|

Bowden quick disconnect type January 18, 2016 06:26PM |

Registered: 8 years ago Posts: 200 |

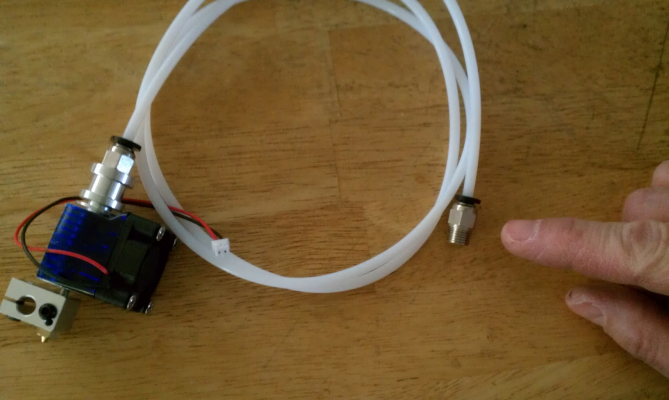

I am wondering if anybody has seen a connection like I am pointing to on the extruder end for the extruder end?

I would love to be able to pull things apart like this. It is away from the activity end so shouldn't be a problem.

Replikeo Prusa I3 Rework, Ramps 1.4, Marlin, Pronterface, Tinkercad.

Plan B is always to be somebody else.

|

Re: Bowden quick disconnect type January 18, 2016 08:08PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Bowden quick disconnect type January 19, 2016 03:19AM |

Registered: 9 years ago Posts: 1,159 |

That is a std Pneumatic Pushfit connector They come in various sizes and threads the ones we are interested in are for 4mm Dia tube (1.75 mm filament) and 6mm tube (3 mm filament) the common thread sizes are M5,M6 and 1/8th BSPP You can get them from various suppliers and EBAY is usually full of them you just need to get one that is the right three for your COLD END Body

Doug

Doug

|

Re: Bowden quick disconnect type January 19, 2016 11:32AM |

Registered: 8 years ago Posts: 200 |

|

Re: Bowden quick disconnect type January 19, 2016 12:54PM |

Registered: 9 years ago Posts: 1,159 |

Quote

Giantkiller

Yep. I installed an R/O water filtering system and used the nylon versions of these.

I just have to design a Thingy interface to house the female part then put that thingy on the extruder thingy.

I am overthinged.

Did you see that I replied to your Design post Found a dual E3D Holder for you?

|

Re: Bowden quick disconnect type January 19, 2016 12:59PM |

Registered: 8 years ago Posts: 200 |

|

Re: Bowden quick disconnect type January 19, 2016 01:03PM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Bowden quick disconnect type January 19, 2016 01:25PM |

Registered: 8 years ago Posts: 200 |

|

Re: Bowden quick disconnect type January 19, 2016 01:30PM |

Registered: 9 years ago Posts: 1,159 |

Quote

Giantkiller

Oh yeah. I pulled that down and am working my interation right now.

The dual e3d mount one?

This one dual E3D for I3

Edited 1 time(s). Last edit at 01/19/2016 01:31PM by dougal1957.

|

Re: Bowden quick disconnect type January 19, 2016 04:34PM |

Registered: 8 years ago Posts: 200 |

|

Re: Bowden quick disconnect type January 19, 2016 06:25PM |

Registered: 8 years ago Posts: 67 |

Getting back on topic, I would like to know why some of those things allow the tube to go through them and others stop it inside? I bought some cheap Chinese ones and they won't allow the tube to pass through, but my hotend came with one that does. Is that a matter of choosing a right thread diameter (like there needs to be a certain difference between that and the tubes diameter), some other type of fitting, or manual modification?

|

Re: Bowden quick disconnect type January 19, 2016 09:20PM |

Registered: 8 years ago Posts: 200 |

I hope this is on track. The pressure fitting enables the tube to slide without deforming the inside diameter of the tube. There are reprap instructions to use a 2mm drill bit to ream the tube once it has been screwed on the initial fitting. I believe part of your concern deals with part of this issue in this way.

We all know variations appear in products due to a previous mechanical failure point.

Edited 1 time(s). Last edit at 01/19/2016 09:21PM by Giantkiller.

We all know variations appear in products due to a previous mechanical failure point.

Edited 1 time(s). Last edit at 01/19/2016 09:21PM by Giantkiller.

|

Re: Bowden quick disconnect type January 20, 2016 02:24AM |

Registered: 9 years ago Posts: 1,159 |

Quote

Giantkiller

I hope this is on track. The pressure fitting enables the tube to slide without deforming the inside diameter of the tube. There are reprap instructions to use a 2mm drill bit to ream the tube once it has been screwed on the initial fitting. I believe part of your concern deals with part of this issue in this way.

We all know variations appear in products due to a previous mechanical failure point.

I think what he means is that on some of the fittings the internal bore is at least 4mm all the way thru so you can pass the PTFE tube all the way thru the fitting which is a good idea and I drill all mine out at the back to allow this to happen, Minimum thread size to do this is M6. The riprap instructions are for there own design which is not the same as these push fit fittings at all.

|

Re: Bowden quick disconnect type January 20, 2016 03:23AM |

Registered: 8 years ago Posts: 67 |

Quote

dougal1957

I think what he means is that on some of the fittings the internal bore is at least 4mm all the way thru so you can pass the PTFE tube all the way thru the fitting which is a good idea and I drill all mine out at the back to allow this to happen, Minimum thread size to do this is M6. The riprap instructions are for there own design which is not the same as these push fit fittings at all.

Yeah, this is what I was trying to say... So, it needs a bit of drilling out then. Thanks.

|

Re: Bowden quick disconnect type January 20, 2016 11:58PM |

Registered: 8 years ago Posts: 916 |

I've drilled out my M6 push fitting to allow the tube to go all the way through.

Take it slowly, it's brass so your drill bit might grab. Also really try to get it straight, there isn't a lot of meat between the hole and the inside of the thread.

Blow it out well once you've done it so that metal fragments don't get down into the hotend.

I like having the tube go through the fitting so that it can get right up close to the extruder drive gear.

Take it slowly, it's brass so your drill bit might grab. Also really try to get it straight, there isn't a lot of meat between the hole and the inside of the thread.

Blow it out well once you've done it so that metal fragments don't get down into the hotend.

I like having the tube go through the fitting so that it can get right up close to the extruder drive gear.

|

Re: Bowden quick disconnect type January 21, 2016 02:51PM |

Registered: 9 years ago Posts: 483 |

|

Re: Bowden quick disconnect type January 23, 2016 04:38PM |

Registered: 9 years ago Posts: 705 |

Sorry, only registered users may post in this forum.