Home

>

Reprappers

>

Topic

Aluminium bed - where to put the temperature sensor

Posted by deckingman

|

Aluminium bed - where to put the temperature sensor September 09, 2016 01:06PM |

Registered: 8 years ago Posts: 622 |

OK, so I've started to commission my printer and have come across an issue. I've got a 600W mains powered heater stuck to an aluminium tooling plate which is insulated on the underside. It will have a glass print surface but forget that for now. I fitted a PT100 between the heat pad and the aluminium by machining a groove in the underside of the plate. Effectively, it is in the same place relative to the plate as the thermistor which was supplied with the heater. On powering it up, it reaches 55 degC in about 65 seconds. However, the top of the plate is barely warm at that time - just to be absolutely clear, that is without any glass which will of course make the matter slightly worse. It takes several more minutes for the heat to permeate through to the top surface. Measuring it with a thermocouple taped to the bed, I was only seeing 45 deg C about 6 minutes after the bottom of the plate had reached 55 deg C. The insulation under the plate is doing it's job because it doesn't feel any warmer than ambient when I put my hand on it.

Obviously and with the benefit of hind site, having the sensor between the heater and the plate is the wrong place to have it, although that's where the supplied thermistor is.

So where do you guys fit the temperature sensor? I guess I could machine another groove on the top surface of the plate so that the sensor is between the top of the plate and the glass print surface but I know that some of you hate the thought of using glass. Then of course, if I did that the bottom of the plate would get extremely hot before the heater switched off and I can foresee all sorts of hysteresis issues. Also, with the sensor between the heater and the plate, it isn't going to react to changes of temperature such as when the fans come on. So where on earth do you fit the sensor when you are printing directly on to the aluminium plate?

Obviously and with the benefit of hind site, having the sensor between the heater and the plate is the wrong place to have it, although that's where the supplied thermistor is.

So where do you guys fit the temperature sensor? I guess I could machine another groove on the top surface of the plate so that the sensor is between the top of the plate and the glass print surface but I know that some of you hate the thought of using glass. Then of course, if I did that the bottom of the plate would get extremely hot before the heater switched off and I can foresee all sorts of hysteresis issues. Also, with the sensor between the heater and the plate, it isn't going to react to changes of temperature such as when the fans come on. So where on earth do you fit the sensor when you are printing directly on to the aluminium plate?

|

Re: Aluminium bed - where to put the temperature sensor September 09, 2016 01:45PM |

Registered: 9 years ago Posts: 1,159 |

I to didn't like the thermistor in my Silicon heater (They actually tend to be under the Silicon ie the side away from the Bed.

What I did (My heater is slightly smaller than my Bed) is to fit a Semitec Thermister E3D V6 Style at the edge of the heater pad and allow a little more in the way of Temp just to make sure the centre is up there at the temp I need

ps mine is a delta so is a round bed and heater?

Doug

What I did (My heater is slightly smaller than my Bed) is to fit a Semitec Thermister E3D V6 Style at the edge of the heater pad and allow a little more in the way of Temp just to make sure the centre is up there at the temp I need

ps mine is a delta so is a round bed and heater?

Doug

|

Re: Aluminium bed - where to put the temperature sensor September 09, 2016 02:23PM |

Registered: 8 years ago Posts: 622 |

|

Re: Aluminium bed - where to put the temperature sensor September 09, 2016 02:52PM |

Registered: 9 years ago Posts: 1,159 |

I drilled a 2mm Dia hole almost thru the Plate and another M3 hole for the screw to hold the Thermister in place you could always get a Threaded cartridge type Semitec Thermister from Ebay if you wish as well I don't personally think you need a PT100 for the bed and a thermister is plenty adequate?

Doug

Doug

|

Re: Aluminium bed - where to put the temperature sensor September 09, 2016 10:04PM |

Registered: 11 years ago Posts: 5,780 |

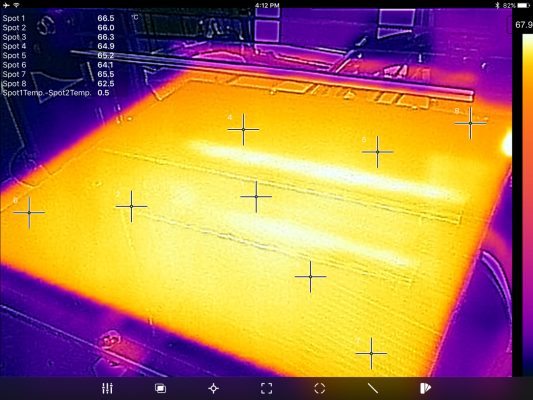

Here's an 6.35 mm aluminum plate with a heater:

Looking at the temperature distribution in the picture, I'd say that you could put the thermistor just about anywhere. The temperature drops a little at the edges so you may end up running a little hot if you put it at the edge of the bed, but a couple simple test prints will have you dialed in fine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Looking at the temperature distribution in the picture, I'd say that you could put the thermistor just about anywhere. The temperature drops a little at the edges so you may end up running a little hot if you put it at the edge of the bed, but a couple simple test prints will have you dialed in fine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminium bed - where to put the temperature sensor September 10, 2016 03:30AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Aluminium bed - where to put the temperature sensor September 10, 2016 06:40AM |

Registered: 8 years ago Posts: 622 |

Quote

dougal1957

I drilled a 2mm Dia hole almost thru the Plate and another M3 hole for the screw to hold the Thermister in place you could always get a Threaded cartridge type Semitec Thermister from Ebay if you wish as well I don't personally think you need a PT100 for the bed and a thermister is plenty adequate?

Doug

Hi Doug,

That seems to be the way to go. Getting the PT100 out would be right pain so I can just leave it there but ignore it. Fortunately, I wired up both the supplied thermistor and the PT100 so it'll be easy to use the existing wiring without too much hassle. I'll maybe drill a few holes here and there and see what works best.

Also in hind site, I regret buying 10mm thick tooling plate. There wasn't much difference in cost so I thought "why not get the thick stuff". Now I know the answer...........Oh well, we live and learn.

DD is going to hate me for this, but I can't help thinking a thin heat spreader and flat glass is the way to go............

Edited 1 time(s). Last edit at 09/10/2016 06:42AM by deckingman.

|

Re: Aluminium bed - where to put the temperature sensor September 11, 2016 09:51AM |

Registered: 8 years ago Posts: 622 |

Quick update. I drilled a hole in the edge of the bed near the top surface. That was a bit hair raising 'cos I couldn't be arsed to strip the bed down so did it in situ. The trouble was, I couldn't get close enough with a cordless drill because of the way I'd mounted the aluminium to it's frame. So I ended up with the drill bit in a pin chuck and the pin chuck held in the main drill chuck. Anyway, I managed to drill a 2.8mm dia hole, 40mm deep in the edge of the plate and close to the top surface without it breaking out of the top. Then I fitted a PT100 into the hole. The only reason for using the PT100 is that I had a spare, but didn't have a spare thermistor to hand. A 2.8mm dia hole was just the right size to make a snug fit for the PT100 with some clear heat shrink around the wires.

So now it's reading sensible temperatures but it takes 4min 15 secs to get from 24 deg C ambient to 55 deg C (and about an hour to cool right down again). It overshot by 2 deg C and took another minute or 2 to get down to 55 but after that it was stable. That was using "bang bang" control so I'll switch to PID which should help.

For me, 10mm thick plate was a big mistake and I'll be changing to something much thinner when get the time (and money).

So now it's reading sensible temperatures but it takes 4min 15 secs to get from 24 deg C ambient to 55 deg C (and about an hour to cool right down again). It overshot by 2 deg C and took another minute or 2 to get down to 55 but after that it was stable. That was using "bang bang" control so I'll switch to PID which should help.

For me, 10mm thick plate was a big mistake and I'll be changing to something much thinner when get the time (and money).

|

Re: Aluminium bed - where to put the temperature sensor September 11, 2016 10:00AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Aluminium bed - where to put the temperature sensor September 11, 2016 10:30AM |

Registered: 11 years ago Posts: 5,780 |

A 10 mm plate is a lot of mass to heat up and cool off. How much power does the heater deliver? Do you have insulation on the underside? Adding insulation to the underside of the plate guarantees longer cool-down time and is unnecessary if the heater delivers enough power to heat the bed to print temperature in reasonable time. Adding glass to the top side guarantees longer heat-up time, and a difference in temperature between the set temperature and the surface temperature of the glass.

I don't know what advantage you'd gain using a PT100 sensor, but it will require an amplifier (unless it's built into your controller board). The absolute accuracy of the sensor isn't as important as its response time, and in this application, even that isn't very important because the time constant of the thermal mass of the bed is going to be orders of magnitude higher than the response time of the sensor. Lead wire resistance doesn't matter with thermistors because it is orders of magnitude smaller than the sensor's resistance (most of the thermistors we use are about 100k Ohms at room temp).

Early on I did some measurements of the bed temperature vs the set temperature in my printer and found it was offset- the thermistor supplied with the bed heater was unknown part number so I always used the default EPCOS thermistor in Smoothieware. I found that setting the temperature in the controller to 95C delivered 105 C on the bed, and used it that way for a couple years. I finally decided that the offset was a PITA, especially when letting others use the printer at the Makerspace, so last night I calibrated using a thermocouple clamped to the bed with a bulldog clip and adjusted the beta value in the firmware so the controller now reads withing 0.5 C of the controller board (using the thermistor) at 105C.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't know what advantage you'd gain using a PT100 sensor, but it will require an amplifier (unless it's built into your controller board). The absolute accuracy of the sensor isn't as important as its response time, and in this application, even that isn't very important because the time constant of the thermal mass of the bed is going to be orders of magnitude higher than the response time of the sensor. Lead wire resistance doesn't matter with thermistors because it is orders of magnitude smaller than the sensor's resistance (most of the thermistors we use are about 100k Ohms at room temp).

Early on I did some measurements of the bed temperature vs the set temperature in my printer and found it was offset- the thermistor supplied with the bed heater was unknown part number so I always used the default EPCOS thermistor in Smoothieware. I found that setting the temperature in the controller to 95C delivered 105 C on the bed, and used it that way for a couple years. I finally decided that the offset was a PITA, especially when letting others use the printer at the Makerspace, so last night I calibrated using a thermocouple clamped to the bed with a bulldog clip and adjusted the beta value in the firmware so the controller now reads withing 0.5 C of the controller board (using the thermistor) at 105C.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Aluminium bed - where to put the temperature sensor September 11, 2016 12:00PM |

Registered: 8 years ago Posts: 622 |

All this was done without glass fitted. The Duet WiFi that I use has a daughter board that takes 2 PT100s. I wanted to use one for the hot end, and as it has 2 channels, I thought why not use the second one for the bed? That's the only reason - I realise I don't need that accuracy. ( I said that in my previous post). Although because the bed moves in Z and the printer is a metre tall, the leads to the bed are around 2 metres long. There may be some advantage to using a 4 wire PRT in this case but as I said, the only reason for using one is that I could. We'll just have to disagree about the use of insulation. Minimising the heat loss from the underside of the plate can only help it to get hotter quicker. The cool down time won't matter when I start using my removable print surface (notice that I said removable print surface - probably, but not necessarily, glass).

|

Re: Aluminium bed - where to put the temperature sensor September 13, 2016 02:54AM |

Registered: 10 years ago Posts: 14,672 |

Deckingman, the arrangement you ended up with sounds good to me. The bed heater on my delta has the thermistor embedded in the heater, which causes problems similar to the ones you experienced at first. It also complicates heater model tuning, because there are in effect two gain parameters: the short term gain and the long term gain. I had to modify the tuning code so that it doesn't get fooled by the short term gain and instead measures the long term gain.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.