Home

>

Reprappers

>

Topic

Big Printer

Posted by Iceman086

|

Big Printer March 17, 2011 12:56AM |

Registered: 13 years ago Posts: 70 |

Hello All,

I am hoping to put together a proposal for a grant to build a plastic printer with a 2'x2'x2' printable area. The goal is to use alot of the same basic principals that alot of people already set up and put out there.

Budget $500 or less.

Set Up

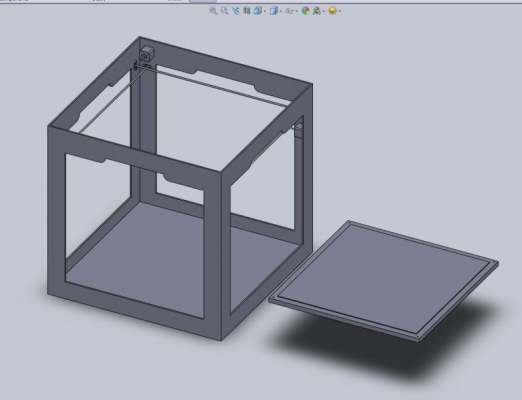

I am hoping to have the printer head move on the XY axis while the build platform moves up and down on the Z. I think that this will help to keep the machine at a decent size without having to create a HUGE box to facilitate a moving (on the XY) build platform.

Control Boards

I would like to use the Arduino Mega 2560 board as the main controller board and the Sanguino v 0.7 as the motor control board.

The thing that I dont know alot about are extruder heads. I was told that the Bowden Extruder would be a good choice as a cheap alternative.

There are a few questions that I have. I am willing to do the research I just need a bit of pointing in the right direction.

Is there a place that sells large enough belts to accommodate 2' of movement for the XY plane? I need to have something that the motors can connect to allow the X and Y movements so that the extruder head will move at the cross points of the X and Y axis.

Are there any suggestions for extruder's or build instructions for an extruder head that are available? The Bowden didn't explain alot about how it was built, though it did explain how it worked.

I will say that I am planning on building the housing for everything out of wood or possibly using box tube depending on how things come together. Also, I do have a friend with a makerbot who is willing to print off parts and I have enough solidworks skills to be able to design parts that can be printed.

Any suggestions or help are hugely welcome.

Thank you,

~Ice

I am hoping to put together a proposal for a grant to build a plastic printer with a 2'x2'x2' printable area. The goal is to use alot of the same basic principals that alot of people already set up and put out there.

Budget $500 or less.

Set Up

I am hoping to have the printer head move on the XY axis while the build platform moves up and down on the Z. I think that this will help to keep the machine at a decent size without having to create a HUGE box to facilitate a moving (on the XY) build platform.

Control Boards

I would like to use the Arduino Mega 2560 board as the main controller board and the Sanguino v 0.7 as the motor control board.

The thing that I dont know alot about are extruder heads. I was told that the Bowden Extruder would be a good choice as a cheap alternative.

There are a few questions that I have. I am willing to do the research I just need a bit of pointing in the right direction.

Is there a place that sells large enough belts to accommodate 2' of movement for the XY plane? I need to have something that the motors can connect to allow the X and Y movements so that the extruder head will move at the cross points of the X and Y axis.

Are there any suggestions for extruder's or build instructions for an extruder head that are available? The Bowden didn't explain alot about how it was built, though it did explain how it worked.

I will say that I am planning on building the housing for everything out of wood or possibly using box tube depending on how things come together. Also, I do have a friend with a makerbot who is willing to print off parts and I have enough solidworks skills to be able to design parts that can be printed.

Any suggestions or help are hugely welcome.

Thank you,

~Ice

|

Re: Big Printer March 17, 2011 01:10AM |

Registered: 13 years ago Posts: 1,780 |

With a build volume that big, you'll have to include not just a heated build platform (bed) but also a heated chamber in your plan. It's hard enough to prevent warping with parts that are under 200 mm. I would guess that your budget might be too low for this project. You might want to build a small one first to get some hands-on experience.

There was a similar question on this forum just recently.

There was a similar question on this forum just recently.

|

Re: Big Printer March 17, 2011 05:35AM |

Admin Registered: 17 years ago Posts: 1,791 |

I would guess that your budget might be too low for this project.

Likewise. That budget will just about cover a vanilla Mendel. I'd suggest you build the vanilla mendel, and then, once you've got it past hello world, start working on the big machine. The drawback is that you'll have to source new quite a bit of new stuff.

http://reprap.org/wiki/What_Tooling_Do_You_Have?

Ah. Re-reading this:

I will say that I am planning on building the housing for everything out of wood or possibly using box tube depending on how things come together.

Carry on.

Wood will be cheaper than box tube, I imagine. I'd suggest t-slot over box tube, but for a 2'x2'x2' box, the cost may add up.

I am hoping to put together a proposal for a grant to build a plastic printer with a 2'x2'x2' printable area.

We want a machine like that.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

Likewise. That budget will just about cover a vanilla Mendel. I'd suggest you build the vanilla mendel, and then, once you've got it past hello world, start working on the big machine. The drawback is that you'll have to source new quite a bit of new stuff.

http://reprap.org/wiki/What_Tooling_Do_You_Have?

Ah. Re-reading this:

I will say that I am planning on building the housing for everything out of wood or possibly using box tube depending on how things come together.

Carry on.

Wood will be cheaper than box tube, I imagine. I'd suggest t-slot over box tube, but for a 2'x2'x2' box, the cost may add up.

I am hoping to put together a proposal for a grant to build a plastic printer with a 2'x2'x2' printable area.

We want a machine like that.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Big Printer March 17, 2011 07:19AM |

Registered: 13 years ago Posts: 818 |

Hi Iceman,

I have just built up a Bowden extruder and Bowden hot-end, it may hep you understand them a little more, it's not completely tested, but starting to work now - Check out my last two Blog posts here

You could use long belts or threaded rod, or maybe even a long rack and pinion system -

Good luck with the Big printer project, my Repstrap has 42cm x 32cm x 30cm build area. a nice flat and big heated bed will cost quite a bit to get running well, your budget is low for a project like this, but go for it, it's the best way to learn.

Read as many Blogs as you can and the Wiki - LeBigRep is a BIG Machine Concept, many other people want a BIG machine, but it's not going to be easy.

[richrap.blogspot.com]

I have just built up a Bowden extruder and Bowden hot-end, it may hep you understand them a little more, it's not completely tested, but starting to work now - Check out my last two Blog posts here

You could use long belts or threaded rod, or maybe even a long rack and pinion system -

Good luck with the Big printer project, my Repstrap has 42cm x 32cm x 30cm build area. a nice flat and big heated bed will cost quite a bit to get running well, your budget is low for a project like this, but go for it, it's the best way to learn.

Read as many Blogs as you can and the Wiki - LeBigRep is a BIG Machine Concept, many other people want a BIG machine, but it's not going to be easy.

[richrap.blogspot.com]

|

Re: Big Printer March 17, 2011 08:04AM |

Registered: 13 years ago Posts: 1,780 |

@richrap - Nice blog! Good idea on using push-fit connectors. That idea would work well with a Wade extruder to mount multiple extruders on a Mendel.

You might have too much heat loss through the two large washers and threaded bolts holding the PEEK block. You might want to use a smaller washers and bolts. I think Adrian's hot end design uses M3 threaded rods for this reason.

Edited 1 time(s). Last edit at 03/17/2011 08:05AM by brnrd.

You might have too much heat loss through the two large washers and threaded bolts holding the PEEK block. You might want to use a smaller washers and bolts. I think Adrian's hot end design uses M3 threaded rods for this reason.

Edited 1 time(s). Last edit at 03/17/2011 08:05AM by brnrd.

|

Re: Big Printer March 17, 2011 11:28AM |

Registered: 13 years ago Posts: 70 |

@SebastienBailard

Wood will be cheaper than box tube, I imagine. I'd suggest t-slot over box tube, but for a 2'x2'x2' box, the cost may add up.

My college has a large scrap pile of 1"x1" box tube and some other various sizes that I am allowed to pick through. If I go the steel route I was going to sandblast the steel to clean it, then after its all welded up and cleaned I was debating using BBQ Grill spray paint (high heat spray paint, $6 a can) or some Truck Bed Liner Spray (also $6 a can) to help to keep the steel from conducting just incase there is a short or exposed wire. Its not likely but better safe than fried.

As for the heated Chamber, I think that it is doable but my concern would be what temperature the chamber would have to stay constant at. I could use Oven Turkey Bags that are opened up and taped together with ceramic tape as a way to close everything in (or maybe just attached to where the windows would be and around the extruder feed line). They can take high heat and some low temp, shielded NiChrome would be able to provide radiant heat that could build up within the chamber or I could get a few of these Honeycomb Ceramic Blocks or even some refractory cement that is spread into a mould with a steel screen inside of it for support. It would be able to provide a good heated surface but then weight on the servos becomes an issue. The build platform though is prolly a later issue once I have done more research on the platforms themselves. For now I am focused on how the extruder head will function with the build platform and the overall layout.

I will comment more later as this is just a quick update. I am going to toss a picture up of What I am wanting the whole machine to look like once I am able to find a mouse.

Thank you to everyone for their advice and comments! More to come later.

Wood will be cheaper than box tube, I imagine. I'd suggest t-slot over box tube, but for a 2'x2'x2' box, the cost may add up.

My college has a large scrap pile of 1"x1" box tube and some other various sizes that I am allowed to pick through. If I go the steel route I was going to sandblast the steel to clean it, then after its all welded up and cleaned I was debating using BBQ Grill spray paint (high heat spray paint, $6 a can) or some Truck Bed Liner Spray (also $6 a can) to help to keep the steel from conducting just incase there is a short or exposed wire. Its not likely but better safe than fried.

As for the heated Chamber, I think that it is doable but my concern would be what temperature the chamber would have to stay constant at. I could use Oven Turkey Bags that are opened up and taped together with ceramic tape as a way to close everything in (or maybe just attached to where the windows would be and around the extruder feed line). They can take high heat and some low temp, shielded NiChrome would be able to provide radiant heat that could build up within the chamber or I could get a few of these Honeycomb Ceramic Blocks or even some refractory cement that is spread into a mould with a steel screen inside of it for support. It would be able to provide a good heated surface but then weight on the servos becomes an issue. The build platform though is prolly a later issue once I have done more research on the platforms themselves. For now I am focused on how the extruder head will function with the build platform and the overall layout.

I will comment more later as this is just a quick update. I am going to toss a picture up of What I am wanting the whole machine to look like once I am able to find a mouse.

Thank you to everyone for their advice and comments! More to come later.

|

Re: Big Printer March 17, 2011 11:42AM |

Registered: 13 years ago Posts: 485 |

Have a look at nophead's blog for information on a heated build chamber. He has it working at about 50°C.

|

Re: Big Printer March 21, 2011 05:36AM |

Registered: 13 years ago Posts: 818 |

@brnrd - Thanks, I had some problems with the PEEK block bending on my previous hot-end, so the washers should help this and maybe help cool the PEEK.

The PEEK is drilled so only a 2mm ring internally touches the hot-end, hopefully this should limit the heat-loss through the PEEK but still provide mechanical support.

I'll update when it's all running.

Rich.

[richrap.blogspot.com]

The PEEK is drilled so only a 2mm ring internally touches the hot-end, hopefully this should limit the heat-loss through the PEEK but still provide mechanical support.

I'll update when it's all running.

Rich.

[richrap.blogspot.com]

|

Re: Big Printer March 22, 2011 02:53AM |

Registered: 13 years ago Posts: 70 |

Thank you to everyone for commenting and helping.

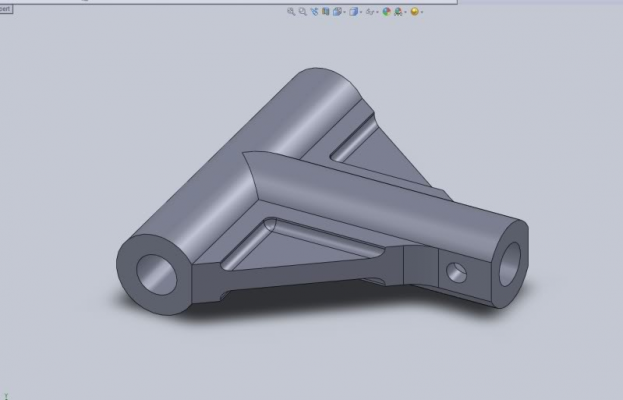

I have been designing and researching over the last few days and here is a piece that I have come up with.

This piece is made for the X and Y movements. The idea being that 4 of these can be printed off, two threaded and two unthreaded, to be used for the printer head movements.

There are 2 parts to this unit. The top of the "T" shape has a hole that runs all the way through it. This would be threaded to allow movement when the threaded rod connected to the motor moves forward and backward.

The second part is at the bottom of the "T" shape. Unthreaded steel rods would be inserted into this part. The two small holes at the tip would have set screws placed in them to help secure the rods in place.

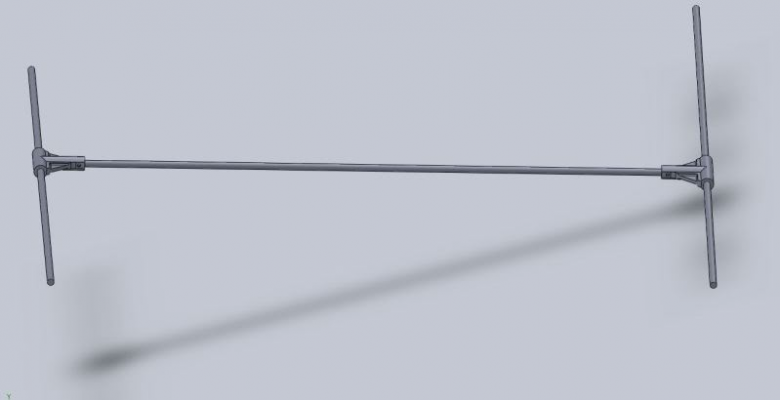

So everything would look somethin' like this.

Any and all thoughts and comments are welcome! More designs and ideas to come later.

I have been designing and researching over the last few days and here is a piece that I have come up with.

This piece is made for the X and Y movements. The idea being that 4 of these can be printed off, two threaded and two unthreaded, to be used for the printer head movements.

There are 2 parts to this unit. The top of the "T" shape has a hole that runs all the way through it. This would be threaded to allow movement when the threaded rod connected to the motor moves forward and backward.

The second part is at the bottom of the "T" shape. Unthreaded steel rods would be inserted into this part. The two small holes at the tip would have set screws placed in them to help secure the rods in place.

So everything would look somethin' like this.

Any and all thoughts and comments are welcome! More designs and ideas to come later.

|

Re: Big Printer March 22, 2011 10:38AM |

Registered: 13 years ago Posts: 581 |

How will you bee keeping the extruder/bed from rotating freely with only one round rod?

Also note, threaded rod will have a lot of backlash when used for an x and y axis. We get away with it for the Z because the dynamic forces are very small compared to gravity, which always makes the same "side" of the threads in contact with the nut.

Also note, threaded rod will have a lot of backlash when used for an x and y axis. We get away with it for the Z because the dynamic forces are very small compared to gravity, which always makes the same "side" of the threads in contact with the nut.

|

Re: Big Printer March 22, 2011 11:01AM |

Registered: 13 years ago Posts: 70 |

@Andrew Diehl

How will you be keeping the extruder/bed from rotating freely with only one round rod?

I only showed set of rods in the assembly above. There will be 2 sets, just like the rods above that cross one another to form an X. Where the rods cross is where the extruder head will be focused to. One set of rods will be slightly higher than the other so that the rods don't rub or cause other problems.

I am trying to make the extruder head as small and light as possible to avoid weight/inertial problems. As for the threaded rods, the length of the sleeve on the T will be threaded to allow for more contact with the threads so that there is less "wiggle room" or extra movement. There could even be a threaded sleeve that could be inserted into the piece in the post above. But if I could find belts large enough then I am not against using them instead of the rods.

How will you be keeping the extruder/bed from rotating freely with only one round rod?

I only showed set of rods in the assembly above. There will be 2 sets, just like the rods above that cross one another to form an X. Where the rods cross is where the extruder head will be focused to. One set of rods will be slightly higher than the other so that the rods don't rub or cause other problems.

I am trying to make the extruder head as small and light as possible to avoid weight/inertial problems. As for the threaded rods, the length of the sleeve on the T will be threaded to allow for more contact with the threads so that there is less "wiggle room" or extra movement. There could even be a threaded sleeve that could be inserted into the piece in the post above. But if I could find belts large enough then I am not against using them instead of the rods.

|

Re: Big Printer March 24, 2011 08:13PM |

Registered: 13 years ago Posts: 31 |

|

Re: Big Printer March 25, 2011 03:04AM |

Registered: 13 years ago Posts: 70 |

Good to know. I did some digging on Amazon for Small Parts Inc. but came up with nothing. I managed to find some Tire Track Teeth belts at McMaster Carr. From what I can figure it will take a belt that is about 640 mm circumference or so to get the right distance. For the life of me I can't seem to be able create a link to the belt that I found. The best that I can do is share a link to the catalog page.

McMaster Carr Timing Belt Page

The part number for the one that I was considering is: 7947K11

I am open to suggestions though for other belts.

**Edit**

I forgot to double the length for the belt to allow for 2 feet of movement. I would need a belt that is around 1440mm. So using the same link as above it would be a belt with the following part number.

7904K117

Edited 1 time(s). Last edit at 03/25/2011 03:16AM by Iceman086.

McMaster Carr Timing Belt Page

The part number for the one that I was considering is: 7947K11

I am open to suggestions though for other belts.

**Edit**

I forgot to double the length for the belt to allow for 2 feet of movement. I would need a belt that is around 1440mm. So using the same link as above it would be a belt with the following part number.

7904K117

Edited 1 time(s). Last edit at 03/25/2011 03:16AM by Iceman086.

|

Re: Big Printer March 25, 2011 03:13AM |

Admin Registered: 17 years ago Posts: 1,791 |

Try sdp-si:

http://www.sdp-si.com/eStore/CoverPg/Drive_Components.htm

Also, don't forget to stuff some docs in the wiki at some point:

http://reprap.org/wiki/IceBot

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

http://www.sdp-si.com/eStore/CoverPg/Drive_Components.htm

Also, don't forget to stuff some docs in the wiki at some point:

http://reprap.org/wiki/IceBot

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Big Printer March 25, 2011 03:23AM |

Registered: 13 years ago Posts: 70 |

Thank you Sebastien. I found a belt that would work for literally 1/3 the price and several other parts! I will toss a list of links up on what I am looking at for parts tomorrow once I have had a better chance at sorting through everything and adjusting my design to use belts instead of rods.

Thank you again!

Thank you again!

|

Re: Big Printer March 27, 2011 05:33PM |

Registered: 13 years ago Posts: 70 |

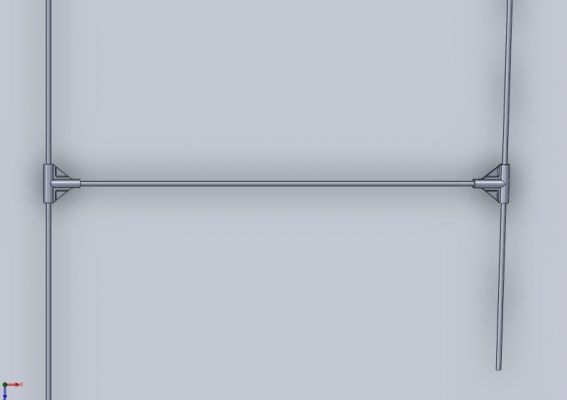

Just a quick little update with some pictures.

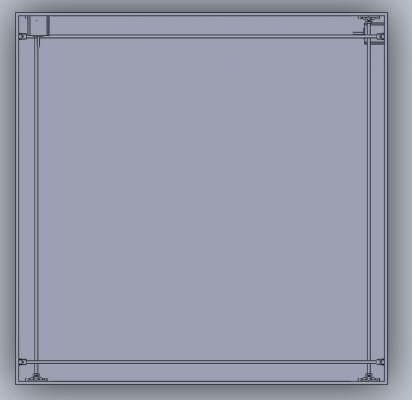

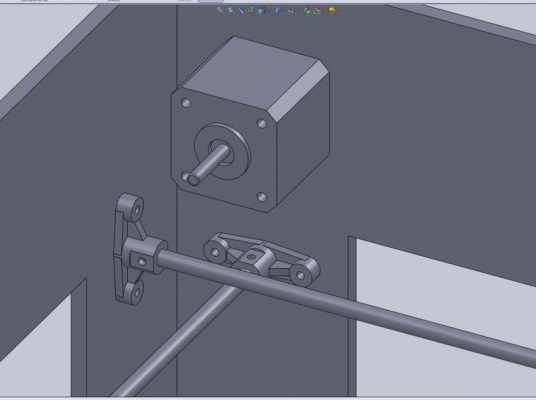

I have been trying to model all of the pieces in SolidWorks (for practice and to see what it will look like ahead of time) and here is where I am at.

Some things I still have to add in and others I still have yet to design. But after finding some belts that will work for the scale of this printer I am adjusting things a bit though the overall design is staying the same. Not everything is in its final place either as I am still learning how to do assemblies in SW.

Top View

Close up for the Nema 17 Motor and the Rod Anchors that I designed.

Thoughts and Ideas are always welcome!

I have been trying to model all of the pieces in SolidWorks (for practice and to see what it will look like ahead of time) and here is where I am at.

Some things I still have to add in and others I still have yet to design. But after finding some belts that will work for the scale of this printer I am adjusting things a bit though the overall design is staying the same. Not everything is in its final place either as I am still learning how to do assemblies in SW.

Top View

Close up for the Nema 17 Motor and the Rod Anchors that I designed.

Thoughts and Ideas are always welcome!

|

Re: Big Printer March 28, 2011 01:06AM |

Admin Registered: 15 years ago Posts: 1,470 |

I don't know how much weight you are going to be pushing around, but you may want to use NEMA 23's. I run 23's on my machine, and though it may be a bit overkill they do run great on the pololu stepper drivers.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Big Printer March 28, 2011 01:24AM |

Registered: 13 years ago Posts: 70 |

I am hoping to keep the extruder light enough to not need more powerful motors on the X Y axis and feed motor. The feed motor will be mounted seperately from the extruder head that will be moving around. The idea being that with a light weight printing head/mount I will be able to get faster prints. The Z axis will need a bit more beef to it so I might consider using a NEMA 23 there.

Until I can actually get ahold of the belts, rods and gears its hard to say (for me anyway) what kind of motor will work well.

Speed is defiantly a big factor as I am looking into printing large objects. How quickly do the NEMA 23's move?

Until I can actually get ahold of the belts, rods and gears its hard to say (for me anyway) what kind of motor will work well.

Speed is defiantly a big factor as I am looking into printing large objects. How quickly do the NEMA 23's move?

|

Re: Big Printer March 28, 2011 01:30AM |

Registered: 13 years ago Posts: 581 |

Just a thought, many of the parts so far are pretty easy to make by hand/powertools out of wood/plastic. It might be a good idea to think about making as much of the machine like that as you can. You said your friend has a makerbot, but relying on others for critical parts can cause severe delays in your progress.

|

Re: Big Printer April 06, 2011 03:59PM |

Registered: 13 years ago Posts: 70 |

***Update***

A few days ago I purchased 4 Nema 23 Motors for about $40 (after shipping) and a 24v Power Supply for $15 (with shipping). So now I have 2 of the 3 things I need to start making stuff move! I have been talking to JoeM about purchasing one of his Sanguinololu 1.0's as well. So hopefully I can start to play with moving motors and things while I begin to put the rest of this beast together.

So far the total spent of the $500 Budget is as follows:

4 - Nema 23 Stepper Motors - $40

1 - 24v Power Supply - $15

--------------------------------------------------

Total Spent: $55

Total Remaining: $435

I am looking at using Masonite for the bulk of the body. While a good plywood can be better, the Masonite can work just as well. Either way I am going to be working on laying out everything within a 4'x8' sheet to see where that leaves budget costs. This will also help me to see if free scrap steel box tube will be the better, more durable option. Or maybe even a combination of the two.

More to come!

A few days ago I purchased 4 Nema 23 Motors for about $40 (after shipping) and a 24v Power Supply for $15 (with shipping). So now I have 2 of the 3 things I need to start making stuff move! I have been talking to JoeM about purchasing one of his Sanguinololu 1.0's as well. So hopefully I can start to play with moving motors and things while I begin to put the rest of this beast together.

So far the total spent of the $500 Budget is as follows:

4 - Nema 23 Stepper Motors - $40

1 - 24v Power Supply - $15

--------------------------------------------------

Total Spent: $55

Total Remaining: $435

I am looking at using Masonite for the bulk of the body. While a good plywood can be better, the Masonite can work just as well. Either way I am going to be working on laying out everything within a 4'x8' sheet to see where that leaves budget costs. This will also help me to see if free scrap steel box tube will be the better, more durable option. Or maybe even a combination of the two.

More to come!

|

Re: Big Printer April 07, 2011 10:13PM |

Registered: 15 years ago Posts: 478 |

I can only asume that Masonite is what we call Hardboard here in the uk.

Hardboard in the uk seems to only come in 3mm thick sheets and seems to be structuraly flimsy Bendy.

Could Masonite also mean MDF?

MDF is avalible in many thickneses 2,3,4,6,9,12mm and is relatively stiff.?

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Hardboard in the uk seems to only come in 3mm thick sheets and seems to be structuraly flimsy Bendy.

Could Masonite also mean MDF?

MDF is avalible in many thickneses 2,3,4,6,9,12mm and is relatively stiff.?

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: Big Printer April 07, 2011 10:40PM |

Registered: 13 years ago Posts: 70 |

Yes, masonite is MDF. It comes in 1/4", 1/2", and 3/4" thickness(about 6, 12 and 19mm respectively).

It is pretty still but I managed to one some good hardwood sheets as well for about $20 US. I think that I should be able to help reinforce the structure with some angle brackets made from L shaped steel channel. As always I am open to suggestions for alternative materials or is something has been known not to work its helpful to know about thw as well.

It is pretty still but I managed to one some good hardwood sheets as well for about $20 US. I think that I should be able to help reinforce the structure with some angle brackets made from L shaped steel channel. As always I am open to suggestions for alternative materials or is something has been known not to work its helpful to know about thw as well.

|

Re: Big Printer April 08, 2011 08:13AM |

Registered: 16 years ago Posts: 169 |

|

Re: Big Printer May 13, 2011 08:25PM |

|

Re: Big Printer May 14, 2011 04:37AM |

Admin Registered: 17 years ago Posts: 7,879 |

Most steppers are rated for 100C. They usually specify the torque at the current that gives 80C rise with two coils on.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

Sorry, only registered users may post in this forum.