Home

>

Reprappers

>

Topic

Belt Z axis part 2: the struggle continues

Posted by Govahnator

|

Belt Z axis part 2: the struggle continues July 06, 2020 05:44PM |

Registered: 9 years ago Posts: 199 |

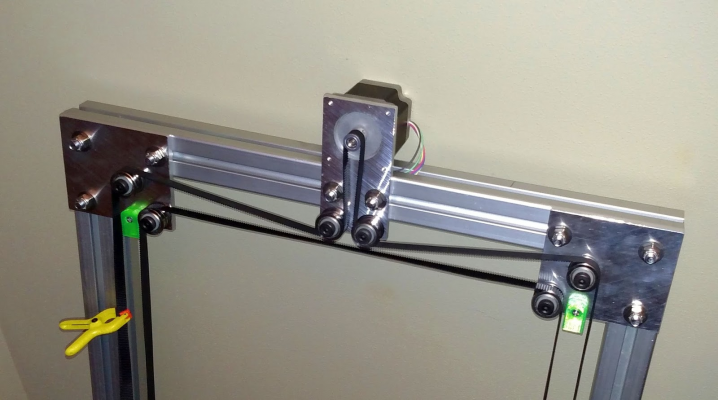

As some of you have read in my previous Thread, i am trying to get my Z axis belt driven. Previous thread: [reprap.org]

I have a wormgeared stepper, with so much backlash that i tried to make my Z axis heavier to counter the lash. It did not work out, even with a 8kg Z axis there still is enough lash to be able to push the z axis a bit down. Link to Worm Stepper [www.aliexpress.com] (This motor can drive the Z axis in both directions really fine)

I gave it a different aproach today, i have a spare 60mm double shaft nema17 laying around and i decided to test it.

No luck either, the motor is not nearly strong enough to be of use. At my first try it was not moving the bed up at all, after loosening the belts it did manage to move the axis upwards.

The motor is rated for 1.7A, it did need 2.5A to be able to get the axis up (without the bed assembly), it can't even carry 500g so the bed assembly cannot be lifted.

I am not sure how to continue, Nema 23? Most likely isn't strong enough either. The dropping of the bed i would counter with a solenoid. I came across another wormgearbox, looks interesting but if it has lash aswel.. [www.aliexpress.com]

Currently not able to find a rhino wormgearbox for a low price in Europe.

Another thing that came to mind, i have another spare of that nema17 motor. I could set them in line, connected shaft to shaft with a coupler. Probably a bad idea and not going to work.

I guess i would have saved me a lot of hassle by just going with ballscrews/leadscrews, it seems like in the end this will be my only "low cost" option.

Edited 6 time(s). Last edit at 07/06/2020 06:45PM by Govahnator.

I have a wormgeared stepper, with so much backlash that i tried to make my Z axis heavier to counter the lash. It did not work out, even with a 8kg Z axis there still is enough lash to be able to push the z axis a bit down. Link to Worm Stepper [www.aliexpress.com] (This motor can drive the Z axis in both directions really fine)

I gave it a different aproach today, i have a spare 60mm double shaft nema17 laying around and i decided to test it.

No luck either, the motor is not nearly strong enough to be of use. At my first try it was not moving the bed up at all, after loosening the belts it did manage to move the axis upwards.

The motor is rated for 1.7A, it did need 2.5A to be able to get the axis up (without the bed assembly), it can't even carry 500g so the bed assembly cannot be lifted.

I am not sure how to continue, Nema 23? Most likely isn't strong enough either. The dropping of the bed i would counter with a solenoid. I came across another wormgearbox, looks interesting but if it has lash aswel.. [www.aliexpress.com]

Currently not able to find a rhino wormgearbox for a low price in Europe.

Another thing that came to mind, i have another spare of that nema17 motor. I could set them in line, connected shaft to shaft with a coupler. Probably a bad idea and not going to work.

I guess i would have saved me a lot of hassle by just going with ballscrews/leadscrews, it seems like in the end this will be my only "low cost" option.

Edited 6 time(s). Last edit at 07/06/2020 06:45PM by Govahnator.

|

Re: Belt Z axis part 2: the struggle continues July 07, 2020 08:11AM |

Registered: 8 years ago Posts: 36 |

have you considered using gear reduction? its not the most compact solution, but its pretty low cost and i have not had any issues with the x gantry dropping on my prusa style machine. i am using two sets of 20 tooth and 80 tooth pulleys with a .09 degree motor and 32 tooth pulleys to to ultimately get to 1600 steps per mm. you would just have to find the right combination of pulleys to reach your desired steps per mm.

|

Re: Belt Z axis part 2: the struggle continues July 07, 2020 08:29AM |

Registered: 6 years ago Posts: 1,007 |

As I wrote earlier..

"You can contact the "engineer" who designed this worm gear box. His name is Sum Sing Wong !

Note, the behavior described in the above post is normal, just that the gear play seems quite big."

Seriously, there is no way to achieve anything worth with a poor quality worm gearbox. Already not easy with a good one.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

"You can contact the "engineer" who designed this worm gear box. His name is Sum Sing Wong !

Note, the behavior described in the above post is normal, just that the gear play seems quite big."

Seriously, there is no way to achieve anything worth with a poor quality worm gearbox. Already not easy with a good one.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Belt Z axis part 2: the struggle continues July 07, 2020 01:33PM |

Registered: 9 years ago Posts: 199 |

Quote

tolar250

have you considered using gear reduction? its not the most compact solution, but its pretty low cost and i have not had any issues with the x gantry dropping on my prusa style machine. i am using two sets of 20 tooth and 80 tooth pulleys with a .09 degree motor and 32 tooth pulleys to to ultimately get to 1600 steps per mm. you would just have to find the right combination of pulleys to reach your desired steps per mm.

I haven't really, i will look into it.

|

Re: Belt Z axis part 2: the struggle continues July 07, 2020 01:33PM |

Registered: 9 years ago Posts: 199 |

Quote

MKSA

As I wrote earlier..

"You can contact the "engineer" who designed this worm gear box. His name is Sum Sing Wong !

Note, the behavior described in the above post is normal, just that the gear play seems quite big."

Seriously, there is no way to achieve anything worth with a poor quality worm gearbox. Already not easy with a good one.

I am aware of that, this thread is not about the worm gearbox, i used a regular Nema17.

|

Re: Belt Z axis part 2: the struggle continues July 08, 2020 06:27PM |

Registered: 9 years ago Posts: 199 |

I am going to try connecting 2 Nema 17's and see what that gives.

Both are dual shaft, i wil connect the shafts with a coupler and make one motor duplicate the signal.

If someone knows in advance it is not even worth trying , please , stop me :-)

I am also thinking about buying 2 of these if it doesn't work out. [www.aliexpress.com]

Edited 1 time(s). Last edit at 07/08/2020 06:27PM by Govahnator.

Both are dual shaft, i wil connect the shafts with a coupler and make one motor duplicate the signal.

If someone knows in advance it is not even worth trying , please , stop me :-)

I am also thinking about buying 2 of these if it doesn't work out. [www.aliexpress.com]

Edited 1 time(s). Last edit at 07/08/2020 06:27PM by Govahnator.

|

Re: Belt Z axis part 2: the struggle continues July 08, 2020 11:07PM |

Registered: 11 years ago Posts: 5,780 |

It should be pretty easy to calculate the lifting power of a motor if you know the motor torque spec and the diameters of the pulleys...

I would get rid of the spring type shaft couplers. They're going to wind and unwind every time the bed moves.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I would get rid of the spring type shaft couplers. They're going to wind and unwind every time the bed moves.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt Z axis part 2: the struggle continues July 09, 2020 05:51PM |

Registered: 9 years ago Posts: 199 |

Quote

the_digital_dentist

It should be pretty easy to calculate the lifting power of a motor if you know the motor torque spec and the diameters of the pulleys...

I would get rid of the spring type shaft couplers. They're going to wind and unwind every time the bed moves.

Agreed for the spring couplers, i have larger stiff ones but only for 8mm shafts.

I have been trying to calculate the needed motor torque, not really able to figure it out. Would you be so kind to help?

The mass of the Z axis will be 10kg at most or 100N, the 2 60T pulley's i am using have a radius of 2cm.

Does this mean i need a motor with 200N.cm to be able to lift and hold 10kg over a 60T pulley?

The Holding torque of the Nema 23 i am looking at is 220N.cm. It also has 8mm dual shaft so my stiff couplers could be put to use.

Edited 2 time(s). Last edit at 07/09/2020 05:54PM by Govahnator.

|

Re: Belt Z axis part 2: the struggle continues July 09, 2020 11:06PM |

Registered: 11 years ago Posts: 5,780 |

200 N cm sounds about right. The holding torque spec is a little higher, so it will probably work OK. Torque drops with speed, but you won;t be moving the Z axis very fast so it will probably be OK.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt Z axis part 2: the struggle continues July 25, 2020 06:15PM |

Registered: 9 years ago Posts: 199 |

So i got the second strongest Nema23 i could find for 3A and installed it.

It barely can lift the bed up. Only with the right belt tension, if the belt is a bit more tight the motor stalls. If i add another kilo on the axis it stalls too.

To bad since the bed does not drop when the belts are really tightened.

It can hold a lot of weight when moving the axis down, so it can hold heavy prints, it would just not be able to get the axis back up.

The printer could work with this config, i guess auto-level would not be possible once a print gets over 1kg and resume after power failure is no option. (not planning to go auto-level though)

A shame since i spent so much time in designing a decent printer.

Not sure how to continue, I am still considering going with ballscrews.

Edited 1 time(s). Last edit at 07/25/2020 06:18PM by Govahnator.

It barely can lift the bed up. Only with the right belt tension, if the belt is a bit more tight the motor stalls. If i add another kilo on the axis it stalls too.

To bad since the bed does not drop when the belts are really tightened.

It can hold a lot of weight when moving the axis down, so it can hold heavy prints, it would just not be able to get the axis back up.

The printer could work with this config, i guess auto-level would not be possible once a print gets over 1kg and resume after power failure is no option. (not planning to go auto-level though)

A shame since i spent so much time in designing a decent printer.

Not sure how to continue, I am still considering going with ballscrews.

Edited 1 time(s). Last edit at 07/25/2020 06:18PM by Govahnator.

|

Re: Belt Z axis part 2: the struggle continues July 25, 2020 10:46PM |

Registered: 11 years ago Posts: 5,780 |

Use smaller drive pulleys and it will be able to lift more.

I don't know why the bed wouldn't drop just because the belts are tight - maybe they're too tight.

Edited 1 time(s). Last edit at 07/25/2020 10:48PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't know why the bed wouldn't drop just because the belts are tight - maybe they're too tight.

Edited 1 time(s). Last edit at 07/25/2020 10:48PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt Z axis part 2: the struggle continues July 26, 2020 05:09AM |

Admin Registered: 11 years ago Posts: 3,096 |

I agree, the only correct adjustment at this stage is to decrease the pulley size. If that doesn't work, think about reducing with a gearbox like tolar250 suggested. Or go a different route like leadscrews.

http://www.marinusdebeer.nl/

http://www.marinusdebeer.nl/

|

Re: Belt Z axis part 2: the struggle continues July 26, 2020 06:15AM |

Registered: 11 years ago Posts: 5,780 |

I had a small 160 Oz-in NEMA 23 motor in the original belt lifted design in UMMD, like this:

I don't recall the pulley size, but it was small, probably 20 teeth. It had no trouble lifting the 3.5 kg bed assembly with motor current no more than 1.2A, driven directly by the smoothieboard driver.

I went to larger pulleys in the final design because with 30:1 reduction in the gear box the maximum Z axis speed would have been too low.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I don't recall the pulley size, but it was small, probably 20 teeth. It had no trouble lifting the 3.5 kg bed assembly with motor current no more than 1.2A, driven directly by the smoothieboard driver.

I went to larger pulleys in the final design because with 30:1 reduction in the gear box the maximum Z axis speed would have been too low.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt Z axis part 2: the struggle continues August 05, 2020 05:16PM |

Registered: 9 years ago Posts: 199 |

Thanks for the advice guys.

I am thinking of keeping the setup, i will test my first prints soon, i will see what it gives.

As long as it can get the bed up to start the print all is good, which it can (barely) do.

I don't think changing to ballscrews would stop the bed from falling either.

As soon as my solenoid arrives i will play with it to act as a Z brake.

I am also considering a double pole double throw relay, to short the Z motor when power is off and maybe stop all movement.

I have not really started a topic of the printer i am building on itself, I have been working on it for over 2 years though. Most of the time looking up parts and waiting for them to get delivered, you know the drill.

Edited 3 time(s). Last edit at 08/05/2020 05:20PM by Govahnator.

I am thinking of keeping the setup, i will test my first prints soon, i will see what it gives.

As long as it can get the bed up to start the print all is good, which it can (barely) do.

I don't think changing to ballscrews would stop the bed from falling either.

As soon as my solenoid arrives i will play with it to act as a Z brake.

I am also considering a double pole double throw relay, to short the Z motor when power is off and maybe stop all movement.

I have not really started a topic of the printer i am building on itself, I have been working on it for over 2 years though. Most of the time looking up parts and waiting for them to get delivered, you know the drill.

Edited 3 time(s). Last edit at 08/05/2020 05:20PM by Govahnator.

|

Re: Belt Z axis part 2: the struggle continues August 05, 2020 09:48PM |

Registered: 11 years ago Posts: 5,780 |

Shorting the motor will slow the drop, but won't stop it. The motor has to spin to generate the magnetic field that will brake the motion. If it doesn't spin, it doesn't brake. If it is spinning, it is dropping.

I had looked into a centrifugal brake similar to the brake used in seat belts in cars. It would probably be pretty easy to make something like that, but the bed will have to drop a bit to activate it.

Ball screws typically have longer lead than trapezoidal screws, and lower friction, so they will usually let the bed drop faster than trapezoidal screws. If you went to shorter lead trapezoidal screws the bed may not drop.

The high ratio worm gear prevents the bed from moving at all (except by the tiny amount the motor will jump when power is restored).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I had looked into a centrifugal brake similar to the brake used in seat belts in cars. It would probably be pretty easy to make something like that, but the bed will have to drop a bit to activate it.

Ball screws typically have longer lead than trapezoidal screws, and lower friction, so they will usually let the bed drop faster than trapezoidal screws. If you went to shorter lead trapezoidal screws the bed may not drop.

The high ratio worm gear prevents the bed from moving at all (except by the tiny amount the motor will jump when power is restored).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Belt Z axis part 2: the struggle continues August 06, 2020 03:40AM |

Registered: 9 years ago Posts: 483 |

Perhaps a better quality geared stepper will work: [www.omc-stepperonline.com] The 50:1 model has torque rating over 2000 oz-in, about 10 times what your Nema 23 motor is rated.

Determining the amount needed can be done by hanging a weight from a pulley above the bed. Keep adding weight until the bed moves.

Determining the amount needed can be done by hanging a weight from a pulley above the bed. Keep adding weight until the bed moves.

Sorry, only registered users may post in this forum.