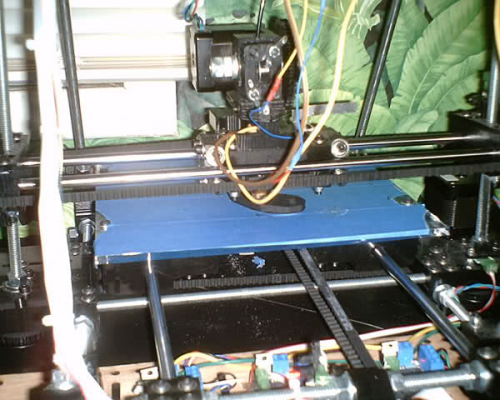

Isaac Mendel build

Posted by jkelso

|

Re: Isaac Mendel build November 09, 2010 10:49AM |

Registered: 14 years ago Posts: 73 |

Be careful: double-sided tape doesn't protect the acrylic bed like blue tape does. If your nozzle gets too close, it will melt through both the double-sided tape and the bed. If it touches, it will be like a hot knife through butter, creating both a hole and causing the bed to warp. I've ruined several acrylic beds this way.

|

Re: Isaac Mendel build November 09, 2010 03:31PM |

Registered: 13 years ago Posts: 418 |

I found a great spool that mounts on the top of a Mendel but the .stl files didn't load into the reprap host software. I'm going to try running that solution to fix the .stl files with netfabb software. Since I've got one good extruder part already I decided to go ahead and print another piece for the Wade's extruder, the smaller gear. This came out excellent and I'm still amazed that it can produce holes in the side of parts, I would expect that the extrusion would collapse where there is a void but apparently not. Very interesting. I did this one with the X and Y mm/min set to 2000 and still looking good. I'm going to keep increasing the number.

|

Re: Isaac Mendel build November 09, 2010 03:34PM |

Registered: 13 years ago Posts: 418 |

I almost purchased sticky one sided laminate sheets from the office supply store and I was going to tape them down with double sided scotch tape. I may want to stick to smaller parts until I get the heated bed running, I'm going to try another large piece and keep a good eye on it to see what's happening. Thanks for the tip tbfleming.

|

Re: Isaac Mendel build November 09, 2010 03:57PM |

Registered: 13 years ago Posts: 418 |

|

Re: Isaac Mendel build November 09, 2010 07:57PM |

Registered: 13 years ago Posts: 418 |

After fixing the part with the netfabb software I sent the gcode with the prefs at 2500mm/min X and Y and changed the extruder max speed to 2500 accordingly. The part will probably take over 4 hours at this speed with virtually no infill gap. I'm thinking that the long build times are more due the infill gap, I've got mine set at .3 and the number of shells at 3. This part is coming out absolutely perfect, the sides look completely smooth. This spool attachment for the top is going to be a sweet upgrade. I'm going to have Milla Jovovich popping out of this thing in no time.

|

Re: Isaac Mendel build November 09, 2010 08:57PM |

Registered: 13 years ago Posts: 418 |

I saw this on someone's ebay page and thought I would take the time to debunk this myth. I just printed a small Wade's gear with a .5 mm extruder nozzle and there are no gaps or holes in any of the teeth or anywhere else that gaps and holes aren't supposed to be. I'm not saying a .4 nozzle might not get a slightly smoother print but this information I'm seeing here is incorrect, I've got the proof right here. I think it's time to upgrade to something better than a Disney digital camera so that I can get good close-ups.

|

Re: Isaac Mendel build November 09, 2010 09:24PM |

Registered: 14 years ago Posts: 73 |

Thanks for debunking this. I have, at times, produced parts like those on the left. After tuning Skeinforge, they looked like parts on the right. That picture should be used to show what can happen when some of Skeinforge's unintelligibly-named ("moon phase over car color") parameters are set too high.

|

Re: Isaac Mendel build November 10, 2010 09:46AM |

Registered: 13 years ago Posts: 418 |

This morning I woke up to find this great looking part all done. I'd like to do some in hot rod red. I'm going to try and get a quicker build time on the next one but this spool vertex looks perfect. I can see that the holes made in the side actually form a teardrop shape at the top. I thought that the reprap teardrop logo was symbolic of the people who have tried and failed to complete a reprap but now I see that I was wrong. You can complete a reprap and the teardrop is merely symbolic of a printer artifact created when printing a horizontally running hole.

|

Re: Isaac Mendel build November 10, 2010 10:01AM |

Registered: 14 years ago Posts: 3,742 |

Quote

RepRapLogo

Adrian Bowyer came up with the name RepRap, and Ed Sells came up with the logo. The teardrop shape is the profile of a cylinder with 45o angles above. Our commercial FDM machine can make a 45o overhang without support material, so - if you want a horizontal hole to put a cylinder through - the teardrop profile gets made without support. This is both faster and neater. And for the vast majority of cases it doesn't matter that it is not completely round.

The teardrop is also an important example of the fact that, with this technology, complexity of shape costs nothing.

YES - that is what it says on the RepRapLogo wiki page!

P.S. Buy a better camera!

P.S.S. Your interpretation may be the better one...

Edited 2 time(s). Last edit at 11/10/2010 10:04AM by rhmorrison.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Isaac Mendel build November 10, 2010 02:48PM |

Registered: 13 years ago Posts: 418 |

|

Re: Isaac Mendel build November 10, 2010 03:14PM |

Registered: 13 years ago Posts: 418 |

Now that I've got things working I'm realizing that these printers make a fair amount of noise and there's a slight odor of heated plastic in the room. I'm going to be shopping around for a gun safe in the future that could hold a reprap with filament spool attached. I found this one online with the perfect specs 2 ft X 2ft X 5ft. I'd like to have a fan and light inside there and a video camera so that I could keep the door closed and monitor the build on video. This one was online for $900 new, it's the first one I found that I liked but I'm going to keep looking around on craigslist too.

Edited 1 time(s). Last edit at 11/10/2010 03:15PM by jkelso.

Edited 1 time(s). Last edit at 11/10/2010 03:15PM by jkelso.

|

Re: Isaac Mendel build November 10, 2010 06:51PM |

Registered: 13 years ago Posts: 418 |

The 2nd spool vertex took 5 hours, this time I left the infill gap at .5 again and upped the X and Y and extruder speed to 3000 mm/minute. I really like what I'm seeing and I'm reluctant to degrade the quality of the parts by setting a larger infill gap. I'm going to keep trying and see what happens with the next settings experiment. I'm laying a 2nd strip of blue tape down and this way everything peels up much easier. I promised myself I wasn't going to give up my jonas brothers camera until nick jonas loses his virginity. I haven't checked on it in a while, it's possible it could be time to upgrade.

|

Re: Isaac Mendel build November 10, 2010 10:09PM |

Registered: 13 years ago Posts: 418 |

I've just produced another part for the filament spool assembly, one of the 4 lower vertex pieces that hold the spool on top of the machine. This one came out in around 2 hours, which is fine I guess. I'm not sure how long a part like this is typically supposed to take but the machine seemed to be moving fast enough. I want to make nice dense parts that are strong so I'm satisfied with the current setting for now. The 5/16" rod fits perfectly through the hole so I'm going to continue printing more of these pieces. I'm going to figure out if maybe I should start putting more objects on the build tray before sending the gcodes to file in the future.

|

Re: Isaac Mendel build November 11, 2010 03:05AM |

Registered: 14 years ago Posts: 3,742 |

Nick Jonas (born September 16, 1992) turned 18 in September and Miley Cyrus has stated that she dated Jonas from June 2006 to December 2007. Cyrus claimed they were "in love" and began dating soon after they first met.

I definitely think it's time to buy a new camera...

P.S. The parts look pretty good based on what one can see in your low resolution blurry photos.

Edited 1 time(s). Last edit at 11/11/2010 03:28AM by rhmorrison.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

I definitely think it's time to buy a new camera...

P.S. The parts look pretty good based on what one can see in your low resolution blurry photos.

Edited 1 time(s). Last edit at 11/11/2010 03:28AM by rhmorrison.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Isaac Mendel build November 11, 2010 03:34AM |

Admin Registered: 17 years ago Posts: 1,791 |

Or possibly a new keyboard?

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Isaac Mendel build November 11, 2010 04:36AM |

Registered: 14 years ago Posts: 3,742 |

Quote

SebastienBailard

Or possibly a new keyboard?

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Isaac Mendel build November 11, 2010 06:42AM |

Admin Registered: 17 years ago Posts: 1,791 |

Ah. Was skimming, and didn't follow your camera reference. I need a new little non-boy-band camera as well. Or possibly a new keyboard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Isaac Mendel build November 11, 2010 06:48AM |

Registered: 14 years ago Posts: 323 |

|

Re: Isaac Mendel build November 11, 2010 06:48AM |

Registered: 14 years ago Posts: 323 |

|

Re: Isaac Mendel build November 11, 2010 07:51AM |

Registered: 14 years ago Posts: 3,742 |

Maybe he bought a NEW camera!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Isaac Mendel build November 11, 2010 07:55AM |

Registered: 14 years ago Posts: 3,742 |

On the other hand... it looks more like a focusing problem to me!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Isaac Mendel build November 11, 2010 05:37PM |

Registered: 13 years ago Posts: 418 |

|

Re: Isaac Mendel build November 11, 2010 05:43PM |

Registered: 13 years ago Posts: 79 |

Quote

I'm going to figure out if maybe I should start putting more objects on the build tray before sending the gcodes to file in the future.

No need to figure. More parts on the tray definitely works better. Less down time, and less chance of overheating small parts.

As you can see by the pic that I took with my $139.00 Canon PowerShot.

My parts aren't “absolutely perfect”.But they are very strong and I think that's the main objective when it comes to printing functional parts.

My parts aren't “absolutely perfect”.But they are very strong and I think that's the main objective when it comes to printing functional parts. Umm.... Maybe it's the camera angle, or maybe it's just these old eyes, but your gear looks to me to be a little oddly shaped and it almost looks as though it has some little bits of plastic sticking out here and there.

Umm.... Maybe it's the camera angle, or maybe it's just these old eyes, but your gear looks to me to be a little oddly shaped and it almost looks as though it has some little bits of plastic sticking out here and there.Edited 2 time(s). Last edit at 12/19/2011 09:34PM by Bruce.

|

Re: Isaac Mendel build November 11, 2010 06:15PM |

Registered: 13 years ago Posts: 418 |

Well yes there are a few imperfections (little extra bits here and there that can be removed with your fingers) but when I look at the gear as compared to the one I bought with my extruder parts on ebay it doesn't look any different. The gear is not misshaped in any way, and I've test fitted it onto a stepper motor. I've been cranking out parts for this filament spool and so far so good. The first side piece I made that holds the bearing pulled up from the tape on one end. However, this warping only affects the slope on one side of the piece, the important side still has the correct geometry and will be fine to use. I've decided to try and build the next side part with a space heater aimed at the tray and so far it hasn't warped. I'll give another report on this when the part finishes.

|

Re: Isaac Mendel build November 11, 2010 07:43PM |

Registered: 13 years ago Posts: 418 |

I'm happy to announce that the space heater solved my warping problems 100 percent. All edges are perfectly flat to the bed. Last night was the first snowfall of the season and I'm running a space heater in the room anyway so this works out great. I'm going to look for one of the smaller desktop heaters that will fit on the stand next to the machine. These can be purchased for under $25. I'm going to get the heated be going eventually before summer comes around but for now aiming the space heater towards the machine is killing 2 birds with one stone, heating the room and warming the plastic.

|

Re: Isaac Mendel build November 11, 2010 08:02PM |

Registered: 13 years ago Posts: 418 |

|

Re: Isaac Mendel build November 12, 2010 12:56AM |

Registered: 14 years ago Posts: 323 |

i think you should still pursue a case around your printer + heated bed just to keep the fumes out of your house.. there's already enough toxins and junk in the air of an average household

but with a gun case you wouldn't be able to sit and stare for hours on end. unless you can get a clear doored one...

in a few weeks when my mendel is up i'm going to design a simple case and take it to a local laser cutter and get it done in clear acrylic. it shouldn't cost too much, no idea really but maybe $40-70. then i'm hoping i can somehow fuse the corners by heating or perhaps glue, with a fan and rubber exhaust pipe going to my studio ceiling and outside

if mine works you could take my specs and go to a lazercutter near you, only diff is i'm going to have my filament stored underneath the mendel with a dc motor or perhaps just another wades geared extruder to feed plastic to the main extruder. i'll try and upload some designs soon

but with a gun case you wouldn't be able to sit and stare for hours on end. unless you can get a clear doored one...

in a few weeks when my mendel is up i'm going to design a simple case and take it to a local laser cutter and get it done in clear acrylic. it shouldn't cost too much, no idea really but maybe $40-70. then i'm hoping i can somehow fuse the corners by heating or perhaps glue, with a fan and rubber exhaust pipe going to my studio ceiling and outside

if mine works you could take my specs and go to a lazercutter near you, only diff is i'm going to have my filament stored underneath the mendel with a dc motor or perhaps just another wades geared extruder to feed plastic to the main extruder. i'll try and upload some designs soon

|

Re: Isaac Mendel build November 12, 2010 03:40AM |

Registered: 14 years ago Posts: 3,742 |

|

Re: Isaac Mendel build November 12, 2010 04:27AM |

Admin Registered: 17 years ago Posts: 1,791 |

mlagana

Sounds very cool. Stuff them into the wiki?

e.g. http://reprap.org/wiki/Nifty_Environmental_Chamber

Edited 1 time(s). Last edit at 11/12/2010 04:58AM by SebastienBailard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

Sounds very cool. Stuff them into the wiki?

e.g. http://reprap.org/wiki/Nifty_Environmental_Chamber

Edited 1 time(s). Last edit at 11/12/2010 04:58AM by SebastienBailard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Isaac Mendel build November 12, 2010 04:35AM |

Registered: 14 years ago Posts: 3,742 |

Yes!

nophead made a a really nice MDF case shown in his blog article "Wooden overcoat" but he never documented the design because he feels it is too simple.

I think he should at least provide the design of the two RepRap parts that he added to his MDF case: one, for the fan and exhaust fumes; two, for the filament with a felt dust catcher. I am hesitent to say he should document the design of the MDF case because he does such excellent work documenting his experiments and much of his work is utilized by the rest of the community, so - nophead - keep up the good work!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

nophead made a a really nice MDF case shown in his blog article "Wooden overcoat" but he never documented the design because he feels it is too simple.

I think he should at least provide the design of the two RepRap parts that he added to his MDF case: one, for the fan and exhaust fumes; two, for the filament with a felt dust catcher. I am hesitent to say he should document the design of the MDF case because he does such excellent work documenting his experiments and much of his work is utilized by the rest of the community, so - nophead - keep up the good work!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Sorry, only registered users may post in this forum.