Home

>

Reprappers

>

Topic

CubeX Trio conversion

Posted by TJM3D

|

CubeX Trio conversion August 21, 2017 11:35PM |

Registered: 6 years ago Posts: 15 |

I've found some conversion information about redoing these things with several different boards but the reports are incomplete as to how multiple steppers are wired for any particular axis. This cubeX has two steppers for the Y travel and I've already come to the conclusion that wiring them in series is the way to go. I have a pretty good idea of how to do this but if there is some schematics/diagrams of how it's been done in the past it'll certainly cut down on the experimental time to get this working. Also, these Y steppers need to travel in opposite directions for the way they are mounted.

Any good, tested wiring suggestions are welcome.

thanks,

tjm

Edited 1 time(s). Last edit at 08/22/2017 12:20AM by TJM3D.

Any good, tested wiring suggestions are welcome.

thanks,

tjm

Edited 1 time(s). Last edit at 08/22/2017 12:20AM by TJM3D.

|

Re: CubeX Trio conversion August 22, 2017 06:54AM |

Registered: 11 years ago Posts: 5,780 |

You might want to have a look through this thread: [forums.reprap.org]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CubeX Trio conversion August 22, 2017 10:55AM |

Registered: 6 years ago Posts: 15 |

Wow! Lot of stuff to browse. I'll get to it eventually as I go through the posts, but did you rewire the Y's serially, and if you did can you point me to the post number for a quick look at how you did it. I have my own idea worked out but I usually find a glitch or two in my designs after viewing other designs.

I'll be using a RUMBA, 8825s and a 24V power supply for mine, all subject to change as I go through your posts. One thing I'll try is to drill and tap the hotends to accept a .4mm nozzle. Rumor has it that it makes a big difference. I'll post my work here as a second source of info and progress, good or bad.

thanks.

I'll be using a RUMBA, 8825s and a 24V power supply for mine, all subject to change as I go through your posts. One thing I'll try is to drill and tap the hotends to accept a .4mm nozzle. Rumor has it that it makes a big difference. I'll post my work here as a second source of info and progress, good or bad.

thanks.

|

Re: CubeX Trio conversion August 22, 2017 01:00PM |

Registered: 11 years ago Posts: 5,780 |

IRIC, I connected them in parallel. I'll take a look at it when I get home.

DRV8825s are not great for 3D printers, but can be made to work better if you add some diodes across the coils. See: www.engineerination.com/2015/02/drv8825-missing-steps.html#!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

DRV8825s are not great for 3D printers, but can be made to work better if you add some diodes across the coils. See: www.engineerination.com/2015/02/drv8825-missing-steps.html#!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CubeX Trio conversion August 22, 2017 07:19PM |

Registered: 6 years ago Posts: 15 |

|

Re: CubeX Trio conversion September 17, 2017 05:36PM |

Registered: 6 years ago Posts: 15 |

Update. The thing actually works.

Details, and pics later, if there is interest.

I tried to use as much of the already routed wiring which worked out nicely. More to do to make it look nice. I constructed a small circuit board with headers to accept the stock connectors from the CubeX board with connections to standard pin headers then link to the RUMBA pin headers with short custom wiring. If I can figure out what the original boards that were mounted on the carriage do, and how they operate, I may be able to do better with the original wiring and functions.

Used the original X and Y min endstops and added X and Y max endstops and min/max endstops for the Z. Switches, but to be replaced with Hall sensors.

This is a RUMBA and DRV8825 drivers in 1/32 mode. The X and Z steppers needed no attention other than a tune for voltage/amp. The dual Y steppers are connected in series to one driver and work perfectly. I did this with another custom circuit board with the 4pin headers wired for serial connectivity so I can use standard motor leads with this board in between the steppers and driver. I notice no skipped steps that were previously mentioned in some other threads. Even so, I added the diode bridge, tried it, no change so removed. I can add them back later if necessary. All of the steppers operate well within the max amp rating of the 8825. And quiet.

Added a 200x200 heated borosilicate glass bed for now and waiting for a 300x300.

Extruders work fine. Of the three J-type (but not exactly) hot ends I broke one seeing how it worked. Two are still good, but removed and replaced with long J-head hot ends machined to fit the hot end bore in each extruder mounting. They're a little shorter than the originals but there's room to make up for that. I like the 12v heaters in the 24v system. The power modulation reduced from 255 to 64 in the Marlin code to give a fast, but not too fast, heating to final temp. I'll do the same with the heated bed. Operating with only one extruder right now as the other hot ends need to be fitted and wired and the build plate dimensions altered to give all three extruders access to a build.

Operating with a minimal number of fans so that's yet to do.

Prints are sized correctly but need some tuning for good looks.

Details, and pics later, if there is interest.

I tried to use as much of the already routed wiring which worked out nicely. More to do to make it look nice. I constructed a small circuit board with headers to accept the stock connectors from the CubeX board with connections to standard pin headers then link to the RUMBA pin headers with short custom wiring. If I can figure out what the original boards that were mounted on the carriage do, and how they operate, I may be able to do better with the original wiring and functions.

Used the original X and Y min endstops and added X and Y max endstops and min/max endstops for the Z. Switches, but to be replaced with Hall sensors.

This is a RUMBA and DRV8825 drivers in 1/32 mode. The X and Z steppers needed no attention other than a tune for voltage/amp. The dual Y steppers are connected in series to one driver and work perfectly. I did this with another custom circuit board with the 4pin headers wired for serial connectivity so I can use standard motor leads with this board in between the steppers and driver. I notice no skipped steps that were previously mentioned in some other threads. Even so, I added the diode bridge, tried it, no change so removed. I can add them back later if necessary. All of the steppers operate well within the max amp rating of the 8825. And quiet.

Added a 200x200 heated borosilicate glass bed for now and waiting for a 300x300.

Extruders work fine. Of the three J-type (but not exactly) hot ends I broke one seeing how it worked. Two are still good, but removed and replaced with long J-head hot ends machined to fit the hot end bore in each extruder mounting. They're a little shorter than the originals but there's room to make up for that. I like the 12v heaters in the 24v system. The power modulation reduced from 255 to 64 in the Marlin code to give a fast, but not too fast, heating to final temp. I'll do the same with the heated bed. Operating with only one extruder right now as the other hot ends need to be fitted and wired and the build plate dimensions altered to give all three extruders access to a build.

Operating with a minimal number of fans so that's yet to do.

Prints are sized correctly but need some tuning for good looks.

|

Re: CubeX Trio conversion September 20, 2017 12:35PM |

Registered: 6 years ago Posts: 15 |

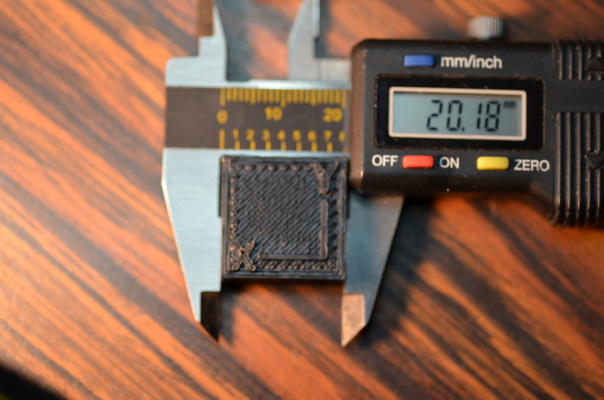

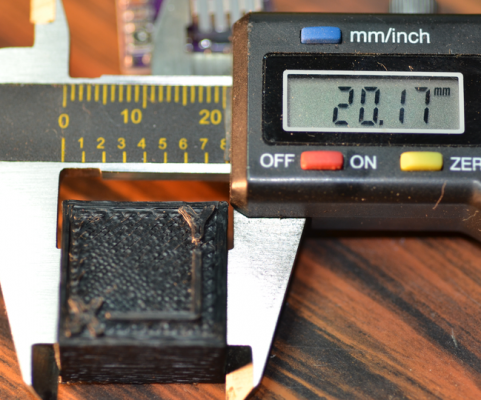

Here are some pics of my second print using one extruder.

It's the 20mm test cube shown from the top and the side. My diagnostics for setting the firmware numbers is lacking so I'd like to get some input about how this looks and what to change to make it better. From the top the print looks a bit rough but better than some others I've seen posted. Looks like it needs more extrusion, but I don't know. From the side you can see a repetitive pattern of layers that are not lined up. I have somel ideas about that but I'd like to know what the experts think. Or, if this is just not that bad for an FDM 3D print. Overall, I think I lucked out in the setup using a lot of the info provided here by 3d printing giants to keep the R&D to a minimum. This is some cheap, black ABS, by the way. I'll also give it a try with some better quality ABS. Thanks.

It's the 20mm test cube shown from the top and the side. My diagnostics for setting the firmware numbers is lacking so I'd like to get some input about how this looks and what to change to make it better. From the top the print looks a bit rough but better than some others I've seen posted. Looks like it needs more extrusion, but I don't know. From the side you can see a repetitive pattern of layers that are not lined up. I have somel ideas about that but I'd like to know what the experts think. Or, if this is just not that bad for an FDM 3D print. Overall, I think I lucked out in the setup using a lot of the info provided here by 3d printing giants to keep the R&D to a minimum. This is some cheap, black ABS, by the way. I'll also give it a try with some better quality ABS. Thanks.

|

Re: CubeX Trio conversion October 09, 2017 12:48PM |

Registered: 6 years ago Posts: 15 |

Doesn't appear to be much interest in these CubeX printers any longer with printer prices dropping significantly.

Anyway, parts for a another mod are on the way for mine. I'm gonna remove the two Y-axis steppers and use one double shaft 23 (same as the Z-stepper in this printer) to drive the Yaxis. Centered and mounted between the left and right sides and shaft driven from each side of the 23 motor to the sprockets. I'll fit a roller bearing at each end near the sprockets for support. This particular 23 is well within the current specs for the 8825 and will eliminate the extra wiring to drive two steppers from the one driver.

Fabricating custom hot ends for length and diameter to match the originals but using regular tips and heaters from standard 6061 1" round. Pics upcoming.

tjm

Anyway, parts for a another mod are on the way for mine. I'm gonna remove the two Y-axis steppers and use one double shaft 23 (same as the Z-stepper in this printer) to drive the Yaxis. Centered and mounted between the left and right sides and shaft driven from each side of the 23 motor to the sprockets. I'll fit a roller bearing at each end near the sprockets for support. This particular 23 is well within the current specs for the 8825 and will eliminate the extra wiring to drive two steppers from the one driver.

Fabricating custom hot ends for length and diameter to match the originals but using regular tips and heaters from standard 6061 1" round. Pics upcoming.

tjm

|

Re: CubeX Trio conversion October 10, 2017 09:06AM |

Registered: 7 years ago Posts: 363 |

|

Re: CubeX Trio conversion October 15, 2017 12:28PM |

Registered: 6 years ago Posts: 15 |

Yup, lots of work, but most of what I hoped to gain was exactly that, learning the 3D machinery, and the thing prints OK, too.

Plus, the local community college has three of these, four counting another personally owned unit, in non-working condition and I'm trying to get a short 3D hardware maintenance class approved specifically to get these machines working again by converting to open source. We'll see.

Plus, the local community college has three of these, four counting another personally owned unit, in non-working condition and I'm trying to get a short 3D hardware maintenance class approved specifically to get these machines working again by converting to open source. We'll see.

|

Re: CubeX Trio conversion October 18, 2017 09:43AM |

Registered: 7 years ago Posts: 363 |

I was in the process of converting mine to CoreXY movement before I sold it. That was a fun challenge. All in all I had less than $250 invested in the printer. Since you've got several of these at your disposal you should look into trying some creative things, especially of the college has a cnc machine you can access.

Edit: Now that I think of it, I still have some linear bearings I ordered from china for my CubeX that I'll probably never use now. If you're interested I can send them to you for cost so they don't go to waste in my garage.

Edited 1 time(s). Last edit at 10/18/2017 09:45AM by obelisk79.

Edit: Now that I think of it, I still have some linear bearings I ordered from china for my CubeX that I'll probably never use now. If you're interested I can send them to you for cost so they don't go to waste in my garage.

Edited 1 time(s). Last edit at 10/18/2017 09:45AM by obelisk79.

|

Re: CubeX Trio conversion August 29, 2018 02:01PM |

Registered: 5 years ago Posts: 4 |

Not to bring back an old post but we are converting one of our high school's CubeX Duo to Reprap and have replaced the PSU to 12v and added a BIQU-Mega2560 and Ramps 1.6. We have tried several times to flash Marlin to the board and it compiles but then... nothing. Any help with the firmware would be appreciated. I can provide more info if needed.

thanks

steve

thanks

steve

|

Re: CubeX Trio conversion November 07, 2018 09:41PM |

Registered: 6 years ago Posts: 15 |

Just happened to check in and found this. I haven't done anything with mine for months but I'm about to restart this project.

Were you able to find the problem with the re-flash? If it compiled I'll make a guess that the communication with the board wasn't right, maybe a USB cable that was too long.

Were you able to find the problem with the re-flash? If it compiled I'll make a guess that the communication with the board wasn't right, maybe a USB cable that was too long.

|

Re: CubeX Trio conversion February 15, 2019 11:34AM |

Registered: 6 years ago Posts: 15 |

Well, I have some time again to fool around with this beast. I have three J-heads machined and installed and still only one working. Physically they all work. Just needed to update the firmware, which I still haven't done. Picked up a Diamond tri-color hot end that looks interesting so very soon I'll remove the custom machined J-heads, heaters, etc and mount the Diamond triple hot end and Bowden extruders and see what happens. In theory it should work nicely with less weight being shoved around on the cart. Marlin mods are available to make it work, maybe, but with the Rumba+, 8825's and a nice, big heated Ultrabase I should be able to get something useable. Pics to come. Honest. Really. Soon.

Edited 1 time(s). Last edit at 02/15/2019 11:35AM by TJM3D.

Edited 1 time(s). Last edit at 02/15/2019 11:35AM by TJM3D.

|

Re: CubeX Trio conversion February 16, 2019 04:33PM |

Registered: 11 years ago Posts: 1,049 |

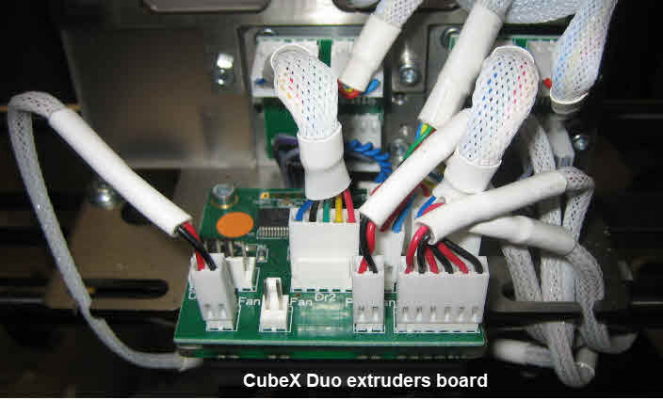

I have a CubeX Duo that I have not upgraded yet.

Did you preserve the extruder PC board above and behind extruders

It appears to have some components on it?

Do these play well with other extruder drivers?

why RUMBA and 24V?

Did you preserve the extruder PC board above and behind extruders

It appears to have some components on it?

Do these play well with other extruder drivers?

why RUMBA and 24V?

|

Re: CubeX Trio conversion February 28, 2019 05:29PM |

Registered: 5 years ago Posts: 1 |

I am in the process of doing a CubeX Duo RepRap Conversion. Using a Rumba Plus board with Octopi and just looking for some help. I have just started the conversion and new to 3d printing but not new to fabrication and electrical.

As for the dual Y-Stepper motors. Does anyone have the best way to wire these? Can you post some pictures of how its wired up.

I was planning on using the stock wires or should I use completely new wires with a larger gauge?

As for the dual Y-Stepper motors. Does anyone have the best way to wire these? Can you post some pictures of how its wired up.

I was planning on using the stock wires or should I use completely new wires with a larger gauge?

|

Re: CubeX Trio conversion March 03, 2019 07:55AM |

Registered: 5 years ago Posts: 6 |

Hi,

I'm in the process of converting a Cubex Duo to Marlin with an MKS Gen L and TMC2208. The way I solved the Y-Axis problem was to buy a second Y Motor driver and use the external output on the MKS Gen L and just have each motor running from their own individual stepper driver. no need to worry about amps/voltage then; just make sure you set the VRef the same.

I'm in the process of converting a Cubex Duo to Marlin with an MKS Gen L and TMC2208. The way I solved the Y-Axis problem was to buy a second Y Motor driver and use the external output on the MKS Gen L and just have each motor running from their own individual stepper driver. no need to worry about amps/voltage then; just make sure you set the VRef the same.

Sorry, only registered users may post in this forum.