An alternative to printed parts?

Posted by drmaestro

|

Re: An alternative to printed parts? July 19, 2018 12:32PM |

Admin Registered: 16 years ago Posts: 13,888 |

... before "RepRap" 3D-printing was the domain of proffessional printers and mostly used for comercial applications.

Most of the "3D-printing concepts" were invented around 1980 and "covered" by IP's, what've blocked or prohibited any related development.

Then, with starting the RepRap project 2006 and end of the "IP-ban" for FDM printing around 2007 the idea and DIY-variants got momentum (or better "media presence"), what developed to the actual situation.

Most of the actual "new" 3D-ptinting companies started either with/from RepRap, or split off comercial routes with many of the basic ideas, found here

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Most of the "3D-printing concepts" were invented around 1980 and "covered" by IP's, what've blocked or prohibited any related development.

Then, with starting the RepRap project 2006 and end of the "IP-ban" for FDM printing around 2007 the idea and DIY-variants got momentum (or better "media presence"), what developed to the actual situation.

Most of the actual "new" 3D-ptinting companies started either with/from RepRap, or split off comercial routes with many of the basic ideas, found here

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: An alternative to printed parts? July 19, 2018 02:14PM |

Registered: 12 years ago Posts: 1,450 |

Assuming that this is a rhetorical question rather than a dismissal of the project. To me RepRap became important when I built my frist 3D printer (A Prusa Mendel) and was able to get the occasionla print which was more accurate and better finished than the Stratasys printer used by the design consultancy that then employed me. That my printer used salvaged parts and cost a few hundred pounds instead of the £75,000 that the Stratasys cost made it very important.Quote

cwaa

When did RepRap become so important? ........

Simplistic ideas about the importance of rigidity without a measure of the forces that are involved and thoughts about the suitability of one material over another do nothing for me. The Pyramid builders went for rigidity but when people started thinking about structure they were able to build cathedrals and then skyscrapers. In the future there may even be space elevators - built largely out of plastic.Quote

I started in 3d printing 3 years ago and didn't use anything from Rep Rap. How is that possible? Well I researched 3d printing for a while and learned a lesson in rigidity. Making frames with plastic joints is not going to make a quality printer......

I can print; My printers do not need constant calibration; I do want to experiment and play (and perhaps make some meaningful contribution to the knowledge base)Quote

You may be able to print, but it will be a toy needing constant calibration. So if you want to experiment and play with RepRap designs go ahead.

If your objective is purely to build a high quality printer then build it by specifying what you want and getting 3D Systems or ExOne [investingnews.com] to do the laborious bit of the job. Trust me, I don't mean to be insulting by this but it will be a better quality printer than you have made. Most people have a budget to work to and the best results can be obtained by good engineering, often withe a lower financial cost.Quote

I wanted to build a high quality printer that would be stable and not require high levels of maintenance. I got my materials from Openbuilds and used Smoothieware. So if your objective is a high quality printer, you have to put the RepRap slogan away.

I don't recall anybody implying that you do not belong here or any loose chat of banishment. You do however have to get used to the fact that the members often won't agree with you.Quote

If that means I don't belong here, fine with me. You can ban me, but the slogan is still not reasonable unless you want to play with toys!

Mike

|

Re: An alternative to printed parts? July 19, 2018 02:40PM |

Admin Registered: 16 years ago Posts: 13,888 |

... to be fair - naming plastic-3D-printing as "toy-fabbing" is one of my point of views too ... although it is also commercially/professionally used everywhere

My focus is to develop "fabbers" capable of fabbing with all sorts of materials - plastic, sand (glass), ceramics, metal, wood (better lignin), living cells ... or any other material available ...

One of the tools, allowing this variances (except living cells) is a laser (or better different lasers/wavelengths for different materials).

This was my intention, when starting the laser-subforums in the main- and German forum ... and now there are all sorts of cheap laser-engravers and -cutters around too - so expect some more development in this direction too

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My focus is to develop "fabbers" capable of fabbing with all sorts of materials - plastic, sand (glass), ceramics, metal, wood (better lignin), living cells ... or any other material available ...

One of the tools, allowing this variances (except living cells) is a laser (or better different lasers/wavelengths for different materials).

This was my intention, when starting the laser-subforums in the main- and German forum ... and now there are all sorts of cheap laser-engravers and -cutters around too - so expect some more development in this direction too

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: An alternative to printed parts? July 19, 2018 03:39PM |

Registered: 7 years ago Posts: 257 |

Mike, I am very capable of building a high quality printer and without RepRap help. Why should I hire someone else to do it for me? I surveyed the industry for months prior to my build and picked up some very useful tips. Now I have a workhorse cartesian and a very stout Delta. Neither have any plastic in the joints or anywhere in the frame.

And finally Mike, I am a mature male well able to defend myself. I don't really give a shit who agrees with me.....I still have my opinion. Why not let me see your simplistic all plastic rods and bearings? How about that all plastic extruder or power supply with printed generator for power? Now if this thread was about a CNC machine being self replicable then I give it a chance. A computer controlled glue gun ain't gonna make it.

Edited 1 time(s). Last edit at 07/19/2018 03:45PM by cwaa.

And finally Mike, I am a mature male well able to defend myself. I don't really give a shit who agrees with me.....I still have my opinion. Why not let me see your simplistic all plastic rods and bearings? How about that all plastic extruder or power supply with printed generator for power? Now if this thread was about a CNC machine being self replicable then I give it a chance. A computer controlled glue gun ain't gonna make it.

Edited 1 time(s). Last edit at 07/19/2018 03:45PM by cwaa.

|

Re: An alternative to printed parts? July 19, 2018 04:51PM |

Registered: 12 years ago Posts: 1,450 |

An opinion seemingly unsupported by anything other than that it is your opinion. Kinda makes me wonder (without wishing to put pressure one way or another) just why you are on the RepRap forum. You don't appear, or won't admit, to having learned anything here; neither does contributing anything seem to be something you would willingly do.Quote

cwaa

.................................................... I don't really give a shit who agrees with me.....I still have my opinion..........................

Mike

|

Re: An alternative to printed parts? July 19, 2018 05:12PM |

Registered: 7 years ago Posts: 363 |

I'm not sure what all the seeming argument is about. There's a place for the reprap 'philosophy' and there's a place for more structurally sound philosophy. I don't see why both can't coexist, they certainly sharemuch of the same technology and design concepts between the two. People can get quite indignant over things like this it seems.

|

Re: An alternative to printed parts? July 19, 2018 09:16PM |

Registered: 7 years ago Posts: 619 |

Quote

cwaa

When did RepRap become so important? I started in 3d printing 3 years ago and didn't use anything from Rep Rap. How is that possible? Well I researched 3d printing for a while and learned a lesson in rigidity. Making frames with plastic joints is not going to make a quality printer. You may be able to print, but it will be a toy needing constant calibration. So if you want to experiment and play with RepRap designs go ahead. I wanted to build a high quality printer that would be stable and not require high levels of maintenance. I got my materials from Openbuilds and used Smoothieware. So if your objective is a high quality printer, you have to put the RepRap slogan away. If that means I don't belong here, fine with me. You can ban me, but the slogan is still not reasonable unless you want to play with toys!

ooh. THAT is provocative! I say that "toy" line to my Linux buds all the time - then they poke fun at my Mac. Oh well.

Anyway, sure, I agree a RepRap printer can't hold a candle to the quality commercial and skilled builder's machine. But I sure hope they will some day! It is a gradual migration, and apparently not a very fast one. I am an ADHD type and get impatient...

(Side thought) I am hoping that we will eventually move past the 8-bit Arduino. But I really want the idea behind the Arduino to stay. Something that can be programmed by anyone without special closed source tools. RepRap and Arduino came from different directions to enable 3D printers "for the masses". What will the next cool (and unrelated) thing be that boosts us past our current development plateu?

IMO,

DLC

|

Re: An alternative to printed parts? July 20, 2018 03:05AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dlc60

(Side thought) I am hoping that we will eventually move past the 8-bit Arduino. But I really want the idea behind the Arduino to stay. Something that can be programmed by anyone without special closed source tools. RepRap and Arduino came from different directions to enable 3D printers "for the masses". What will the next cool (and unrelated) thing be that boosts us past our current development plateu?

AFAIK all modern 32-bit processors can be programmed using open source tools. The ATSAM processors used on the Duets certainly can, we use Eclipse, GCC and Bossa. We could even use the Arduino IDE to program it if we wanted, but although Arduino is great for novices to write small programs in, Eclipse is far more productive when developing serious software.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: An alternative to printed parts? July 20, 2018 04:41AM |

Registered: 12 years ago Posts: 2,470 |

ReRap started and enabled printer electronics and firmware development. It sparked the creation and production of cheap but capable printers. That most of the currently sold mass market printers have their technical roots in the reprap world, even though they aren't RepRaps themself, doesn't take away from that. Without Darwin and Mendel the current 3D printing world would look quite different.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: An alternative to printed parts? July 20, 2018 08:42AM |

Registered: 8 years ago Posts: 622 |

I'd like to think that my printer is a RepRap as far as possible - even RepRap Pro Mendels (my first printer) had what were called "Minerals" consisting of metal items such as threaded rod, nuts bolts and screws. So in my case, I use OpenBuilds extrusion instead of threaded rod but otherwise most of the original parts were printed on my RepRapPro Mendel and since then, in true RepRap style, all the upgraded parts have been printed on the printer itself. That's motor mounts, gantry plates, carriages, idler mounts, bearing housings, cover plates, enclosures, and numerous other assorted items.

By the definitions given above, that makes my printer a toy. It's a 5 colour, dual gantry CoreXYUV with build volume of about 360mm x 360mm x 750mm that has been demonstrated to be capable of printing at up to 300mm/sec toy. This particular toy has done hundreds if not thousands of hours with hardly any adjustments or re-calibrations. It has been transported 60 miles or so in a van, the bed level re-adjusted then with no further adjustment it spent 3 days solid printing 5 colour objects to impress the visitors at the TCT show in Birmingham. The parts produced were given to employees of E3D who were also impressed and one item has ended up in a Museum in Switzerland.

I don't use any form of orthogonal axis compensation, nor bed levelling nor, flatness compensation. I have the homing files in my start.g code so to print something I simply select the file and hit "Print".

I say all this not to brag or boast, but simply to point out that self REPlicating RAPid prototyping doesn't mean making toys that aren't capable of producing good quality FDM prints.

Not bad for a toy IMO.

[somei3deas.wordpress.com]

[www.youtube.com]

By the definitions given above, that makes my printer a toy. It's a 5 colour, dual gantry CoreXYUV with build volume of about 360mm x 360mm x 750mm that has been demonstrated to be capable of printing at up to 300mm/sec toy. This particular toy has done hundreds if not thousands of hours with hardly any adjustments or re-calibrations. It has been transported 60 miles or so in a van, the bed level re-adjusted then with no further adjustment it spent 3 days solid printing 5 colour objects to impress the visitors at the TCT show in Birmingham. The parts produced were given to employees of E3D who were also impressed and one item has ended up in a Museum in Switzerland.

I don't use any form of orthogonal axis compensation, nor bed levelling nor, flatness compensation. I have the homing files in my start.g code so to print something I simply select the file and hit "Print".

I say all this not to brag or boast, but simply to point out that self REPlicating RAPid prototyping doesn't mean making toys that aren't capable of producing good quality FDM prints.

Not bad for a toy IMO.

[somei3deas.wordpress.com]

[www.youtube.com]

|

Re: An alternative to printed parts? July 20, 2018 09:05AM |

Admin Registered: 16 years ago Posts: 13,888 |

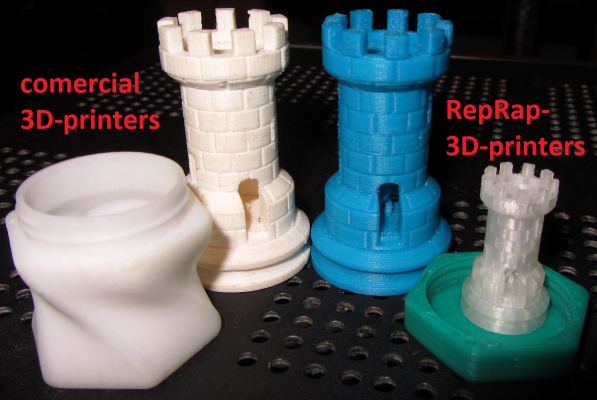

... I wouldn't say, RepRap printers are less capable than comercial ones -- here an example with two "comercial made" parts on the left side and made with much cheaper (22500€ vs. 600€) hobby printers on the right:

But I'm expecting even more quality and capabilities with "evolving" them in the next years

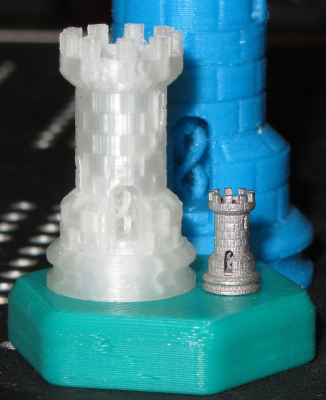

The small metal rook is actually made with a comercial SLS machine ... be prepared to see this made with "hobby" systems in the next time:

And for "FDM-printed" vs. moulded:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But I'm expecting even more quality and capabilities with "evolving" them in the next years

The small metal rook is actually made with a comercial SLS machine ... be prepared to see this made with "hobby" systems in the next time:

And for "FDM-printed" vs. moulded:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: An alternative to printed parts? July 20, 2018 10:21AM |

Registered: 7 years ago Posts: 257 |

|

Re: An alternative to printed parts? July 20, 2018 10:38AM |

Registered: 8 years ago Posts: 1,671 |

The Sci-Fi idea of a Replic8tor could be so far off, it might as well never exist (at least for some aging Mortals)

Though I can't say it will never exist...(I have far more confidence in technology than in a deity)

When we see a replicator or teleporter in a film ... do we ROFL or Suspend our Disbelief?

The next step is all we need to take our machines to next level, ie an AFFORDABLE material we feel copes as well as metal,

even that might be too late for some

It would be a big step up(small shift) to start designing smaller thinner parts you know won't break,

because at the moment my printer isnt used to test out ideas for metal parts, just over sized less than perfect stopgap parts.

The next step is all thats needed to open things up exponentially.

The first two years my head was full of shapes & ideas(mainly for printer parts), and then as you whittle them down to the point of virtually none, because you dont want plastic, and then move over to design for CNC/Mill/Lathe...the part ideas seem to have shrunk further(my mind seems to be less curious than it was, not testing/designing as many shapes in my head as usual)...so until I can make super strong parts...I'll have to think of something else to do with it, something not printer related...or toy related...but hell some people make money selling toys...

Though I can't say it will never exist...(I have far more confidence in technology than in a deity)

When we see a replicator or teleporter in a film ... do we ROFL or Suspend our Disbelief?

The next step is all we need to take our machines to next level, ie an AFFORDABLE material we feel copes as well as metal,

even that might be too late for some

It would be a big step up(small shift) to start designing smaller thinner parts you know won't break,

because at the moment my printer isnt used to test out ideas for metal parts, just over sized less than perfect stopgap parts.

The next step is all thats needed to open things up exponentially.

The first two years my head was full of shapes & ideas(mainly for printer parts), and then as you whittle them down to the point of virtually none, because you dont want plastic, and then move over to design for CNC/Mill/Lathe...the part ideas seem to have shrunk further(my mind seems to be less curious than it was, not testing/designing as many shapes in my head as usual)...so until I can make super strong parts...I'll have to think of something else to do with it, something not printer related...or toy related...but hell some people make money selling toys...

|

Re: An alternative to printed parts? July 20, 2018 11:18AM |

Registered: 12 years ago Posts: 1,450 |

I tried to resist commenting on both of these things but have failed

Mike

- I have seen deckingman's printer at the TCT show and it was better made and printed better than most of the 3D printers on commercial printer stands. .

- Linux is the operating system used on ALL (as in every last one) of the top 200 supercomputers

Mike

|

Re: An alternative to printed parts? July 20, 2018 12:40PM |

Admin Registered: 16 years ago Posts: 13,888 |

... life is a game - with many "toys" to play through it

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: An alternative to printed parts? July 20, 2018 12:57PM |

Registered: 12 years ago Posts: 1,450 |

Quote

VDX

... life is a game - with many "toys" to play through it

btw, I miss-spoke - it was the top 500 supercomputers [www.zdnet.com]

Mike

Edited 1 time(s). Last edit at 07/20/2018 12:58PM by leadinglights.

|

Re: An alternative to printed parts? July 20, 2018 05:39PM |

Registered: 9 years ago Posts: 465 |

Quote

cwaa

When did RepRap become so important? I started in 3d printing 3 years ago and didn't use anything from Rep Rap.

I got my materials from Openbuilds and used Smoothieware.

Quote

cwaa

Now I have a workhorse cartesian and a very stout Delta

Openbuilds and Smoothieware would probably not exist if not for RepRap, or developers who were working towards that as a design goal. Delta printers similarly became possible with 3D printed parts, only after gaining in popularity getting to custom made machined parts, so I'd say it's fair to say that without this, you wouldn't have a 3D printer.

For me, that doesn't mean that I want to be restricted to 3D FDM printed parts. I'm using laser-cut wood, acryllic and polycarbonate parts, too, because I have some connections with people who have commercial grade laser cutters. I am starting the parts collection and manufacturing phase on a cnc router. It's first job will likely be to make better parts for itself than I can manufacture with a table saw, drill press and hand tools. In all likelihood though my cnc router will be made using principles that I've learned from my toy 3D printer. chances are pretty good that I'll be making some Gen 1 parts for the router on the 3D printer, probably replacing them with parts made on the router for Gen 2. Some of the plastic parts in my 3D printer will be rebuilt with the router, too, which should increase the quality of what the printer is able to produce.

At present, I don't think that my 'toy' falls too far short of what a commercial unit's capabilities. It currently takes a bit more work on my part to set up than what I'd accept from a production unit, but that's why I'm working with integrating better control boards, and working with better sensors. As my machine's capabilities improve, I intend to use them to improve themselves and each other.

That said, I'm not looking at something that can completely replicate itself. I leave that for people more ambitious than I am, but I'm grateful for the work that they do to pave the way for me to have something that I can do other useful things.

|

Re: An alternative to printed parts? July 21, 2018 08:43PM |

Registered: 7 years ago Posts: 619 |

Quote

leadinglights

I tried to resist commenting on both of these things but have failed

Opinion on the meaning of the word "toy" may vary.

- I have seen deckingman's printer at the TCT show and it was better made and printed better than most of the 3D printers on commercial printer stands. .

- Linux is the operating system used on ALL (as in every last one) of the top 200 supercomputers

Mike

Toy is a kind of euphemism for me. To me "toy" doesn't mean something that isn't serious, it means something that the masses typically can't use, only those who know it inside and out can use it. Because I am a tech geek too, I call what I do in the esoterica of my "toys", "playing".

Linux is awesome, I love playing with it to build very custom tools. I feel the same way about my 3D printers and my robots. I can't give them to anyone else to use, but I sure can use them.

IMO,

DLC

|

Re: An alternative to printed parts? July 22, 2018 04:46AM |

Admin Registered: 16 years ago Posts: 13,888 |

... I agree - "toys" may be a little misleading... some of my "toys" are remnants from industrial and research projects around microtechnology and lasers, hardly within reach for "normal people"

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: An alternative to printed parts? November 24, 2019 04:29PM |

Admin Registered: 16 years ago Posts: 13,888 |

... this is another "evolving step", from "toy" to "usefull equipment"

The left part is printed with a DLP-3D-printer (UV-curing resin in a vat through illuminating the bottom) ... then inserted into an injection-molding machine and filled with molten plastic ... last put into a water filled dish and solved/removed the mould:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The left part is printed with a DLP-3D-printer (UV-curing resin in a vat through illuminating the bottom) ... then inserted into an injection-molding machine and filled with molten plastic ... last put into a water filled dish and solved/removed the mould:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.