Home

>

Reprappers

>

Topic

Folger Aluminum Kossel corners - warning!

Folger Aluminum Kossel corners - warning!

Posted by tadawson

Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 20, 2015 07:15PM |

Registered: 8 years ago Posts: 606 |

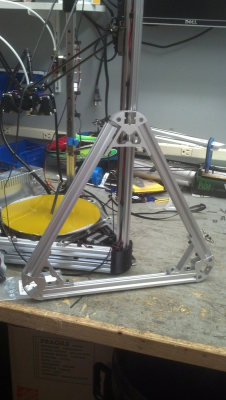

I got a set of the just available Kossel 2020 corners in from Folger today, and unfortunately, they are machined in error, and are unusable.

Bottom line, you put the three pieces of extrusion and three corners together to make a triangular frame, and it won't close, even with a good press. You would have to deform either the corner or the extrusion to close it, and I won't go there . . .

Apparently, Chinese QA/QC at it's finest.

I have notified Folger, and hopefully they will check the rest of their stock . . . I can only speak for the 9 pieces I have, but upon examination, they are all exactly alike in this regard - IE, it's not just one bad piece . . . so I suspect that the problem goes beyond just what I have.

I'll update if/when I know more, but for now, I would hold off on ordering these, because it looks like you may end up sending them right back . . .

- Tim

Edited 3 time(s). Last edit at 07/20/2015 11:03PM by tadawson.

Bottom line, you put the three pieces of extrusion and three corners together to make a triangular frame, and it won't close, even with a good press. You would have to deform either the corner or the extrusion to close it, and I won't go there . . .

Apparently, Chinese QA/QC at it's finest.

I have notified Folger, and hopefully they will check the rest of their stock . . . I can only speak for the 9 pieces I have, but upon examination, they are all exactly alike in this regard - IE, it's not just one bad piece . . . so I suspect that the problem goes beyond just what I have.

I'll update if/when I know more, but for now, I would hold off on ordering these, because it looks like you may end up sending them right back . . .

- Tim

Edited 3 time(s). Last edit at 07/20/2015 11:03PM by tadawson.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 20, 2015 09:55PM |

Registered: 9 years ago Posts: 977 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 20, 2015 11:02PM |

Registered: 8 years ago Posts: 606 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 21, 2015 10:43AM |

Admin Registered: 13 years ago Posts: 6,998 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 21, 2015 10:53AM |

Registered: 11 years ago Posts: 335 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 21, 2015 01:08PM |

Registered: 8 years ago Posts: 606 |

I have a good combination square with a protractor on it, but the problem is that with the 'head' on the corner, it's not possible to fit the part into it squarely to measure. I spent the day yesterday installing new printed corners, since my old ones had deformed from heat, and after waiting two months for these I was just sick, and could not wait any more. Let me see if I can find a better way - perhaps scanning one and then measuring the 2d image . . .

- Tim

- Tim

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 21, 2015 03:10PM |

Registered: 8 years ago Posts: 606 |

Here's a shot of one of the corners . . . looking again, I agree with likely a sawn extrusion, with a few other bits of work - IE the bottom corners are clearance radiused on one side for the motor, but that was likely done afterwards. The profile of all, top and bottom is identical.

- Tim

PS, working with the print and a protractor, I get 61 degrees . . . close, but no banana . . .

- Tim

Edited 3 time(s). Last edit at 07/21/2015 03:28PM by tadawson.

- Tim

PS, working with the print and a protractor, I get 61 degrees . . . close, but no banana . . .

- Tim

Edited 3 time(s). Last edit at 07/21/2015 03:28PM by tadawson.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 21, 2015 07:22PM |

Registered: 9 years ago Posts: 1,873 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 21, 2015 08:17PM |

Registered: 8 years ago Posts: 606 |

Ironically, my printed corners are a perfect fit, it's just the tolerance to heat that lacks, but having a fan cooled heatsink on each motor helps with that.

If all else fails, the set from Robotdigg is only $7 more, and if they are actually correct, it's a small price to pay, plus the Robotdigg parts are single piece bottom, which has got to be more solid. They also provide a machined idler, and hardware to hold it in place . . .

So, still waiting for a reply from Folger, and if no resolution, these will be going back. I don't want that much stress in the chassis . . . even if I could force it together. That, and doing a refit, where one corner is swapped at a time on an assembled machine, distribution seems like it would be a major pain, perhaps requiring a full teardown.

- Tim

Edited 2 time(s). Last edit at 07/21/2015 08:24PM by tadawson.

If all else fails, the set from Robotdigg is only $7 more, and if they are actually correct, it's a small price to pay, plus the Robotdigg parts are single piece bottom, which has got to be more solid. They also provide a machined idler, and hardware to hold it in place . . .

So, still waiting for a reply from Folger, and if no resolution, these will be going back. I don't want that much stress in the chassis . . . even if I could force it together. That, and doing a refit, where one corner is swapped at a time on an assembled machine, distribution seems like it would be a major pain, perhaps requiring a full teardown.

- Tim

Edited 2 time(s). Last edit at 07/21/2015 08:24PM by tadawson.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 22, 2015 04:39AM |

Registered: 9 years ago Posts: 977 |

Quote

691175002

Quote

AndrewBCN

Are these parts actually CNC machined or is it just cast aluminum, sandblasted?

From the pictures I'm about 95% sure its sawed extrusion. Screwing up the extrusion die is an expensive mistake.

I guess you are right! And indeed, extrusion dies are not cheap, and a 1 degree error in the corner angle will require a new die for sure. Also, they might just as well throw out the entire batch of already extruded profile. Quite a few thousands of dollars worth, that one mistake...

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 22, 2015 06:00AM |

Registered: 9 years ago Posts: 1,873 |

If they are willing to sell them off cheap a hobbiest could correct an oversize 1 degree error with a file and get a reasonable fit. It's only 1/2 a degree per side after all. Someone with a mill and a rotary table could do better of course, but the set-up time would make it impractical for large quantities. Careful use of a belt sander would probably have the job done in no time

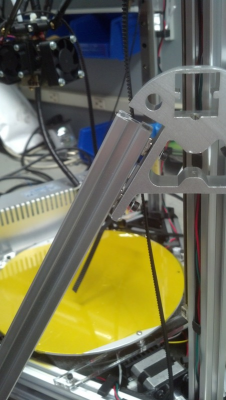

In the photo it's hard to tell exactly how bad the problem is because it looks like the nuts might be trapped between the outside of the extrusion and the bracket. It would be nice to see another photo with the fasteners removed on that last joint so that we could see a clear air gap.

In the photo it's hard to tell exactly how bad the problem is because it looks like the nuts might be trapped between the outside of the extrusion and the bracket. It would be nice to see another photo with the fasteners removed on that last joint so that we could see a clear air gap.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 22, 2015 11:23AM |

Registered: 8 years ago Posts: 606 |

The nuts were is clear air - no contact whatsoever . . . the pieces were floating in free space, with no contact, as well as the nuts turned endwise in line with the slot in the extrusion. I was able to attempt to flex it together, and found the amount of tension excessive, so did not attempt to go that route . . .

Unfortunately, the printer is reassembled with printed parts, so no more chance for photo ops.

I scaled the image (better res on original), so hopefully this will verify what I just wrote . . .

- Tim

Edited 4 time(s). Last edit at 07/22/2015 11:32AM by tadawson.

Unfortunately, the printer is reassembled with printed parts, so no more chance for photo ops.

I scaled the image (better res on original), so hopefully this will verify what I just wrote . . .

- Tim

Edited 4 time(s). Last edit at 07/22/2015 11:32AM by tadawson.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 23, 2015 04:49PM |

Registered: 8 years ago Posts: 606 |

Well, I got my first reply from Folger today . . . They recommended putting a corner on each section of extrusion to make three pieces, and then basically distribute the gap, and force it together, pretty much like the prototype part user ended up doing. I'm not sure I consider that an acceptable solution for parts of this cost, and have asked that if they cannot provide parts that actually fit, what are the details to return these for refund.

And basically, I did assemble it that way . . . I just tightened the corners one at a time, not even remotely imagining that this might be an issue . . . And the tension in the frame is the same, not matter how you assemble it, so while that may get it together, I still think it's a really bad idea to put that much stress in the frame . . .

- Tim

And basically, I did assemble it that way . . . I just tightened the corners one at a time, not even remotely imagining that this might be an issue . . . And the tension in the frame is the same, not matter how you assemble it, so while that may get it together, I still think it's a really bad idea to put that much stress in the frame . . .

- Tim

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 24, 2015 06:16AM |

Registered: 9 years ago Posts: 977 |

That basically means they just intend to sell these parts exactly like that, and there is no hint that they'll either scrap that defective batch and/or have another extrusion die manufactured.

I would insist on a refund and avoid buying from them from now on. Sooner or later another company is going to offer the same or a similar product but with the correct dimensions and tolerances.

I would insist on a refund and avoid buying from them from now on. Sooner or later another company is going to offer the same or a similar product but with the correct dimensions and tolerances.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 24, 2015 06:51AM |

Registered: 9 years ago Posts: 1,159 |

Quote

AndrewBCN

That basically means they just intend to sell these parts exactly like that, and there is no hint that they'll either scrap that defective batch and/or have another extrusion die manufactured.

I would insist on a refund and avoid buying from them from now on. Sooner or later another company is going to offer the same or a similar product but with the correct dimensions and tolerances.

Andrew

Robotdigg already offer a set of Metal corners that are spot on they also do metal Carriages and effectors for a kossel as well the full set is around $100 or so and in my view well worth it

see Metal Delta parts I now have 2 sets of these and about to start assembling the second delta.

Doug

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 24, 2015 09:59AM |

Registered: 9 years ago Posts: 977 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! July 24, 2015 11:59AM |

Registered: 8 years ago Posts: 606 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! August 21, 2015 03:09PM |

Registered: 8 years ago Posts: 4 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! August 22, 2015 12:22AM |

Registered: 8 years ago Posts: 606 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! August 22, 2015 02:22AM |

Registered: 8 years ago Posts: 5,232 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! August 26, 2015 06:39PM |

Registered: 13 years ago Posts: 5 |

Might be repeating others here, I ran into this on the last corner after tightening corners one-by-one, and so loosened the previous 2 corners and then was able to hook and gradually tighten all 3.

It was still a squeeze, maybe 10 or 20 lbs of leaning on the triangle for the final round of tightening.

It was still a squeeze, maybe 10 or 20 lbs of leaning on the triangle for the final round of tightening.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 04, 2015 11:09PM |

Registered: 10 years ago Posts: 3 |

umm, i have this issue with mine as well. the corners are slightly out of angle. adding the error as you go around making the final one impossible to complete. i started by up doing what leoleor did, loosening all around and slowly bringing them in to complete the triangle. but as i had already sent them back to folger once i'm going to fix this set on my mill. needless to say they really should fix this.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 07, 2015 09:09AM |

Registered: 8 years ago Posts: 1 |

From what I see in photo it is an extruded part cut to thickness maybe have the angle cut to, then the part is smoothed in a tumbler to deburr. As far as the angle of the part if it's a true triangle then the angle should be 45 degrees.

Your best fix would be to first check your 2020 bar as they could also be bent or miss formed as well. As far as stress on the frame the amount of pressure put in would be nothing when all said and done. The aluminum is soft it will flex enough to relieve the stress and most likely a planned aspect of that part. By putting in a angle that's a bit off would ultimately give a stonger frame.

Your best fix would be to first check your 2020 bar as they could also be bent or miss formed as well. As far as stress on the frame the amount of pressure put in would be nothing when all said and done. The aluminum is soft it will flex enough to relieve the stress and most likely a planned aspect of that part. By putting in a angle that's a bit off would ultimately give a stonger frame.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 07, 2015 11:33AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Bluedragon456

From what I see in photo it is an extruded part cut to thickness maybe have the angle cut to, then the part is smoothed in a tumbler to deburr. As far as the angle of the part if it's a true triangle then the angle should be 45 degrees.

Your best fix would be to first check your 2020 bar as they could also be bent or miss formed as well. As far as stress on the frame the amount of pressure put in would be nothing when all said and done. The aluminum is soft it will flex enough to relieve the stress and most likely a planned aspect of that part. By putting in a angle that's a bit off would ultimately give a stonger frame.

Actuaaly as they form an equilateral triangle the angle should be 60 degrees NOT 45.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 07, 2015 11:47AM |

Registered: 8 years ago Posts: 150 |

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 07, 2015 11:36PM |

Registered: 9 years ago Posts: 116 |

You could also fill the gap with something like Bondo and then tighten it after it is set. We use Bondo a lot as temporary tooling/fixturing where I work. Better yet, use a metal filled epoxy, JB WELD is it, to make up the gap and have a stiffer frame in the end. Bake it in an oven to a temp higher that what you would see when using the part and you should be all set.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 08, 2015 12:12AM |

Registered: 8 years ago Posts: 606 |

Frankly, I am amazed by the number of folks who are willing to kludge something together to utilize a clearly defective part . . . rather than sending a clear message that you will not accept junk, such that the vendor will provide non-defective parts.

And, for what it's worth, the angle looks like it may be due to a machining error. The main part is clearly extruded, but the rib down the mating surfaces (to the 2020) cannot be extruded - that is the result of machining down the areas outside of it - an operation that basically sets the angle of the part, and which could be corrected moving forward, without needing to make a new extrusion die . . .

- Tim

And, for what it's worth, the angle looks like it may be due to a machining error. The main part is clearly extruded, but the rib down the mating surfaces (to the 2020) cannot be extruded - that is the result of machining down the areas outside of it - an operation that basically sets the angle of the part, and which could be corrected moving forward, without needing to make a new extrusion die . . .

- Tim

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 08, 2015 01:04AM |

Registered: 8 years ago Posts: 150 |

Don't do this, a unsymmetrical frame will cause all sort of odd errors in the effector movement.Quote

Ecky

You could also fill the gap with something like Bondo and then tighten it after it is set. We use Bondo a lot as temporary tooling/fixturing where I work. Better yet, use a metal filled epoxy, JB WELD is it, to make up the gap and have a stiffer frame in the end. Bake it in an oven to a temp higher that what you would see when using the part and you should be all set.

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 08, 2015 06:01AM |

Registered: 10 years ago Posts: 903 |

Quote

tadawson

Frankly, I am amazed by the number of folks who are willing to kludge something together to utilize a clearly defective part . . . rather than sending a clear message that you will not accept junk, such that the vendor will provide non-defective parts.

I'm amazed that people do business with Folger at all, with the way that they have offloaded their tech support operation by telling everyone to ask for help in the "Reprappers" sub-forum on this site. This defective part (and their refusal to stop selling it and make the people who already bought it whole) seems to be par for the course.....

Re:  Folger Aluminum Kossel corners - warning! Folger Aluminum Kossel corners - warning! September 10, 2015 12:07PM |

Registered: 8 years ago Posts: 606 |

All in all, the kit I got was decent for the price, and support has been OK . . . this is my one exception, and hence the reason I posted this thread. Every time I had a bad part, a replacement was quickly on the way . . . the problem here is that someone at Folger seems to think that this massive of an error does not a bad part make (which I cannot understand). Ironically, a guy who got beta parts told me they were the same . . . and either nobody griped, or ? ? ? because Folger chose to build parts they knew up front would be out of spec . .

To the other point, since they didn't write Marlin . . . or Pronterface . . . or Cura . . . or Repetier . . ., telling folks to look to more qualified support sources doesn't really bother me . . .

- Tim

Edited 1 time(s). Last edit at 09/10/2015 12:12PM by tadawson.

To the other point, since they didn't write Marlin . . . or Pronterface . . . or Cura . . . or Repetier . . ., telling folks to look to more qualified support sources doesn't really bother me . . .

- Tim

Edited 1 time(s). Last edit at 09/10/2015 12:12PM by tadawson.

Sorry, only registered users may post in this forum.