Home

>

Reprappers

>

Topic

Acid (H2SO4) resistant hard and flex materials

Posted by spmp

|

Acid (H2SO4) resistant hard and flex materials March 29, 2017 05:28PM |

Registered: 7 years ago Posts: 4 |

I need to make prints that must contain H2SO4 (concentration TBC), sometimes under pressure.

I would like to incorporate a flex material to act as a gasket between parts. This flex material would also need to be acid resistant.

Ideally the materials would have the same or similar temperature characteristics so that they can be printed with a mixing head.

Printing with standard RepRap printers.

I greatly appreciate any suggestions of materials, or better pairs of materials.

Thank you.

I would like to incorporate a flex material to act as a gasket between parts. This flex material would also need to be acid resistant.

Ideally the materials would have the same or similar temperature characteristics so that they can be printed with a mixing head.

Printing with standard RepRap printers.

I greatly appreciate any suggestions of materials, or better pairs of materials.

Thank you.

|

Re: Acid (H2SO4) resistant hard and flex materials March 29, 2017 08:42PM |

Registered: 7 years ago Posts: 267 |

Well it all depends on the Concentration and temperature,

A quick goolge will lead you to a chemical comparability chart (Like this one [sevierlab.vet.cornell.edu]), these charts are used in the chemical manufacturing industry to determine what material instruments and valves should be made from and what seals to use.

Polypropylene would be a good choice, as for the seals you might be better getting a sheet of EPDM and cutting them yourself

A quick word of warning, these charts are used for solid materials and not one that has been created layer by layer, maybe use the chart as a guide then do your own tests with different layer heights and thicknesses.

Edited 1 time(s). Last edit at 03/29/2017 11:38PM by scottybfg.

A quick goolge will lead you to a chemical comparability chart (Like this one [sevierlab.vet.cornell.edu]), these charts are used in the chemical manufacturing industry to determine what material instruments and valves should be made from and what seals to use.

Polypropylene would be a good choice, as for the seals you might be better getting a sheet of EPDM and cutting them yourself

A quick word of warning, these charts are used for solid materials and not one that has been created layer by layer, maybe use the chart as a guide then do your own tests with different layer heights and thicknesses.

Edited 1 time(s). Last edit at 03/29/2017 11:38PM by scottybfg.

|

Re: Acid (H2SO4) resistant hard and flex materials March 30, 2017 02:47AM |

Admin Registered: 16 years ago Posts: 13,888 |

... to "seal" the surface of a printed part, what's resistant to solvents too (so not suited for "vapour-smoothing"), you can use a small blow-torch to melt the surface.

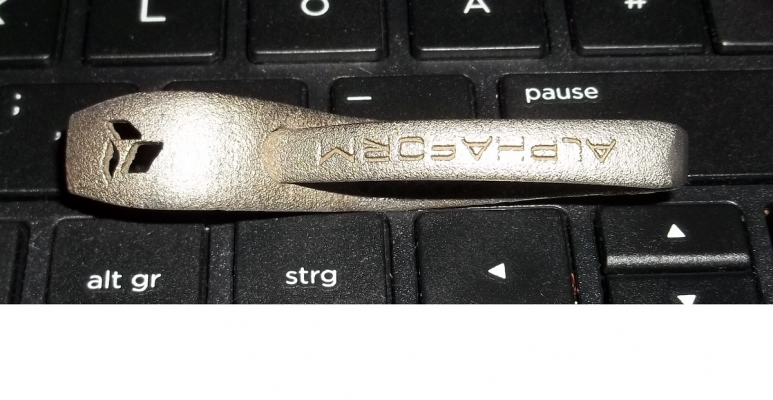

I've done something similar to a metal part, powderbed-SLS-printed from titanium powder.

This is the original surface:

... and here manually "remelted" and "compacted" with a laser:

With plastic material this can be done with a CO2-laser or, if dark dyed, with a laserdiode ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I've done something similar to a metal part, powderbed-SLS-printed from titanium powder.

This is the original surface:

... and here manually "remelted" and "compacted" with a laser:

With plastic material this can be done with a CO2-laser or, if dark dyed, with a laserdiode ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Acid (H2SO4) resistant hard and flex materials March 30, 2017 03:39AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Acid (H2SO4) resistant hard and flex materials March 30, 2017 05:54AM |

Registered: 7 years ago Posts: 4 |

Based on my rusty chemistry knowledge, it appears the upper limit is 6M H2S04 which is roughly 46% w/w.

According to the Chemical Compatibility Chart some materials are resistant at this concentration in the range of temperatures around 20 ̊. Good news!

According to the chart LDPE, HDPE, PMP, FEP, TFE, PFA, ECTFE, ETFE, Rigid PVC, PSF, PS, FLPE, RESMER, and PVDF are resistant at 20 ̊.

FEP, TFE, ECTFE, ETFE, PSF and PVDF are resistant at 60 ̊.

But how does this chart relate to filament products that we can buy! I know that PPSF/PPSU - which can be got as filament - will work, but a 390 ̊ extrusion temperature is a little extreme! Not to mention that I doubt there is a flex that has a similar melting point.

The makers of NinjaFlex did not believe their product was resistant to H2S04, but did not ask temperature or concentration questions.

Are there any other suggestions of filaments that could form gaskets?

Am I to understand that without surface treatment all FDM prints will leak?

The project is an attempt to make frames for Vanadium Redox Battery cell stacks, very similar to what is shown in these pages:

[jss.ecsdl.org]

[jss.ecsdl.org]

So the design is highly planar and not suited to a silicone balloon.

The plan was to have the flow direction channels within the frame (i.e in the middle layers, and not visible) This could cause issues with leakage due to not being able to seal them...

The SLS prints look amazing BTW!

According to the Chemical Compatibility Chart some materials are resistant at this concentration in the range of temperatures around 20 ̊. Good news!

According to the chart LDPE, HDPE, PMP, FEP, TFE, PFA, ECTFE, ETFE, Rigid PVC, PSF, PS, FLPE, RESMER, and PVDF are resistant at 20 ̊.

FEP, TFE, ECTFE, ETFE, PSF and PVDF are resistant at 60 ̊.

But how does this chart relate to filament products that we can buy! I know that PPSF/PPSU - which can be got as filament - will work, but a 390 ̊ extrusion temperature is a little extreme! Not to mention that I doubt there is a flex that has a similar melting point.

The makers of NinjaFlex did not believe their product was resistant to H2S04, but did not ask temperature or concentration questions.

Are there any other suggestions of filaments that could form gaskets?

Am I to understand that without surface treatment all FDM prints will leak?

The project is an attempt to make frames for Vanadium Redox Battery cell stacks, very similar to what is shown in these pages:

[jss.ecsdl.org]

[jss.ecsdl.org]

So the design is highly planar and not suited to a silicone balloon.

The plan was to have the flow direction channels within the frame (i.e in the middle layers, and not visible) This could cause issues with leakage due to not being able to seal them...

The SLS prints look amazing BTW!

|

Re: Acid (H2SO4) resistant hard and flex materials March 30, 2017 09:11AM |

Admin Registered: 16 years ago Posts: 13,888 |

Quote

spmp

Am I to understand that without surface treatment all FDM prints will leak?

You can get watertight surfaces with FDM fabbing, but only with (related to the used material) very high printing temperatures, so the new material will extrude pretty low viscous and remelt the solid surface, to get a solid/watertight bond.

With reheating/remelting the surface afterwards this will be easier and less fault-prone ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Acid (H2SO4) resistant hard and flex materials March 30, 2017 06:57PM |

Registered: 7 years ago Posts: 267 |

Quote

spmp

According to the chart LDPE, HDPE, PMP, FEP, TFE, PFA, ECTFE, ETFE, Rigid PVC, PSF, PS, FLPE, RESMER, and PVDF are resistant at 20 ̊.

FEP, TFE, ECTFE, ETFE, PSF and PVDF are resistant at 60 ̊.

But how does this chart relate to filament products that we can buy!

!

I would do a test with polypropylene [gizmodorks.com] at 30% its fine and at 60% it shows little to no damage after 30 days. I dont think anyone here is going to be able to give you a hard answer.

As for the gasket, EPDM is a good choice for sulphuric acid, just buy the roll and cut it yourself.

|

Re: Acid (H2SO4) resistant hard and flex materials March 30, 2017 07:39PM |

Registered: 7 years ago Posts: 4 |

|

Re: Acid (H2SO4) resistant hard and flex materials March 30, 2017 09:09PM |

Registered: 7 years ago Posts: 267 |

I just chose PP because i know it comes in filament form and people have printed with it. Have a search and see if you can find any of the others as filament.

The EPDM, buy the material sheet and cut your own gaskets, should be easy to do as i imagine this being between the plates, no internal geometry. Also you will get a better seal then with printed due to air gaps in the print.

The research paper you linked was interesting, they used ABS for testing and had no real issued, so this could be a solution while prototyping or while testing the PP of long term acid resistance

The EPDM, buy the material sheet and cut your own gaskets, should be easy to do as i imagine this being between the plates, no internal geometry. Also you will get a better seal then with printed due to air gaps in the print.

The research paper you linked was interesting, they used ABS for testing and had no real issued, so this could be a solution while prototyping or while testing the PP of long term acid resistance

|

Re: Acid (H2SO4) resistant hard and flex materials April 02, 2017 05:58PM |

Registered: 7 years ago Posts: 4 |

Thanks for the head start ppl!

Its a stub atm but will fill out as we go if you are interested in following the project. WIll have a hackaday etc. eventually as well:

[github.com]

I can get EPDM locally no problem 8)

BUt... I have been reading a bit about FDM with Polypropylene and it seems that it may not be suitable for our purposes due to its tendancy to warp. Is there

a) Anyone who regularly prints in PP who can indicate if this will be a problem for what will essentially be thin relativly large rectangles that must be highly uniform and flat...

b) Another suggestion for a material that is both acid resistant, and prints without warping 8)

Its a stub atm but will fill out as we go if you are interested in following the project. WIll have a hackaday etc. eventually as well:

[github.com]

I can get EPDM locally no problem 8)

BUt... I have been reading a bit about FDM with Polypropylene and it seems that it may not be suitable for our purposes due to its tendancy to warp. Is there

a) Anyone who regularly prints in PP who can indicate if this will be a problem for what will essentially be thin relativly large rectangles that must be highly uniform and flat...

b) Another suggestion for a material that is both acid resistant, and prints without warping 8)

Sorry, only registered users may post in this forum.