Home

>

Reprappers

>

Topic

Can you suggest a better way to tighten belts?

Posted by drmaestro

|

Can you suggest a better way to tighten belts? April 08, 2017 03:44AM |

Registered: 9 years ago Posts: 330 |

Hi,

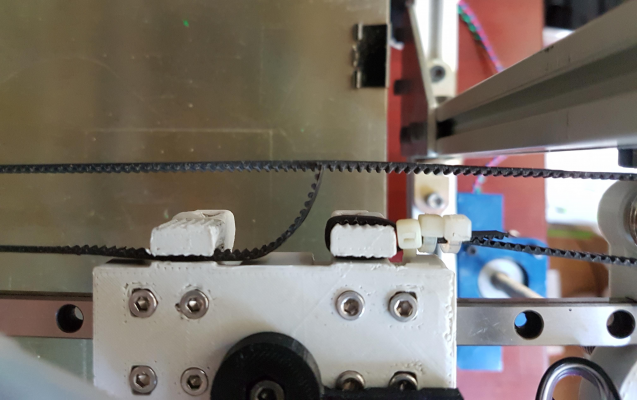

Some of the answers to the print quality questions I have posted suggested backlash or not enough tension on belts. Here is how my belt setup looks from top-down view:

As you can see, I have to make 2 loops (on the picture there is only 1 in place). The first loop doesn't really matter, as it is the anchoring point. But the second loop is the step that adjusts tightness, so it is crucial. What I do right now is to try to pull the belt manually as tight as I can, then make the loop and immedialtely attach 2 zipties to hold it in place. The interlocking belt teeth prevent any slipping if the zipties are firmly in place. However it seems that I am never able to get the required tension. To test the degree of tension that is achievable, I used a pliers to hold the loose end and rotated it a few turns to make the belt tight. What I can achieve this way is really perfect but there is no way to fix it in place because the end of the belt is now rolled and any attempt to remove pliers without loosing tension always fails.

If I tighten it manually, I use belt tensioners but they never achieve the degree of tension acheivable by using the pliers. The spring belt tenisoners seem to introduce some artifacts as they are not rigid and tend to introduce some backlash themselves. Printed rigid tensioners are limited on what they can achieve, as you can never achieve the same amount tightness using pliers.

I've looked at metal pieces to hold GT2 belts in place but they are not adjustable.

So, what can I do to make these belts tight? Any method or device?

Thanks

Some of the answers to the print quality questions I have posted suggested backlash or not enough tension on belts. Here is how my belt setup looks from top-down view:

As you can see, I have to make 2 loops (on the picture there is only 1 in place). The first loop doesn't really matter, as it is the anchoring point. But the second loop is the step that adjusts tightness, so it is crucial. What I do right now is to try to pull the belt manually as tight as I can, then make the loop and immedialtely attach 2 zipties to hold it in place. The interlocking belt teeth prevent any slipping if the zipties are firmly in place. However it seems that I am never able to get the required tension. To test the degree of tension that is achievable, I used a pliers to hold the loose end and rotated it a few turns to make the belt tight. What I can achieve this way is really perfect but there is no way to fix it in place because the end of the belt is now rolled and any attempt to remove pliers without loosing tension always fails.

If I tighten it manually, I use belt tensioners but they never achieve the degree of tension acheivable by using the pliers. The spring belt tenisoners seem to introduce some artifacts as they are not rigid and tend to introduce some backlash themselves. Printed rigid tensioners are limited on what they can achieve, as you can never achieve the same amount tightness using pliers.

I've looked at metal pieces to hold GT2 belts in place but they are not adjustable.

So, what can I do to make these belts tight? Any method or device?

Thanks

|

Re: Can you suggest a better way to tighten belts? April 08, 2017 04:06AM |

Admin Registered: 13 years ago Posts: 6,999 |

Use two additional large (6mm) zip ties.

Ie keep one end of the belt around the plastic, the other looped around nothing just zip tied on itself, use larger 6mm zip tie just around the plastic and the last 6mm zip tie to join the loped belt and the zip tie around the plastic. tension by pulling the zip tie

eg like this

You just have to make sure the extra zip tie doesn’t hit or interfere with anything.

Edited 1 time(s). Last edit at 04/08/2017 04:09AM by Dust.

Ie keep one end of the belt around the plastic, the other looped around nothing just zip tied on itself, use larger 6mm zip tie just around the plastic and the last 6mm zip tie to join the loped belt and the zip tie around the plastic. tension by pulling the zip tie

eg like this

You just have to make sure the extra zip tie doesn’t hit or interfere with anything.

Edited 1 time(s). Last edit at 04/08/2017 04:09AM by Dust.

|

Re: Can you suggest a better way to tighten belts? April 08, 2017 05:50AM |

Registered: 9 years ago Posts: 238 |

|

Re: Can you suggest a better way to tighten belts? April 08, 2017 08:49AM |

Registered: 11 years ago Posts: 5,780 |

Quote

drmaestro

Hi,

Some of the answers to the print quality questions I have posted suggested backlash or not enough tension on belts. Here is how my belt setup looks from top-down view:

[attachment 92780 belt.jpg]

s

You've gone to a lot of trouble and some expense to use linear guides to get high precision, but you have a fundamental error, visible in your photo. The right side attachment where you have locked the belt with zip ties is too high. The belt segments that attach to the carriage have to be parallel to the guide rail at all positions along the rail or the belt tension will vary with the position of the carriage and the prints will be distorted.

The same is true in the Y axis. The belts must be kept parallel to the guide rails or you will have problems.

Edited 1 time(s). Last edit at 04/08/2017 08:50AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Can you suggest a better way to tighten belts? April 08, 2017 03:44PM |

Registered: 9 years ago Posts: 330 |

Quote

the_digital_dentist

Quote

drmaestro

Hi,

Some of the answers to the print quality questions I have posted suggested backlash or not enough tension on belts. Here is how my belt setup looks from top-down view:

[attachment 92780 belt.jpg]

s

You've gone to a lot of trouble and some expense to use linear guides to get high precision, but you have a fundamental error, visible in your photo. The right side attachment where you have locked the belt with zip ties is too high. The belt segments that attach to the carriage have to be parallel to the guide rail at all positions along the rail or the belt tension will vary with the position of the carriage and the prints will be distorted.

The same is true in the Y axis. The belts must be kept parallel to the guide rails or you will have problems.

Thanks for mentioning that. I'll try to correct it. It is probably due to the diameter of the idler, which is 16 mm. I have another one which measures 12 mm, maybe it will help with the alignement.

|

Re: Can you suggest a better way to tighten belts? April 12, 2017 08:18PM |

Registered: 10 years ago Posts: 39 |

If you can, do the final tensioning by adjusting the motor or pulley mount. This is one of the reasons slotted rail is so handy.

Another popular trick is to remove all but one screw from the motor so that that the motor can rotate in the mount, attach your belt ends at the right length, pivot the motor back into place, and replace motor screws.

Also, here's how Prusa3d does it:

Tighten Y Axis

Tighten X Axis

Another popular trick is to remove all but one screw from the motor so that that the motor can rotate in the mount, attach your belt ends at the right length, pivot the motor back into place, and replace motor screws.

Also, here's how Prusa3d does it:

Tighten Y Axis

Tighten X Axis

|

Re: Can you suggest a better way to tighten belts? April 13, 2017 03:16AM |

Registered: 12 years ago Posts: 2,470 |

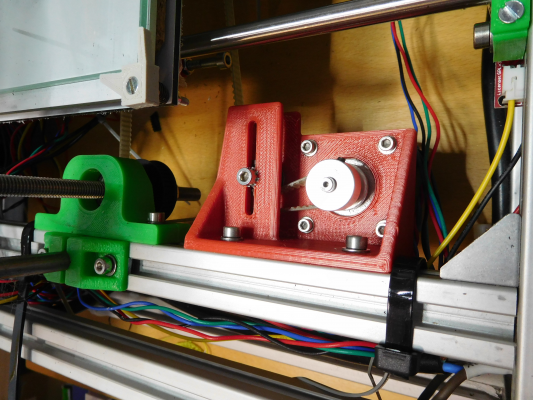

I use a bearing that is adjustable to tighten my Z and Y belt

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Can you suggest a better way to tighten belts? April 13, 2017 06:52AM |

Registered: 7 years ago Posts: 51 |

At the risk of under-complicating things. . .

The simple tensioner spring does a very good job of taking up slack and keeps a positive 'sprung' tension on the belt without needing a mechanically set position of motor/ pulley

The simple tensioner spring does a very good job of taking up slack and keeps a positive 'sprung' tension on the belt without needing a mechanically set position of motor/ pulley

|

Re: Can you suggest a better way to tighten belts? April 13, 2017 07:50AM |

Registered: 12 years ago Posts: 2,470 |

While that solution is very common, it introduces elasticity where you usually do not want it. The belts have steel or fibre wires to prevent stretching and to minimize elasticity along the length. Adding such a spring counteracts this intention.Quote

Ed would

At the risk of under-complicating things. . .

[attachment 92951 bspring.JPG]

The simple tensioner spring does a very good job of taking up slack and keeps a positive 'sprung' tension on the belt without needing a mechanically set position of motor/ pulley

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Can you suggest a better way to tighten belts? April 14, 2017 09:55AM |

Registered: 9 years ago Posts: 17 |

I agree, this solution basically reduces the stiffness of the belt to the stiffness of the spring. Also it introduced stiffness dependency on the carriage position because the stiffness of the belt from the motor to the carriage has two routes and one now has the belt stiffness while the other has the spring stiffness. This could also decrease the dynamic properties especially if u have relative heavy carriages.

I like to look around here to get some inspiration for a nice design: [www.thingiverse.com]

Edited 1 time(s). Last edit at 04/14/2017 09:56AM by Evan.

I like to look around here to get some inspiration for a nice design: [www.thingiverse.com]

Edited 1 time(s). Last edit at 04/14/2017 09:56AM by Evan.

|

Re: Can you suggest a better way to tighten belts? April 18, 2017 04:57AM |

Registered: 7 years ago Posts: 51 |

I take you point but I think they are fine.

I only write from a position of personal experience.

The springs do stretch when pulled hard. I don't have anything to measure the force required to deflect per distance so I can't give you any numbers to calculate but I 'feel' that for an average reprap type setup of Nema17/ GT2/ low mass, the spring rate would be enough to overcome the forces applied to it.

I'd be interested if anyone has properly measured it. I'm happy to eat my words.

Ed

I only write from a position of personal experience.

The springs do stretch when pulled hard. I don't have anything to measure the force required to deflect per distance so I can't give you any numbers to calculate but I 'feel' that for an average reprap type setup of Nema17/ GT2/ low mass, the spring rate would be enough to overcome the forces applied to it.

I'd be interested if anyone has properly measured it. I'm happy to eat my words.

Ed

|

Re: Can you suggest a better way to tighten belts? April 18, 2017 05:20AM |

Registered: 12 years ago Posts: 2,470 |

It is a matter of mass and acceleration. If you use a core x/y printer with a bowden hotend and normal acceleration chances are you wont see any problems. If you use a Bulldog extruder on a cartesian printer with high acceleration i would avoid a setup like this like the plague.Quote

Ed would

I take you point but I think they are fine.

I only write from a position of personal experience.

The springs do stretch when pulled hard. I don't have anything to measure the force required to deflect per distance so I can't give you any numbers to calculate but I 'feel' that for an average reprap type setup of Nema17/ GT2/ low mass, the spring rate would be enough to overcome the forces applied to it.

I'd be interested if anyone has properly measured it. I'm happy to eat my words.

Ed

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Can you suggest a better way to tighten belts? April 22, 2017 07:45PM |

Registered: 7 years ago Posts: 27 |

|

Re: Can you suggest a better way to tighten belts? April 29, 2017 04:20AM |

Registered: 7 years ago Posts: 13 |

|

Re: Can you suggest a better way to tighten belts? May 02, 2017 01:32PM |

Registered: 7 years ago Posts: 1 |

The way I do it is to slightly loosen the left side hold down, grab the excess belt on the left side with needle nose pliers, holding the belt with the pliers lay the pliers up against the hold down, turn the pliers until you get the tension you need, and tighten the hold down.

Hope this helps.

Steve

Hope this helps.

Steve

|

Re: Can you suggest a better way to tighten belts? May 03, 2017 04:14PM |

Registered: 9 years ago Posts: 109 |

I wish I had a picture but saw a really easy idea at a maker fair the guy took a sharpie pen cap made a loop in the belt around the cap and zip tied the belt loosely then connected up the loose end. After he had it connected up tightened the zip tie to tighten the belt around the pen cap. It was a bush fix type deal but fixed this kids printer in a few minutes. Could print a nicer way of doing it but the pen cap works in a pinch if you need it.

|

Re: Can you suggest a better way to tighten belts? May 03, 2017 04:29PM |

Registered: 9 years ago Posts: 978 |

I've designed and use a simple belt tensioner.

This works well on my Delta, where there's a fair amount of belt that doesn't go through any pulleys. I've intentionally left the tensioner slightly weak, so that it breaks if undue tension is put on the belt (e.g. nozzle is driven into the bed or crashes against the side of the print) and hopefully reduces stress and damage to other parts of the printer. I always keep a couple of spare tensioners on hand.

This works well on my Delta, where there's a fair amount of belt that doesn't go through any pulleys. I've intentionally left the tensioner slightly weak, so that it breaks if undue tension is put on the belt (e.g. nozzle is driven into the bed or crashes against the side of the print) and hopefully reduces stress and damage to other parts of the printer. I always keep a couple of spare tensioners on hand.

Sorry, only registered users may post in this forum.