Home

>

Reprappers

>

Topic

Tiny FDM machines

Posted by oliverracing

|

Tiny FDM machines November 26, 2019 02:14PM |

Registered: 4 years ago Posts: 3 |

I've been scheming a tiny FDM machine over the past few weeks and been trying to find any other examples of similar projects.

My aim is to make something around 15*15*15cm (packed size) that can print ABS, nylon, igus i180 etc so it'll need a heated bed and enclosed build chamber. It'll only have a build volume of about 7.5*7.5*6cm but this will work nicely alongside my main large printer to make higher precision parts such as gears etc. (Main printer lives with a 1mm nozzle for large parts made quickly)

I've been searching for similar projects but can't find much alike which is making me think this has probably been tried and failed a few times? Anyone got any experience of how some of the small (but not quite micro) steppers work? This seems to be the biggest difficulty, finding steppers that are powerful enough without being huge.

Gonna use an old partly blown duet WiFi I have sat in the drawer so won't have a big screen, maybe just a little one showing temps and IP address, only concern is whether the drivers can do a low enough current! (100ma steps)

My aim is to make something around 15*15*15cm (packed size) that can print ABS, nylon, igus i180 etc so it'll need a heated bed and enclosed build chamber. It'll only have a build volume of about 7.5*7.5*6cm but this will work nicely alongside my main large printer to make higher precision parts such as gears etc. (Main printer lives with a 1mm nozzle for large parts made quickly)

I've been searching for similar projects but can't find much alike which is making me think this has probably been tried and failed a few times? Anyone got any experience of how some of the small (but not quite micro) steppers work? This seems to be the biggest difficulty, finding steppers that are powerful enough without being huge.

Gonna use an old partly blown duet WiFi I have sat in the drawer so won't have a big screen, maybe just a little one showing temps and IP address, only concern is whether the drivers can do a low enough current! (100ma steps)

|

Re: Tiny FDM machines November 27, 2019 03:18AM |

Registered: 5 years ago Posts: 9 |

Have a look at the DICE (20cm on all sides, corexy). It's a nice little machine, but i am probably a bit biased as i own one ;-)

[well-engineered.net]

“The problem in this business isn’t to keep people from stealing your ideas; it's making them steal your ideas!” - Howard Aiken

Blog: [sam42lab.blogspot.com]

[well-engineered.net]

“The problem in this business isn’t to keep people from stealing your ideas; it's making them steal your ideas!” - Howard Aiken

Blog: [sam42lab.blogspot.com]

|

Re: Tiny FDM machines November 27, 2019 07:00AM |

Admin Registered: 16 years ago Posts: 13,886 |

... my "smallest FDM" was a project with laser-melting wires with diameters at and below 0,1mm -- the thinnest were platinum wires with 10 microns diameter.

The overall moving range with PZT-nano-motors (Piezolegs) was 23mm in X/Y/Z with "step-accuracy" of 150 nanometers (or sub-nanometers in "clamped" bending mode).

This was for a R&D-project for micro-assembling and with heavy NDA's, so no images or videos from that setup ... but have maybe 6-8 of this "nano-motors" left for my own use - so will build something similar for my own projects, when in need (and time at hand)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The overall moving range with PZT-nano-motors (Piezolegs) was 23mm in X/Y/Z with "step-accuracy" of 150 nanometers (or sub-nanometers in "clamped" bending mode).

This was for a R&D-project for micro-assembling and with heavy NDA's, so no images or videos from that setup ... but have maybe 6-8 of this "nano-motors" left for my own use - so will build something similar for my own projects, when in need (and time at hand)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Tiny FDM machines November 27, 2019 07:58AM |

Registered: 4 years ago Posts: 3 |

|

Re: Tiny FDM machines November 27, 2019 08:30AM |

Registered: 5 years ago Posts: 9 |

I do recommend looking at the DICE though for inspiration if nothing else,Its well made and there are some interesting design choices/trade-offs in that machine for your own build and it is scalable.

Another small build i am aware of is the createbot super mini. certainly worth looking at for inspiration as it has some rather different design choices to the DICE, but is roughly the same size. Alternatively its also feasible to scale-down most other printer designs (like the I3) depending on what features you are looking for?

“The problem in this business isn’t to keep people from stealing your ideas; it's making them steal your ideas!” - Howard Aiken

Blog: [sam42lab.blogspot.com]

Another small build i am aware of is the createbot super mini. certainly worth looking at for inspiration as it has some rather different design choices to the DICE, but is roughly the same size. Alternatively its also feasible to scale-down most other printer designs (like the I3) depending on what features you are looking for?

“The problem in this business isn’t to keep people from stealing your ideas; it's making them steal your ideas!” - Howard Aiken

Blog: [sam42lab.blogspot.com]

|

Re: Tiny FDM machines November 27, 2019 09:07AM |

Registered: 12 years ago Posts: 2,470 |

A realy nice and small printer is the Tiny from Protoworx [www.protoworx.de]

It does not come with a housing, but that is rather easy to add.

The print results are among the best i have ever seen from a FDM machine.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

It does not come with a housing, but that is rather easy to add.

The print results are among the best i have ever seen from a FDM machine.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Tiny FDM machines November 27, 2019 09:39AM |

Registered: 4 years ago Posts: 3 |

Oooh, those really are lovely bits of kit but considering I will be printing 90% of the chassis, designs like these are likely I bit out of my league (at least to start with).

Definitely will use some of the design elements as inspiration, going back to the drawing board as think what I've got will be way too flexible at the moment.

Edited 2 time(s). Last edit at 11/27/2019 11:16AM by oliverracing.

Definitely will use some of the design elements as inspiration, going back to the drawing board as think what I've got will be way too flexible at the moment.

Edited 2 time(s). Last edit at 11/27/2019 11:16AM by oliverracing.

|

Re: Tiny FDM machines November 27, 2019 11:07AM |

Registered: 7 years ago Posts: 619 |

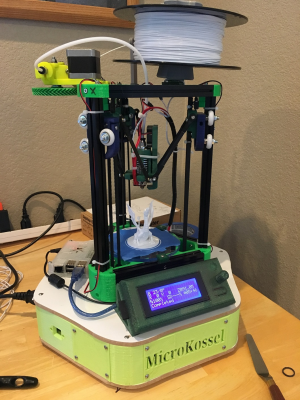

My smallest may be too big for what you are looking for. My "MicroKossel" project has a build volume of 60mmx60mmx90mm and uses NEMA 14 steppers. It would be a bout 20cm on a side and about 30cm tall made from Maker Beam XL (15x15) T-slot. I mounted it on a hexagonal box to hold the controller, wires and power supply. My design spec required it to print PLA and PETG for tabletop gaming miniatures.

This is the first prototype, the final build has a little more polish.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

This is the first prototype, the final build has a little more polish.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

|

Re: Tiny FDM machines November 27, 2019 01:47PM |

Admin Registered: 16 years ago Posts: 13,886 |

... remembers me on my "Mini-tripod" from 2007 with roughly 50x50x60mm building area -- but the builders blog is longe gone and all the posts and images too

Could be, I'll find some images somewhere in my old archives ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Could be, I'll find some images somewhere in my old archives ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Tiny FDM machines November 27, 2019 01:55PM |

Admin Registered: 16 years ago Posts: 13,886 |

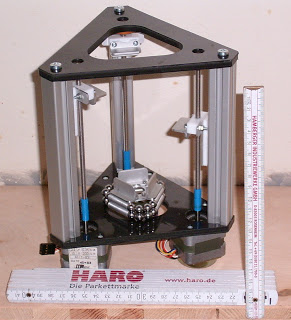

... ahh -- remembered the "waybackmachine" and even found the blog!! (only the video wasn't stored):

[web.archive.org]

Here an image of the assembled setup and the size with a measure:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[web.archive.org]

Here an image of the assembled setup and the size with a measure:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Tiny FDM machines November 28, 2019 03:18AM |

Admin Registered: 11 years ago Posts: 3,096 |

Love those tiny delta's but I believe a Delta has a rather inefficient machine size/bed size ratio.

Cartesian machines have a smaller form factor while still retaining a rather big bed size. A CoreXY with motors placed in unorthodox places might give the best results since you can make the frame collapsible easily since most of the rlectronics are placed around the top.

http://www.marinusdebeer.nl/

Cartesian machines have a smaller form factor while still retaining a rather big bed size. A CoreXY with motors placed in unorthodox places might give the best results since you can make the frame collapsible easily since most of the rlectronics are placed around the top.

http://www.marinusdebeer.nl/

|

Re: Tiny FDM machines November 28, 2019 03:52AM |

Admin Registered: 16 years ago Posts: 13,886 |

... could be, the smallest form-factor would be achieved with a "magnetic guided string-delta", clinged to the ceiling, with "hanging" bed -- here some of the old ideas for this:

[reprap.org]

[reprap.org]

Actually there are some more recent threads in the hang-printer forum - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[reprap.org]

[reprap.org]

Actually there are some more recent threads in the hang-printer forum - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Tiny FDM machines November 28, 2019 03:44PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Ohmarinus

Love those tiny delta's but I believe a Delta has a rather inefficient machine size/bed size ratio.

On the contrary, deltas have a more efficient bed area to desk space desk space ratio than typical Cartesian and CoreXY printers, as long as you don't mind the additional height and the usually round print area. I think that CoreXY printers and Cartesian printers with the bed or gantry moving in Z could in theory been quite space efficient, but in practice they tend not to be.

Edited 1 time(s). Last edit at 11/28/2019 04:26PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tiny FDM machines November 28, 2019 04:07PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

dc42

Quote

Ohmarinus

Love those tiny delta's but I believe a Delta has a rather inefficient machine size/bed size ratio.

On the contrary, deltas have a more efficient bed area to desk space desk space ratio than Cartesian and CoreXY printers, as long as you don't mind the additional height and the usually round print area.

Of course, this is also true. But I was talking specifically about the relation between bed size and footprint. My Delta has a footprint of 300x300x300 and a max printable size diameter of 140/150mm. Deltas also tend to get less precise towards the edges and the print volume has a cone shape on the top. I do not believe I can enlarge the print surface without having to add space between the towers? So in that sense..

I would expect CoreXY/Hbot to be the most flexible solution for smallest bot with largest print surface because you can apply many nifty tricks to maximize the use of space and the motors can be moved around by smart belt management. And you can print the full square volume with these machines in all dimensions with no loss of resolution on any place of the bed.

http://www.marinusdebeer.nl/

|

Re: Tiny FDM machines November 28, 2019 04:46PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Ohmarinus

I would expect CoreXY/Hbot to be the most flexible solution for smallest bot with largest print surface because you can apply many nifty tricks to maximize the use of space and the motors can be moved around by smart belt management. And you can print the full square volume with these machines in all dimensions with no loss of resolution on any place of the bed.

At first sight you would think that; but the CoreXY printers I have seen generally have substantially larger footprints that printable areas. Just like deltas, the smaller a CoreXY printer is, the lower the ratio of printable area to desk space

My delta takes up a triangle of side 470mm on the desk, and has a printable area 300mm diameter. So the space overhead is about 170mm each way, just a little higher than yours. As for resolution, the XY resolution of a delta is way more than I need, especially with 0.9deg motors. It's only the Z resolution that is significantly worse. I have 2 Cartesian, 1 Delta, 1 CoreXY and one SCARA printer; and I do almost all my prints on the delta because it is fast and reliable.

Where a large rectangular print surface is needed, I agree that CoreXY is the way to go.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Tiny FDM machines November 28, 2019 05:18PM |

Admin Registered: 16 years ago Posts: 13,886 |

... if you're looking for the smallest footprint vs. build size, then a parallel SCARA (more overall precision than a common serial one) could be interesting too ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Tiny FDM machines December 02, 2019 01:32AM |

Registered: 6 years ago Posts: 93 |

I'm designing a mini right now, with a 150x150mm Keenovo 500 watt 120 volt heater.

To get the drive-line on the same plane as the rails, I'm having to make it a 300mm cube (not a fan of off center drive like railcore etc. use).

For now it's a collection of parts and plans.. budget ripples are slowing me.

To get the drive-line on the same plane as the rails, I'm having to make it a 300mm cube (not a fan of off center drive like railcore etc. use).

For now it's a collection of parts and plans.. budget ripples are slowing me.

Sorry, only registered users may post in this forum.