Isaac Mendel build

Posted by jkelso

|

Re: Isaac Mendel build November 15, 2010 01:18PM |

Registered: 13 years ago Posts: 418 |

After switching the stepper wires to the extruder board, I was getting movement but it was going the wrong way. Then I reversed the motor wires to try it again but now I'm not getting any temp reading, it's just showing a 0. The usb seems to be connected, I can move the X and Y motors, and when I push extrude nothing happens. This sucks, I've tried everything, I think I may have another extruder board problem again.

Edited 1 time(s). Last edit at 11/15/2010 01:19PM by jkelso.

Edited 1 time(s). Last edit at 11/15/2010 01:19PM by jkelso.

|

Re: Isaac Mendel build November 15, 2010 02:26PM |

Registered: 13 years ago Posts: 418 |

I put in an email to techzone about the extruder board. Hopefully I get a quick reply so that I'm not waiting on his answer for days. I guess extra electronics are a good thing to have around anyway if you're going to be into this. I made the revised spool model available on thingiverse:

[www.thingiverse.com]

[www.thingiverse.com]

|

Re: Isaac Mendel build November 15, 2010 02:27PM |

Registered: 13 years ago Posts: 418 |

I put in an email to techzone about the extruder board. Hopefully I get a quick reply so that I'm not waiting on his answer for days. I guess extra electronics are a good thing to have around anyway if you're going to be into this. I made the revised spool model available on thingiverse:

user: sketchyj I reposted this message because the first one got a message that I was posting spam and it was blocked

Edited 1 time(s). Last edit at 11/15/2010 02:28PM by jkelso.

user: sketchyj I reposted this message because the first one got a message that I was posting spam and it was blocked

Edited 1 time(s). Last edit at 11/15/2010 02:28PM by jkelso.

|

Re: Isaac Mendel build November 15, 2010 08:13PM |

Registered: 14 years ago Posts: 1,092 |

|

Re: Isaac Mendel build November 16, 2010 12:17PM |

Registered: 13 years ago Posts: 418 |

No I turned off power before I tried reconnecting the wires to the extruder board. I got an email back from Lambert Andrus at Techzone and he says he will exchange the extruder board for me again. I was very pleased to hear this, he's come through for me on this one, I was prepared to buy another extruder board if the answer was no. He also told me that my motor running through my extruder must be of at least 6 ohms resistance. My motor was measuring 1.4 ohm on each 2 sets of wiress (2.8 ohms total?) which allowed too much power through the system, frying the board. I have a NEMA 14 motor on hand which measures 2.9 ohms per set of wires (5.8 total?) which could work. However, I'm planning to run the extruder from a separate stepper motor once again so that I don't have to cram that tiny motor sideways into the slot. It should be a more preferable setup using an extra stepper driver to run the extruder stepper anyway. So I'm going to exchange the extruder board free of charge and order another good stepper driver from Techzone, I feel very comfortable with using their products now and I know that they will stand behind what they sell.

|

Re: Isaac Mendel build November 16, 2010 01:19PM |

Admin Registered: 17 years ago Posts: 7,879 |

You should be able to drive a 2.8 ohm motor but you have to set the PWM value to no more than 47%. A proper stepper driver will work much better though.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Isaac Mendel build November 16, 2010 06:10PM |

Registered: 16 years ago Posts: 438 |

I agree - using the extruder board to drive a stepper has always been a nasty hack. While you CAN run a low-Ohm stepper with it, you then are depending on the software to behave correctly at all times. I've always though that putting "don't blow up" in software is a generally bad idea. I'm doubly concerned about trying that kind of thing with an arduino, which has a ten second "bootloader" delay, during which odd things have been known to happen to un-initialized hardware.

There's actually a design being worked on to use a almost identical setup though - with the difference that there's also a sense resistor so the firmware actively monitors the current levels and adjusts accordingly. Which is the same thing that the Pololu stepper drivers (or any micro-stepping stepper drive) is doing anyway. I'm still a little hesitant about it 'cause it's still putting "don't blow up" in software, but at least it's a proven design and the software can tell if the hardware is about to blow up!

--

I'm building it with Baling Wire

There's actually a design being worked on to use a almost identical setup though - with the difference that there's also a sense resistor so the firmware actively monitors the current levels and adjusts accordingly. Which is the same thing that the Pololu stepper drivers (or any micro-stepping stepper drive) is doing anyway. I'm still a little hesitant about it 'cause it's still putting "don't blow up" in software, but at least it's a proven design and the software can tell if the hardware is about to blow up!

--

I'm building it with Baling Wire

|

Re: Isaac Mendel build November 21, 2010 02:23PM |

Registered: 13 years ago Posts: 418 |

|

Re: Isaac Mendel build November 22, 2010 02:43PM |

Registered: 13 years ago Posts: 418 |

I went down to the CAD lab at CCD where I'm pursuing an Engineering Graphics degree today and got a look at the new Uprint plus 3D printer. There were no teachers there today, the lab was open for painters and maintenance workers. I did get a look at a sample of parts the printer made and was very impressed with the build quality. The build size is still 8"X8"X6"H and there were parts there with moving pieces inside, objects that could not be produced with a reprap. I guess for $20,000 you get what you pay for. It was pretty cool, I can't wait to find out about how much I'll be able to use it once school lets back in after the break. I got my techzone driver in the mail but I'm still waiting for the exchange on the extruder board, hopefully in the next few days.

|

Re: Isaac Mendel build November 24, 2010 11:28PM |

Registered: 13 years ago Posts: 29 |

|

Re: Isaac Mendel build November 28, 2010 08:37PM |

Registered: 13 years ago Posts: 418 |

The parts Iooked at did have a smoother finish than what I've seen from my reprap. If money were no object I'd love to have something like that, but for me now I could not see spending that kind of money on a machine that's $20K. I'm still waiting for the extruder board exchange, I think I'm going to just order another one soon I'm getting anxious to begin where I left off.

|

Re: Isaac Mendel build December 06, 2010 05:29PM |

Registered: 13 years ago Posts: 418 |

I did get the extruder board I've been waiting for back in the mail today and I'm getting ready to hook it all back up again. Initial quality looks good, I don't see any visible problems on the board. I don't think I'll have the heated bed up and running until next month but this will work for now. I'm going to continue now with printing the parts I engineered for the spool I'm building. This spool is going to be great, I've spent the last half hour or so trying to untangle the 5lb roll of plastic that became tangled and twisted. I had to cut the roll into several smaller sections, it first started out as what looked like one tangle, but as I tried to get the roll under control it developed into a giant cluster of junk.

|

Re: Isaac Mendel build December 08, 2010 10:32PM |

Registered: 13 years ago Posts: 418 |

Tonight I finally got the new electronics wired together again and I've been able to control the steppers all just fine but I'm not getting anything out of the extruder board. In the temp value I'm reading 000 and a white bar. I've tried playing around with reversing the wires that transmit the temp signal back to the motherboard and also I've tried reloading the extruder firmware and I've rechecked the configuration h settings. I'm seeing a solid green light under the A+/- mosfet terminals and also 3 other lights on near the bottom of the board that I don't remember being on before. I've been playing with this for hours but not having any progress getting a temp value reading. I'll try more tomorrow again.

|

Re: Isaac Mendel build December 09, 2010 10:05AM |

Registered: 14 years ago Posts: 73 |

|

Re: Isaac Mendel build December 09, 2010 10:19AM |

Registered: 13 years ago Posts: 418 |

Yes I was able to upload the firmware I think. It compiled and when it said "binary sketch size" I pushed the reset button. However, I did not see the usual flashing LED that I see when the firmware uploaded on my other extruder board. The arduino software finally indicated that it worked and it said "done uploading". I rechecked my configuration h file to make sure it was set up for a thermistor. Next I'm going to unsolder the thermistor wires and check to see if it works by touching a thermistor directly to the pins, maybe it's a short in the wires to the thermistor.

|

Re: Isaac Mendel build December 09, 2010 11:28AM |

Registered: 13 years ago Posts: 418 |

I suppose it bears mentioning that my win XP machine died a few days ago, I'm waiting for a new optical drive in the mail. In the meantime I've had to reinstall the reprap host software to my 64 bit Win 7 machine. I've had very little success in even getting the axis to move through the reprap host software control panel. Even during those times that it works I'm still not seeing any evidence that the extruder board is working yet. I may have to go back through my blog here and research what I had them set to the time it worked. I haven't reuploaded the firmware to the motherboard, I didn't think it would be necessary.

|

Re: Isaac Mendel build December 09, 2010 11:38AM |

Registered: 14 years ago Posts: 3,742 |

If it was working before then the problem is not with the motherboard or extruder board firmware.

It is with the PC software (driver).

Did you install the FTDI driver?

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

It is with the PC software (driver).

Did you install the FTDI driver?

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Isaac Mendel build December 09, 2010 02:37PM |

Registered: 13 years ago Posts: 418 |

I'm not sure what that is...ftdi driver...

I am getting this message when the reprap software boots up...

I am getting this message when the reprap software boots up...

|

Re: Isaac Mendel build December 09, 2010 03:35PM |

Registered: 13 years ago Posts: 103 |

What that means is that the Java Library that the host software is using is 1 version behind that actual Library it interfaces with. (This is the RXTX Java libraries for interfacing with various platforms).

I think this will happen if using the host on ubuntu. (I will check my machine) and you use the RXTX Java library that is bundled with some an earlier version of the host software (Jonathan's ubuntu package is different if I remember correctly), as this is a version behind the RXTX library supplied with Ubuntu

(I hope that makes sense, the coffee is still kicking in)

David

I think this will happen if using the host on ubuntu. (I will check my machine) and you use the RXTX Java library that is bundled with some an earlier version of the host software (Jonathan's ubuntu package is different if I remember correctly), as this is a version behind the RXTX library supplied with Ubuntu

(I hope that makes sense, the coffee is still kicking in)

David

|

Re: Isaac Mendel build December 09, 2010 03:59PM |

Registered: 13 years ago Posts: 418 |

|

Re: Isaac Mendel build December 09, 2010 05:08PM |

Registered: 13 years ago Posts: 103 |

It is all to do with your java library path and your java classpath

Look at the reprap script and see how the actual application is called. Mine pointed to a local version of RXTXcomm.jar but used the system jni library. Changing it to point to the system provided RXTXcomm.jar file (normally found in /usr/share/java) fixed the problem for me. The system jni file is located in /usr/lib/jni

(This is on Ubuntu 10.10)

David

Look at the reprap script and see how the actual application is called. Mine pointed to a local version of RXTXcomm.jar but used the system jni library. Changing it to point to the system provided RXTXcomm.jar file (normally found in /usr/share/java) fixed the problem for me. The system jni file is located in /usr/lib/jni

(This is on Ubuntu 10.10)

David

|

Re: Isaac Mendel build December 10, 2010 03:34PM |

Registered: 13 years ago Posts: 418 |

Thanks David very much. I'm going to try doing all that, although it seems much simpler to me to just wait for the new optical drive I ordered to arrive so that I can go back to using the Win XP machine that worked before. Your answer sounds like it's leading me in the right direction, however I'm not exactly sure what you mean when you say to look at the reprap script(where, how?) and see how the actual application is called? Your terminology here is still very vague to me, excuse my lack of computer science knowledge.

|

Re: Isaac Mendel build December 10, 2010 06:25PM |

Registered: 13 years ago Posts: 103 |

Not a problem:

I am assuming you are using Unix/Linux here. (or else most of this will be useless).

When you start the RepRap host software you use a script called reprap. If you are just typing reprap on the command line then type the following

more `which reprap` (Note these are backticks and not the normal quotes). This should display the contents of the script and let you see where it is looking for the RXTX libraries. There will be a line something like

CLASSPATH=$CLASSPATH:./RXTXcomm.jar

In it. What you need to do is look at that and the java.library.path which may also be set.

Hope that makes sense

David

I am assuming you are using Unix/Linux here. (or else most of this will be useless).

When you start the RepRap host software you use a script called reprap. If you are just typing reprap on the command line then type the following

more `which reprap` (Note these are backticks and not the normal quotes). This should display the contents of the script and let you see where it is looking for the RXTX libraries. There will be a line something like

CLASSPATH=$CLASSPATH:./RXTXcomm.jar

In it. What you need to do is look at that and the java.library.path which may also be set.

Hope that makes sense

David

|

Re: Isaac Mendel build December 12, 2010 11:21PM |

Registered: 13 years ago Posts: 23 |

|

Re: Isaac Mendel build December 27, 2010 09:54PM |

Registered: 13 years ago Posts: 418 |

Well I haven't actually touched anything for a few weeks now. Since last time I tried to get it running again I suffered 2 crashes on both of my machines and it's taken quite a while just to get everything back up and running and all my normal programs reinstalled. Now I'm back to square 1 trying to get my win xp machine to start communicating with the reprap again. So far I've been trying to set the COM 1 port setting in the preferences, it kept showing up on the black startup screen as error reading COM 1, then I realized there wasn't supposed to be a space in between. Now it's not showing the error any more but I'm still not getting anything to work. I've been through so much now with just getting my computers back online that trying to fiddle with the reprap now seems to be draining too much out of me, I'm getting computer repair burnout. I see that now I've downloaded a new reprap host software program with new features. One thing I've noticed is that before I was using COM4 and now it's only showing COM1, I don't know why. Also, when I used to plug the usb in from the reprap to my computer I would hear some clicking of the steppers as the lights came on and initialized. I'm not hearing those steppers clicking any more when I plug in the machine.

|

Re: Isaac Mendel build March 09, 2011 03:01PM |

I am trying to put an Isaac together and i have trouble figuring out if i have all the cables. So for i have bought the RAMPS DIY kit for $50, the A4983 Stepper Motor Driver Carrier. 4 nema 17s, 6opto endstops. Are all the calbes included in these kits or do i have to buy separate one? If so what cables should i get?

|

Re: Isaac Mendel build May 18, 2011 01:59PM |

|

Re: Isaac Mendel build June 30, 2011 08:26PM |

Registered: 13 years ago Posts: 418 |

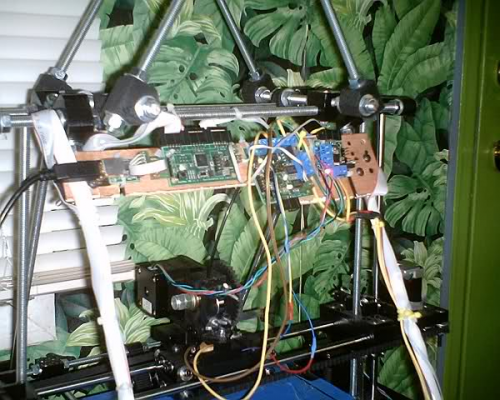

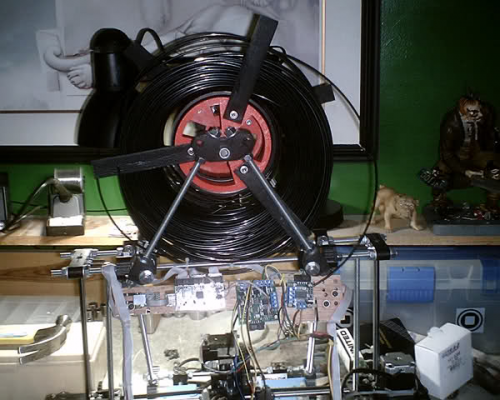

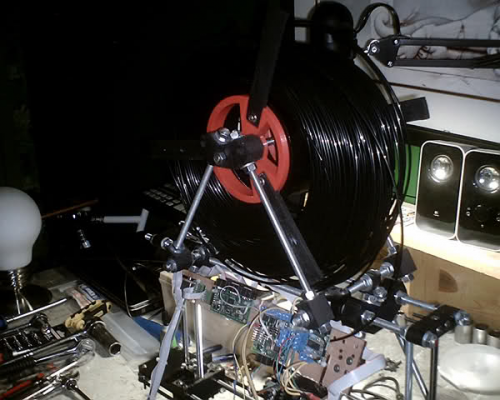

After many months of not touching the reprap, I still have not purchased any replacement electronics for the machine. I'm thinking it needs a new extruder board, but I have so many other things in need of my time and attention. At school I have free access to the $20,000 Uprint plus 3D printer. Yesterday I printed the final parts needed to complete my filament spool attachment for my Mendel, the circular inner spool as shown in red. The other black plastic parts used for the spool were printed by my Mendel before it stopped working again. The inner black plastic tube was purchased at Home Depot for a few bucks. The center red parts each use a press in bearing and the back side of the part has indentations for the nuts to press into. M4 bolts connect the plastic parts together and a 5/16 threaded rod goes through the center with a nut on each side to hold it on. I cut some spacers for the inside to give the spool about an inch clearance between the bearing and the outer part. I found a similar design on thingiverse but I redesigned it using a part I found at Home Depot for the center tube and a new spool center I created in Inventor. It rolls perfectly, I'm now thinking about getting this thing running again and getting that heated bed sometime soon after that. The parts made with the Uprint look perfect, the reprap parts look very rough in comparison, hopefully the heated bed will solve many of the warping problems. I'm thinking of shooting for having it all together by the end of August. The Uprint requires you to wash the part in a liquid to remove the support material, which leaves the part seeping water for days, other than that it comes out in perfect form and very smooth. Instead of using a heated bed, the printer uses disposable plastic trays for each build. I notice that the printer calibrates the level before each print at 4 areas on the build tray, something the reprap does not. The parts are much larger and beefier, it uses huse Lin Engineering steppers and much larger guide bars and belts. I wonder how much it would cost to build a printer like the Uprint with your own sourced parts? If anyone is interested in downloading the parts to build this spool go to thingiverse and search for user sketchyj

|

Re: Isaac Mendel build July 01, 2011 01:35AM |

Registered: 14 years ago Posts: 3,742 |

Quote

jkelso

I notice that the printer calibrates the level before each print at 4 areas on the build tray, something the reprap does not.

nophead's HydraRaptor machine now does this too!

Read his blog article "Auto bed leveling".

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Isaac Mendel build July 01, 2011 03:47AM |

Admin Registered: 17 years ago Posts: 7,879 |

Any idea what the "disposable plastic trays" are made from?

How do you remove the parts?

Does it print directly on the the tray or does it use a raft?

[www.hydraraptor.blogspot.com]

How do you remove the parts?

Does it print directly on the the tray or does it use a raft?

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.