Help with print quality with ABS

Posted by Waiasaur

|

Re: Help with print quality with ABS January 15, 2011 02:07PM |

Registered: 13 years ago Posts: 56 |

|

Re: Help with print quality with ABS January 15, 2011 05:02PM |

Registered: 13 years ago Posts: 188 |

First off, I need to correct some of the things I said earlier. Perimeter width over layer thickness in the carve tab does not change the infill of solid layers. It only effects the spacing between the perimeter and the interior extrusions. You need to look at infill width over thickness in the fill tab instead. Sorry for my stupid mix up and any aggravation it may have caused.

Fixing solid layer gaps:

The gaps will go away once your tool path spacing matches the thickness of your extrusion though. To improve resolution, you need to minimize your extrusion thickness, which means running at higher feed rates or slower flow rates to stretch the filament thinner - unless you want to get a smaller nozzle instead. Judging from the prints I have seen from other users, smaller nozzles can drastically improve resolution, but you would be stuck with printing at that fine, slow resolution even when you maybe don't need it. At any rate, as you minimize the extrusion thickness, you need to adjust your layer thickness and infill width over thickness so your tool path will tighten up and layers are still bonded well.

Fixing blobby posts

The simplest way to print small posts is probably as Nophead suggests. Print two parts to keep the heat from building up. I suggest turning "tower" off so that it consistently moves from one post to the other rather than building a few layers at a time then moving. Also note that the part with a post must be equal to or shorter than the height of the second part for this effect to work. If you don't want to print two parts just because one has a post, you are going to have to adjust skeinforge parameters. Tackling that while trying to improve resolution is just going to add frustration. I suggest putting it off until you are happy with your other settings.

Perimeter quality

It also looks like your infill overlaps the perimeter too much. I see it sticking through on some of the layers. Lower your infill perimeter overlap ratio. Adding shells might help a little too. If it causes gaps between the infill and outline perhaps your axes have too much backlash? Try tightening your belts.

Removing parts from the build plate

I recommend building a heated build plate. There are lots of designs floating around, but I'm currently using an aluminum plate as a heat spreader and a kapton covered glass sheet for the actual build surface. If you want to print ABS, you have to cover the glass with kapton or some other adhesive surface, but I'm told that PLA will stick to plain heated glass. I think you will be much happier with the durability of non-acrylic build plates and having a heated surface reduces warpage. It is extra work and expense, but it pays off in the end. If you wait for the plate to cool, parts will be very easy to remove and you can't accidentally melt pits or lines into the glass like you can with the acrylic. If your tape is damaged, it can be easily replaced with a new coating.

Fixing solid layer gaps:

The gaps will go away once your tool path spacing matches the thickness of your extrusion though. To improve resolution, you need to minimize your extrusion thickness, which means running at higher feed rates or slower flow rates to stretch the filament thinner - unless you want to get a smaller nozzle instead. Judging from the prints I have seen from other users, smaller nozzles can drastically improve resolution, but you would be stuck with printing at that fine, slow resolution even when you maybe don't need it. At any rate, as you minimize the extrusion thickness, you need to adjust your layer thickness and infill width over thickness so your tool path will tighten up and layers are still bonded well.

Fixing blobby posts

The simplest way to print small posts is probably as Nophead suggests. Print two parts to keep the heat from building up. I suggest turning "tower" off so that it consistently moves from one post to the other rather than building a few layers at a time then moving. Also note that the part with a post must be equal to or shorter than the height of the second part for this effect to work. If you don't want to print two parts just because one has a post, you are going to have to adjust skeinforge parameters. Tackling that while trying to improve resolution is just going to add frustration. I suggest putting it off until you are happy with your other settings.

Perimeter quality

It also looks like your infill overlaps the perimeter too much. I see it sticking through on some of the layers. Lower your infill perimeter overlap ratio. Adding shells might help a little too. If it causes gaps between the infill and outline perhaps your axes have too much backlash? Try tightening your belts.

Removing parts from the build plate

I recommend building a heated build plate. There are lots of designs floating around, but I'm currently using an aluminum plate as a heat spreader and a kapton covered glass sheet for the actual build surface. If you want to print ABS, you have to cover the glass with kapton or some other adhesive surface, but I'm told that PLA will stick to plain heated glass. I think you will be much happier with the durability of non-acrylic build plates and having a heated surface reduces warpage. It is extra work and expense, but it pays off in the end. If you wait for the plate to cool, parts will be very easy to remove and you can't accidentally melt pits or lines into the glass like you can with the acrylic. If your tape is damaged, it can be easily replaced with a new coating.

|

Re: Help with print quality with ABS January 18, 2011 05:59AM |

Registered: 13 years ago Posts: 56 |

Has anyone ever encountered random stringiness in their prints? I noticed in my earlier prints that the surfaces would be uniform and nice, and then in certain parts the lines would thin significantly becoming stringy. Only in some parts though, so the extruder is working normally and then all of a sudden not extruding enough causing the stringiness for a few cm and then working normally again.

This problem has become a lot more apparent when I tried what dazed.dnc suggested, to extrude less at a higher speed to create a thinner filament. Trying that, my parts came out with holes everywhere and super brittle. I seem to have no problems extruding the outside perimeter though. My perimeters are very shapely and look quite nice. Also I set the cool command in skeinforge to take 25 seconds per layer at minimum and set to slow, and my tall thin towers look great. I assumed it was my extruder not performing well and choking up, but i cleaned the hobbed bolt and watched it extrude over thin air and it looked totally fine.

This problem has become a lot more apparent when I tried what dazed.dnc suggested, to extrude less at a higher speed to create a thinner filament. Trying that, my parts came out with holes everywhere and super brittle. I seem to have no problems extruding the outside perimeter though. My perimeters are very shapely and look quite nice. Also I set the cool command in skeinforge to take 25 seconds per layer at minimum and set to slow, and my tall thin towers look great. I assumed it was my extruder not performing well and choking up, but i cleaned the hobbed bolt and watched it extrude over thin air and it looked totally fine.

|

Re: Help with print quality with ABS January 18, 2011 07:52AM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes a drop in flow rate causes stringiness.

Ii can be caused by the pinch wheel slipping, but in that case it leaves plastic in the teeth and from then on does it once per revolution and never recovers. When you dismantle it the hobbed teeth should be clean, no matter how long it has been running. If they are clogged it means it slipped and if you ever notice it slipping you need to clean the teeth.

I have also had it from loose motor connections and slipping drive gear due to a loose set screw or cracked gear.

[www.hydraraptor.blogspot.com]

Ii can be caused by the pinch wheel slipping, but in that case it leaves plastic in the teeth and from then on does it once per revolution and never recovers. When you dismantle it the hobbed teeth should be clean, no matter how long it has been running. If they are clogged it means it slipped and if you ever notice it slipping you need to clean the teeth.

I have also had it from loose motor connections and slipping drive gear due to a loose set screw or cracked gear.

[www.hydraraptor.blogspot.com]

|

Re: Help with print quality with ABS January 18, 2011 02:22PM |

Registered: 13 years ago Posts: 28 |

Just a note about printing on acrylic: I've been doing this with my repstrap, and ABS bonds very well to acrylic. So a properly filled solid layer should be... as you found out... almost impossible to remove.

I'd highly recommend printing on a raft. I've had to spend a bit of work tuning the parameters to get the raft to bond well enough to itself to resist warping forces, but once the part is printed it is much easier to remove. I then remove what's left of the raft with a knife, or I've also found that a chisel with the edge flat against the print bed works well.

Keep in mind though, that I'm using a 1/4 inch acrylic sheet... and after a few prints it tends to bow. I've flipped the sheet over and started printing on the other side to work around this but an acrylic print bed will definitely have a limited life span.

Hope this helps!

I'd highly recommend printing on a raft. I've had to spend a bit of work tuning the parameters to get the raft to bond well enough to itself to resist warping forces, but once the part is printed it is much easier to remove. I then remove what's left of the raft with a knife, or I've also found that a chisel with the edge flat against the print bed works well.

Keep in mind though, that I'm using a 1/4 inch acrylic sheet... and after a few prints it tends to bow. I've flipped the sheet over and started printing on the other side to work around this but an acrylic print bed will definitely have a limited life span.

Hope this helps!

|

Re: Help with print quality with ABS February 01, 2011 08:19PM |

Registered: 13 years ago Posts: 56 |

Hey guys, when printing thin walled things that are thick enough to have an infill, what fill pattern do you use and at what density ratio for it to be reasonably strong enough? For example a cup.

also for a cup like object, for some reason my skeinforge is importing it upside down. how can i turn it right side up?

Edited 1 time(s). Last edit at 02/02/2011 05:02PM by Waiasaur.

also for a cup like object, for some reason my skeinforge is importing it upside down. how can i turn it right side up?

Edited 1 time(s). Last edit at 02/02/2011 05:02PM by Waiasaur.

|

Re: Help with print quality with ABS February 10, 2011 08:31PM |

Registered: 13 years ago Posts: 56 |

|

Re: Help with print quality with ABS February 11, 2011 02:45AM |

Admin Registered: 17 years ago Posts: 7,879 |

If you have a stepper extruder you can eliminate it completely by fast reversal at the end of a filament run and fast forward at the start.

You can set that up in Skeinforge Dimension I believe.

The retract distance needs to be about 1mm of feedstock but in SF it is extrudate distance, so you have to work that out depending on the layer height. The restart should be the same distance. The speed should be as fast as your extruder can go without skipping steps.

[www.hydraraptor.blogspot.com]

You can set that up in Skeinforge Dimension I believe.

The retract distance needs to be about 1mm of feedstock but in SF it is extrudate distance, so you have to work that out depending on the layer height. The restart should be the same distance. The speed should be as fast as your extruder can go without skipping steps.

[www.hydraraptor.blogspot.com]

|

Re: Help with print quality with ABS February 11, 2011 01:10PM |

Registered: 13 years ago Posts: 56 |

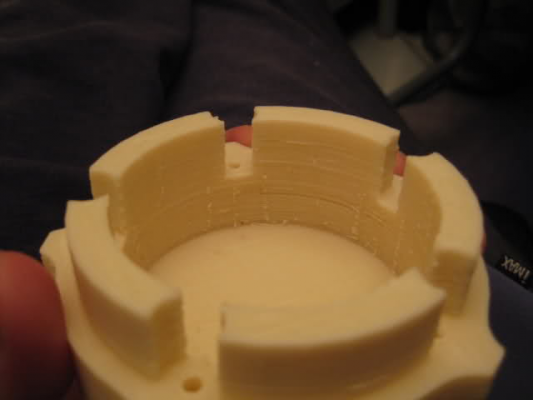

Thanks nophead. I do have retraction distance set but I'll try to crank up my speed. are a few more pictures of what i've been working on. Its the base part of the shorty iris box found on thingiverse.

.

.

|

Re: Help with print quality with ABS February 11, 2011 03:10PM |

Admin Registered: 17 years ago Posts: 7,879 |

It looks like your extruder is slipping. Some layers are missing plastic in the outline and the lower surface in the last picture seems to have bits of infill missing. Classic symptoms of the extruder having slipped once causing a few teeth of the pinch wheel to be clogged. After that it slips every turn.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Help with print quality with ABS February 11, 2011 04:09PM |

Registered: 13 years ago Posts: 79 |

Skeinforge settings. Here's what I'm using

Retraction speed: I run at 1000, I tried 1200 but that got a little sketchy so I dialed it back.

I'm currently using layer height of .33 with retraction set to 35. That changes with layer height of course.

Restart extra distance set to -2, which still doesn't get rid of the restart nubs but it helps a bit. Doesn't work well with tiny prints though. Too many starts and stops tends to drain the nozzle.

I have a little rubber disk with a little hole punched through it that I use to drag dust off of the incoming filament. It rides right on top of the extruder block and lifts when the extruder reverses. To reiterate what nophead said. When I change my settings I watch for the lift and adjust the retraction rate until I lifts about a millimeter off the block.

Retraction speed: I run at 1000, I tried 1200 but that got a little sketchy so I dialed it back.

I'm currently using layer height of .33 with retraction set to 35. That changes with layer height of course.

Restart extra distance set to -2, which still doesn't get rid of the restart nubs but it helps a bit. Doesn't work well with tiny prints though. Too many starts and stops tends to drain the nozzle.

I have a little rubber disk with a little hole punched through it that I use to drag dust off of the incoming filament. It rides right on top of the extruder block and lifts when the extruder reverses. To reiterate what nophead said. When I change my settings I watch for the lift and adjust the retraction rate until I lifts about a millimeter off the block.

|

Re: Help with print quality with ABS February 11, 2011 04:51PM |

Registered: 13 years ago Posts: 65 |

|

Re: Help with print quality with ABS February 11, 2011 05:06PM |

Registered: 13 years ago Posts: 56 |

hmm i check my hobbed bolt regularly to see if it needs to be cleaned. perhaps it is a section of the hobbed teeth itself that is defective. There is a small section on the teeth that seem a little less sharp than the rest but i didnt think it was a big deal.

Here is more printed stuff!

i printed all 4 little gears at once and they required a lot of cleanup with a razor blade but this was done before nophead's suggestion to max out retraction speed. I sanded down the little gears because they were lumpy, but the big gears I did not finish. I thought it would be nice to see the natural lines of the printer, as well as the slight defects my printer still produces.

Here is more printed stuff!

i printed all 4 little gears at once and they required a lot of cleanup with a razor blade but this was done before nophead's suggestion to max out retraction speed. I sanded down the little gears because they were lumpy, but the big gears I did not finish. I thought it would be nice to see the natural lines of the printer, as well as the slight defects my printer still produces.

|

Re: Help with print quality with ABS February 12, 2011 01:01AM |

Registered: 13 years ago Posts: 56 |

nophead says to have restart extra distance to be equal to retraction distance, but Bruce says to have the restart extra distance to be -2. Is there a reason for such difference?

Personally I think it would make sense for restart distance to be equal to retract distance but I have not done the test yet. The clarification between filament retraction distance versus extrudate distance helped me. Before I thought I should set retract to 1 mm, I had it at 5 mm because nothing was improving. Now that I realize it is filament distance I did the math based on volume and have come to 1 mm of filament = 36 mm of retraction.

Edited 1 time(s). Last edit at 02/12/2011 01:05AM by Waiasaur.

Personally I think it would make sense for restart distance to be equal to retract distance but I have not done the test yet. The clarification between filament retraction distance versus extrudate distance helped me. Before I thought I should set retract to 1 mm, I had it at 5 mm because nothing was improving. Now that I realize it is filament distance I did the math based on volume and have come to 1 mm of filament = 36 mm of retraction.

Edited 1 time(s). Last edit at 02/12/2011 01:05AM by Waiasaur.

|

Re: Help with print quality with ABS February 12, 2011 01:12AM |

Registered: 13 years ago Posts: 79 |

|

Re: Help with print quality with ABS February 12, 2011 01:25PM |

Admin Registered: 17 years ago Posts: 7,879 |

But then there will be a bit of plastic missing after every restart so the filament will be too thin at the start of each run.

I think the problem is you are not fast forwarding fast enough so the plastic has chance to flow out while you are still building up the pressure. Either that or there is a pause before moving off.

With a Wade's extruder I can fast forward so fast that I need a little pause to give the filament time to flow from the nozzle to the bed and stick before moving off. I rewind and fast forward about 0.75mm at 10mm/s, so that only takes 75ms. I then have to pause 30ms to give the filament time to flow out of the nozzle.

[www.hydraraptor.blogspot.com]

I think the problem is you are not fast forwarding fast enough so the plastic has chance to flow out while you are still building up the pressure. Either that or there is a pause before moving off.

With a Wade's extruder I can fast forward so fast that I need a little pause to give the filament time to flow from the nozzle to the bed and stick before moving off. I rewind and fast forward about 0.75mm at 10mm/s, so that only takes 75ms. I then have to pause 30ms to give the filament time to flow out of the nozzle.

[www.hydraraptor.blogspot.com]

|

Re: Help with print quality with ABS February 12, 2011 06:41PM |

Registered: 13 years ago Posts: 56 |

|

Re: Help with print quality with ABS February 12, 2011 11:59PM |

Registered: 13 years ago Posts: 79 |

So..... There you have it in a nut shell.

I set Retraction to 24 to get @ .75 and Extra distance to 0 and it looks about the same, possibly a little bigger. To be honest, with all the different settings that we've tried over the past few months speed included, nothing seems to make much difference.

Using -2 does leave a bit of a dip but it seems to drag a little bit of the blurb with it, making it look a little smaller.

As for fast forwarding, between back and forth, not sure how to measure it but it's the blink of an eye so I don't think that's the problem.

Pausing before moving off, maybe. We do loops then perimeter. When the first machine was running slower it seemed as though when it shifted from the outside loop to perimeter it actually paused for a split second and spurted a bit before started moving on the perimeter line. The machines are so fast now, between the fast retraction and travel feed rate of 120 mm/sec, from loop to perimeter you just hear a little bump.

Just to make things worse, it almost always starts the perimeter directly beside the start of the loop. Each one leaves a little blurb, the perimeter blurb right beside the loop blurb, argh.

Waiasaur I use nichrome, it's just a matter of preference. So........ How is your printing going now?

Edited 1 time(s). Last edit at 12/19/2011 09:38PM by Bruce.

|

Re: Help with print quality with ABS February 13, 2011 12:33AM |

Registered: 14 years ago Posts: 323 |

|

Re: Help with print quality with ABS February 13, 2011 03:06AM |

Admin Registered: 17 years ago Posts: 7,879 |

Waiasaur Wrote:

-------------------------------------------------------

> hey nophead, I noticed on your blog that you made

> your heated bed using resistors hooked up in

> parallel. Why didnt you use resistive wire

> (nichrome?)instead? Wouldn't it be easier to use

> resistive wire to evenly cover an area once you've

> got the proper length cut out?

To use nichrome you need to attach it to the bed with something that is a good electrical insulator but a good conductor of heat. That is difficult to do but the nice people at the resistor factory will do it for me for a reasonable amount of money. I know the reprap project likes to make its own parts from raw ingredients but I prefer to buy my resistors ready assembled.

They are in series, not parallel, and I run them from the mains, so they need to be insulated to a high standard to be safe.

[www.hydraraptor.blogspot.com]

-------------------------------------------------------

> hey nophead, I noticed on your blog that you made

> your heated bed using resistors hooked up in

> parallel. Why didnt you use resistive wire

> (nichrome?)instead? Wouldn't it be easier to use

> resistive wire to evenly cover an area once you've

> got the proper length cut out?

To use nichrome you need to attach it to the bed with something that is a good electrical insulator but a good conductor of heat. That is difficult to do but the nice people at the resistor factory will do it for me for a reasonable amount of money. I know the reprap project likes to make its own parts from raw ingredients but I prefer to buy my resistors ready assembled.

They are in series, not parallel, and I run them from the mains, so they need to be insulated to a high standard to be safe.

[www.hydraraptor.blogspot.com]

|

Re: Help with print quality with ABS February 13, 2011 03:18AM |

Admin Registered: 17 years ago Posts: 7,879 |

Bruce,

What speed are you printing at? I do my outlines at only 18mm/s, so the pressure I have to achieve in the extruder before moving off may be lower. The fast forward needs to be fast relative to your normal extrusion speed, so if that is very fast it could be the reason.

[www.hydraraptor.blogspot.com]

What speed are you printing at? I do my outlines at only 18mm/s, so the pressure I have to achieve in the extruder before moving off may be lower. The fast forward needs to be fast relative to your normal extrusion speed, so if that is very fast it could be the reason.

[www.hydraraptor.blogspot.com]

|

Re: Help with print quality with ABS February 13, 2011 07:35PM |

Registered: 13 years ago Posts: 79 |

nophead,

That print was done at 72 mm/s fill and 54 mm/s outline, however, we have printed at various speeds on three different machines and got similar results. I went and dug through a bag of old parts and found a few that were printed on our old Makerbot. If I remember correctly, they were printed at 24/18, they have marks too but not nearly as well defined, more like small subtle bulges. The melt zone on that extruder of that machine was, how should I put this..... LARGE! I was just learning about hot ends at the time, and it also used the standard DC drive. My newer hot ends are so much more reactive, and stepper board driven motors as well.

I know just enough about software and firmware to set up my machine, beyond that I'm lost. Just wondering, maybe you would know: Is there something somewhere in the magical world of coding that could cause the extruder motor to initiate a split second before X and Y? Maybe to compensate for filament lag. Grasping at straws here.

That print was done at 72 mm/s fill and 54 mm/s outline, however, we have printed at various speeds on three different machines and got similar results. I went and dug through a bag of old parts and found a few that were printed on our old Makerbot. If I remember correctly, they were printed at 24/18, they have marks too but not nearly as well defined, more like small subtle bulges. The melt zone on that extruder of that machine was, how should I put this..... LARGE! I was just learning about hot ends at the time, and it also used the standard DC drive. My newer hot ends are so much more reactive, and stepper board driven motors as well.

I know just enough about software and firmware to set up my machine, beyond that I'm lost. Just wondering, maybe you would know: Is there something somewhere in the magical world of coding that could cause the extruder motor to initiate a split second before X and Y? Maybe to compensate for filament lag. Grasping at straws here.

|

Re: Help with print quality with ABS February 13, 2011 08:11PM |

Registered: 13 years ago Posts: 79 |

mlagana,

If you are interested...... I tried M3 and M4 taps at a number of different depths of cut. Inevitably, I'd be out in my workshop trying to focus on the job at hand and Jeremy “who was running the printer at the time” would walk in with that ever mournful look on his face saying “Slipped again”. One day I got frustrated to the point where I said: FINE, followed by some very colourful adjectives. See, the problem we were having was that the filament surface layer was being sheared off by those little teeth. I thought: If Adrain can push filament with a gear, why can't I use a bigger tap? So I grabbed my trusty old box of taps and sorted through. I live in the land of SAE (Canada), so bear with my sizes. I tried a 1/4”-20 and it worked a bit better but still not quite enough grab for the filament of the day so I went to a 5/16”-18, which is comparable to the M8 thread on the bolt. I've never had a slippage problem since. Oh also, if your interested. I reversed the way the bolt mounts into the extruder block so that it holds the gear securely on the shaft while allowing the shaft to float in the bearings. I goes like this Hobbed Bolt

If you are interested...... I tried M3 and M4 taps at a number of different depths of cut. Inevitably, I'd be out in my workshop trying to focus on the job at hand and Jeremy “who was running the printer at the time” would walk in with that ever mournful look on his face saying “Slipped again”. One day I got frustrated to the point where I said: FINE, followed by some very colourful adjectives. See, the problem we were having was that the filament surface layer was being sheared off by those little teeth. I thought: If Adrain can push filament with a gear, why can't I use a bigger tap? So I grabbed my trusty old box of taps and sorted through. I live in the land of SAE (Canada), so bear with my sizes. I tried a 1/4”-20 and it worked a bit better but still not quite enough grab for the filament of the day so I went to a 5/16”-18, which is comparable to the M8 thread on the bolt. I've never had a slippage problem since. Oh also, if your interested. I reversed the way the bolt mounts into the extruder block so that it holds the gear securely on the shaft while allowing the shaft to float in the bearings. I goes like this Hobbed Bolt

|

Re: Help with print quality with ABS February 13, 2011 08:21PM |

Admin Registered: 17 years ago Posts: 7,879 |

Bruce Wrote:

-------------------------------------------------------

> Is there

> something somewhere in the magical world of coding

> that could cause the extruder motor to initiate a

> split second before X and Y? Maybe to compensate

> for filament lag. Grasping at straws here.

The whole point of the 5D code is that the extruder step signal is generated in the same loop as the XYZ, so it should start exactly the same time unless the g-code tells it to do otherwise.

[www.hydraraptor.blogspot.com]

-------------------------------------------------------

> Is there

> something somewhere in the magical world of coding

> that could cause the extruder motor to initiate a

> split second before X and Y? Maybe to compensate

> for filament lag. Grasping at straws here.

The whole point of the 5D code is that the extruder step signal is generated in the same loop as the XYZ, so it should start exactly the same time unless the g-code tells it to do otherwise.

[www.hydraraptor.blogspot.com]

|

Re: Help with print quality with ABS February 13, 2011 11:49PM |

Registered: 14 years ago Posts: 323 |

|

Re: Help with print quality with ABS February 13, 2011 11:57PM |

Registered: 14 years ago Posts: 323 |

Sorry, only registered users may post in this forum.