Home

>

Reprappers

>

Topic

Heated print bed unable to reach desired temparature

Posted by cheddy

|

Heated print bed unable to reach desired temparature July 29, 2017 10:43AM |

Registered: 6 years ago Posts: 19 |

I have an Flsun i3 Prusa clone from 3DPrinterCreator that has a heated print bed. The bed heating works fine for PLA printing (I run it at 60C for PLA, otherwise the models won't stick to the bed.) My problem comes when trying to print ABS, which requires a much hotter print bed (110-120C.) My printer in incapable of heating the bed much above 93C, at which point the heat is dissipating faster than the heater can supply it and it never gets any hotter. I have tried the trick of putting some insulation on top of the bed while it heats, and that works to get it up to the desired temperature, but as soon as I remove it when the printing starts the bed temperature starts to drop and the print model comes loose.

Are there any simple solutions to this problem? Do I need to get a better print-bed, or will a more powerful PSU give it some more umph? (e.g. a 360W PSU instead of the 240W one that came with the printer.)

I have read on other posts about flickering led lights on the RAMPS controller board (a BT7272A integrated RAMPS 1.4 board) and the implication was that the flickering is due to power consumption exceeding the capacity of the PSU. However, in my case the LED lights always flicker whenever the board is in heat-up mode, either heating the bed or the extruder, so I have always considered that to be normal operation. Am I wrong? Should the LED lights flicker while heating or is my PSU deficient?

P.S. I realize that these Chinese printer kits are cheap knock-offs and a more expensive brand name one would do a better job, but I was hoping that this kit would give me some experience with 3D printing before I shell out big bucks for a better unit. So far PLA printing is going pretty well, and if I can get the ABS printing to work I'll be a happy camper.

Are there any simple solutions to this problem? Do I need to get a better print-bed, or will a more powerful PSU give it some more umph? (e.g. a 360W PSU instead of the 240W one that came with the printer.)

I have read on other posts about flickering led lights on the RAMPS controller board (a BT7272A integrated RAMPS 1.4 board) and the implication was that the flickering is due to power consumption exceeding the capacity of the PSU. However, in my case the LED lights always flicker whenever the board is in heat-up mode, either heating the bed or the extruder, so I have always considered that to be normal operation. Am I wrong? Should the LED lights flicker while heating or is my PSU deficient?

P.S. I realize that these Chinese printer kits are cheap knock-offs and a more expensive brand name one would do a better job, but I was hoping that this kit would give me some experience with 3D printing before I shell out big bucks for a better unit. So far PLA printing is going pretty well, and if I can get the ABS printing to work I'll be a happy camper.

|

Re: Heated print bed unable to reach desired temparature July 29, 2017 10:50AM |

Registered: 10 years ago Posts: 14,672 |

This is a common problem when using PCB bed heaters with ATX power supplies. Measure the voltage across the RAMPS bed heater power input terminals, the bed heater output terminals, and on the bed itself to see where the voltage is being lost. Ideally all three measurements will be very close to 12V.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heated print bed unable to reach desired temparature July 29, 2017 04:35PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Heated print bed unable to reach desired temparature July 30, 2017 05:46AM |

Registered: 9 years ago Posts: 893 |

The silicone-covered cable used in electric RC models is very suitable for this job - it's flexible, the insulation will withstand the elevated temperatures, and its current-carrying capacity is high. It's designed for electric motors that run at tens of Amps, so it's more than capable of supplying the heatbed.

Have you tried putting insulation under the print bed? I have a PCB heater on both of my printers (the aluminium version) and I made a sandwich - PCB on top, 2 layers of thin cork sheet, then another metal plate on the bottom. This, plus a bit of corrugated card on top while heating up, allows it to get up to 100C in a reasonable amount of time. A cold room, or draughts, may prevent it reaching the target temp though. The chances of getting to 110C or 120C are very slim - I'd have to change the heatbed to something more powerful to get to those temps - though 100C is OK for ABS, in my experience.

Have you tried putting insulation under the print bed? I have a PCB heater on both of my printers (the aluminium version) and I made a sandwich - PCB on top, 2 layers of thin cork sheet, then another metal plate on the bottom. This, plus a bit of corrugated card on top while heating up, allows it to get up to 100C in a reasonable amount of time. A cold room, or draughts, may prevent it reaching the target temp though. The chances of getting to 110C or 120C are very slim - I'd have to change the heatbed to something more powerful to get to those temps - though 100C is OK for ABS, in my experience.

|

Re: Heated print bed unable to reach desired temparature July 30, 2017 08:49AM |

Registered: 6 years ago Posts: 1,863 |

Quote

cheddy

P.S. I realize that these Chinese printer kits are cheap knock-offs and a more expensive brand name one would do a better job, but I was hoping that this kit would give me some experience with 3D printing before I shell out big bucks for a better unit. So far PLA printing is going pretty well, and if I can get the ABS printing to work I'll be a happy camper.

I Have 2 Cheap Chinese Aluminum Frame knockoffs, and with proper wiring, new linear bearings additional heat-sinks they print as well as the best of them in a 220x270x190 Print Area.

Be careful the Chinese knockoffs usually have exposed 110/220 power leads that can lead to electrical shock, your first print should be a cover for these exposed wires and terminal leads.

Include a power Switch as pulling the power cord to turn off your 3D Printer is for the Birds.

Edited 5 time(s). Last edit at 07/30/2017 12:10PM by Roberts_Clif.

|

Re: Heated print bed unable to reach desired temparature July 30, 2017 01:42PM |

Registered: 6 years ago Posts: 19 |

|

Re: Heated print bed unable to reach desired temparature August 10, 2017 03:55PM |

Registered: 6 years ago Posts: 1 |

I am needing to reach a temperature of 150C+ for research and am investing in an independent 24V power supply with plenty of amps to run it. I just am wondering if the MK2 heated bed can handle it and how high of a temperature it can reach? Are there other print beds that can reach higher temperatures? If so, which ones? Thanks for the help in advance!

|

Re: Heated print bed unable to reach desired temparature August 10, 2017 05:14PM |

Registered: 10 years ago Posts: 14,672 |

I advise against using any type of PCB heater to reach that temperature. Use a flat aluminum plate (preferably cast aluminium tooling plate) with a silicone heater slightly smaller in size attached to the underside. A power density of 0.5W per sq cm should be plenty. If it's a large bed, consider using an AC mains voltage heater controlled via a SSR instead of a 24V heater.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heated print bed unable to reach desired temparature August 30, 2017 05:18PM |

Registered: 6 years ago Posts: 19 |

Quote

David J

Have you tried putting insulation under the print bed? I have a PCB heater on both of my printers (the aluminium version) and I made a sandwich - PCB on top, 2 layers of thin cork sheet, then another metal plate on the bottom. This, plus a bit of corrugated card on top while heating up, allows it to get up to 100C in a reasonable amount of time. A cold room, or draughts, may prevent it reaching the target temp though. The chances of getting to 110C or 120C are very slim - I'd have to change the heatbed to something more powerful to get to those temps - though 100C is OK for ABS, in my experience.

I have tried your suggestion. I put a double layer of cork (@ 10mm) under the build plate with an aluminum plate under that to hold it in place. I had to get longer corner/leveling screws and I had to switch to #6 imperial screws as metric screws are impossible to source around here and I'm not waiting weeks for mail order to arrive. That meant filing out some of the holes a bit (#6 is 3.3mm). I hate mixing metric and imperial, but what can you do?

Results: the bed heat now maxes out at 107.6C (target temp: 115C). The last 2 or 3 degrees took quite a while. I'll try printing ABS as 100C bed temp and see how it goes.

Thanks for the help.

P.S. In the meantime I've been experimenting with PETG. That is now printing very nicely, once I'd found the 'sweet spot' for bed and extruder temperatures (70C and 260C respectively.)

|

Re: Heated print bed unable to reach desired temparature August 30, 2017 06:32PM |

Registered: 6 years ago Posts: 1,863 |

I have two 3D Printers one has a 250 watt supply the other has a 480watt supply.

One has a 12V the 250watt the other has 24V 280watt both on the Same Style 3D Printer both are equally preforming in prints.

It is hard to tell you that you need a larger power supply, as someone tole me that I needed a larger power supply after purchasing it found that the wire was the problem.

If you measure the voltage as stated earlier by someone in this thread, and his suggestion proves true then purchase a better supply, but don't blindly purchase a supply.

One has a 12V the 250watt the other has 24V 280watt both on the Same Style 3D Printer both are equally preforming in prints.

It is hard to tell you that you need a larger power supply, as someone tole me that I needed a larger power supply after purchasing it found that the wire was the problem.

If you measure the voltage as stated earlier by someone in this thread, and his suggestion proves true then purchase a better supply, but don't blindly purchase a supply.

|

Re: Heated print bed unable to reach desired temparature September 02, 2017 12:01PM |

Registered: 7 years ago Posts: 257 |

|

Re: Heated print bed unable to reach desired temparature September 03, 2017 10:40AM |

Registered: 6 years ago Posts: 19 |

I tried printing ABS with the bed at 100C (105C for first layer) and my test print went fine. The model stayed stuck to the bed and wasn't too difficult to remove after printing (I'm using BuildTak as the bed surface.) That was only a fairly small test model, so I'm not sure if it will work as well with larger models, but so far it looks good.

If it will print OK at those temperatures (extruder at 240C, 245C for first layer) then I'm happy and don't want to go to the bother of swapping PSUs or heat beds.

If it will print OK at those temperatures (extruder at 240C, 245C for first layer) then I'm happy and don't want to go to the bother of swapping PSUs or heat beds.

|

Re: Heated print bed unable to reach desired temparature September 06, 2017 01:41AM |

Registered: 6 years ago Posts: 11 |

I tried ABS for the first time last night on my DIY Prusa I3 clone and with a 240W 12V supply a PCB heater on a 3mm aluminium print bed with 2 10mm thick pieces of cork underneath I couldn't get more than 105 C and that took ages to reach.

In the end I settled on 100C and ABS printed fine, as good as my Davinci 1.0 prints it, I was printing onto buildtak.

In the end I settled on 100C and ABS printed fine, as good as my Davinci 1.0 prints it, I was printing onto buildtak.

|

Re: Heated print bed unable to reach desired temparature September 18, 2017 11:56AM |

Registered: 10 years ago Posts: 477 |

|

Re: Heated print bed unable to reach desired temparature September 18, 2017 12:33PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Heated print bed unable to reach desired temparature September 19, 2017 12:30PM |

Registered: 10 years ago Posts: 477 |

|

Re: Heated print bed unable to reach desired temparature September 19, 2017 09:34PM |

Registered: 6 years ago Posts: 1,863 |

Quote

SteveRoy

ABS print on Buildtak at 65c

I have pictures of my cardboard box enclosure around somewhere.

I found keeping the room temperature constant and the printer enclosed is very important to getting ABS to stick to the bed

I can print PLA on just about anything.

I have A buildtac surface though it take too long to get it adjusted for PLA to stick, believe I have tried every height and temp up to 60C Bed.

When it sticks it really sticks. I Print on a vinyl transfer adhesive paper on top of the Buildtac surface. (similar to Blue Tape only one pass covers the Bed)

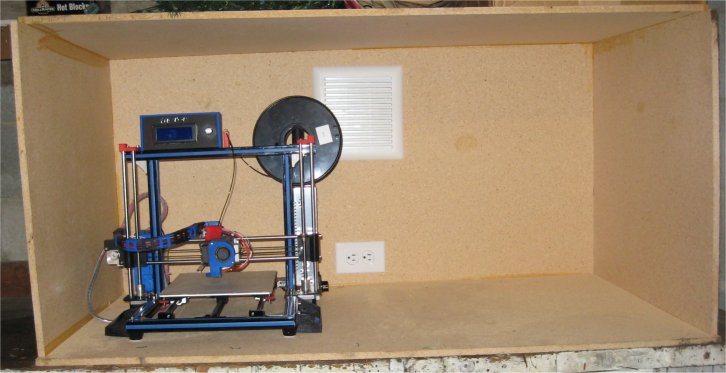

I am building a environmental chamber for the 3D Printers. hoping if I can keep the best conditions for printing the quality will improve.

Was told I could not do any more 3D Printing until I got rid of the odors. Even though the odor in question emanates from an outside source.

Fires in the west an all. So I have decided to build my enclosure with a bathroom fan and a 60mm respirator filter. Printed a holder for the Filter.

Do not get me wrong I print Really well now!!!

Toy Truck printing and Releasable Carpet glue, with Original Bearings.

[youtu.be]

Bathroom fan w/Filter

Two Printer Enclosure

Thinking I want to line the enclosure with something that looks nice? What do you think would work without coming apart, Adhesive floor tiles?.

Edited 4 time(s). Last edit at 09/19/2017 10:03PM by Roberts_Clif.

Sorry, only registered users may post in this forum.