Home

>

Reprappers

>

Topic

Self made Delta duet 3d, dimensional accuracy problem :O

Posted by Rox93

|

Self made Delta duet 3d, dimensional accuracy problem :O March 11, 2019 10:58AM |

Registered: 5 years ago Posts: 13 |

Hi everybody, i made myself this delta 3d printer (check image) but i am having troubles with dimensional accuracy, i have print a lot of xyz calibration cubes with cool results (sometimes 20*20*20 perfect, sometimes +- 0.04) but in some models in particular when i have a extrusion hole in the print it get a lot smaller then it should be, and maybe the perimeter of the print its good in dimension, not perfect but still +-0,2 mm on a 40mm print

and sometimes on bigger models i get a nice accuray, this printer its new so i havent done a lot of them, still in supertesting mood.

actually i did a lot of test and changes but i am not really good with the software since this is my first reprap and first delta ever, electronic its full duet and its pretty new to me, need to get more used. so what i am asking is, is there any test/print test/software test i can do to find where is the error that make this printer going so bad? or anybody got problems like this and know how to overcome it?

Thank you everybody for your help

and sometimes on bigger models i get a nice accuray, this printer its new so i havent done a lot of them, still in supertesting mood.

actually i did a lot of test and changes but i am not really good with the software since this is my first reprap and first delta ever, electronic its full duet and its pretty new to me, need to get more used. so what i am asking is, is there any test/print test/software test i can do to find where is the error that make this printer going so bad? or anybody got problems like this and know how to overcome it?

Thank you everybody for your help

|

Re: Self made Delta duet 3d, dimensional accuracy problem :O March 11, 2019 12:12PM |

Admin Registered: 13 years ago Posts: 6,998 |

holes in 3d prints have to be designed correctly in the cad, or they always turn out to small.

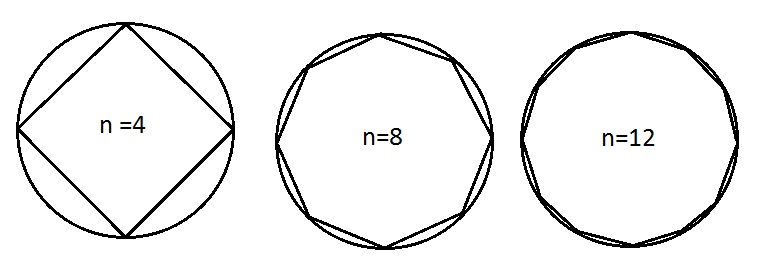

The issue is that a circle is an approximation with a polygon... now if your cad puts the polygon inside the circle (which most do) of the requested diameter, the result is to small.

eg

Edited 2 time(s). Last edit at 03/11/2019 12:18PM by Dust.

The issue is that a circle is an approximation with a polygon... now if your cad puts the polygon inside the circle (which most do) of the requested diameter, the result is to small.

eg

Edited 2 time(s). Last edit at 03/11/2019 12:18PM by Dust.

|

Re: Self made Delta duet 3d, dimensional accuracy problem :O March 11, 2019 12:34PM |

Registered: 9 years ago Posts: 465 |

This seems to be inherent with the .STL file layout, in that it does things as polygons without arcs.

I know that Tinkercad has this problem, which can be resolved by rotating the "cylinder" based on the number of sides, so that the measurement is edge to edge, instead of corner to corner. Tinkercad's default cylinder is a 20 sided polygon, which can be increased to 64 if you want. If you rotate a 20 sided polygon 9° then the corner to corner measurement will become edge-to-edge. You can do similar things in other CAD programs as well.

There is also the fact that your 3D printer does not actually make sharp corners. The nozzle will drag a small amount of material into the inside edges of a corner, or even an arc, which tends to make the inside dimensions a little smaller. It shouldn't amount to much, but if you are making high tolerance parts, it can be significant.

I forget where it is offhand, but there is documentation out there that specifies the minimum number of sides needed to get (reasonably) accurate dimension holes, based on the hole diameter, and I think that it was something like the hole diameter divided by your nozzle diameter, with a minimum of 3 sides, also assuming that your desired radius is edge to edge, and not corner to corner. (I haven't had a problem going to the nearest multiple of 4.)

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

I know that Tinkercad has this problem, which can be resolved by rotating the "cylinder" based on the number of sides, so that the measurement is edge to edge, instead of corner to corner. Tinkercad's default cylinder is a 20 sided polygon, which can be increased to 64 if you want. If you rotate a 20 sided polygon 9° then the corner to corner measurement will become edge-to-edge. You can do similar things in other CAD programs as well.

There is also the fact that your 3D printer does not actually make sharp corners. The nozzle will drag a small amount of material into the inside edges of a corner, or even an arc, which tends to make the inside dimensions a little smaller. It shouldn't amount to much, but if you are making high tolerance parts, it can be significant.

I forget where it is offhand, but there is documentation out there that specifies the minimum number of sides needed to get (reasonably) accurate dimension holes, based on the hole diameter, and I think that it was something like the hole diameter divided by your nozzle diameter, with a minimum of 3 sides, also assuming that your desired radius is edge to edge, and not corner to corner. (I haven't had a problem going to the nearest multiple of 4.)

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: Self made Delta duet 3d, dimensional accuracy problem :O March 14, 2019 07:16AM |

Registered: 5 years ago Posts: 13 |

|

Re: Self made Delta duet 3d, dimensional accuracy problem :O March 25, 2019 01:19PM |

Registered: 5 years ago Posts: 13 |

while i was trying to overcome the problem, now a new one, while i was printing both temp of extruder and bed went at 2000°, console say's:

Error: VSSA fault, check thermistor wiring

this problem happened during a print so i am wondering why, i can understand that the termistor of the head failed, but why the other one too? what could be the cause?

Error: VSSA fault, check thermistor wiring

this problem happened during a print so i am wondering why, i can understand that the termistor of the head failed, but why the other one too? what could be the cause?

|

Re: Self made Delta duet 3d, dimensional accuracy problem :O March 25, 2019 05:47PM |

Registered: 10 years ago Posts: 14,672 |

"VSSA fault" means that you have a short between the thermistor and a heater or fan wire. This is usually caused by two separate issues:

- A short between the thermistor and the hot end metalwork. If you are using a bead thermistor, this is typically due to an uninsulated wire closed to the bead.

- A short between the hot end metalwork and the heating element (or a fan wire). This could be due to careless wiring, or because of an internal short in the heater cartridge, between the heating element and the metal casing (perhaps only when the heater is hot).

If you get a VSSA fault then all thermistors will mis-read even though only there is only a short in the vicinity of one of them. If you fix that one, the other will read correctly again.

Edited 2 time(s). Last edit at 03/25/2019 05:50PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- A short between the thermistor and the hot end metalwork. If you are using a bead thermistor, this is typically due to an uninsulated wire closed to the bead.

- A short between the hot end metalwork and the heating element (or a fan wire). This could be due to careless wiring, or because of an internal short in the heater cartridge, between the heating element and the metal casing (perhaps only when the heater is hot).

If you get a VSSA fault then all thermistors will mis-read even though only there is only a short in the vicinity of one of them. If you fix that one, the other will read correctly again.

Edited 2 time(s). Last edit at 03/25/2019 05:50PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.