My Prusa MGN

Posted by bme

|

Re: My Prusa MGN June 15, 2016 06:00PM |

Registered: 8 years ago Posts: 88 |

|

Re: My Prusa MGN June 15, 2016 11:59PM |

Registered: 7 years ago Posts: 49 |

You can print it as you like.

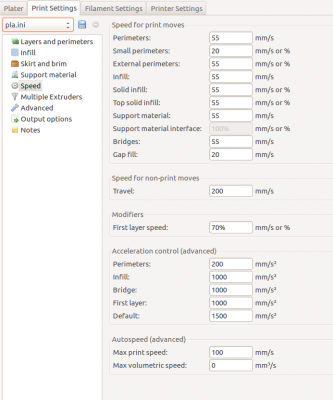

My speed settings:

Every speed in Slicer3r = 55 mm/sec

layer height = 0.2 mm

travel = 200 mm /sec

gap fill = 20 mm/sec

Extruder = 90 mm/sec

Retraction = 6 mm

Repetier:

Travel acceleration = 1500 mm/s2

Print acceleration = 1000 mm/s2

Edited 1 time(s). Last edit at 06/16/2016 12:04AM by bme.

My speed settings:

Every speed in Slicer3r = 55 mm/sec

layer height = 0.2 mm

travel = 200 mm /sec

gap fill = 20 mm/sec

Extruder = 90 mm/sec

Retraction = 6 mm

Repetier:

Travel acceleration = 1500 mm/s2

Print acceleration = 1000 mm/s2

Edited 1 time(s). Last edit at 06/16/2016 12:04AM by bme.

|

Re: My Prusa MGN June 16, 2016 01:24AM |

Registered: 7 years ago Posts: 49 |

|

Re: My Prusa MGN June 16, 2016 05:04AM |

Registered: 8 years ago Posts: 88 |

|

Re: My Prusa MGN June 16, 2016 02:27PM |

Registered: 7 years ago Posts: 49 |

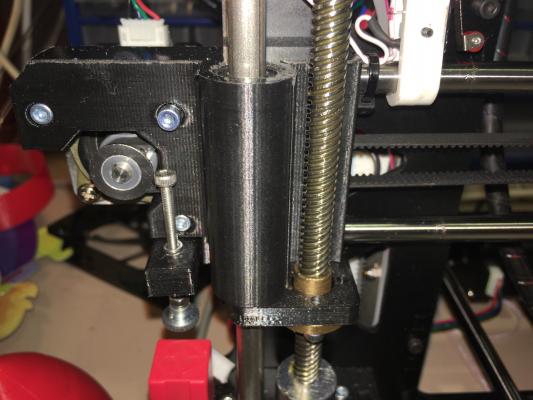

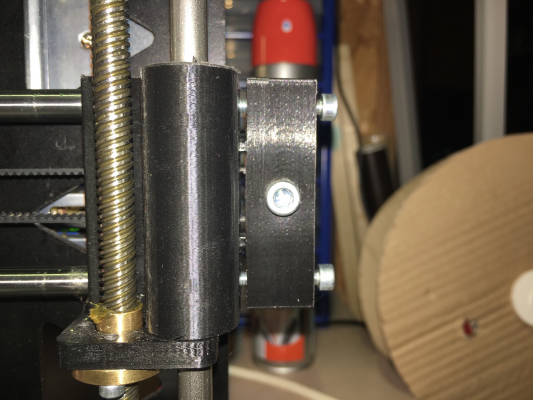

Sigxcpu--> Your print is very good. You can consider if you need to buy MGN12. I know that MGN12 has less

play then LM8UU.

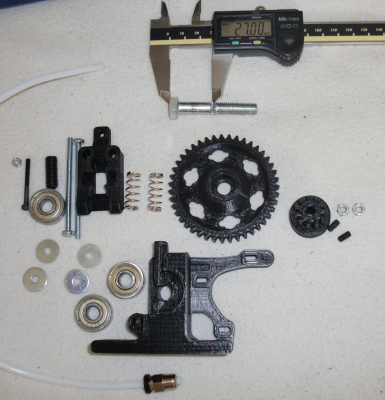

My printer is not yet finished. I am satisfied with quality now. I can improve it. I work on hot end holder.

As it looks now my 8000 rpm fan can cause some noise I don't like. Last week I removed some aluminum profiles.

Much work to do.

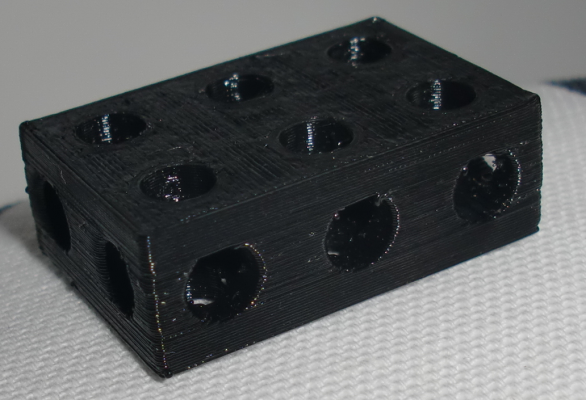

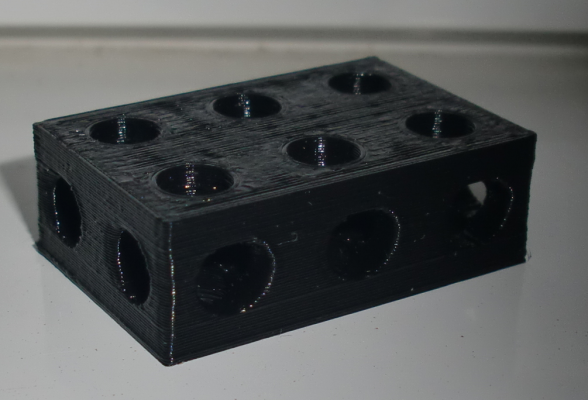

This is my last file. Second image is with my privies Prusa i3 based on LM8UU.

Edited 1 time(s). Last edit at 06/16/2016 02:49PM by bme.

play then LM8UU.

My printer is not yet finished. I am satisfied with quality now. I can improve it. I work on hot end holder.

As it looks now my 8000 rpm fan can cause some noise I don't like. Last week I removed some aluminum profiles.

Much work to do.

This is my last file. Second image is with my privies Prusa i3 based on LM8UU.

Edited 1 time(s). Last edit at 06/16/2016 02:49PM by bme.

|

Re: My Prusa MGN June 16, 2016 04:01PM |

Registered: 8 years ago Posts: 88 |

Converting P3 Steel to MGN12 is the 2nd and optional project. The linear guides were primarily acquired for a new printer. I want to do a CoreXY. Today I've made the frame (2020) and learned some stuff: do not force the tap if it doesn't want to go. Always use oil if you want to tap ~25mm depth. After snapping 2 taps in one hole, did 34 M5 threads @25mm with a single tap. I'm pretty proud of myself. I've also used @the_digital_dentist's method to join the extrusions, after testing the "cubes". Next sub-project is the XY mechanism using the MGN12 rails and then the Z.

Thank you for the nice words on the print quality. This machine was a MigBot i3 at the beginning. All is left are motors, wires and the MKS BASE controller which is nice. Everything else was changed.

Do your MGN12 carriages move butter smooth without belts? I think the high frequency modulation you have on your prints may come from them. I've had a "bad" one, super tight and you would feel a vibration when moving. Checking in light, the ball grooves in the rail got a fine, regulated, pattern, so I assume that rail will send those vibrations in the print. Luckily, I have 6 of them to play with, so no big deal. They are slightly more expensive here in Romania than Ali, so I can get more for the P3 Steel makeover. Now I need that printer for small printed stuff on the CoreXY.

Edited 1 time(s). Last edit at 06/16/2016 04:06PM by sigxcpu.

Thank you for the nice words on the print quality. This machine was a MigBot i3 at the beginning. All is left are motors, wires and the MKS BASE controller which is nice. Everything else was changed.

Do your MGN12 carriages move butter smooth without belts? I think the high frequency modulation you have on your prints may come from them. I've had a "bad" one, super tight and you would feel a vibration when moving. Checking in light, the ball grooves in the rail got a fine, regulated, pattern, so I assume that rail will send those vibrations in the print. Luckily, I have 6 of them to play with, so no big deal. They are slightly more expensive here in Romania than Ali, so I can get more for the P3 Steel makeover. Now I need that printer for small printed stuff on the CoreXY.

Edited 1 time(s). Last edit at 06/16/2016 04:06PM by sigxcpu.

|

Re: My Prusa MGN June 16, 2016 04:42PM |

Registered: 8 years ago Posts: 88 |

These are nice parts to me (except the perfectly aligned vibration on the motor mount perimeter which I'm actually chasing  ).

).

).

).|

Re: My Prusa MGN June 17, 2016 01:48AM |

Registered: 7 years ago Posts: 49 |

|

Re: My Prusa MGN June 18, 2016 05:50AM |

Registered: 7 years ago Posts: 49 |

Here is my first print with Rugged MEGA:

[www.youtube.com]

It works is fully compatible with ATMEGA2560.

Edited 1 time(s). Last edit at 06/18/2016 05:52AM by bme.

[www.youtube.com]

It works is fully compatible with ATMEGA2560.

Edited 1 time(s). Last edit at 06/18/2016 05:52AM by bme.

|

Re: My Prusa MGN June 18, 2016 03:10PM |

Registered: 8 years ago Posts: 88 |

Is the "rugged" just a hobby of yours or you have a valid point in investing ~100$ in the microcontroller board and get the same shitty RAMPS + drivers, instead of putting those money against a good 32-bit embedded board?

As far as my understanding goes, in the MEGA+RAMPS+stepper drivers, the weak parts are: undercooled "stepsticks" then RAMPS polyfuses and, last, the ATMega 2560 processing power. I would tackle these in that order, not the other way around.

As far as my understanding goes, in the MEGA+RAMPS+stepper drivers, the weak parts are: undercooled "stepsticks" then RAMPS polyfuses and, last, the ATMega 2560 processing power. I would tackle these in that order, not the other way around.

|

Re: My Prusa MGN June 18, 2016 04:01PM |

Registered: 7 years ago Posts: 49 |

I like to test things. When something works I have difficult to change it.

Ramps 1.4, Atmega2560 or DRV8825 allways works in my case. No problem as you described.

I can have up 300 mm/sec speed, high acceleration and everithing with 32 micro stepping.

Tell me advantages with your own or others motherboards?

What can you do more then me with my electronic?

Ramps 1.4, Atmega2560 or DRV8825 allways works in my case. No problem as you described.

I can have up 300 mm/sec speed, high acceleration and everithing with 32 micro stepping.

Tell me advantages with your own or others motherboards?

What can you do more then me with my electronic?

|

Re: My Prusa MGN June 20, 2016 03:06PM |

Registered: 7 years ago Posts: 49 |

|

Re: My Prusa MGN June 20, 2016 03:25PM |

Registered: 8 years ago Posts: 88 |

Quote

bme

I like to test things. When something works I have difficult to change it.

Ramps 1.4, Atmega2560 or DRV8825 allways works in my case. No problem as you described.

I can have up 300 mm/sec speed, high acceleration and everithing with 32 micro stepping.

Tell me advantages with your own or others motherboards?

What can you do more then me with my electronic?

It is just the idea of getting the best bang for the buck. A $100 "rugged" arduino will give you zero advantage over the standard $10 clone. But for $100 you can get a branded 32-bit board or a clone and a LCD (e.g MKS SBASE, which is a Smoothieware clone). A 32-bit board will give you smoother control over the steppers, a native web interface, better performance if you want to move from cartesian to CoreXY or Delta in the future and almost all of them come with properly installed stepper drivers (PCB cooling underneath).

The 2560 + RAMPS is a very cheap entry level setup, just to get you started in 3D printing world. After that, pumping money should not get you another 2560+RAMPS.

|

Re: My Prusa MGN June 20, 2016 05:02PM |

Registered: 7 years ago Posts: 49 |

I already have an Odroid C1 with Octoprint. I don't think a 32-bit board will give me smoother control over my printer like in my

case with speed up to 300 mm/sec. A signal is just a signal regardless of which controller I use.

I can understand if I need more micro stepping like 64, 128 or 256 then I need a 32-bit board to keep the same speed.

I think protection is very important thing in 3D printing World. That's why I bought Rugged MEGA.

case with speed up to 300 mm/sec. A signal is just a signal regardless of which controller I use.

I can understand if I need more micro stepping like 64, 128 or 256 then I need a 32-bit board to keep the same speed.

I think protection is very important thing in 3D printing World. That's why I bought Rugged MEGA.

|

Re: My Prusa MGN June 21, 2016 04:42AM |

Registered: 8 years ago Posts: 88 |

It is not about signals. For starters some/all of the 32-bit CPUs have hardware floating point units. All the motion in a 3d printer (except Teacup firmware) is computed in floating point, so the performance gain is significant. You feel then when you have tons of little segments (e.g. circles). 300mm/s are reachable, if ever, on long, straight lines only. Even then, at 80 steps/mm which is the usual configuration it means 24000 steps/sec.

Base on this page (http://reprap.org/wiki/Step_rates) an 8-bit CPU will reach <10k steps/sec in total (all axes combined) in single step and <40k steps/sec in quad step (that has its own issues because the steps are not evenly distributed).

So, in 8-bit, there are two slowdowns:

- motion compute, because of the software floating point. This is felt in LCD UI, serial communication buffer underrun and stuttering

- not so smooth movement becaue of tricks like quadstepping

Octoprint is just a G-Code sender with nice UI, it doesn't help with motion control at all.

Things like overcurrent protection, I/O voltage protection, static discharge protection found in "rugged" versions are almost useless for a board in place. They help when you are tinkering with unknown configurations or the board is not in circuit, so static can build up.

If you really want to go with signal quality, you should study the cheapest chinese CNC controller (with the dreadful TB65xx, I give you that), that has better implementation than the best 3d printer controller: optocouplers for all the signals, so the computer has full electrical isolation from the motion board, signal conditioning and recovery on all step/dir lines to enhance noise immunity.

Base on this page (http://reprap.org/wiki/Step_rates) an 8-bit CPU will reach <10k steps/sec in total (all axes combined) in single step and <40k steps/sec in quad step (that has its own issues because the steps are not evenly distributed).

So, in 8-bit, there are two slowdowns:

- motion compute, because of the software floating point. This is felt in LCD UI, serial communication buffer underrun and stuttering

- not so smooth movement becaue of tricks like quadstepping

Octoprint is just a G-Code sender with nice UI, it doesn't help with motion control at all.

Things like overcurrent protection, I/O voltage protection, static discharge protection found in "rugged" versions are almost useless for a board in place. They help when you are tinkering with unknown configurations or the board is not in circuit, so static can build up.

If you really want to go with signal quality, you should study the cheapest chinese CNC controller (with the dreadful TB65xx, I give you that), that has better implementation than the best 3d printer controller: optocouplers for all the signals, so the computer has full electrical isolation from the motion board, signal conditioning and recovery on all step/dir lines to enhance noise immunity.

|

Re: My Prusa MGN June 21, 2016 02:08PM |

Registered: 7 years ago Posts: 49 |

You probably have right. I can consider about that board next time.

I have some 0.4 mm nozzles. I made a 1 mm hole in the nozzle.

[www.youtube.com]

I have some 0.4 mm nozzles. I made a 1 mm hole in the nozzle.

[www.youtube.com]

|

Re: My Prusa MGN June 22, 2016 05:28AM |

Registered: 13 years ago Posts: 7,616 |

Quote

sigxcpu

300mm/s are reachable, if ever, on long, straight lines only. Even then, at 80 steps/mm which is the usual configuration it means 24000 steps/sec.

Base on this page (http://reprap.org/wiki/Step_rates) an 8-bit CPU will reach <10k steps/sec in total

Nice you looked at the Step rates wiki page - and obviously missed that Teacup can do 40k steps/s on 8-bit CPUs without quadstepping.

These "long, straight lines" you mean are lines taking longer than 1/100 of a second. Computing a movement command from G-code to speed and steps takes about 35'000 clock ticks on Teacup (don't have the numbers for other firmwares), or 0.0025 seconds, so you have to have a sequence of 50+ segments shorter than 1 mm to even start seeing a gain of faster controllers. 50+ segments, because this computation happens before a movement is stuffed into the movement queue, so the controller has to drain the queue before running into a computation power shortage.

All this said, there's no reason why ARM based controllers are more expensive than ATmega based ones, so this additional computing power essentially comes for free. Gen7-ARM is even a few Euros cheaper than the previous Gen7-AVR.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: My Prusa MGN June 23, 2016 04:43AM |

Registered: 8 years ago Posts: 88 |

I know about Teacup, I've looked it a little, but now that you've opened the topic, here's what I would do if I were you:

- we (me?) are spoiled by graphical LCDs. I'm using Repetier firmware right now and I like the tons of information in the primary screen and the myriad of settings and menus without G-codes or re-uploading the firmware. Does Teacup have that?

- The config tool is cumbersome at least. Why don't you use the "normal", float, numbers format and transform them to integers right when you generate the configuration file? There is no need for an user to see the internal huge numbers representation because Teacup is using integers.

- are the usual G-code senders (PrintRun, Octoprint, Repetier Server/Host) compatible with Teacup? Can you emulate "marlin" or "repetier" like RepRapFirmware does?

Second one is not a big issue, because we all can multiply by 1000, even if that looks somewhat ugly. But the abused LCD is a very nice feature of every controller when the user has one or two printers. I agree this may not apply if you have a forest of them.

Based on my advice to @bme above, I totally agree with you. We need more powerful CPUs for printers when we are sure that we've reached the maximum potential of the 8-bit ones, which Teacup is nicely doing.

- we (me?) are spoiled by graphical LCDs. I'm using Repetier firmware right now and I like the tons of information in the primary screen and the myriad of settings and menus without G-codes or re-uploading the firmware. Does Teacup have that?

- The config tool is cumbersome at least. Why don't you use the "normal", float, numbers format and transform them to integers right when you generate the configuration file? There is no need for an user to see the internal huge numbers representation because Teacup is using integers.

- are the usual G-code senders (PrintRun, Octoprint, Repetier Server/Host) compatible with Teacup? Can you emulate "marlin" or "repetier" like RepRapFirmware does?

Second one is not a big issue, because we all can multiply by 1000, even if that looks somewhat ugly. But the abused LCD is a very nice feature of every controller when the user has one or two printers. I agree this may not apply if you have a forest of them.

Based on my advice to @bme above, I totally agree with you. We need more powerful CPUs for printers when we are sure that we've reached the maximum potential of the 8-bit ones, which Teacup is nicely doing.

|

Re: My Prusa MGN June 23, 2016 06:15AM |

Registered: 13 years ago Posts: 7,616 |

Quote

sigxcpu

- we (me?) are spoiled by graphical LCDs. I'm using Repetier firmware right now and I like the tons of information in the primary screen and the myriad of settings and menus without G-codes or re-uploading the firmware. Does Teacup have that?

- The config tool is cumbersome at least. Why don't you use the "normal", float, numbers format and transform them to integers right when you generate the configuration file? There is no need for an user to see the internal huge numbers representation because Teacup is using integers.

- are the usual G-code senders (PrintRun, Octoprint, Repetier Server/Host) compatible with Teacup? Can you emulate "marlin" or "repetier" like RepRapFirmware does?

Good ideas.

Driving LCDs in a way not hurting printing performance is non-trivial. Nevertheless it's done now, additional messages are as trivial as adding a printf(). Essentially Teacup needs users now finding out how well it works for them and finding out how to make best usage of the display area available.

Re-uploading the firmware is as easy as saving a file. Both, an SD card and ATmega program memory are Flash storage, after all. Why insist people on a more complicated way? Obviously they're used to it and expect Teacup to produce the same mess.

Teacup supports sufficient G-code for printing whatever the heart desires. Using Pronterface, OctoPrint or whatever. What else should a printer do? Play MP3s? :-)

"Emulating" Marlin would be a step backwards ... and also make Teacup pointless, because there's no point in having yet another firmware doing the same. Much of the better performance Teacup offers is the result of doing things the way it does it. Like configuring the firmware before uploading, not after the fact. For example, Teacup has established an entire hardware abstraction layer (HAL) on the precompiler level. That level means: do one-time calculations on a high performance machine (PC) once instead of on a low performance machine (controller) repeatedly at runtime.

I mean I'm well aware that complicated ways and moderate performance are more attractive to people than simple usage and high performance. Maybe because it gives the feeling of having mastered a beast. Maybe because people can't imagine things to "just work". Still it occasionally bugs me seeing people struggling with that complicated thing while apparently not being aware of easier solutions. That's why I occasionally chime in :-)

Teacups goal is to make configuring a printer a joyful, self-explaning ride. Like giving interactive step by step instructions for steps/mm, PID values, print area size and such stuff, entering the results and re-writing the firmware along the way. You remember Macintosh computers? They were always easier to use than competitors, still it took many years until they were kind of accepted. You remember Gnome for Linux? Ubuntu? Teacup is apparently on a similar way. Joyful for the user, powerful under the hood :-)

Regarding the steps/mm thing, see [github.com]

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: My Prusa MGN June 23, 2016 09:03AM |

Registered: 8 years ago Posts: 88 |

Thanks for the Github issue posted. I've tried again today to configure the firmware and I have another observation to make: specify units everywhere in the config tool. I've needed the RepRap wiki page to understand what does the config tool wants from me for "maximum feedrate" (mm/min), "endstop clearance" (microns), "travel limits" (mm/sec?), search feedrate (mm/min?), "acceleration' (mm/s^2?), "jerk" and so on. The UI should stick to consistent units and the config.h cand have whatever firmware wants. Even tooltips in the UI will be helpful.

I think resorting to documentation every time a configuration change is needed is painful. Having the documentation right where the configuration happens is much more useful (for example, I find KiSSlicer very nice. It has tooltips on each tunable, even in "expert" mode).

I promise you two things:

- I will try to configure completely and upload the firmware

- I will get a Gen7 board because it seems to be the cheapest way to go into 32-bit world (when I will be able to finish my new printer).

Regarding post-upload configuration, I don't agree with you. Having a way to tweak stuff after upload is good because it is cheaper in consumed time. Code development for such feature is one time. Tweaking settings by the users happens many times.

@bme: again, sorry to hijack your thread.

I think resorting to documentation every time a configuration change is needed is painful. Having the documentation right where the configuration happens is much more useful (for example, I find KiSSlicer very nice. It has tooltips on each tunable, even in "expert" mode).

I promise you two things:

- I will try to configure completely and upload the firmware

- I will get a Gen7 board because it seems to be the cheapest way to go into 32-bit world (when I will be able to finish my new printer).

Regarding post-upload configuration, I don't agree with you. Having a way to tweak stuff after upload is good because it is cheaper in consumed time. Code development for such feature is one time. Tweaking settings by the users happens many times.

@bme: again, sorry to hijack your thread.

|

Re: My Prusa MGN June 23, 2016 09:24AM |

Registered: 13 years ago Posts: 7,616 |

Quote

sigxcpu

Having a way to tweak stuff after upload is good because it is cheaper in consumed time.

You change the value, hit build, upload and it's done. Consumes like 3 to 5 seconds.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: My Prusa MGN June 23, 2016 02:14PM |

Registered: 8 years ago Posts: 88 |

|

Re: My Prusa MGN June 23, 2016 02:28PM |

Registered: 7 years ago Posts: 49 |

@bme: again, sorry to hijack your thread.

No problem at all!

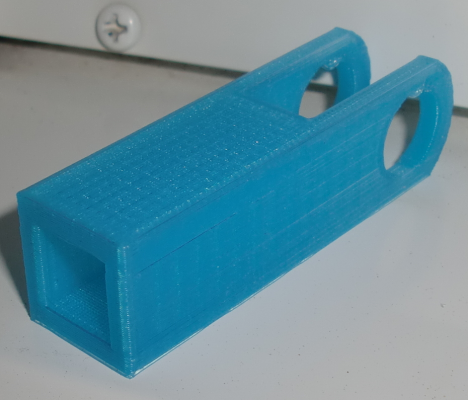

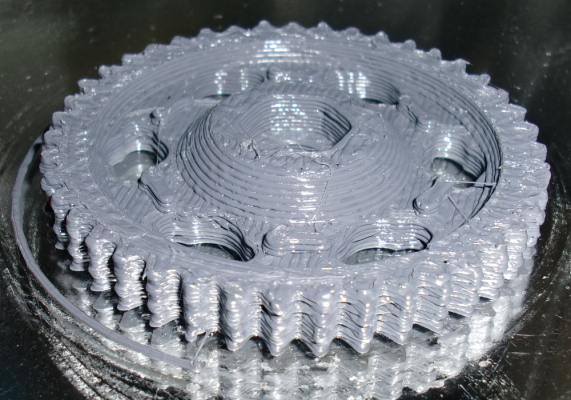

I work more with mechanical design like now some tests with 0.8 mm layer height.

It is very difficult to cool such amount of PLA.

No problem at all!

I work more with mechanical design like now some tests with 0.8 mm layer height.

It is very difficult to cool such amount of PLA.

|

Re: My Prusa MGN June 23, 2016 02:33PM |

Registered: 9 years ago Posts: 1,159 |

|

Re: My Prusa MGN June 23, 2016 02:35PM |

Registered: 8 years ago Posts: 88 |

Quote

bme

@bme: again, sorry to hijack your thread.

No problem at all!

I work more with mechanical design like now some tests with 0.8 mm layer height.

It is very difficult to cool such amount of PLA.

[attachment 80277 CIMG2602.JPG]

Lower the speed or increase the minimum layer time in slic3r and blast the fans. Except needle-like features, I always get away with that.

|

Re: My Prusa MGN June 23, 2016 02:43PM |

Registered: 7 years ago Posts: 49 |

The nozzle is 1 mm in diameter. I drilled a hole in a 0.4 mm nozzle.

Not so big precision but it works for some tests.

Not so big precision but it works for some tests.

|

Re: My Prusa MGN June 23, 2016 02:46PM |

Registered: 7 years ago Posts: 49 |

|

Re: My Prusa MGN June 23, 2016 02:49PM |

Registered: 9 years ago Posts: 1,159 |

Quote

bme

The nozzle is 1 mm in diameter. I drilled a hole in a 0.4 mm nozzle.

Not so big precision but it works for some tests.

[attachment 80278 nozzle.jpg]

In that Case I would suggest that you shouldn't try to go above 0.8 layer hight

The normal rule of thumb is no more than 80% of Nozzle Diameter?

Doug

p.s. If you really want to print big like that think aboudt an E3D Volcano which has a longer melt zone and Nozzles upto 1.2 Diam

Doug

|

Re: My Prusa MGN June 23, 2016 03:19PM |

Registered: 7 years ago Posts: 49 |

This nozzle is the cheapest nozzle € 0,28. It works perfect.

As I wrote before I have problem with cooling. I have good melt zone with this nozzle.

I usually buy all metal hotend witch costs around 3-4 dollars (see it the image below). All my prints are made with such a hotend.

I never never never have any problem with any hotend or any kind of plastic.

Thank you for your inputs and tips!

As I wrote before I have problem with cooling. I have good melt zone with this nozzle.

I usually buy all metal hotend witch costs around 3-4 dollars (see it the image below). All my prints are made with such a hotend.

I never never never have any problem with any hotend or any kind of plastic.

Thank you for your inputs and tips!

|

Re: My Prusa MGN June 24, 2016 11:58AM |

Registered: 7 years ago Posts: 49 |

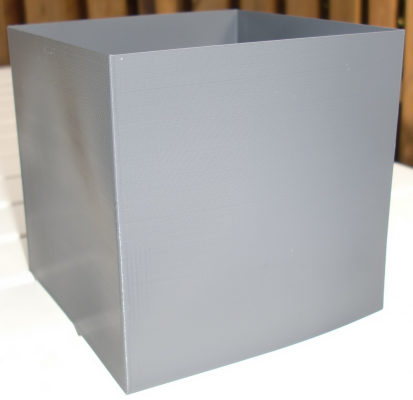

This is my last test. The printer is finished. This printer can be an upgrade for someone who already know to build a printer.

Here are some necessary STL files to upgrade your printer:

[www.onel.se]

You need for this printer some MGN12 rails and carriages:

2 * L350 mm on Y axis (bed)

2 * L250 mm on Z axis

1 * L400 mm on X axis

2 Pcs GT2 Pulley 16 / 20 Gear With Teeth Pulley Bore 3MM

Capacitive Proximity sensor

Hotend 1.75 long

[www.youtube.com]

Edited 3 time(s). Last edit at 06/24/2016 04:56PM by bme.

Here are some necessary STL files to upgrade your printer:

[www.onel.se]

You need for this printer some MGN12 rails and carriages:

2 * L350 mm on Y axis (bed)

2 * L250 mm on Z axis

1 * L400 mm on X axis

2 Pcs GT2 Pulley 16 / 20 Gear With Teeth Pulley Bore 3MM

Capacitive Proximity sensor

Hotend 1.75 long

[www.youtube.com]

Edited 3 time(s). Last edit at 06/24/2016 04:56PM by bme.

Sorry, only registered users may post in this forum.