Home

>

Reprappers

>

Topic

Cookie extruder

Posted by owad

|

Cookie extruder October 15, 2007 03:08PM |

Registered: 17 years ago Posts: 40 |

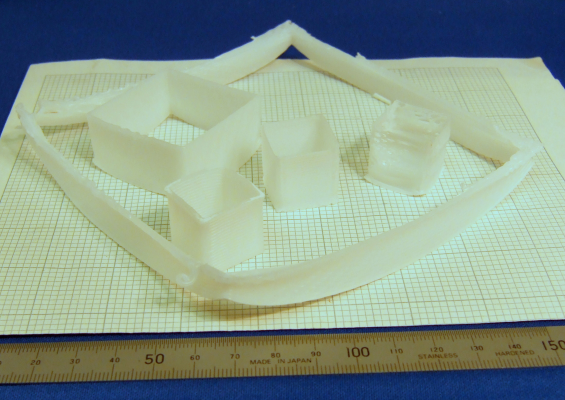

I was playing around a bit today.

This uses the same motor as the standard extruder, and I have it wired so it can be controlled by the Extruder Controller (no sensors, though). It works just fine empty, but I haven't tried it loaded. I don't know how to make cookie dough!

This uses the same motor as the standard extruder, and I have it wired so it can be controlled by the Extruder Controller (no sensors, though). It works just fine empty, but I haven't tried it loaded. I don't know how to make cookie dough!

|

Re: Cookie extruder October 15, 2007 03:27PM |

Admin Registered: 17 years ago Posts: 1,487 |

|

Anonymous User

Re: Cookie extruder October 15, 2007 04:44PM |

Hah, I love it! And just in time for the holiday season. A standard spritz cookie recipe ought to do just fine. You might need to have the extruder very close to the cookie sheet (less than the width of the filament -- uhm... cookie dough) to make it stick to the cookie sheet. Can't wait to see the results.

|

Re: Cookie extruder October 16, 2007 02:29AM |

Registered: 17 years ago Posts: 161 |

|

Re: Cookie extruder October 16, 2007 04:07AM |

Admin Registered: 16 years ago Posts: 13,888 |

... i looked in a local toolstore for fast hardening pastes and found some 1K- and 2K-types from 'Fischer' for fixing bolts in walls, which harden temperature-forced in some minutes to a extreme durable solid ...

So it could be interesting testing with outputting a single sheet, pause the reprap, then heat the sheet with a thermo-radiator until hardening (or bake the cookie sheet-wise ) and then process next sheets, and so on ...

) and then process next sheets, and so on ...

With this approach you can stack very soft pastes too, which wouldn't have enough stability, to hold more then two or three sheets without going away and distort.

In the next weeks i want to perform some test with the 'Fischer'-pastes, hot chocolade or gelatine, then i'll post my results ...

Viktor

So it could be interesting testing with outputting a single sheet, pause the reprap, then heat the sheet with a thermo-radiator until hardening (or bake the cookie sheet-wise

) and then process next sheets, and so on ...

) and then process next sheets, and so on ...With this approach you can stack very soft pastes too, which wouldn't have enough stability, to hold more then two or three sheets without going away and distort.

In the next weeks i want to perform some test with the 'Fischer'-pastes, hot chocolade or gelatine, then i'll post my results ...

Viktor

|

Anonymous User

Re: Cookie extruder October 22, 2007 01:23AM |

The dough is easy to make. It's the cookie-makeing technique that's hard.

This kind of cookie press may be a little trickier than you think. The press needs downward pressure during extrusion to make the dough stick to the metal sheet, then it needs to be pulled up just right to break off the bit of extruded dough, and if it isn't done perfectly, the dough will pull off the surface and stay attached to the nozzle.

There are machines that extrude cookies automatically in commercial bakeries. You might want to do some research and find out how they solved this problem.

This kind of cookie press may be a little trickier than you think. The press needs downward pressure during extrusion to make the dough stick to the metal sheet, then it needs to be pulled up just right to break off the bit of extruded dough, and if it isn't done perfectly, the dough will pull off the surface and stay attached to the nozzle.

There are machines that extrude cookies automatically in commercial bakeries. You might want to do some research and find out how they solved this problem.

|

Re: Cookie extruder October 22, 2007 08:12AM |

Admin Registered: 17 years ago Posts: 7,879 |

>The press needs downward pressure during extrusion to make the dough stick to the metal sheet, then it needs to be pulled up just right to break off the bit of extruded dough, and if it isn't done perfectly, the dough will pull off the surface and stay attached to the nozzle.

Its exactly the same with HDPE, except I don't think you can get it to stick to a conductive surface like metal.

[www.hydraraptor.blogspot.com]

Its exactly the same with HDPE, except I don't think you can get it to stick to a conductive surface like metal.

[www.hydraraptor.blogspot.com]

|

Re: Cookie extruder October 22, 2007 08:57AM |

Admin Registered: 17 years ago Posts: 1,915 |

nophead Wrote:

-------------------------------------------------------

>

> Its exactly the same with HDPE, except I don't

> think you can get it to stick to a conductive

> surface like metal.

>

Um... yes, you can... if the metal is hot. That is, you can with copper at least.

[3dreplicators.com]

A curious thing happened to the HDPE, though. I melted it onto copper and as it melted it suddenly contracted in length by a factor of over three quite dramatically. I suspect that the extruded 3 mm diameter piece of HDPE that I used for the experiment retained a memory of it's diameter before it was heated and stretched to it's final diameter.

I've been meaning to see if this same phenomena happens with the 0.6 mm filament that my Mk I AEM extruder produces. If it does it might explain a LOT about the contraction problems we are having.

-------------------------------------------------------

>

> Its exactly the same with HDPE, except I don't

> think you can get it to stick to a conductive

> surface like metal.

>

Um... yes, you can... if the metal is hot. That is, you can with copper at least.

[3dreplicators.com]

A curious thing happened to the HDPE, though. I melted it onto copper and as it melted it suddenly contracted in length by a factor of over three quite dramatically. I suspect that the extruded 3 mm diameter piece of HDPE that I used for the experiment retained a memory of it's diameter before it was heated and stretched to it's final diameter.

I've been meaning to see if this same phenomena happens with the 0.6 mm filament that my Mk I AEM extruder produces. If it does it might explain a LOT about the contraction problems we are having.

|

Re: Cookie extruder October 22, 2007 10:52AM |

Admin Registered: 17 years ago Posts: 7,879 |

I think 2% contraction is just the amount HDPE contracts when going from its melting point to room temperature. If you make something 100mm long then each new layers wants to come in 1mm at each end causing the curl.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Cookie extruder October 22, 2007 11:00AM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Cookie extruder October 22, 2007 11:38AM |

Admin Registered: 17 years ago Posts: 7,879 |

Memory effect may play a part but I think the 2% is enough to explain the curling I see. Remember it is 2% per layer so each layer is trying to be 2% shorter than the layer below. I.e. the first layer lands at 100mm then shrinks to 98mm. The next layer on top intially overlaps it by 1mm at each end but then the 98mm in contact tries to contract to 96mm and so on. Each successive layer tries to make the bottom layer 2% shorter until they get too far away for their effect to be felt.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Cookie extruder October 22, 2007 12:15PM |

Admin Registered: 17 years ago Posts: 1,915 |

When I was printing the polymer pump the distance between top and bottom was a bit under 70 mm. From your presentation one would expect that after 5-10 layers the offset due to cooling would be around half of the width of the extruded filament. Looking at the piece, flawed as it is, I don't observe anything like that.

The bottom curl is there, mind.

The bottom curl is there, mind.

|

Curner curling October 22, 2007 01:54PM |

Admin Registered: 17 years ago Posts: 7,879 |

I think this montage shows the effect well. With these thin walled objects I always get the same distinctive waist near the bottom as well as the corners curling upwards.

If the first layer sticks to the table or a raft it gets held so that it cannot contract before it sets. The layers immediately above manage to pull in and cause the corners to lift. Once a few layers are down there is enough set plastic to resist the contraction of the new layers and the wall start to come out again. I expect a finite element analysis would show that the curves are all the same basic shape, like that fact that washing lines all hang in a catenary.

[www.hydraraptor.blogspot.com]

If the first layer sticks to the table or a raft it gets held so that it cannot contract before it sets. The layers immediately above manage to pull in and cause the corners to lift. Once a few layers are down there is enough set plastic to resist the contraction of the new layers and the wall start to come out again. I expect a finite element analysis would show that the curves are all the same basic shape, like that fact that washing lines all hang in a catenary.

[www.hydraraptor.blogspot.com]

|

Re: Cookie extruder October 22, 2007 03:15PM |

Admin Registered: 17 years ago Posts: 1,915 |

I wonder if anybody here has a finite element analysis package that they can access? I used to when I was lecturing at university, but it's been a few years now.

I've been thinking about the problem of shrinkage and might just have thought of something. I've got to think about it some more, though, before I want to commit anything to the blog.

I've been thinking about the problem of shrinkage and might just have thought of something. I've got to think about it some more, though, before I want to commit anything to the blog.

|

Re: Cookie extruder October 22, 2007 05:37PM |

Registered: 16 years ago Posts: 622 |

Forrest,

Just did a search on google for Finite Element Analysis Software and came up with:

[www.freebyte.com]

They looked promessing but I'm not completely sure what you are looking at. Also, I have access to MATLab but I don't know if they will do what you want.

Demented

Just did a search on google for Finite Element Analysis Software and came up with:

[www.freebyte.com]

They looked promessing but I'm not completely sure what you are looking at. Also, I have access to MATLab but I don't know if they will do what you want.

Demented

|

Re: Cookie extruder October 22, 2007 06:17PM |

Admin Registered: 17 years ago Posts: 1,915 |

Yeah, Lisa would do the job properly. I doubt, though, whether I could make it happen with 1,300 nodes. To get more than that costs upwards of US$2K.

If I had Kurt and Julotta like when I worked at this back in Sweden, I expect that he and I could cook up a network to do it. As it is, I've got to be able to lay hot tracks of new material on a cooling system. That's going to be a bastard. I did something like this once, but I didn't have new material being added to the system on the fly, so to speak. I can do this, but I don't really have the months that it would take to write the code anymore. Hell, I don't even have the months, period.

Hmmm... maybe I can confect some meaningful thought experiments instead.

If I had Kurt and Julotta like when I worked at this back in Sweden, I expect that he and I could cook up a network to do it. As it is, I've got to be able to lay hot tracks of new material on a cooling system. That's going to be a bastard. I did something like this once, but I didn't have new material being added to the system on the fly, so to speak. I can do this, but I don't really have the months that it would take to write the code anymore. Hell, I don't even have the months, period.

Hmmm... maybe I can confect some meaningful thought experiments instead.

|

Anonymous User

Re: Cookie extruder October 25, 2007 01:09PM |

Forrest Higgs Wrote:

-------------------------------------------------------

> nophead Wrote:

> A curious thing happened to the HDPE, though. I

> melted it onto copper and as it melted it suddenly

> contracted in length by a factor of over three

> quite dramatically. I suspect that the extruded 3

> mm diameter piece of HDPE that I used for the

> experiment retained a memory of it's diameter

> before it was heated and stretched to it's final

> diameter.

Maybe there's somthing that could be added to the plastic that would cause the "memory" structure to break apart when melted in the extruder. But this would probably also make the plastic a lot weaker.

-------------------------------------------------------

> nophead Wrote:

> A curious thing happened to the HDPE, though. I

> melted it onto copper and as it melted it suddenly

> contracted in length by a factor of over three

> quite dramatically. I suspect that the extruded 3

> mm diameter piece of HDPE that I used for the

> experiment retained a memory of it's diameter

> before it was heated and stretched to it's final

> diameter.

Maybe there's somthing that could be added to the plastic that would cause the "memory" structure to break apart when melted in the extruder. But this would probably also make the plastic a lot weaker.

Sorry, only registered users may post in this forum.