Home

>

Reprappers

>

Topic

PEI Sheet Update

Posted by elwood127

|

PEI Sheet Update November 24, 2016 01:34AM |

Registered: 9 years ago Posts: 705 |

|

Re: PEI Sheet Update November 24, 2016 08:51AM |

Registered: 11 years ago Posts: 5,780 |

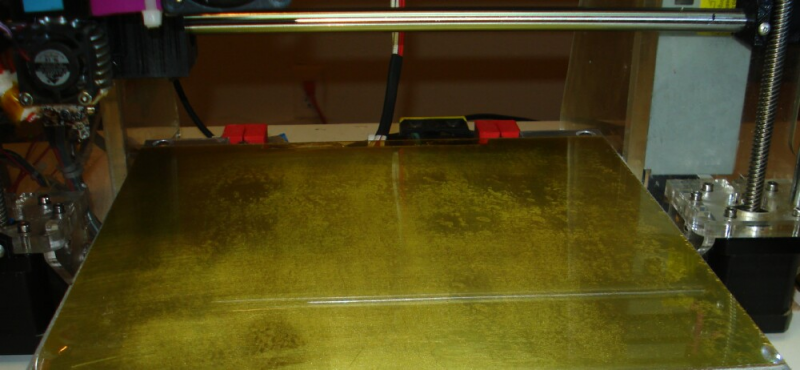

I put 60 mil PEI on my printer a few weeks ago. I used to have 5 mil kapton on it. I am finding that it is a bit easier to get ABS to stick to the PEI. PLA seems to stick well too, and both release pretty easily when the bed has cooled. The matte surface of the PEI (I stuck the glossy side to the bed plate) leaves a very smooth but not shiny bottom surface on the prints, and I get no more lines from tiny gaps in the kapton tape.

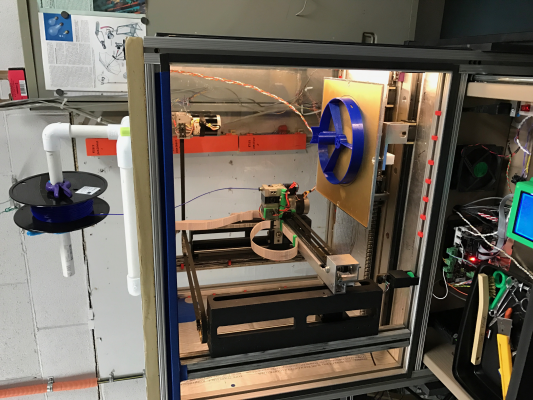

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: PEI Sheet Update November 26, 2016 04:27PM |

Registered: 8 years ago Posts: 36 |

|

Re: PEI Sheet Update November 26, 2016 05:33PM |

Registered: 9 years ago Posts: 705 |

Machine:

Cheezy acrylic I3 with everything replaced accept the frame (I know, the one thing I should replace). 3/16" build plate with a self adhered Keenovo 400 watt silicone heater and a dedicated 35 amp P.S.

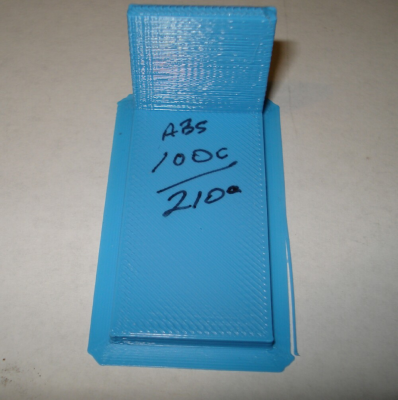

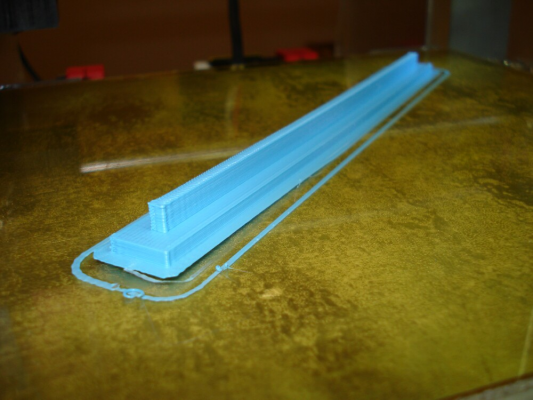

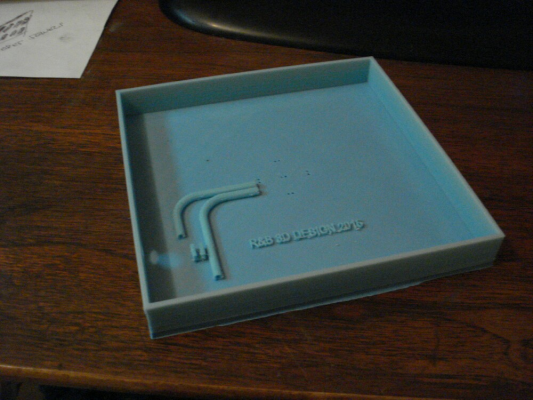

Ok, I think I have got my act together now, here goes. Great call DD on using the matte side to hide gaps in the first layer. Unfortunately my PEI is gloss on both sides. I ran multiple test prints with ABS and PLA. Hotend Temps (ABS @ 230c and PLA @ 180c). Heatbed Temps (ABS @ 120c, 110c and 100c). (PLA @ 110c, 100c and 90c). I printed each of these three parts at each temp. The big one being the torture test and has historically curled a bit on the corners with abs and pla.

Conclusion:

Ultimately, with small/ medium sized parts both filaments did great. I settled on these temps. ABS (230c and 110c). PLA (190c and 100c).

The part removal (safety) being paramount. I did find that using alcohol or windex with a rag left surface slick. A paper towel left the surface more sticky. I prefer the windex.

ALSO, applied to a cold surface seems to work better than hot.

The big print gave similar results as with glass or tape. (See pics)

Make sure that if you use PEI sheet that your build plate is perfect beforehand. Once it's on there there is no going back to file high spots and such.

Heatup times without glass are staggering. Max 5 minutes to 120c. With old hard heater and glass, an hour to 100c. Rarely got to 110c.

One more thing, I finally figured out how to get closeups with my camera. Below pics show some of the test prints. In case you can't see (your) finish, the difference between ABS @ 210c and .3 layer height and 230c and .2 layer height are amazing.

Edited 1 time(s). Last edit at 11/26/2016 05:51PM by elwood127.

Cheezy acrylic I3 with everything replaced accept the frame (I know, the one thing I should replace). 3/16" build plate with a self adhered Keenovo 400 watt silicone heater and a dedicated 35 amp P.S.

Ok, I think I have got my act together now, here goes. Great call DD on using the matte side to hide gaps in the first layer. Unfortunately my PEI is gloss on both sides. I ran multiple test prints with ABS and PLA. Hotend Temps (ABS @ 230c and PLA @ 180c). Heatbed Temps (ABS @ 120c, 110c and 100c). (PLA @ 110c, 100c and 90c). I printed each of these three parts at each temp. The big one being the torture test and has historically curled a bit on the corners with abs and pla.

Conclusion:

Ultimately, with small/ medium sized parts both filaments did great. I settled on these temps. ABS (230c and 110c). PLA (190c and 100c).

The part removal (safety) being paramount. I did find that using alcohol or windex with a rag left surface slick. A paper towel left the surface more sticky. I prefer the windex.

ALSO, applied to a cold surface seems to work better than hot.

The big print gave similar results as with glass or tape. (See pics)

Make sure that if you use PEI sheet that your build plate is perfect beforehand. Once it's on there there is no going back to file high spots and such.

Heatup times without glass are staggering. Max 5 minutes to 120c. With old hard heater and glass, an hour to 100c. Rarely got to 110c.

One more thing, I finally figured out how to get closeups with my camera. Below pics show some of the test prints. In case you can't see (your) finish, the difference between ABS @ 210c and .3 layer height and 230c and .2 layer height are amazing.

Edited 1 time(s). Last edit at 11/26/2016 05:51PM by elwood127.

|

Re: PEI Sheet Update November 26, 2016 05:38PM |

Registered: 9 years ago Posts: 705 |

|

Re: PEI Sheet Update November 27, 2016 04:31AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: PEI Sheet Update November 27, 2016 10:20AM |

Registered: 9 years ago Posts: 705 |

Yes. They say that abs is more difficult but I'm finding that pla is more problematic. At 80c part pops off immediately when done. At 100 it seems to stay a bit better stuck. 2 seconds after finishing this review I started printing some name badges for my grand daughters robotic team meet. New silver filament. Fail after fail. Half popped off during print. Still trying to figure it all out. But like we know, if things weren't going wrong occasionally we'd be bored.

|

Re: PEI Sheet Update November 27, 2016 01:00PM |

Registered: 12 years ago Posts: 2,470 |

I found that PLA is one of the few materials that does not work well with PEI. Nylon is another.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: PEI Sheet Update November 27, 2016 02:19PM |

Registered: 10 years ago Posts: 14,672 |

I print PLA on PEI heated to about 50C. The only problem I have with this combination is that the print sometimes sticks to the PEI too well and I need to freeze the print or use a hammer to release it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: PEI Sheet Update November 27, 2016 08:14PM |

Registered: 7 years ago Posts: 558 |

I too print PLA on PEI. I have a sheet from McMaster that was 0.040" thick painted black on one side and then glued to a piece of glass with some 3M 468MP Adhesive Transfer Tape from Amazon. It was glossy on both sides, but the flat black paint on one side covered the side I glued to the glass, and the print side I scrubbed down with steel wool, and rubbing alcohol to kill some of the gloss and remove any greasy fingerprints. I use PLA with the bed at 65C and PETG with the bed at 85, and ABS with the bed at 110C.

Stuff sticks to it while printing and then comes off with a little force at room temperature.

However, It sticks too well to Ninjaflex which completely destroys the Ninjaflex print, so I exclusively use just glass with Ninjaflex.

Stuff sticks to it while printing and then comes off with a little force at room temperature.

However, It sticks too well to Ninjaflex which completely destroys the Ninjaflex print, so I exclusively use just glass with Ninjaflex.

|

Re: PEI Sheet Update November 27, 2016 10:48PM |

Registered: 11 years ago Posts: 5,780 |

I ran a couple more ABS prints and found that they can stick too well if the bed temperature is too high for too long. One of the folks at the makerspace clued me in to a trick to get the prints to release more easily. After the bed has cooled, apply a few drops of 91% IPA around the base of the print. I don't know why/how it works, but you'll start to hear little cracking sounds as the print releases itself. Maybe as the alcohol evaporates it causes some localized cooling which puts stress on the ABS/PEI junction. After several seconds the print can be removed without too much mechanical effort. IPA doesn't do any damage to either the ABS or the PEI.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: PEI Sheet Update November 29, 2016 11:55PM |

Registered: 9 years ago Posts: 705 |

Hey all, I failed to mention in my original post that at abs temps this product gases terribly. My printer being in the basement allowed me to print. Had I been upstairs my wife would have sent me packing. PLA temps cause moderate stink but ABS temps really get it fumeing. Because of the stench I decided to try something. I applied Elmers Purple Glue Stick to the PEI sheet (cold). I printed PLA with no heat or brim and it worked awesomely. It actually stuck better than it did directly on the pei with heat but popped off easily when done. A warm washcloth removed the glue easier than from glass. Applied another coat of glue and am now printing with ABS cold. Showing some signs of curling. Will do another ABS print cold with a brim. If that doesn,t work I'll gradually apply some bed heat and see what happens. If lower bed temp works it will be much better. I shall return.

|

Re: PEI Sheet Update November 30, 2016 01:28AM |

Registered: 9 years ago Posts: 705 |

|

Re: PEI Sheet Update November 30, 2016 04:26AM |

Registered: 8 years ago Posts: 5,232 |

So we are back to square one with elmers glue and all the little helpers we actually wanted to avoid by using special sheets....

I'd like to know if the PEI fumes forever, or just in the first few hours of usage? And if it stops stinking, will that change the materials characteristics?

Maybe the fumes comes from a solvent, which makes it more flexible, but it starts getting brittle...

I'd like to know if the PEI fumes forever, or just in the first few hours of usage? And if it stops stinking, will that change the materials characteristics?

Maybe the fumes comes from a solvent, which makes it more flexible, but it starts getting brittle...

|

Re: PEI Sheet Update November 30, 2016 08:40AM |

Registered: 11 years ago Posts: 5,780 |

I haven't noticed any smell but the standard ABS smell. How did you separate the PEI smell from the ABS smell?

After a few more prints at varying temperatures where long straight portions pulled up from the bed, I'm starting to think this stuff isn't really any better than the kapton I've been using for the last few years. Except... I was using 5 mil kapton and it would eventually wear or tear and have to be replaced. I was using 2" wide strips and there would inevitably be gaps between the strips that would show up in the bottom surface of the prints. I am using 60 mil PEI which should be nearly indestructible and there are no seams so the bottom of prints comes out perfectly smooth and flat (when I can get the print to stay put). So PEI still has a slight edge over kapton. Maybe with more experimentation I'll find the magic combo of temperature settings that will get prints to stick reliably regardless of shape.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

After a few more prints at varying temperatures where long straight portions pulled up from the bed, I'm starting to think this stuff isn't really any better than the kapton I've been using for the last few years. Except... I was using 5 mil kapton and it would eventually wear or tear and have to be replaced. I was using 2" wide strips and there would inevitably be gaps between the strips that would show up in the bottom surface of the prints. I am using 60 mil PEI which should be nearly indestructible and there are no seams so the bottom of prints comes out perfectly smooth and flat (when I can get the print to stay put). So PEI still has a slight edge over kapton. Maybe with more experimentation I'll find the magic combo of temperature settings that will get prints to stick reliably regardless of shape.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: PEI Sheet Update December 01, 2016 06:24PM |

Registered: 9 years ago Posts: 705 |

|

Re: PEI Sheet Update December 02, 2016 03:48PM |

Registered: 10 years ago Posts: 14,672 |

My PEI bed doesn't smell when I heat it to 120C.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: PEI Sheet Update December 07, 2016 06:19PM |

Registered: 9 years ago Posts: 705 |

|

Re: PEI Sheet Update December 07, 2016 06:58PM |

Registered: 10 years ago Posts: 14,672 |

I used 8153LE adhesive sheet, not 468MP. However, looking at the product specifications, 468MP should be at least as good as 8153LE.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: PEI Sheet Update December 07, 2016 08:50PM |

Registered: 11 years ago Posts: 5,780 |

PLA printed on PEI- no problems. It's a spider to mount the diagonal mirror in an 8" telescope:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.