Home

>

Reprappers

>

Topic

carriage wheels for 1515 extrusions?

Posted by dlc60

|

carriage wheels for 1515 extrusions? October 06, 2017 01:56PM |

Registered: 7 years ago Posts: 619 |

I am building a "tiny" desktop Kossel Delta using 1515 extrusions. I have done some of my own pieces, but found a project on Thingiverse whose carriages use wheels whose bore is m4. My carriage wheels are m5, so my choices are roll my own carriage for m5 bore wheels or find out where to get nylon rollers like the common Kossel m5 bore wheels, that are m4 bore.

So.

Do such things as nylon wheels with m4 bores? I'd like something like that to keep the parts more "petite" and in character with the very small Kossel I am trying to build.

Thanks,

DLC

So.

Do such things as nylon wheels with m4 bores? I'd like something like that to keep the parts more "petite" and in character with the very small Kossel I am trying to build.

Thanks,

DLC

|

Re: carriage wheels for 1515 extrusions? October 07, 2017 11:56AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: carriage wheels for 1515 extrusions? October 07, 2017 12:12PM |

Registered: 7 years ago Posts: 619 |

Quote

o_lampe

I'd use linear rails like mgn9 instead of the 1515 towers. That way you gain a lot of printarea and the carriers can be much smaller too.

OTOH,you could probably replace the bearings in the wheels to match M4 screws.

Your bearing idea is pretty. Good. The rails are a non-starter however, I am crafting a truly desktop Kossel that is only 30cm tall and rails are spendy, and not all that configurable...

My quick solution was to re-mesh the carriage to use m5 bolts. That didn't take too terribly long, and while the wheels are kind of big at this scale, they are cheap and easy to find.

Thanks!

DLC

|

Re: carriage wheels for 1515 extrusions? October 13, 2017 11:29PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: carriage wheels for 1515 extrusions? October 14, 2017 12:53PM |

Registered: 7 years ago Posts: 619 |

Quote

MechaBits

I have 5x IKO 9mm Linear Guides 275mm long(ish) with dual carriages that I might not get around to using, open to offer.

Thanks for the offer! I think that they would still be too long though, the rails sre 300mm, but I use about 30mm up with the top and bottom corners.

What I did was mod the “door roller” mounts to be m5 instead of m4 and used the standard hardware. Yeah, it makes them a little clunky looking on this petit printer, but this is the prototype anyway. The NEXT one will be cooler looking as I find alternatives. This one will work well enough to get firmware tuned up.

I really need to open a separate Reprapper thread for this project in case anyone really cares...

Thanks,

DLC

|

Re: carriage wheels for 1515 extrusions? October 15, 2017 07:14AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: carriage wheels for 1515 extrusions? October 15, 2017 01:26PM |

Registered: 10 years ago Posts: 14,672 |

Quote

dougal1957

you could check out think3dprint3d they used some mini wheels on 15x15 extrusion on there mini Kossel design they may well have some wheels spare (think they might be M3 though)

V-Wheels

Yes they are M3.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: carriage wheels for 1515 extrusions? October 15, 2017 07:39PM |

Registered: 7 years ago Posts: 619 |

|

Re: carriage wheels for 1515 extrusions? October 23, 2017 12:48AM |

Registered: 7 years ago Posts: 619 |

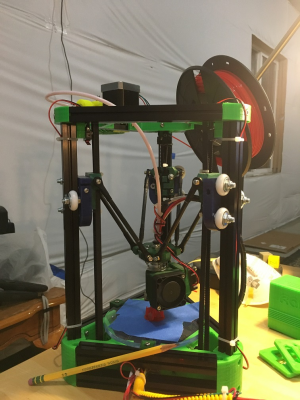

I re-meshed a carriage that used m5 bolts and ran with the big, ugly shower door rollers. They work fine, just a bit big on this design. And I completed the prototype.

My MicroKossel delta uses Makerbeam XL extruded aluminum (1515). The vertical rails are 300mm tall and 150mm for the side rails. I redesigned some Mini Kossel bottom corners to take either NEMA14 or NEMA17 steppers. This proto unit uses NEMA14 to save on power since the whole thing is running on a power brick that is 12V/4.5Amp. There is no heated bed, so it is PLA and PETG only. I am using a Arduino Mega/Ramps 1.4 controller with the Reprap smart graphics controller (with SD card). The extruder is a Thingiverse geared extruder (https://www.thingiverse.com/make:359923), my base parts started out as this Thing (https://www.thingiverse.com/thing:287103), but I modified the end effector, base corners, carriages and bed holders. My bed is a 5" 1/4" thick piece of acrylic and the hotend is a generic reprap modified with an all-metal heat break. I am using clunky mechanical endstops, manually leveled with no auto-leveling being used.

Specs:

Old Marlin firmware (no revision number I could find.)

Speed: 80-100mm/s print

120-140mm moves

.4mm nozzle, typically .2mm layers

print area: 80mm diameter, 45.7mm vertical

The smooth rods are 110mm "hole-to-hole" and are good for up to 100mm diameter, but I doubt that I'll get more than 80. Which is all fine, this design is for a desk top unit that will make game parts and toys. It is just plain cute.

There is a part cooler fan and a WAY too powerful heat break fan.

I have attached a picture of it. The #2 pencil in the picture helps give it scale.

This proto is using PLA corners and PETG carriage, end effector and fan mounts.

The NEXT version will make the fan holders WAY MORE PETITE so I can expand the print area and not run into the belts! I will move the hot end above the end effector as well which will net me at least another 40mm vertical space. The entire thing will be of PETG and will use optical end stop detection. If I can find 240mm linear guides I will use those instead of shower door rollers, if not, well, the rollers work fine.

Thanks for the help and ideas guys!

DLC

Edited 2 time(s). Last edit at 10/23/2017 07:04AM by dlc60.

My MicroKossel delta uses Makerbeam XL extruded aluminum (1515). The vertical rails are 300mm tall and 150mm for the side rails. I redesigned some Mini Kossel bottom corners to take either NEMA14 or NEMA17 steppers. This proto unit uses NEMA14 to save on power since the whole thing is running on a power brick that is 12V/4.5Amp. There is no heated bed, so it is PLA and PETG only. I am using a Arduino Mega/Ramps 1.4 controller with the Reprap smart graphics controller (with SD card). The extruder is a Thingiverse geared extruder (https://www.thingiverse.com/make:359923), my base parts started out as this Thing (https://www.thingiverse.com/thing:287103), but I modified the end effector, base corners, carriages and bed holders. My bed is a 5" 1/4" thick piece of acrylic and the hotend is a generic reprap modified with an all-metal heat break. I am using clunky mechanical endstops, manually leveled with no auto-leveling being used.

Specs:

Old Marlin firmware (no revision number I could find.)

Speed: 80-100mm/s print

120-140mm moves

.4mm nozzle, typically .2mm layers

print area: 80mm diameter, 45.7mm vertical

The smooth rods are 110mm "hole-to-hole" and are good for up to 100mm diameter, but I doubt that I'll get more than 80. Which is all fine, this design is for a desk top unit that will make game parts and toys. It is just plain cute.

There is a part cooler fan and a WAY too powerful heat break fan.

I have attached a picture of it. The #2 pencil in the picture helps give it scale.

This proto is using PLA corners and PETG carriage, end effector and fan mounts.

The NEXT version will make the fan holders WAY MORE PETITE so I can expand the print area and not run into the belts! I will move the hot end above the end effector as well which will net me at least another 40mm vertical space. The entire thing will be of PETG and will use optical end stop detection. If I can find 240mm linear guides I will use those instead of shower door rollers, if not, well, the rollers work fine.

Thanks for the help and ideas guys!

DLC

Edited 2 time(s). Last edit at 10/23/2017 07:04AM by dlc60.

|

Re: carriage wheels for 1515 extrusions? October 23, 2017 03:53AM |

Registered: 8 years ago Posts: 5,232 |

Quote

I am using a Arduino Mega/Ramps 1.4 controller with the Reprap smart graphics controller (with SD card)

I'm glad you made it work, but the graphic LCD on a Delta usually causes stuttering steppers. If you notice any of that, you better choose the 20x4 LCD.

Maybe the Marlin guys have solved this issue, because on Repetier it is known to run smoother. So it's not only a hardware issue.

If you don't find 240mm rails, you can get 300mm and cut them to length.

Edited 1 time(s). Last edit at 10/23/2017 03:57AM by o_lampe.

|

Re: carriage wheels for 1515 extrusions? October 23, 2017 07:03AM |

Registered: 7 years ago Posts: 619 |

Quote

o_lampe

Quote

I am using a Arduino Mega/Ramps 1.4 controller with the Reprap smart graphics controller (with SD card)

I'm glad you made it work, but the graphic LCD on a Delta usually causes stuttering steppers. If you notice any of that, you better choose the 20x4 LCD.

Maybe the Marlin guys have solved this issue, because on Repetier it is known to run smoother. So it's not only a hardware issue.

If you don't find 240mm rails, you can get 300mm and cut them to length.

Those rails will be "no fun" with a hack saw.

But that is a good idea - Rails are stupid expensive regardless, the rollers are cheap, great for a proof of concept.

But that is a good idea - Rails are stupid expensive regardless, the rollers are cheap, great for a proof of concept.I have wondered about that, I have seen a couple pauses, but no actual stuttering. In this proto I am not using the latest Marlin, this code is about 4 years old, but is simple to change. The newest Marlin is much more complex to configure and I chose "old and easy" to get the proto up and running. The next rev. will use the latest. I'll have to find a 4x20 display with an SD card and see what I see. You have me curious.

Thanks,

DLC

|

Re: carriage wheels for 1515 extrusions? October 24, 2017 01:13AM |

Registered: 6 years ago Posts: 70 |

|

Re: carriage wheels for 1515 extrusions? October 25, 2017 07:41PM |

Registered: 7 years ago Posts: 619 |

|

Re: carriage wheels for 1515 extrusions? October 26, 2017 04:14AM |

Registered: 6 years ago Posts: 70 |

I agree with wanting more control, but with such a tiny printer only being able to produce small parts, 100% fan is probably the only way you could go. So, use a large enough fan to get the part cooled quickly, but have enough flow left over to keep the hot end cooled down. And being able to only print small parts, heat creep over a long period won't shouldn't be an issue.

|

Re: carriage wheels for 1515 extrusions? October 26, 2017 11:11AM |

Registered: 7 years ago Posts: 619 |

|

Re: carriage wheels for 1515 extrusions? October 29, 2017 04:39PM |

Registered: 7 years ago Posts: 59 |

If you want it max RepRap, print the carriages and use my delrin bushing design, it works very well compared to V-Wheels or cheaper rails.

MiltyKoss on Thingiverse

I think you just need the carriages and carriage brackets

its cost of prints and one Delrin Acetal rod, which should be around 5-8 USD depending on source and shipping. it's useful for other things as well, camera time lapse motion systems etc.

MiltyKoss on Thingiverse

I think you just need the carriages and carriage brackets

its cost of prints and one Delrin Acetal rod, which should be around 5-8 USD depending on source and shipping. it's useful for other things as well, camera time lapse motion systems etc.

Sorry, only registered users may post in this forum.