Home

>

Reprappers

>

Topic

Cable Management

Posted by FMeerkat

|

Cable Management December 21, 2019 04:03AM |

Registered: 4 years ago Posts: 1 |

|

Re: Cable Management December 21, 2019 04:12AM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Cable Management December 21, 2019 04:20AM |

Registered: 10 years ago Posts: 14,672 |

I use all of the following:

- Zip ties - great where they won't be seen, a bit ugly if they will be on the exposed parts

- Braided polyester sleeving, with heatshrink sleeving on the ends to prevent it fraying

- Spiral wrap (see photo below)

- Printed cable holders attached to extrusions, sometimes in conjunction with braided polyester sleeving (see photo below)

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

- Zip ties - great where they won't be seen, a bit ugly if they will be on the exposed parts

- Braided polyester sleeving, with heatshrink sleeving on the ends to prevent it fraying

- Spiral wrap (see photo below)

- Printed cable holders attached to extrusions, sometimes in conjunction with braided polyester sleeving (see photo below)

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cable Management December 21, 2019 04:57AM |

Admin Registered: 11 years ago Posts: 3,096 |

I'm surprised the magnets don't come loose with such thick cables on that Delta. I must be using really low quality magnets and balls.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: Cable Management December 21, 2019 07:57AM |

Registered: 11 years ago Posts: 5,780 |

Electrical tape will leave sticky residue all over the cables. Over time the sticky stuff will ooze out of the cable and the whole thing will become a sticky mess.

Twist pairs, such as motor coil wires, heater wires, fan wires, and thermistor wires, and wires to LEDs, etc. That will help prevent crosstalk between higher current carrying pairs and high Rin pairs like thermistor leads. I use a printed tool on my electric drill to do the twisting.

Now you have a bunch of twisted pairs- what do you do with those? I often braid them to keep all the wires under control. You can braid any number of wires >2. It isn't very convenient if you have to service the cable, but it's free, and it's lightweight. Braided cable weave is OK too, but it can be a PITA to fit over multiple wires, and to finish the ends. The split cable jacketing is pretty good because you can install and remove it without disconnecting the cables you're covering with it. Drag chain can be used to guide cables to moving parts of the machine, but be careful not to use too small a radius of curvature or the wires may fail from being flexed too much.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Twist pairs, such as motor coil wires, heater wires, fan wires, and thermistor wires, and wires to LEDs, etc. That will help prevent crosstalk between higher current carrying pairs and high Rin pairs like thermistor leads. I use a printed tool on my electric drill to do the twisting.

Now you have a bunch of twisted pairs- what do you do with those? I often braid them to keep all the wires under control. You can braid any number of wires >2. It isn't very convenient if you have to service the cable, but it's free, and it's lightweight. Braided cable weave is OK too, but it can be a PITA to fit over multiple wires, and to finish the ends. The split cable jacketing is pretty good because you can install and remove it without disconnecting the cables you're covering with it. Drag chain can be used to guide cables to moving parts of the machine, but be careful not to use too small a radius of curvature or the wires may fail from being flexed too much.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Cable Management December 21, 2019 01:53PM |

Registered: 12 years ago Posts: 1,450 |

I also braid my wires as DD mentions above. Putting a superelastic wire (0.5mm Nitinol) down the middle of the bunch makes for a good flexible link and can replace a lightweight cable chain.

Braided cable above includes 4 wires to extruder motor, 4 for 24V heater element, 2 for thermistor and 2 for fan - all in thin wall 7/0.1mm PVC hookup wire.

Also worth noting is that the good ventilation of a braided cable allows thinner wires for any given current handling capacity.

Mike

Braided cable above includes 4 wires to extruder motor, 4 for 24V heater element, 2 for thermistor and 2 for fan - all in thin wall 7/0.1mm PVC hookup wire.

Also worth noting is that the good ventilation of a braided cable allows thinner wires for any given current handling capacity.

Mike

|

Re: Cable Management December 22, 2019 03:16AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Ohmarinus

I'm surprised the magnets don't come loose with such thick cables on that Delta. I must be using really low quality magnets and balls.

They are magnets and rods from Haydn Huntley. They have never disconnected during a print. I have tested the machine with a 1.5kg water bottle slung beneath the effector.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Cable Management December 22, 2019 03:51AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

dc42

Quote

Ohmarinus

I'm surprised the magnets don't come loose with such thick cables on that Delta. I must be using really low quality magnets and balls.

They are magnets and rods from Haydn Huntley. They have never disconnected during a print. I have tested the machine with a 1.5kg water bottle slung beneath the effector.

Thanks for sharing, I had seen it before but didn't realize this was so strong. Just converted back to balljoints, but if I'm ever going to upscale the machine I'll be sure to get those and the effector.

http://www.marinusdebeer.nl/

|

Re: Cable Management December 24, 2019 03:48AM |

Registered: 14 years ago Posts: 128 |

As already said, PVC Electrical tape is not good as it goes sticky and generally comes off after a while.

However I found Tesa adhesive cloth fabric for wiring loom is good.

The coroplast type I have found better than the non coroplast.

The coroplast I have had has a furry soft surface and appears to stick better.

It's listed on Ebay. - it comes in different widths and lengths, I have only used 19mm x 15m. You can always cut down for smaller jobs...

Some car makers use it on there wiring harnesses.

It can be easy to unwrap when first applied, but I have found that after a while it can very hard to unwrap and you may have to cut it off should you wish to remove it.

I have had some on a car trailer light cable that's been outside for several years and it has lasted well. PVC Electrical tape would have fallen off long ago .

Cheers Bruce

However I found Tesa adhesive cloth fabric for wiring loom is good.

The coroplast type I have found better than the non coroplast.

The coroplast I have had has a furry soft surface and appears to stick better.

It's listed on Ebay. - it comes in different widths and lengths, I have only used 19mm x 15m. You can always cut down for smaller jobs...

Some car makers use it on there wiring harnesses.

It can be easy to unwrap when first applied, but I have found that after a while it can very hard to unwrap and you may have to cut it off should you wish to remove it.

I have had some on a car trailer light cable that's been outside for several years and it has lasted well. PVC Electrical tape would have fallen off long ago .

Cheers Bruce

|

Re: Cable Management December 24, 2019 07:10AM |

Registered: 11 years ago Posts: 5,780 |

I use a lot of velcro tape to manage cables, too. Just cut it to the length needed to wrap around the wire bundle, and use as many pieces as necessary to control the cable. Release and reclose one loop at a time so the whole cable remains controlled even as you add or remove wires.

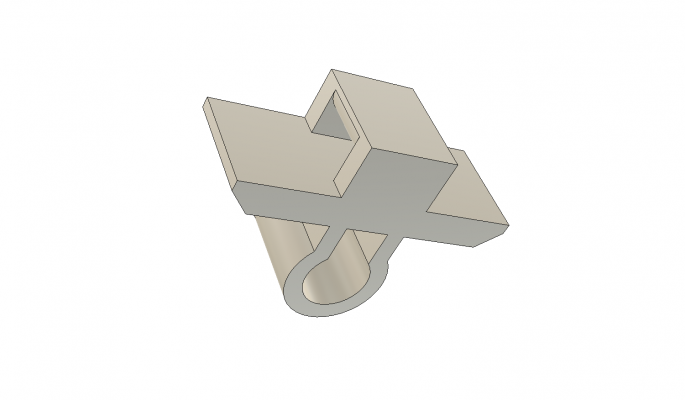

I have printed small pound-in plastic pieces that fit into t-slot and have loops for zip-ties. This is good for cables that are too big to fit inside the t-slot, or to hold other parts securely.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I have printed small pound-in plastic pieces that fit into t-slot and have loops for zip-ties. This is good for cables that are too big to fit inside the t-slot, or to hold other parts securely.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Cable Management December 24, 2019 09:57AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

the_digital_dentist

I have printed small pound-in plastic pieces that fit into t-slot and have loops for zip-ties. This is good for cables that are too big to fit inside the t-slot, or to hold other parts securely.

[attachment 113756 frameclipziptiev4.png]

I'm a great fan of these cable clips for 2020 extrusions:

[www.thingiverse.com]

Edited 1 time(s). Last edit at 12/24/2019 09:58AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Cable Management December 28, 2019 02:42PM |

Registered: 9 years ago Posts: 893 |

This was my solution to one cable problem: Thingiverse

(nothing like a bit of self-publicity to make the day go by!)

(nothing like a bit of self-publicity to make the day go by!)

Sorry, only registered users may post in this forum.