|

Nozzle maintenance... September 13, 2015 10:43AM |

Registered: 9 years ago Posts: 61 |

Hi Folks!

Ok, Here's my Printer....

Sunhokey i3 fitted with a E3d V6 hot end, 0.4mm nozzle.

a print cooling fan (I need to configure this as cooling from the start seems to upset the first layer)

a PCB MK2B Dual Power heatbed and a Borosilicate glass Plate.

I think I'm also going to change the X carriage for an aluminium one???

Here's my problem for today....

I started a print and all looked normal as I gazed in awe and wondered how it works out where to go next and then it started the 2nd layer and right away I noticed it wasn't laying any material down...

It did complete the first layer but it just stopped on the 2nd????

The extruder was running but it was banging like it was jammed... this normally happens but clears after a while.... I think it's clogging in the hot end???

Any ideas on what I can do???

What is the best way to clean a nozzle???

I'm going to get some more nozzles and maybe try running a 0.2mm???

Ok, Here's my Printer....

Sunhokey i3 fitted with a E3d V6 hot end, 0.4mm nozzle.

a print cooling fan (I need to configure this as cooling from the start seems to upset the first layer)

a PCB MK2B Dual Power heatbed and a Borosilicate glass Plate.

I think I'm also going to change the X carriage for an aluminium one???

Here's my problem for today....

I started a print and all looked normal as I gazed in awe and wondered how it works out where to go next and then it started the 2nd layer and right away I noticed it wasn't laying any material down...

It did complete the first layer but it just stopped on the 2nd????

The extruder was running but it was banging like it was jammed... this normally happens but clears after a while.... I think it's clogging in the hot end???

Any ideas on what I can do???

What is the best way to clean a nozzle???

I'm going to get some more nozzles and maybe try running a 0.2mm???

|

Re: Nozzle maintenance... September 13, 2015 01:06PM |

Registered: 9 years ago Posts: 1,159 |

Quote

KillerDave

Hi Folks!

Ok, Here's my Printer....

Sunhokey i3 fitted with a E3d V6 hot end, 0.4mm nozzle.

a print cooling fan (I need to configure this as cooling from the start seems to upset the first layer)

a PCB MK2B Dual Power heatbed and a Borosilicate glass Plate.

I think I'm also going to change the X carriage for an aluminium one???

Here's my problem for today....

I started a print and all looked normal as I gazed in awe and wondered how it works out where to go next and then it started the 2nd layer and right away I noticed it wasn't laying any material down...

It did complete the first layer but it just stopped on the 2nd????

The extruder was running but it was banging like it was jammed... this normally happens but clears after a while.... I think it's clogging in the hot end???

Any ideas on what I can do???

What is the best way to clean a nozzle???

I'm going to get some more nozzles and maybe try running a 0.2mm???

What material are you printing with is the first question that needs to be answered then what type of extruder do you have (Geared or direct) and what temps are you running on the hotend and also what layer hieghts are you printing at?

Doug

|

Re: Nozzle maintenance... September 13, 2015 04:17PM |

Registered: 9 years ago Posts: 61 |

|

Re: Nozzle maintenance... September 13, 2015 09:24PM |

Registered: 10 years ago Posts: 477 |

|

Re: Nozzle maintenance... September 13, 2015 11:45PM |

Registered: 8 years ago Posts: 49 |

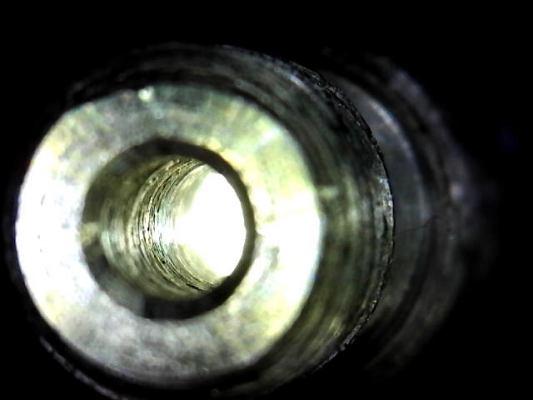

The chinese knock-off E3D's can be mighty temperamental unless you do some finish machining. For example, here is what a heatbreak typically looks like straight from China:

That will clog things up very quickly, particularly with a sticky material like PETG.

I do the following (10 minutes):

(1) use a dremel to spin some steel wool in the heatbreak

(2) use a dremel and pipe cleaner to polish with a medium abrasive rubbing compound

(3) use a dremel and pipe cleaner to polish with a fine abrasive rubbing compound

(4) use a dremel to spin some fine steel wool in the heatbreak

(5) use a dremel and pipe cleaner to polish with toothpaste

After all that, the same heatbreak looks like this:

I then season the heatbreak by coating the inside with vegetable oil and rasing it to 290C for 30 minutes, cooling it, and then cycling it up to 210C several times for 10 minutes at a time.

I coat the upper threads with Z5 thermal grease (high temp, 350C)

After that treatment, things work flawlessly.

That will clog things up very quickly, particularly with a sticky material like PETG.

I do the following (10 minutes):

(1) use a dremel to spin some steel wool in the heatbreak

(2) use a dremel and pipe cleaner to polish with a medium abrasive rubbing compound

(3) use a dremel and pipe cleaner to polish with a fine abrasive rubbing compound

(4) use a dremel to spin some fine steel wool in the heatbreak

(5) use a dremel and pipe cleaner to polish with toothpaste

After all that, the same heatbreak looks like this:

I then season the heatbreak by coating the inside with vegetable oil and rasing it to 290C for 30 minutes, cooling it, and then cycling it up to 210C several times for 10 minutes at a time.

I coat the upper threads with Z5 thermal grease (high temp, 350C)

After that treatment, things work flawlessly.

|

Re: Nozzle maintenance... September 14, 2015 01:09AM |

Registered: 9 years ago Posts: 61 |

|

Re: Nozzle maintenance... September 14, 2015 07:40AM |

Registered: 8 years ago Posts: 49 |

|

Re: Nozzle maintenance... September 14, 2015 07:56AM |

Registered: 9 years ago Posts: 893 |

|

Re: Nozzle maintenance... September 14, 2015 12:00PM |

Registered: 8 years ago Posts: 49 |

|

Re: Nozzle maintenance... September 15, 2015 09:39AM |

Registered: 9 years ago Posts: 722 |

Hi,

Probably it's a hotend cooling issue causing clogging.

On the Sunhockey, the fan looks like a bit high to work properly,

the good position is the fan level wih the lower wing of the hotend.

Cooling the lowpart of the heatsink is crucial.

I did not know Sunhockey provide genuine E3D V6 on its printers,

I thought that was V5 copies...

Sunhockey looks like to be a chinese clone's reseller BTW.

Sometimes everything is ok but you get a lazy cooling fan.

between the genuine and the chinese.

++JM

Edited 1 time(s). Last edit at 09/15/2015 09:40AM by J-Max.

Probably it's a hotend cooling issue causing clogging.

On the Sunhockey, the fan looks like a bit high to work properly,

the good position is the fan level wih the lower wing of the hotend.

Cooling the lowpart of the heatsink is crucial.

I did not know Sunhockey provide genuine E3D V6 on its printers,

I thought that was V5 copies...

Sunhockey looks like to be a chinese clone's reseller BTW.

Sometimes everything is ok but you get a lazy cooling fan.

I have both. Actualy I can't make any differenceQuote

SteveRoy

Is it a genuine E3D of a China knockoff?

between the genuine and the chinese.

++JM

Edited 1 time(s). Last edit at 09/15/2015 09:40AM by J-Max.

|

Re: Nozzle maintenance... September 15, 2015 10:25AM |

Registered: 8 years ago Posts: 49 |

Well, I definitely have better results with the above polishing method, seasoning with vegetable oil (at 290C for 30 min, cool, then several cycles at 210C), and using Z5 high-temp thermal grease on the upper threads of the heatbreak.

Also check your coldend extruder. There are a lot of bad ones out there, including some that are very popular. I have had excellent luck with this one: http://www.thingiverse.com/thing:669459

Also check your coldend extruder. There are a lot of bad ones out there, including some that are very popular. I have had excellent luck with this one: http://www.thingiverse.com/thing:669459

|

Re: Nozzle maintenance... September 17, 2015 09:20AM |

Registered: 9 years ago Posts: 722 |

Hi,

Instead of vegetable oil, you can consider a teflon tubing in the heat break :

++JM

Edited 1 time(s). Last edit at 09/17/2015 09:20AM by J-Max.

Instead of vegetable oil, you can consider a teflon tubing in the heat break :

++JM

Edited 1 time(s). Last edit at 09/17/2015 09:20AM by J-Max.

|

Re: Nozzle maintenance... September 17, 2015 11:01AM |

Registered: 8 years ago Posts: 49 |

Quote

J-Max

Hi,

Instead of vegetable oil, you can consider a teflon tubing in the heat break :

++JM

Of course this could work also...but only for PLA. Teflon doesn't handle higher temperatures.

Also, my experience with those heatbreaks is that the teflon tube doesn't go all the way through the melt zone. Your mileage may vary.

Edited 1 time(s). Last edit at 09/17/2015 11:02AM by wfcook.

|

Re: Nozzle maintenance... September 17, 2015 11:24AM |

Registered: 8 years ago Posts: 58 |

I had this all the time, what i done was chamfer the end of the PTFE tube so that it seats properly in the heatbreak. I was still getting the odd blockage after i done this but it was much better. So what i did next was reduce the retraction amount, it is currently set at 0.8mm, i haven't had a block since. Maybe it would be easier to play with the retraction settings first.

The problem arrives when the filament swells then is too big to fit through the heatbreak, so make sure the cooling fan is working ok on the fins, and also make sure the air flow is good, its ok having the fan blowing the fins, but if its hitting an obstacle on the other side it wont be as efficient as it needs to be. Good luck, this is one annoying problem to solve.

Edited 1 time(s). Last edit at 09/17/2015 11:24AM by xelad.

The problem arrives when the filament swells then is too big to fit through the heatbreak, so make sure the cooling fan is working ok on the fins, and also make sure the air flow is good, its ok having the fan blowing the fins, but if its hitting an obstacle on the other side it wont be as efficient as it needs to be. Good luck, this is one annoying problem to solve.

Edited 1 time(s). Last edit at 09/17/2015 11:24AM by xelad.

|

Re: Nozzle maintenance... September 17, 2015 12:56PM |

Registered: 9 years ago Posts: 722 |

|

Re: Nozzle maintenance... September 17, 2015 05:13PM |

Registered: 9 years ago Posts: 445 |

Quote

J-Max

Hi again,

I print ABS @235°C and teflon does not matter.

Maybe if you print nylon or PETG ?

++JM

I think PTFE is good up to 240°C, if you are going to print something hotter you need to go all metal.

Reference for the temperature: [e3d-online.com]

Edited 1 time(s). Last edit at 09/17/2015 05:17PM by Koenig.

|

Re: Nozzle maintenance... December 17, 2015 04:27PM |

Registered: 8 years ago Posts: 3 |

|

Re: Nozzle maintenance... January 13, 2016 07:59AM |

Registered: 8 years ago Posts: 6 |

|

Re: Nozzle maintenance... January 13, 2016 11:58AM |

Registered: 8 years ago Posts: 49 |

Quote

SpodFab

wfcook,

Your fix looks great, I want to do this with mine. How did you fixed the steel wool to the Dremel?

I used the dremel #4486 multipro chuck.

I have changed the process ever so slightly. I now season using flaxseed oil by following something close to this process: http://sherylcanter.com/wordpress/2010/01/a-science-based-technique-for-seasoning-cast-iron/

But I am still getting great results.

|

Re: Nozzle maintenance... January 14, 2016 10:31PM |

Registered: 9 years ago Posts: 1,873 |

Quote

Koenig

I think PTFE is good up to 240°C, if you are going to print something hotter you need to go all metal.

Reference for the temperature: [e3d-online.com]

I print nylon at 265 through ptfe with no problems yet. Also abs and petg.

Sorry, only registered users may post in this forum.