Home

>

Reprappers

>

Topic

Problem slicing a part

Posted by Koenig

|

Problem slicing a part July 27, 2015 05:41AM |

Registered: 9 years ago Posts: 445 |

I have problems slicing a to "upgrade" to my printer with.

See this: [forums.reprap.org]

Now I have tried other slicers as well, Simplify3D and Cura they all give different results regarding the holes but none to my satisfaction.

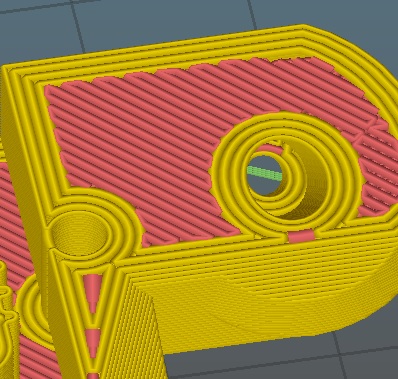

This is how Sli3r does it, creating a bigger hole inside... How am I going to get the threads to stick in that...

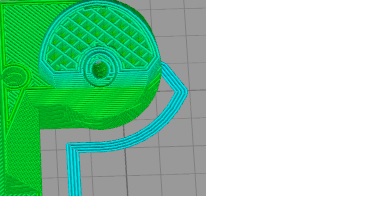

This is Simplify3D, creating a hole in a tube in a hole....

When I sliced it with cura I think the result was similar to that of Sli3r, not real sure, but it was not good anyway.

Trying to print the part in PETG with a 0.4 nozzle and accuracy/quality is why I'm trying to print this part (0.2 layer height).

Now, what can I do?

See this: [forums.reprap.org]

Now I have tried other slicers as well, Simplify3D and Cura they all give different results regarding the holes but none to my satisfaction.

This is how Sli3r does it, creating a bigger hole inside... How am I going to get the threads to stick in that...

This is Simplify3D, creating a hole in a tube in a hole....

When I sliced it with cura I think the result was similar to that of Sli3r, not real sure, but it was not good anyway.

Trying to print the part in PETG with a 0.4 nozzle and accuracy/quality is why I'm trying to print this part (0.2 layer height).

Now, what can I do?

|

Re: Problem slicing a part July 27, 2015 11:37AM |

Registered: 11 years ago Posts: 342 |

Sorry, I can't be sure, but I think you are showing us views of one of the 45 degree rotated cylinders on [www.thingiverse.com]. If you haven't already done so, I would open the STL up in a STL viewer and rotate it around to verify that the output of the slicer is really at fault. The slicer might be doing exactly what the source STL is telling it to.

If that isn't the issue then I'm going to guess it has something to do with the solid of the top part of the hole and the solid of the bottom part of the hole being defined in two different pieces with two different voids making the holes in them. You would have to have the source files to verify this. In the case of an scad file, I would recommend making sure the solids of those two pieces extend into each other and one long void is used to make the hole in both of them. That said, I've never had Slic3r do me wrong like this.

Edited 1 time(s). Last edit at 07/27/2015 11:38AM by appdev007.

If that isn't the issue then I'm going to guess it has something to do with the solid of the top part of the hole and the solid of the bottom part of the hole being defined in two different pieces with two different voids making the holes in them. You would have to have the source files to verify this. In the case of an scad file, I would recommend making sure the solids of those two pieces extend into each other and one long void is used to make the hole in both of them. That said, I've never had Slic3r do me wrong like this.

Edited 1 time(s). Last edit at 07/27/2015 11:38AM by appdev007.

|

Re: Problem slicing a part July 27, 2015 01:06PM |

Registered: 9 years ago Posts: 445 |

Quote

appdev007

Sorry, I can't be sure, but I think you are showing us views of one of the 45 degree rotated cylinders on [www.thingiverse.com]. If you haven't already done so, I would open the STL up in a STL viewer and rotate it around to verify that the output of the slicer is really at fault. The slicer might be doing exactly what the source STL is telling it to.

If that isn't the issue then I'm going to guess it has something to do with the solid of the top part of the hole and the solid of the bottom part of the hole being defined in two different pieces with two different voids making the holes in them. You would have to have the source files to verify this. In the case of an scad file, I would recommend making sure the solids of those two pieces extend into each other and one long void is used to make the hole in both of them. That said, I've never had Slic3r do me wrong like this.

Yeah, seems like there was an issue with the model, after many tries with different settings and all other modifications i could think of I gave up and made one just like it from scratch and it sliced just fine, at least using Simplify3D.

|

Re: Problem slicing a part July 28, 2015 12:10AM |

Registered: 9 years ago Posts: 705 |

"SolidView" is an excellent STL viewer and it's free. [download.cnet.com]

Sorry, only registered users may post in this forum.