Home

>

Reprappers

>

Topic

Riddle me this.

Posted by elwood127

|

Riddle me this. June 08, 2015 06:20PM |

Registered: 9 years ago Posts: 705 |

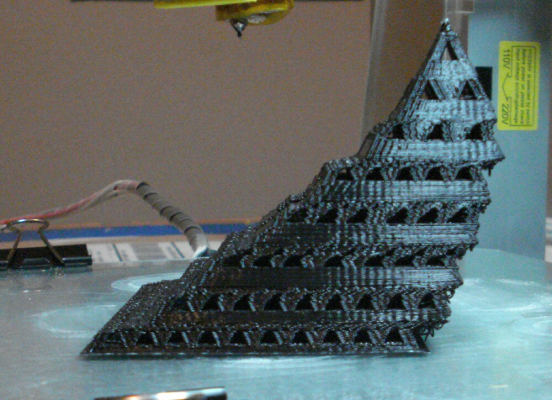

Noticed some shifting going on lately so I made sure glass wasn't moving and marked my Y pulley and belt with a felt tip to check for belt slippage after installing a new y tensioner. Ran this last night. Belt and pulley marks are exactly where they were before printing. Not quite a pyramid. Can software be slicing weird. Using Cura and Repetier.

|

Re: Riddle me this. June 08, 2015 06:41PM |

Registered: 9 years ago Posts: 606 |

It's not the belt slipping on the pulley that you need to worry about, it's a motor skipping steps, which appears to be the case here. Make certain that the wonky axis moves freely, verify that the driver voltage is set correctly, and if both of those are OK and the motor on that axis is not too hot, consider upping the drive voltage on that axis.

- Tim

Edited 1 time(s). Last edit at 06/08/2015 06:41PM by tadawson.

- Tim

Edited 1 time(s). Last edit at 06/08/2015 06:41PM by tadawson.

|

Re: Riddle me this. June 08, 2015 06:53PM |

Registered: 9 years ago Posts: 705 |

|

Re: Riddle me this. June 08, 2015 06:54PM |

Registered: 9 years ago Posts: 705 |

|

Re: Riddle me this. June 08, 2015 08:20PM |

Registered: 10 years ago Posts: 770 |

|

Re: Riddle me this. June 08, 2015 11:21PM |

Registered: 9 years ago Posts: 705 |

For what it's worth, I'm reprinting it using Slic3r right now and it's perfect so far. What up with that?

|

Re: Riddle me this. June 08, 2015 11:24PM |

Registered: 9 years ago Posts: 606 |

Different speed, such that it does not stress the motor to the point of skipping?

You can look at the gcode for a given layer, and see if the two files are going to the same X/Y position to be certain, but first I would compare the speed settings between the two slicers, especially the nom-print moves, which tend to be the fastest with the highest accelerations.

- Tim

You can look at the gcode for a given layer, and see if the two files are going to the same X/Y position to be certain, but first I would compare the speed settings between the two slicers, especially the nom-print moves, which tend to be the fastest with the highest accelerations.

- Tim

|

Re: Riddle me this. June 09, 2015 03:26AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Riddle me this. June 09, 2015 07:10PM |

Registered: 9 years ago Posts: 705 |

I did as not to put added stress on the Y motor. Print finished perfect. Just a note on Cura slicing, When I started the bad print it was half off the build plate. Killed print, resliced and got it to start in the center but print was scewed. Slic3r took about and hour more but printed correctly. Guess I'll stick with Slic3r.

|

Re: Riddle me this. June 10, 2015 03:31AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Riddle me this. June 10, 2015 06:22PM |

Registered: 9 years ago Posts: 705 |

|

Re: Riddle me this. June 10, 2015 07:08PM |

Registered: 9 years ago Posts: 705 |

|

Re: Riddle me this. June 10, 2015 07:15PM |

Registered: 9 years ago Posts: 705 |

Sorry, I just answered my own question. Am printing a test cube at 25.4 x 25.4 x 25.4mm since Cura won't read inch parts. I neede to be dragged into the 21st century kicking and screaming. Thank God for calipers that switch between the two. Seems to be printing fine. Will have to retry the pyramid and see what happens.

|

Re: Riddle me this. June 11, 2015 03:04AM |

Registered: 8 years ago Posts: 5,232 |

Quote

elwood127

Ok, I've been using Cura strictly within Repetier. Opening Cura seperately offers much more setup data. Can I just slice in Cura and export the Gcode and bring it into Repetier? Thanks.

Cura has an expert section, which has even more options. ( like my fav "black magic")

The only annoying thing about Cura is, it starts slicing as soon as the first part is on the table. When you change values, it starts over and over again.

So you better make your settings before you place a part.

You can write the g-code from Cura on SD-Card, when you right-click the middle symbol of the three symbols ontop of the 3D-view

-Olaf

Edited 1 time(s). Last edit at 06/11/2015 03:07AM by o_lampe.

|

Re: Riddle me this. June 11, 2015 06:31PM |

Registered: 9 years ago Posts: 705 |

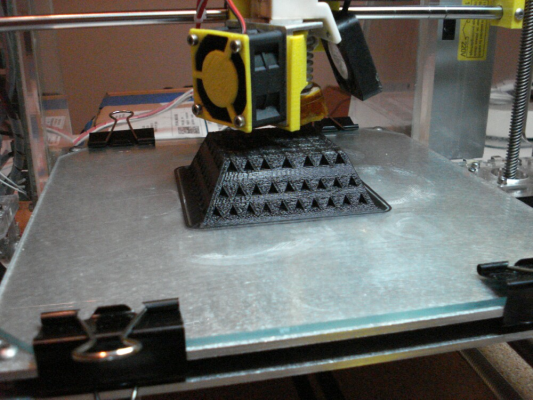

Hey Olaf, I was able to do just that. Took a minute to figure out that it was automatically slicing. Nice thing is the tutorials that come up when holding your mouse over a setting. Very informative. Nice also to see the instant reslice when changing settings and seeing the time difference per setting change. I reprinted the pyramid from Cura gcode imported to Repetier and got a much smoother and pointier pyramid. Very happy. Thanks guys.

|

Re: Riddle me this. June 11, 2015 11:04PM |

Registered: 9 years ago Posts: 705 |

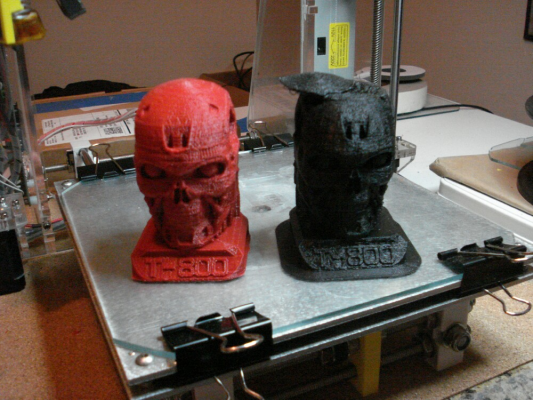

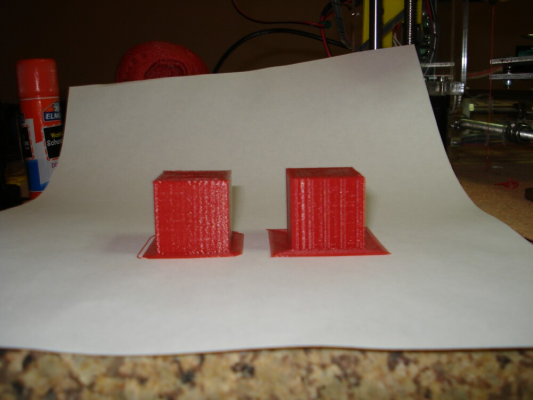

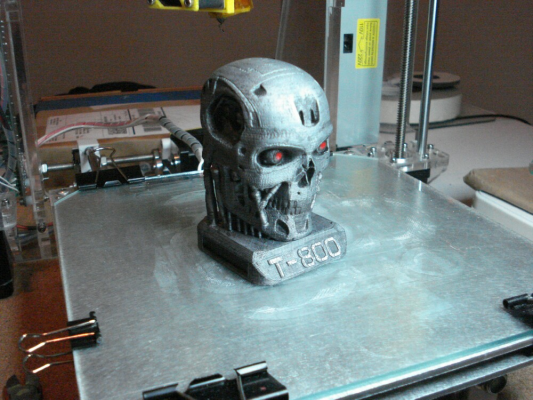

Well. after getting a nice print of the pyramid with Cura I decided to use it to create the Terminator skull to compare with the one I had done using Slic3r. Red is the Slic3r print. I'm totally confused now. Granted the settings are faster in Cura so I'll try it again matching my Slic3r settings and report back.

|

Re: Riddle me this. June 11, 2015 11:15PM |

Registered: 9 years ago Posts: 705 |

|

Re: Riddle me this. June 11, 2015 11:38PM |

Registered: 10 years ago Posts: 814 |

|

Re: Riddle me this. June 12, 2015 12:18AM |

Registered: 9 years ago Posts: 396 |

|

Re: Riddle me this. June 12, 2015 12:44AM |

Registered: 9 years ago Posts: 705 |

.24 layer height. .4 nozzle. Here is the resliced and printed Cura next to the Slic3r print. I killed it because it had shifted an inch already. What the hell?

|

Re: Riddle me this. June 12, 2015 01:45AM |

Registered: 8 years ago Posts: 5,232 |

The black skull sure got chopped from a nozzle driving into the previous layers. Try reducing the fill-rate or e-steps. It´s soo frustating to have a 99% finished print going wrong.

Looks like you have a binding axis.

Still too much tension on the belts or not enough current to the steppers? Or a bad linear bearing grinding into the smooth rod?

What´s the temp of the steppers? Can you still touch them after a longer print? Then they are ready to take more current.

It is not only the speed, that is important but also acceleration causes skipped steps.

For x&y, I reduced the acceleration from 9000 to 6000.

In your case ( with the lead screws ), it would be good to lower z-speed and z-acceleration as well.

-Olaf

Edited 1 time(s). Last edit at 06/12/2015 01:53AM by o_lampe.

Looks like you have a binding axis.

Still too much tension on the belts or not enough current to the steppers? Or a bad linear bearing grinding into the smooth rod?

What´s the temp of the steppers? Can you still touch them after a longer print? Then they are ready to take more current.

It is not only the speed, that is important but also acceleration causes skipped steps.

For x&y, I reduced the acceleration from 9000 to 6000.

In your case ( with the lead screws ), it would be good to lower z-speed and z-acceleration as well.

-Olaf

Edited 1 time(s). Last edit at 06/12/2015 01:53AM by o_lampe.

|

Re: Riddle me this. June 12, 2015 08:25AM |

Registered: 8 years ago Posts: 5,232 |

I just had a similar failure like your black skull accident.

The z-axis stopped moving, although everything was cold ( steppers and driver )

The printer moved on printing, but started rubbing against the layers, so I got alarmed and stopped the print.

Reason:

I have set the max height of my printarea to 150mm in Marlin, but 200mm ( Default ) in Cura.

So the slicer wasn´t aware of the limited z-height and Marlin refused to raise z higher than 150mm

Lucky it was just a testprint. The real print with 0.2 nozzle and 0.1 layer would´t have taken 34h....

-Olaf

Edited 1 time(s). Last edit at 06/12/2015 08:27AM by o_lampe.

The z-axis stopped moving, although everything was cold ( steppers and driver )

The printer moved on printing, but started rubbing against the layers, so I got alarmed and stopped the print.

Reason:

I have set the max height of my printarea to 150mm in Marlin, but 200mm ( Default ) in Cura.

So the slicer wasn´t aware of the limited z-height and Marlin refused to raise z higher than 150mm

Lucky it was just a testprint. The real print with 0.2 nozzle and 0.1 layer would´t have taken 34h....

-Olaf

Edited 1 time(s). Last edit at 06/12/2015 08:27AM by o_lampe.

|

Re: Riddle me this. June 12, 2015 06:40PM |

Registered: 9 years ago Posts: 705 |

|

Re: Riddle me this. June 12, 2015 06:49PM |

Registered: 9 years ago Posts: 705 |

|

Re: Riddle me this. June 12, 2015 10:46PM |

Registered: 9 years ago Posts: 705 |

I ran a test cube and cylinder each using Slic3r and Cura. Settings as close as posible given their differences. The left cylinder is Slic3r @ 21 minutes, the right is Cura @ 10 minutes. As you can see the left is smoother, the right misaligned on the last layer in the Y axis and is much rougher.

The left cube is Slic3r @60 minutes, the right is Cura @ 13 minutes. The left is smoother with soft corners, the right is rougher but has crisp corners.

One interesting note, the terminators first misalignment ( using Cura) is at 1 inch up, exactly where the cylinders misalignment took place yet nothing on the cube.

I'm not sure what to make of all this data. Atleast it's confimed that slower printing yields better finishes. As far as the time differences using similar settings, I'm not sure.

You all may want to do some tests and see what you get.

The left cube is Slic3r @60 minutes, the right is Cura @ 13 minutes. The left is smoother with soft corners, the right is rougher but has crisp corners.

One interesting note, the terminators first misalignment ( using Cura) is at 1 inch up, exactly where the cylinders misalignment took place yet nothing on the cube.

I'm not sure what to make of all this data. Atleast it's confimed that slower printing yields better finishes. As far as the time differences using similar settings, I'm not sure.

You all may want to do some tests and see what you get.

|

Re: Riddle me this. June 13, 2015 12:46AM |

Registered: 9 years ago Posts: 705 |

I went back into Cura and drop to 60mm/sec from 80mm speed with no noticable change. Finally got down to 30mm/sec to mimmick Slic3r movements. (Left) is the Slic3r cube @ 80mm/sec (Center) is Cura @ 30mm/sec and (Right) is Cura @ 80mm/sec.

At 30 Cura is almost as smooth as Slic3r. How can these 2 programs be so different regarding speed settings? Last time I checked 30 is not 80. Maybe one of you brainiacs can ask whoever knows these things. Am reprinting Arnold at slower settings to see what happens.

Edited 1 time(s). Last edit at 06/13/2015 06:16PM by elwood127.

Edited 1 time(s). Last edit at 06/13/2015 06:16PM by elwood127.

|

Re: Riddle me this. June 13, 2015 02:36AM |

Registered: 8 years ago Posts: 5,232 |

Cura has been set to higher default speeds for the ultimaker 2.

Slic3r has a more conservative default setting.

Both will print ugly at high speed and both do good at normal speed on your average prusa i3 clone.

-Olaf

I´d check the smooth rods and leadscrews at 1 inch height, if the run free

Slic3r has a more conservative default setting.

Both will print ugly at high speed and both do good at normal speed on your average prusa i3 clone.

-Olaf

I´d check the smooth rods and leadscrews at 1 inch height, if the run free

|

Re: Riddle me this. June 13, 2015 06:22PM |

Registered: 9 years ago Posts: 705 |

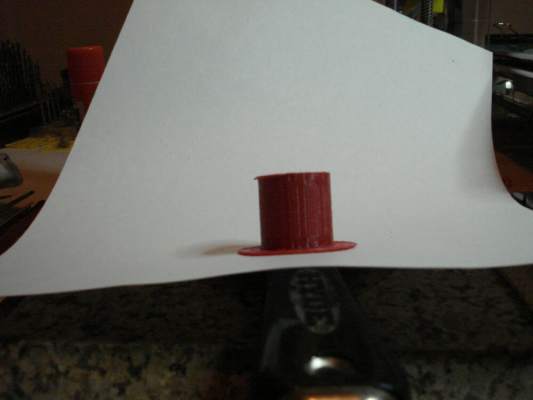

The problem is that there is a 50mm/sec difference to get the two programs to run at the same speed. I wonder if there is a way to measure actual speed. A lot of people are trying Cura and getting crappy results thinking they are using the same settings as Slic3r. Thanks to everyone for your input. Here is the T-800 ran on Cura @ 30mm/sec.

|

Re: Riddle me this. June 13, 2015 08:09PM |

Registered: 9 years ago Posts: 351 |

Two things on the speed settings...

1) What are your cooling settings? Those test cubes are tiny, and if you're using anything even loosely resembling the Slic3r default profiles, the speeds it uses will probably be minimum-layer-time/minimum-speed driven.

2) Are you using the same type of infill on both slicers? A more complex infill pattern may mean the speed never actually reaches what is set, depending on acceleration settings in the slicer and the machine firmware.

Edited 1 time(s). Last edit at 06/13/2015 08:10PM by IMBoring25.

1) What are your cooling settings? Those test cubes are tiny, and if you're using anything even loosely resembling the Slic3r default profiles, the speeds it uses will probably be minimum-layer-time/minimum-speed driven.

2) Are you using the same type of infill on both slicers? A more complex infill pattern may mean the speed never actually reaches what is set, depending on acceleration settings in the slicer and the machine firmware.

Edited 1 time(s). Last edit at 06/13/2015 08:10PM by IMBoring25.

Sorry, only registered users may post in this forum.