Home

>

Reprappers

>

Topic

What to do about persistent cobwebbing?

Posted by dlc60

|

What to do about persistent cobwebbing? May 22, 2018 12:36AM |

Registered: 7 years ago Posts: 619 |

Well, I have a pretty problem. I just installed a E3Dv6 clone on my A8, and it prints like crap. I am using eSun PLA, which has been a great filament for me for a long time.

It has an enormous amount of threading between parts of the model and nothing that I have tried has worked.

I have reduced the temperature until I don't get layer 1 adhesion.

I have increased the retraction amount until the head jammed because it pulled back too far.

I have increased the retraction rate until the stepper skipped.

I have increased the movement speed, to no effect.

I have precision tuned the extraction rate, and then reduced it until I had gaps in the print.

I have increased the part cooling to 100 percent and felt the wind of it blowing.

Using Simplify3D I have introduced "coasing" so that the filament wouldn't be flowing at the end of a loop.

Nothing has any affect whatsoever that I could see.

My bag of tricks is empty and now I am looking for unreasonable things to do to fix this.

Here are some of my crazy ideas.

1) This print head is POS and I should just toss it - But if works fine as long as I have a solid piece with no open spaces.

2) Maybe the nozzle isn't 0.4mm? Would a larger opening than what is expected act like this?

3) Replace the heat gap or the nozzle - Some defect there?

Other?

In the last 15 months that I have been working with 3D printers I have learned a lot, and used it all on this project and am confounded.

Help me Obiwan Kenobi, your my final hope.

Thanks,

DLC

It has an enormous amount of threading between parts of the model and nothing that I have tried has worked.

I have reduced the temperature until I don't get layer 1 adhesion.

I have increased the retraction amount until the head jammed because it pulled back too far.

I have increased the retraction rate until the stepper skipped.

I have increased the movement speed, to no effect.

I have precision tuned the extraction rate, and then reduced it until I had gaps in the print.

I have increased the part cooling to 100 percent and felt the wind of it blowing.

Using Simplify3D I have introduced "coasing" so that the filament wouldn't be flowing at the end of a loop.

Nothing has any affect whatsoever that I could see.

My bag of tricks is empty and now I am looking for unreasonable things to do to fix this.

Here are some of my crazy ideas.

1) This print head is POS and I should just toss it - But if works fine as long as I have a solid piece with no open spaces.

2) Maybe the nozzle isn't 0.4mm? Would a larger opening than what is expected act like this?

3) Replace the heat gap or the nozzle - Some defect there?

Other?

In the last 15 months that I have been working with 3D printers I have learned a lot, and used it all on this project and am confounded.

Help me Obiwan Kenobi, your my final hope.

Thanks,

DLC

|

Re: What to do about persistent cobwebbing? May 22, 2018 08:39AM |

Registered: 6 years ago Posts: 63 |

Have you tried decreasing the extrusion multiplier? If enough pressure is built up in the nozzle coasting will not do much. Are you getting blobs were the filament is retracted?

If you are not getting blobs then I would say your filament is either getting printed too hot or it is possibly wet. Have you tried a different roll of pla? while i like esuns selection, i have had a little bit of inconsistency in quality.

If it is an issue with the hotend, its probably how you assembled it. Stringing can come from an improperly sealed hotend. I use thermal paste on the threads of the parts to make sure it seals well.

If you are not getting blobs then I would say your filament is either getting printed too hot or it is possibly wet. Have you tried a different roll of pla? while i like esuns selection, i have had a little bit of inconsistency in quality.

If it is an issue with the hotend, its probably how you assembled it. Stringing can come from an improperly sealed hotend. I use thermal paste on the threads of the parts to make sure it seals well.

|

Re: What to do about persistent cobwebbing? May 22, 2018 09:23AM |

Registered: 7 years ago Posts: 619 |

Quote

warbunniex

Have you tried decreasing the extrusion multiplier? If enough pressure is built up in the nozzle coasting will not do much. Are you getting blobs were the filament is retracted?

If you are not getting blobs then I would say your filament is either getting printed too hot or it is possibly wet. Have you tried a different roll of pla? while i like esuns selection, i have had a little bit of inconsistency in quality.

If it is an issue with the hotend, its probably how you assembled it. Stringing can come from an improperly sealed hotend. I use thermal paste on the threads of the parts to make sure it seals well.

Yup. Decreased extrusion mult until there were gaps in the print, no effect.

There is no oozing around the heat break or the nozzle, all tight.

Hmm. Wet, I had to move my stuff to the garage to work on the basement, so that is a possibility - My other printer out there did not have this issue though. And I have used this reel with that other printer inside with no issue - but this is Colorado where "high" humidity means in the 20% range.

Hmm,

DLC

|

Re: What to do about persistent cobwebbing? May 23, 2018 04:00AM |

Registered: 7 years ago Posts: 507 |

Does another spool of filament yield these same results on your printer? I would joke about the quality of chinese hotends but my printer runs one as well...

So this is an issue as of installing the new hotend? If so it is worth checking the nozzle bore and whether it is clean or has debris in there. Another thing is they could have sent you an odd sized nozzle like 0.6 or something, they're usually written on the side of the hex so it's worth checking. I imagine a smaller (or partially blocked) nozzle would cause something like this as a thinner but longer string of plastic than intended would be extruded. Another thing is for your heatsink fan, is there good airflow or is there something behind the heatsink blocking it? It could be causing the heatsink to warm up, softening the PLA inside and and making extrusion/retraction less responsive causing this sort of issue. You could also try decreasing print speed, printing fast builds up more pressure in the hotend, which results in more ooze at the end of an extrusion move. What sort of print speeds/temp are you using?

Other than that I'd suggest trying a different roll of plastic maybe, but it doesn't sound like it'll help considering the filament is working fine on another printer.

So this is an issue as of installing the new hotend? If so it is worth checking the nozzle bore and whether it is clean or has debris in there. Another thing is they could have sent you an odd sized nozzle like 0.6 or something, they're usually written on the side of the hex so it's worth checking. I imagine a smaller (or partially blocked) nozzle would cause something like this as a thinner but longer string of plastic than intended would be extruded. Another thing is for your heatsink fan, is there good airflow or is there something behind the heatsink blocking it? It could be causing the heatsink to warm up, softening the PLA inside and and making extrusion/retraction less responsive causing this sort of issue. You could also try decreasing print speed, printing fast builds up more pressure in the hotend, which results in more ooze at the end of an extrusion move. What sort of print speeds/temp are you using?

Other than that I'd suggest trying a different roll of plastic maybe, but it doesn't sound like it'll help considering the filament is working fine on another printer.

|

Re: What to do about persistent cobwebbing? May 23, 2018 02:45PM |

Registered: 7 years ago Posts: 619 |

Quote

Trakyan

Does another spool of filament yield these same results on your printer? I would joke about the quality of chinese hotends but my printer runs one as well...

So this is an issue as of installing the new hotend? If so it is worth checking the nozzle bore and whether it is clean or has debris in there. Another thing is they could have sent you an odd sized nozzle like 0.6 or something, they're usually written on the side of the hex so it's worth checking. I imagine a smaller (or partially blocked) nozzle would cause something like this as a thinner but longer string of plastic than intended would be extruded. Another thing is for your heatsink fan, is there good airflow or is there something behind the heatsink blocking it? It could be causing the heatsink to warm up, softening the PLA inside and and making extrusion/retraction less responsive causing this sort of issue. You could also try decreasing print speed, printing fast builds up more pressure in the hotend, which results in more ooze at the end of an extrusion move. What sort of print speeds/temp are you using?

Other than that I'd suggest trying a different roll of plastic maybe, but it doesn't sound like it'll help considering the filament is working fine on another printer.

Two different spools from two different brands do this.

The heatsink has good airflow and no blockages.

I have used this type of hotend in another printer at about the same speeds (40-60 mm/s) with a similar geared extruder without issue. So I would not have thought that speed would be an issue, but... I have also tried Simplify3D's "coasting" to reduce filament ooze at the end of a loop, but, no dice on those tests as of yet.

I will check out the nozzle hole size. It isn't blocked, I do not see the typical "pigtailing" of thin streams that you usually see with a blockage.

Because I recently moved my printer to garage, I am also going to find a corner in the house to test, it could be that the garage is just more humid and it is geeking the prints.

Thanks all,

DLC

|

Re: What to do about persistent cobwebbing? May 23, 2018 09:34PM |

Registered: 7 years ago Posts: 507 |

I guess the last possibility is you drew the short straw and got a badly machined part? The reason I mentioned the heatsink thing is a lot of mounts have something positioned behind the heatsink, exactly where the air from the cooling fan would be exiting. For me this caused some jamming and oozing/stringing issues but I guess it wasn't the case for you.

Another thing worth checking is the heatbreak itself. There seem to be a couple of versions coming out of china, some thin ones machined to spec and some thicker ones. The other v6 hotend you have might have the thinner heatbreak while this one might have a thicker one which is letting more heat creep up and softening the PLA.

Another thing worth checking is the heatbreak itself. There seem to be a couple of versions coming out of china, some thin ones machined to spec and some thicker ones. The other v6 hotend you have might have the thinner heatbreak while this one might have a thicker one which is letting more heat creep up and softening the PLA.

|

Re: What to do about persistent cobwebbing? May 23, 2018 10:13PM |

Registered: 6 years ago Posts: 109 |

Dumb question. Is it REALLY retracting?

Cause this is the problem I was having, but my bowden extruder is 3d printed and was flexing, so it wasn't really extruding.

E3Dv6 clones prefer small retracts too, like 1.5-2.5mm, so you have to run the temp as low as you can within those bounds to prevent dripping, and jams.

Cause this is the problem I was having, but my bowden extruder is 3d printed and was flexing, so it wasn't really extruding.

E3Dv6 clones prefer small retracts too, like 1.5-2.5mm, so you have to run the temp as low as you can within those bounds to prevent dripping, and jams.

|

Re: What to do about persistent cobwebbing? May 24, 2018 11:58AM |

Registered: 7 years ago Posts: 619 |

Quote

orbitalair

Dumb question. Is it REALLY retracting?

Cause this is the problem I was having, but my bowden extruder is 3d printed and was flexing, so it wasn't really extruding.

E3Dv6 clones prefer small retracts too, like 1.5-2.5mm, so you have to run the temp as low as you can within those bounds to prevent dripping, and jams.

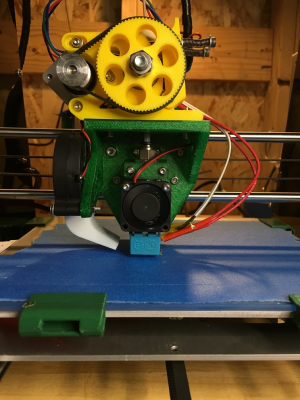

I get that. I have a direct mount system on my Anet A8. Sort of. Since I use a geared extruder, spacing of the whole system means that I have about 2cm longer between the hobbed bolt and the hot end. See picture. Basically it is a direct mount. I have done 2mm to 5mm retracts, with the same results. I am quite sure that it is retracting.

I am moving my printer in from the garage to get better humidity control. I will post after some experiments.

Addendum. Clearly this isn't the Anet A8 default firmware. I have installed Marlin 1.1.8 and used the default configuration files, with the exception of adjusting the min/max values to get the bed offsets correct and changing the extruder steps/mm settings for the geared extruder. I am wondering if I need to "lint" those files to get this printer to do well.

UPDATE

Moving the printer into the house didn't help, or if it did, it was only a little. I am getting a _real_ E3D heatbreak that I will install into my "clone" to see if that helps it out. More on that as data comes in. Fun. It is rare that a new design works out of the gate, so eventually I will find what the real problem is. This is why we "reprap", we love the challenge!

Thanks,

DLC

Edited 2 time(s). Last edit at 05/25/2018 10:52AM by dlc60.

|

Re: What to do about persistent cobwebbing? May 26, 2018 04:56PM |

Registered: 7 years ago Posts: 619 |

Next update.

I replaced the Y carriage bearings with drylin bearings. I could not make both sets align with no binding, so keeping in mind the aphorism "three points define a plane, four points define a potato chip", I left one out and installed the single in the center of that side's run. Works beautifully.

The cobwebbing was reduced to much finer and a little bit fewer, hairs, but not eliminated. My surface finish is much better and I don't get "grumbling" when the bed moves. So that is all good.

I await a new authentic E3Dv6 heat break to rework this thing and see if that helps.

DLC

I replaced the Y carriage bearings with drylin bearings. I could not make both sets align with no binding, so keeping in mind the aphorism "three points define a plane, four points define a potato chip", I left one out and installed the single in the center of that side's run. Works beautifully.

The cobwebbing was reduced to much finer and a little bit fewer, hairs, but not eliminated. My surface finish is much better and I don't get "grumbling" when the bed moves. So that is all good.

I await a new authentic E3Dv6 heat break to rework this thing and see if that helps.

DLC

Sorry, only registered users may post in this forum.