Home

>

Reprappers

>

Topic

Homegrown reprap only prints for a while, then "jams"

Posted by dlc60

|

Homegrown reprap only prints for a while, then "jams" August 08, 2017 12:39PM |

Registered: 7 years ago Posts: 619 |

I have a frustrating problem and my knowledge is incomplete.

A friend gave me a box of parts and a Drop Box list of supplies, mechanical drawings and STL files to make a large bed Cartesian printer. It is assembled and works.

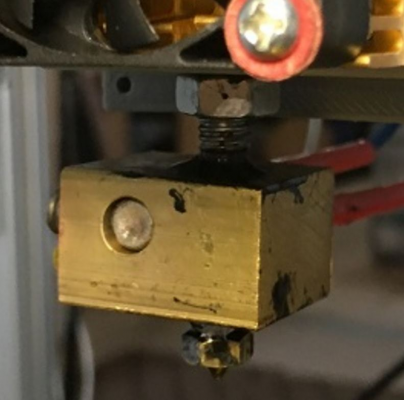

Mostly. The printhead came from a nameless Chinese supplier that called it a "Makerbox Mendel Print head". I have a picture of it attached. It has a massive heater block and a very primitive extruder mechanism that is just a loosely held arm with a small bearing on it that you use an M6 bolt to tighten against the filament. Ick.

Anyway, my problem is thus. It will only extrude (and quite well) for some volume of filament, or perhaps some period of time, before it simply stops extruding and starts stripping the filament against the gear. If I take the nozzle off, the filament pushes out no problem, but re-installing the nozzle will still not allow the material to extrude properly, and again it jams. If I allow it to cool down, it will again work for some period of time and jam.

History:

At first I could not get the heat block up to 200C for PLA work. I replaced the heater cartridge and that problem was solved. Sort of.

Next while tuning the system I started to see the nozzle blowing smoke rings! Yeah, that ain't right! I found that the thermister bead was only half inserted into its hole in the heater block. The insulation on the leads to this thermister were scorched black! I replaced the thermister, properly inserted completely into the cavity it used. But I am pretty sure that the heater exceeded the 240C limit required by standard reprap heat break. But I soldiered on and am now in the place that I am in.

As an experiment, I wanted to make sure that I was really reaching 200C and staying there, so with this massive heater block I put a .8mm nozzle on and quickly extruded a sloppy-fast model. So, yes, I am maintaining heat because you simply cannot do that without a huge volume heat source.

I have never had this kind of trouble with a hot end before, it seems like it isn't hot enough, but it is, and it seems like it jams, but then it isn't jammed in the traditional "can't go forward or back" kind of issue. The "smoke through the nozzle" is a good indicator that it got WAY too hot with the faulty thermister install. The fact that it prints great for a while, and then jams seems to indicate a damaged PTFE insert in the feeder tube.

I have ordered some new extruder tubes on the chance that this will correct a problem caused by a damaged PTFE tube in this one. I'll let you know if that fixes anything.

So, can I ask for the consensus of the illuminated out there? Has anyone else seen this kind of confusing behavior? Did you fix it, and how?

Many thanks,

DLC

A friend gave me a box of parts and a Drop Box list of supplies, mechanical drawings and STL files to make a large bed Cartesian printer. It is assembled and works.

Mostly. The printhead came from a nameless Chinese supplier that called it a "Makerbox Mendel Print head". I have a picture of it attached. It has a massive heater block and a very primitive extruder mechanism that is just a loosely held arm with a small bearing on it that you use an M6 bolt to tighten against the filament. Ick.

Anyway, my problem is thus. It will only extrude (and quite well) for some volume of filament, or perhaps some period of time, before it simply stops extruding and starts stripping the filament against the gear. If I take the nozzle off, the filament pushes out no problem, but re-installing the nozzle will still not allow the material to extrude properly, and again it jams. If I allow it to cool down, it will again work for some period of time and jam.

History:

At first I could not get the heat block up to 200C for PLA work. I replaced the heater cartridge and that problem was solved. Sort of.

Next while tuning the system I started to see the nozzle blowing smoke rings! Yeah, that ain't right! I found that the thermister bead was only half inserted into its hole in the heater block. The insulation on the leads to this thermister were scorched black! I replaced the thermister, properly inserted completely into the cavity it used. But I am pretty sure that the heater exceeded the 240C limit required by standard reprap heat break. But I soldiered on and am now in the place that I am in.

As an experiment, I wanted to make sure that I was really reaching 200C and staying there, so with this massive heater block I put a .8mm nozzle on and quickly extruded a sloppy-fast model. So, yes, I am maintaining heat because you simply cannot do that without a huge volume heat source.

I have never had this kind of trouble with a hot end before, it seems like it isn't hot enough, but it is, and it seems like it jams, but then it isn't jammed in the traditional "can't go forward or back" kind of issue. The "smoke through the nozzle" is a good indicator that it got WAY too hot with the faulty thermister install. The fact that it prints great for a while, and then jams seems to indicate a damaged PTFE insert in the feeder tube.

I have ordered some new extruder tubes on the chance that this will correct a problem caused by a damaged PTFE tube in this one. I'll let you know if that fixes anything.

So, can I ask for the consensus of the illuminated out there? Has anyone else seen this kind of confusing behavior? Did you fix it, and how?

Many thanks,

DLC

|

Re: Homegrown reprap only prints for a while, then "jams" August 08, 2017 01:12PM |

Registered: 6 years ago Posts: 1,863 |

Yes the PTFE can become distorted cause your delima, Have had several filament throat Barrel PTFE liners go bad.

Been told that if you change from PLA to ABA and back to PLA the different materials leaves a residue this causes the filament to get stuck in the Nozzle.

When replacing the throat Barrel make sure the barrel is screwed in far enough so when you screw the nozzle in it rest on the barrel,

as a gap between the two will lead to a similar problem.

Edited 2 time(s). Last edit at 08/08/2017 01:43PM by Roberts_Clif.

Been told that if you change from PLA to ABA and back to PLA the different materials leaves a residue this causes the filament to get stuck in the Nozzle.

When replacing the throat Barrel make sure the barrel is screwed in far enough so when you screw the nozzle in it rest on the barrel,

as a gap between the two will lead to a similar problem.

Edited 2 time(s). Last edit at 08/08/2017 01:43PM by Roberts_Clif.

|

Re: Homegrown reprap only prints for a while, then "jams" August 08, 2017 03:10PM |

Registered: 7 years ago Posts: 619 |

Quote

Roberts_Clif

Yes the PTFE can become distorted cause your delima, Have had several filament throat Barrel PTFE liners go bad.

Been told that if you change from PLA to ABA and back to PLA the different materials leaves a residue this causes the filament to get stuck in the Nozzle.

When replacing the throat Barrel make sure the barrel is screwed in far enough so when you screw the nozzle in it rest on the barrel,

as a gap between the two will lead to a similar problem.

Thanks. I have experienced the PLA<->ABS exchange thing, I crank up the heat to flood the old out, which has worked well, but usually I switch nozzles to avoid it.

This machine has never seen ABS, only PLA, so I am safe there.

I was warned ahead of time about the "gap between heat-break and nozzle" blockage, so I checked that out too - This block is so huge that there is a space in the center that each end butts up against to make that seal certain. But the threads are crappy on the heat block so I use Teflon plumbers tape to try to seal that.

I am crossing my fingers that a new feeder tube will fix my issue!

Regards,

DLC

|

Re: Homegrown reprap only prints for a while, then "jams" August 08, 2017 07:50PM |

Registered: 9 years ago Posts: 978 |

Sounds to me like something is gradually getting hotter: Incidentally the tension on the extruder should be such that the extruder motor skips before it begins stripping the filament.

Some things to look at:

1. Is the fan on your hotend running all the time?

2. Check that 200C according to your thermistor is actually 200C. It may be that you have the wrong thermistor table in your firmware, or some other issue like that.

3. Try lowering your print temperature... I print PLA at 190C. Too high a temperature can cause the heat to creep back up the filament and soften/swell it up inside the cold end.

4. Check to see whether the problem is dependent on time or the amount of filament printed. Try reducing print speed.

5. Look at the temperature graph... it should be stable within a couple of degrees while printing. Check out PID tuning if not.

6. Is your extruder calibrated? If you tell it to deliver 100mm, is it actually delivering that?

7. If your hot end isn't assembled right,molten filament can ooze into corners and jam.

Some things to look at:

1. Is the fan on your hotend running all the time?

2. Check that 200C according to your thermistor is actually 200C. It may be that you have the wrong thermistor table in your firmware, or some other issue like that.

3. Try lowering your print temperature... I print PLA at 190C. Too high a temperature can cause the heat to creep back up the filament and soften/swell it up inside the cold end.

4. Check to see whether the problem is dependent on time or the amount of filament printed. Try reducing print speed.

5. Look at the temperature graph... it should be stable within a couple of degrees while printing. Check out PID tuning if not.

6. Is your extruder calibrated? If you tell it to deliver 100mm, is it actually delivering that?

7. If your hot end isn't assembled right,molten filament can ooze into corners and jam.

|

Re: Homegrown reprap only prints for a while, then "jams" August 09, 2017 04:23AM |

Registered: 11 years ago Posts: 528 |

when you installed the nozzle you raise the the temp to 280C there abouts?

clear that crap of the top, while it cold have it where the heatbreak and the nozzle got about 5 mm from the block then heat up too 280 then wrench the nozzle while holding the heater block " WITH A SPANNER". though it appears the nozzle got an angle to it so the thread may have gone bad!.

I just replace it with a new block they only couple of $ of ali.Quote

dlc

I was warned ahead of time about the "gap between heat-break and nozzle" blockage, so I checked that out too - This block is so huge that there is a space in the center that each end butts up against to make that seal certain. But the threads are crappy on the heat block so I use Teflon plumbers tape to try to seal that.

Edited 1 time(s). Last edit at 08/09/2017 04:28AM by jinx.

|

Re: Homegrown reprap only prints for a while, then "jams" August 09, 2017 10:05AM |

Registered: 10 years ago Posts: 770 |

|

Re: Homegrown reprap only prints for a while, then "jams" August 09, 2017 01:42PM |

Registered: 7 years ago Posts: 619 |

Yes there is a LOT of PLA ooze coming out of the threads! Both the heat break and the nozzle are tight and still it oozes. I am indeed looking at replacing the block. First I will try plumbers tape to fill the gaps. And again, yes the tube seems to be at an angle. But really it is the nut that is threaded poorly.

I will report back with the results of my rebuild.

Thanks,

DLC

I will report back with the results of my rebuild.

Thanks,

DLC

|

Re: Homegrown reprap only prints for a while, then "jams" August 09, 2017 08:13PM |

Registered: 9 years ago Posts: 978 |

As per @Jinx, you need to assemble the hotend while it is hot. I don't think it needs to be at 280C though... I just do it at normal printing temperature.

1. Screw the nozzle all the way in, finger-tight.

2. Back out the nozzle about a half-turn

3. Screw in the heat break, finger tight. It is not strong.

4. Tighten the nozzle against the heater block with a wrench. Inside, this will tighten the top of the nozzle hard against the bottom of the heatbreak.

With practice, you'll be able to do this without burning your fingers

You will probably get lots of practice.

1. Screw the nozzle all the way in, finger-tight.

2. Back out the nozzle about a half-turn

3. Screw in the heat break, finger tight. It is not strong.

4. Tighten the nozzle against the heater block with a wrench. Inside, this will tighten the top of the nozzle hard against the bottom of the heatbreak.

With practice, you'll be able to do this without burning your fingers

You will probably get lots of practice.

|

Re: Homegrown reprap only prints for a while, then "jams" August 10, 2017 10:05AM |

Registered: 7 years ago Posts: 619 |

I have finally beaten this problem, with a little help you folks of course.

Here is what I had to do:

Replace heat break tube

Replace nozzle AND pre-wrap it with Teflon plumbers tape to fill in the heat block's thread gaps.

Replace heater cartridge

Replace Thermister

Adjust exact length of the heat break from the mount block and replace defective nut that held it there.

Adjust flow rate and modify temperature a little.

Now I am getting full and decent prints. I still ooze out of the top of the heat block. Tonight that will get the Teflon tape treatment.

The print I did is a "marvin" calibration test print I modified a little.

Thanks all,

DLC

Here is what I had to do:

Replace heat break tube

Replace nozzle AND pre-wrap it with Teflon plumbers tape to fill in the heat block's thread gaps.

Replace heater cartridge

Replace Thermister

Adjust exact length of the heat break from the mount block and replace defective nut that held it there.

Adjust flow rate and modify temperature a little.

Now I am getting full and decent prints. I still ooze out of the top of the heat block. Tonight that will get the Teflon tape treatment.

The print I did is a "marvin" calibration test print I modified a little.

Thanks all,

DLC

|

Re: Homegrown reprap only prints for a while, then "jams" August 14, 2017 06:53AM |

Registered: 11 years ago Posts: 528 |

the 280C came from the notion, had to tighten up some degrees above what you gonna use the hotend at, so if you at 260 with abs 280 doesnt seem to bad you mind if I ever quote those four steps you explained it so much better than me.Quote

frank

As per @Jinx, you need to assemble the hotend while it is hot. I don't think it needs to be at 280C though... I just do it at normal printing temperature.

congrats Dlc on solving it and happy printing.

|

Re: Homegrown reprap only prints for a while, then "jams" August 14, 2017 06:01PM |

Registered: 7 years ago Posts: 619 |

Quote

jinx

the 280C came from the notion, had to tighten up some degrees above what you gonna use the hotend at, so if you at 260 with abs 280 doesnt seem to bad you mind if I ever quote those four steps you explained it so much better than me.Quote

frank

As per @Jinx, you need to assemble the hotend while it is hot. I don't think it needs to be at 280C though... I just do it at normal printing temperature.

congrats Dlc on solving it and happy printing.

I can't crank it up quite that high anyway since I have a "standard" RepRap end with PTFE tube. I did go higher than I normally print to get all of the "gummyness" out of the system. Now I have to solve the wavy vertical walls, no doubt caused by jerk by going too fast with a Cartesian printer. Or perhaps put it on a more solid table...

Anyway, thanks. I love having this large format printer. Also, unlike my delta, I only needed to level the bed once, a combination of mechanical and Z height tweak.

DLC

|

Re: Homegrown reprap only prints for a while, then "jams" August 15, 2017 04:02AM |

Registered: 9 years ago Posts: 978 |

Quote

jinx

you mind if I ever quote those four steps you explained it so much better than me.

Be my guest! I summarised them from someone else's post somewhere, which helped me hugely at the time. I must have written them dozens of times, and I'm happy for someone else to take over this mission!

Sorry, only registered users may post in this forum.