last edit at 09/03/2015 01:15PM by biskero.

I completed the Extruder and it's working fine on first tests, so it's holding fine and pull up and down the filament with no problem.

Now I am facing an issue that ggherbaz mentioned. Basically everything works fine if the extruder is not moving.

If I move the extruder in the x direction, the servos starts to jerk left and right.

It's strange since if it was interference from the motor or other wiring, I would expect it even when I am not moving the extruder in x direction.

Instead the issue appears only when I move it, not when I extrude in a still position.

Here are couple of pics:

From the pic above, if I move left and right in the x direction (without extruding), the servos starts to move.

Any suggestions?

Alessandro

Edited 1 time(s). Last edit at 09/03/2015 01:15PM by biskero.

|

Re: Multi Material extruder and one motor+servos September 04, 2015 03:30AM |

Registered: 8 years ago Posts: 5,232 |

If it´s not the extruder motor making noise but the x-stepper, than the problem is probably on the Ramps or arduino board.

Maybe the servo-signal path is too close to the x-stepper pins.

Or the firmware has design flaws to sync step and PWM signals. ( different interrupt or register )

Can you try different servo pins or reassign them?

-Olaf

Maybe the servo-signal path is too close to the x-stepper pins.

Or the firmware has design flaws to sync step and PWM signals. ( different interrupt or register )

Can you try different servo pins or reassign them?

-Olaf

|

Re: Multi Material extruder and one motor+servos September 04, 2015 04:44AM |

Registered: 8 years ago Posts: 69 |

Ciao,

I am using the first 2 pins on the servo pin on the RAMPS, right above is the X stepper driver.

So it might be that as you mention, I can try to reassign the pins but all the pins are very close to the drivers on the RAMPS.

About the firmware I am using Kimbra-Marlin as the developer helped me with my 1 motor 3/4 extruder configuration.

Will check the code.

Thanks

Alessandro

Edited 1 time(s). Last edit at 09/04/2015 04:45AM by biskero.

I am using the first 2 pins on the servo pin on the RAMPS, right above is the X stepper driver.

So it might be that as you mention, I can try to reassign the pins but all the pins are very close to the drivers on the RAMPS.

About the firmware I am using Kimbra-Marlin as the developer helped me with my 1 motor 3/4 extruder configuration.

Will check the code.

Thanks

Alessandro

Edited 1 time(s). Last edit at 09/04/2015 04:45AM by biskero.

|

Re: Multi Material extruder and one motor+servos September 04, 2015 04:50AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Multi Material extruder and one motor+servos September 04, 2015 11:24AM |

Registered: 8 years ago Posts: 69 |

|

Re: Multi Material extruder and one motor+servos September 04, 2015 12:47PM |

Registered: 8 years ago Posts: 69 |

|

Re: Multi Material extruder and one motor+servos September 04, 2015 10:45PM |

Registered: 10 years ago Posts: 466 |

|

Re: Multi Material extruder and one motor+servos September 05, 2015 02:45AM |

Registered: 8 years ago Posts: 5,232 |

Sorry, only registered users may post in this forum.