Home

>

Reprappers

>

Topic

Upgrade to 30x30 aluminium extrusions?

Posted by drmaestro

|

Upgrade to 30x30 aluminium extrusions? April 09, 2017 04:24PM |

Registered: 9 years ago Posts: 330 |

Hi,

My printer's main construction is based on 20x20 aluminium extrusions. It is a 20x20x20 cm cartesian unit. While I tried to make it solid using additional metal plaques or joining components, it still flexes, especially on the upper parts.My current geometric configuration would allow me to change these extrusions to 30x30s with only some minor design changes (by using just longer T-slot nuts with same bolt sizes and by lengthening Z elevators by a few milimeters), but of course it will require a complete rebuild and calibration. Is it worth it? Does a 10x10 mm difference make a tangible change?

Thanks.

My printer's main construction is based on 20x20 aluminium extrusions. It is a 20x20x20 cm cartesian unit. While I tried to make it solid using additional metal plaques or joining components, it still flexes, especially on the upper parts.My current geometric configuration would allow me to change these extrusions to 30x30s with only some minor design changes (by using just longer T-slot nuts with same bolt sizes and by lengthening Z elevators by a few milimeters), but of course it will require a complete rebuild and calibration. Is it worth it? Does a 10x10 mm difference make a tangible change?

Thanks.

|

Re: Upgrade to 30x30 aluminium extrusions? April 09, 2017 04:39PM |

Registered: 10 years ago Posts: 14,672 |

Stiffness is proportional to the cube of thickness, so if flexing of the extrusions is the main issue, I think that a 50% increase in thickness should reduce the displacement due to flexing to 8/27 of the current amount. This assumes that 3030 extrusions also have 50% thicker walls than 2020. If they have the same thickness then I think the reduction would only be to 4/9 of the current amount.

If the flexing is in only one direction, then 2040 extrusions suitably oriented may be a better choice.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If the flexing is in only one direction, then 2040 extrusions suitably oriented may be a better choice.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Upgrade to 30x30 aluminium extrusions? April 09, 2017 05:43PM |

Registered: 9 years ago Posts: 330 |

The flexing is mostly on the mediolateral direction. The anteroposterior direction is quite stable.

The 2040 would probably be advantageous here, as it won't require any hardware (nuts and bolts) change, as it will have the same channel dimension. The real problem here would be related to the distance between the lateral vertical extrusions and the heated bed, which is approximately 10 mm on each side. It would be really nice if I could expand by going inwards, but it is impossible without hitting the bed so I'd have to expand outwards by 20 mm on each side (3030 extrusion would allow me to expand in both directions by 5 mm). My X axis is mounted on linear rails which are 400 mm long. I'd probably have to make a slight design change on the Z cars (where the rails are mounted) to compansate for the lost 40 mm, as I really don't one to buy new rails.

If I make this change, would that mean the flex in the lateral direction will be 1/8 of what it is now? That's quite good. Also, it will allow me to use more connection elements in the anteroposterior direction (as there are two 20 mm extrusions side by side). Maybe that could also make the device more robust.

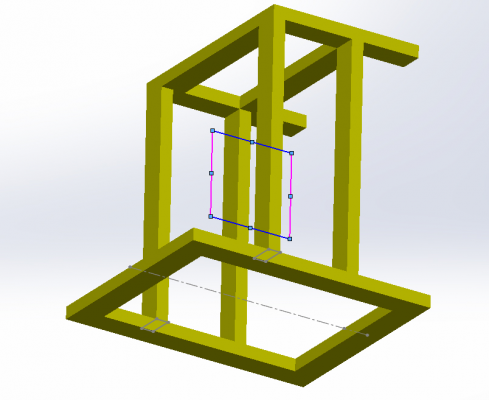

Edit: I have made a quick sketch of my printer in case I have used 2040 extrusions:

What do you think about the 2 horizontal ones on top of the printer? Is it better to rotate them 90 degrees so that they are parallel to the vertical ones or is it more stable like this?

Thanks...

Edited 1 time(s). Last edit at 04/09/2017 07:20PM by drmaestro.

The 2040 would probably be advantageous here, as it won't require any hardware (nuts and bolts) change, as it will have the same channel dimension. The real problem here would be related to the distance between the lateral vertical extrusions and the heated bed, which is approximately 10 mm on each side. It would be really nice if I could expand by going inwards, but it is impossible without hitting the bed so I'd have to expand outwards by 20 mm on each side (3030 extrusion would allow me to expand in both directions by 5 mm). My X axis is mounted on linear rails which are 400 mm long. I'd probably have to make a slight design change on the Z cars (where the rails are mounted) to compansate for the lost 40 mm, as I really don't one to buy new rails.

If I make this change, would that mean the flex in the lateral direction will be 1/8 of what it is now? That's quite good. Also, it will allow me to use more connection elements in the anteroposterior direction (as there are two 20 mm extrusions side by side). Maybe that could also make the device more robust.

Edit: I have made a quick sketch of my printer in case I have used 2040 extrusions:

What do you think about the 2 horizontal ones on top of the printer? Is it better to rotate them 90 degrees so that they are parallel to the vertical ones or is it more stable like this?

Thanks...

Edited 1 time(s). Last edit at 04/09/2017 07:20PM by drmaestro.

|

Re: Upgrade to 30x30 aluminium extrusions? April 15, 2017 10:44AM |

Registered: 7 years ago Posts: 257 |

|

Re: Upgrade to 30x30 aluminium extrusions? April 15, 2017 12:08PM |

Registered: 9 years ago Posts: 330 |

|

Re: Upgrade to 30x30 aluminium extrusions? April 20, 2017 08:48AM |

Registered: 9 years ago Posts: 17 |

Looking at the structure at the drawing i think the stiffness can be best increased by increasing the torsion stiffness. This is almost always the problem with these kind of structures. Using thicker profiles can increase the stiffness but i would consider using triangular plates on the corners (see added image).

If extrusion profiles of 20x20 are properly used i could see no reason that they won't be stiff enough. Maybe adding some pictures of the structure helps.

Edited 1 time(s). Last edit at 04/20/2017 08:50AM by Evan.

If extrusion profiles of 20x20 are properly used i could see no reason that they won't be stiff enough. Maybe adding some pictures of the structure helps.

Edited 1 time(s). Last edit at 04/20/2017 08:50AM by Evan.

|

Re: Upgrade to 30x30 aluminium extrusions? April 20, 2017 11:14AM |

Registered: 7 years ago Posts: 270 |

Sorry, only registered users may post in this forum.