Home

>

Reprappers

>

Topic

Smooth Bolts for Idler bearings's (instead of threaded screws)

Posted by Govahnator

|

Smooth Bolts for Idler bearings's (instead of threaded screws) August 14, 2019 09:36AM |

Registered: 9 years ago Posts: 199 |

Hi Guys,

My flanged bearings arrived f608zz and f636zz

[scontent-bru2-1.xx.fbcdn.net]

Now i dont want to use regular bolts, shims and nuts to make it all fit.

Some people use smooth rods with shims, wich aren't ideal either.

The proper way imo is to use pins that have to be pressed into the bearings, i am having a hard time finding the correct name for these. I found them on aliexpress as "shoulder bolts" like these [www.aliexpress.com]

And Clevis pins [www.aliexpress.com]

I am not sure if these can be pressed fit with a hammer or have play and need shims/washers.

What i would prefer to do is print a tool where a bearings clicks in, than hold that piece with the bearing inside and hit the pins through the bearings with a hammer up to the required height.

Basically i am looking for sort of smooth rod that doen't have any play.

Can anyone help me with the correct names or links of what i am looking for? Thanks!

Edited 1 time(s). Last edit at 08/14/2019 09:44AM by Govahnator.

My flanged bearings arrived f608zz and f636zz

[scontent-bru2-1.xx.fbcdn.net]

Now i dont want to use regular bolts, shims and nuts to make it all fit.

Some people use smooth rods with shims, wich aren't ideal either.

The proper way imo is to use pins that have to be pressed into the bearings, i am having a hard time finding the correct name for these. I found them on aliexpress as "shoulder bolts" like these [www.aliexpress.com]

And Clevis pins [www.aliexpress.com]

I am not sure if these can be pressed fit with a hammer or have play and need shims/washers.

What i would prefer to do is print a tool where a bearings clicks in, than hold that piece with the bearing inside and hit the pins through the bearings with a hammer up to the required height.

Basically i am looking for sort of smooth rod that doen't have any play.

Can anyone help me with the correct names or links of what i am looking for? Thanks!

Edited 1 time(s). Last edit at 08/14/2019 09:44AM by Govahnator.

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 14, 2019 10:55AM |

Registered: 12 years ago Posts: 2,470 |

I don’t know the name, but maybe i can offer an alternative. I resolved a similar problem with a printed part that has a hollow split shaft on which the bearing is put. The hole in the shaft was designed to expand when a screw is put in, thus fixing the bearing without any play, while the screw gave the setup the necessary stability.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 14, 2019 11:06AM |

Registered: 11 years ago Posts: 5,780 |

Shoulder screws are made to have bearings mounted on them, clevis pins are not. Also, using a hammer to drive the shaft into a too-tight bearing is a great way to quickly destroy a bearing. Bolts that have unthreaded shanks can be used like shoulder screws, but shoulder screws are made and finished better. There is going to be variation in the hole diameter in the bearings and in whatever rods or shoulder screws you use, so if you're looking for a tight fit you may have to try multiple bearings against multiple shafts/bolts to find good matches.

I wouldn't rely on a tight fit to keep the bearing captive on the shaft. Will it still be tight and captive if the temperature rises a bit?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I wouldn't rely on a tight fit to keep the bearing captive on the shaft. Will it still be tight and captive if the temperature rises a bit?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 15, 2019 03:12AM |

Registered: 9 years ago Posts: 483 |

Actually, shoulder bolts were not designed for bearings although many people use them for this. Most shoulder bolt shoulders are .002" to .004" undersized which makes for a very loose fit in a bearing. McMaster-Carr has precision shoulder bolts which are -.001" to 0" and would be a better choice.

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 15, 2019 12:06PM |

Registered: 9 years ago Posts: 465 |

I've seen a number of CNC plans using 608 bearings mounted on 5/16" shoulder bolts. 5/16" is 7.9375mm, so even at full size, there is a BIT of play for the bearing to sit on the bolt, but not enough to introduce any actual slop, even for fairly precise CNC tolerances, the bearing quality still makes more of a difference. Also, since the bearing is loaded, there isn't any opportunity under normal operation for that slight discrepancy to make any actual difference.

I suppose that an actual press-fit bearing might have advantages though, particularly if you don't want to have any lateral movement of hte bearing without needing to use washers or shims to keep the bearing in place. Such a fit would probably be temperature sensitive, and shouldn't really be trusted anyway, unless the tolerances are SUPER tight, in which case, swapping out hte bearings becomes problematic. Once you need a press to install or remove bearings, your bearings had better be made to withstand those kinds of forces. The inexpensive 608 type bearings that we are using for these kinds of applications are NOT made that way, you'd likely do damage tot he bearing races trying to press them into place.

I suppose that an actual press-fit bearing might have advantages though, particularly if you don't want to have any lateral movement of hte bearing without needing to use washers or shims to keep the bearing in place. Such a fit would probably be temperature sensitive, and shouldn't really be trusted anyway, unless the tolerances are SUPER tight, in which case, swapping out hte bearings becomes problematic. Once you need a press to install or remove bearings, your bearings had better be made to withstand those kinds of forces. The inexpensive 608 type bearings that we are using for these kinds of applications are NOT made that way, you'd likely do damage tot he bearing races trying to press them into place.

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 15, 2019 04:58PM |

Registered: 10 years ago Posts: 651 |

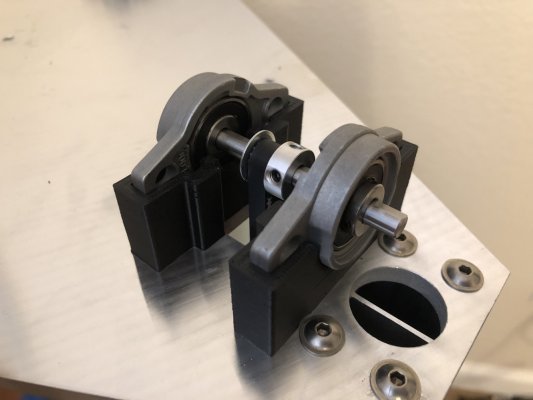

During the design of my printer, I contemplated many of the same things.

Definitely don't use fully threaded bolts. I find that no matter how close the outer diameter of the bolt is to the inner diameter of the bearing that they're still not perfect and there's some play there. Then the bearings chatter on the bolt. Plus you're playing a game of putting a nut or spacer up against the inner hub of the bearings. If you tighten them to remove the chatter then they don't spin. I also saw that the bolts would actually eat into the bearing, creating threads and metal shavings to fall down on other moving parts of my printer.

Something like a smooth rod would be better, the problems I found are is that generally whatever diameter smooth rod doesn't fit into the bearing with the same diameter because of their tolerances. I never thought to try, but you could try finding a smooth rod that just barely doesn't fit your bearings and throw it in the freezer. See if the cold has shrunk it enough to slide the bearing on it. Position it where you want and let it warm back up. That could lock the bearing in place. Though you're kind of stuck if you ever want to change it.

I didn't think about Clevis pins, I could see the same thing happening with the bearings chattering though,

Without having to machine some crazy custom part, The only real solution I found was this:

Basically took the rotational movement away from the pulley. I used mounted bearings with set screws, a d-shaft with a flat and a pulley to fit.

Edited 1 time(s). Last edit at 08/15/2019 04:59PM by blt3dp.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

Instagram

Twitter

Definitely don't use fully threaded bolts. I find that no matter how close the outer diameter of the bolt is to the inner diameter of the bearing that they're still not perfect and there's some play there. Then the bearings chatter on the bolt. Plus you're playing a game of putting a nut or spacer up against the inner hub of the bearings. If you tighten them to remove the chatter then they don't spin. I also saw that the bolts would actually eat into the bearing, creating threads and metal shavings to fall down on other moving parts of my printer.

Something like a smooth rod would be better, the problems I found are is that generally whatever diameter smooth rod doesn't fit into the bearing with the same diameter because of their tolerances. I never thought to try, but you could try finding a smooth rod that just barely doesn't fit your bearings and throw it in the freezer. See if the cold has shrunk it enough to slide the bearing on it. Position it where you want and let it warm back up. That could lock the bearing in place. Though you're kind of stuck if you ever want to change it.

I didn't think about Clevis pins, I could see the same thing happening with the bearings chattering though,

Without having to machine some crazy custom part, The only real solution I found was this:

Basically took the rotational movement away from the pulley. I used mounted bearings with set screws, a d-shaft with a flat and a pulley to fit.

Edited 1 time(s). Last edit at 08/15/2019 04:59PM by blt3dp.

My 3D Printing YouTube Channel

Better Living Through 3D Printing

Follow me on Instagram and Twitter

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 15, 2019 05:57PM |

Registered: 11 years ago Posts: 5,780 |

I had a piece-o-junk from something I took apart years ago with two 1/4" bearings press fit into it. I needed to make an idler pulley for the Y axis in one of my printers and discovered that an off-the-shelf 20 tooth GT2 pulley fit perfectly between the bearings. IRIC, I put two small washers on either side of the pulley to ensure that it could only contact the inner rings of the bearings. I had a 1/4" shaft from some other piece of junk I took apart.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 16, 2019 02:29AM |

Registered: 6 years ago Posts: 1,007 |

With ball bearings, the fixed part doesn't need to be a tight fit only the moving one. In fact it is better if it isn't as it makes assembly/disassembly easier and allows thermal expansion.

Refer to manufacturer doc for details. No need to invent wrong or unnecessary complex mount.

Here for the regular idler found in 3D printer, the bearing is and must be a tight fit in the pulley but not the shaft. Play should be minimal, less than 1/20 to reduce wobbling. Blue Loctite can be used to reduce it without making a tight bond.

Of course threaded rod are not suitable. 4, 5 mm smooth rods are common. Just in case, plenty to be found in old printers, scanners.

On a stepper motor, the bearings are a tight fit on the shaft but not in the body.

Edited 2 time(s). Last edit at 08/16/2019 02:33AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Refer to manufacturer doc for details. No need to invent wrong or unnecessary complex mount.

Here for the regular idler found in 3D printer, the bearing is and must be a tight fit in the pulley but not the shaft. Play should be minimal, less than 1/20 to reduce wobbling. Blue Loctite can be used to reduce it without making a tight bond.

Of course threaded rod are not suitable. 4, 5 mm smooth rods are common. Just in case, plenty to be found in old printers, scanners.

On a stepper motor, the bearings are a tight fit on the shaft but not in the body.

Edited 2 time(s). Last edit at 08/16/2019 02:33AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 16, 2019 11:36AM |

Registered: 8 years ago Posts: 1,671 |

Nice little Bearing Block pity about them screws.Quote

the_digital_dentist

I had a piece-o-junk from something I took apart years ago with two 1/4" bearings press fit into it. I needed to make an idler pulley for the Y axis in one of my printers and discovered that an off-the-shelf 20 tooth GT2 pulley fit perfectly between the bearings. IRIC, I put two small washers on either side of the pulley to ensure that it could only contact the inner rings of the bearings. I had a 1/4" shaft from some other piece of junk I took apart.

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 16, 2019 02:07PM |

Registered: 11 years ago Posts: 5,780 |

Them screws is OK. The conical surface of the screw heads helps center the whole part to keep it aligned.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 17, 2019 12:42AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 17, 2019 02:55AM |

Registered: 6 years ago Posts: 93 |

I was pondering last night about spring pins, using a close fitting clevis or yolk with the same size holes to contain the bearing and pin. They're basically a spring steel tube with tapered ends made to drive into a dowel hole, but hold with outward spring tension instead of adhesives or an interference fit.

Untried, but a thought none the less.

It doesn't take a great deal of force to insert a spring pin, so unlikely to damage the bearing.

Probably not useful for a one sided mount.

Edited 3 time(s). Last edit at 08/17/2019 03:11AM by Diggrr.

Untried, but a thought none the less.

It doesn't take a great deal of force to insert a spring pin, so unlikely to damage the bearing.

Probably not useful for a one sided mount.

Edited 3 time(s). Last edit at 08/17/2019 03:11AM by Diggrr.

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 17, 2019 03:27AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Diggrr

I was pondering last night about spring pins, using a close fitting clevis or yolk with the same size holes to contain the bearing and pin. They're basically a spring steel tube with tapered ends made to drive into a dowel hole, but hold with outward spring tension instead of adhesives or an interference fit.

Untried, but a thought none the less.

It doesn't take a great deal of force to insert a spring pin, so unlikely to damage the bearing.

Probably not useful for a one sided mount.

Why don't you simply read some doc about ball bearing use and assembly ? There are simple rules, don't follow them and for sure get funny problems later that you will spend time figuring out.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 17, 2019 05:42AM |

Registered: 12 years ago Posts: 1,450 |

Spring pins may well work with bearings but the following things may cause problems:-

Mike.

- Spring pins are quite badly formed in terms of circularity and might force the inner race out of circularity causing tight spots.

- Both the bearing and the hole(s) in which the pin mounts should be very close in size as the pin shrinks to fit the smallest one

Mike.

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 17, 2019 04:32PM |

Registered: 11 years ago Posts: 1,049 |

Quote

etfrench

Actually, shoulder bolts were not designed for bearings although many people use them for this. Most shoulder bolt shoulders are .002" to .004" undersized which makes for a very loose fit in a bearing. McMaster-Carr has precision shoulder bolts which are -.001" to 0" and would be a better choice.

What were shoulder bolts designed for?

??

|

Re: Smooth Bolts for Idler bearings's (instead of threaded screws) August 19, 2019 10:58AM |

Registered: 6 years ago Posts: 1,007 |

Quote

cozmicray

Quote

etfrench

Actually, shoulder bolts were not designed for bearings although many people use them for this. Most shoulder bolt shoulders are .002" to .004" undersized which makes for a very loose fit in a bearing. McMaster-Carr has precision shoulder bolts which are -.001" to 0" and would be a better choice.

What were shoulder bolts designed for?

??

Indeed, one of the purpose is for bearing, hinge ....

But the topic of this discussion is to avoid the use of the proper standard readily available "shaft" like smooth rods (OK, you need to cut it to length) with Loctite if and where needed (on the rotating part) or shoulder bolt !

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.